Multi-Damage Identification of Multi-Span Bridges Based on Influence Lines

Abstract

:1. Introduction

2. Numerical Methods and Materials

2.1. Relevant Parameters of Calculation Model

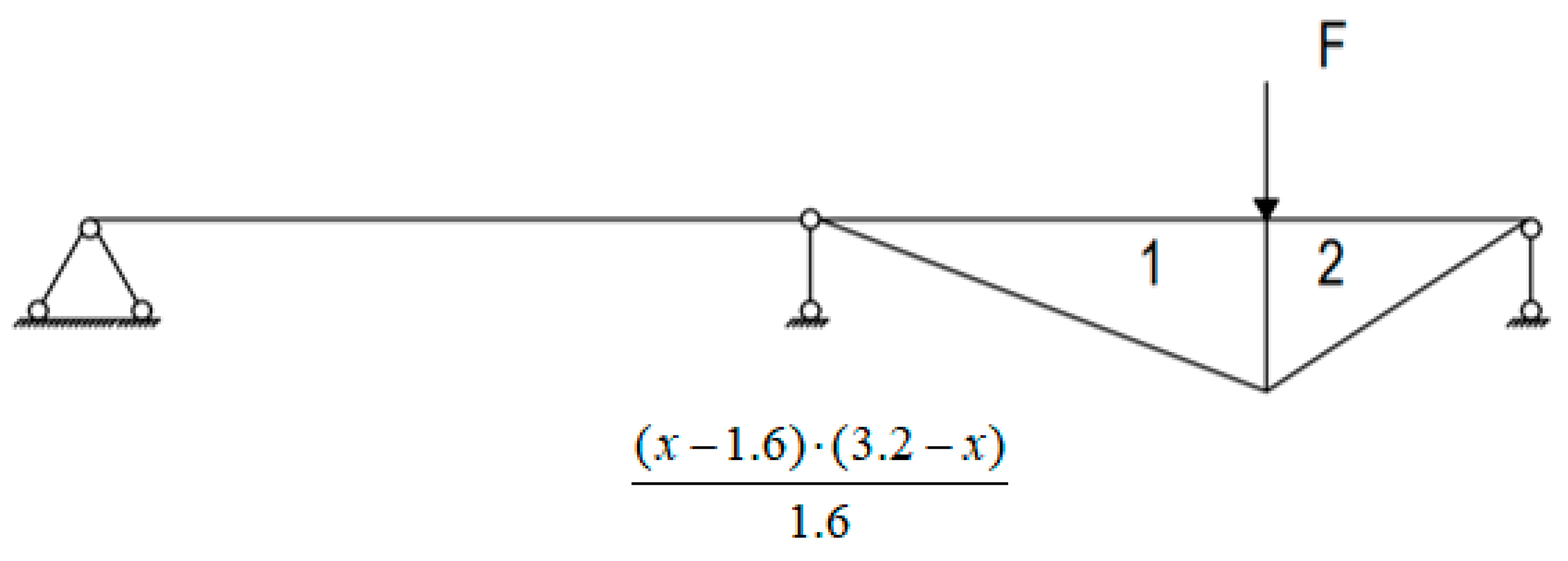

2.2. Deflection Influences Line Equation of Structure without Loss

- (1)

- When the Cg is all in the 2nd equation:

- (2)

- When the Cg of Area 1 is in the 2nd equation: ;

- (3)

- When the Cg of Area 1 and Area 2 is in the 3rd equation:

3. Study on Deflection Influence Line Identification of Continuous Beam with Multiple Damage under Ideal Condition

3.1. Establishment of Multiple Damage Model

3.2. Multi-Point Destruction Recognition of Deflection Influence Line

3.3. Multi-Point Damage Identification Based on 1st Derivative of Deflection Influence Line

3.4. Multi-Point Damage Identification Based on the 2nd Derivative of Deflection Influence Line

3.5. Multi-Point Damage Identification Based on Deflection Influence Line Difference

3.6. Multi-Point Damage Identification Based on 1st Derivative of Deflection Influence Line Difference

3.7. Multi-Point Damage Identification Based on the Second Derivative of Deflection Influence Line Difference

4. Laboratory Validation of the Theoretical Model

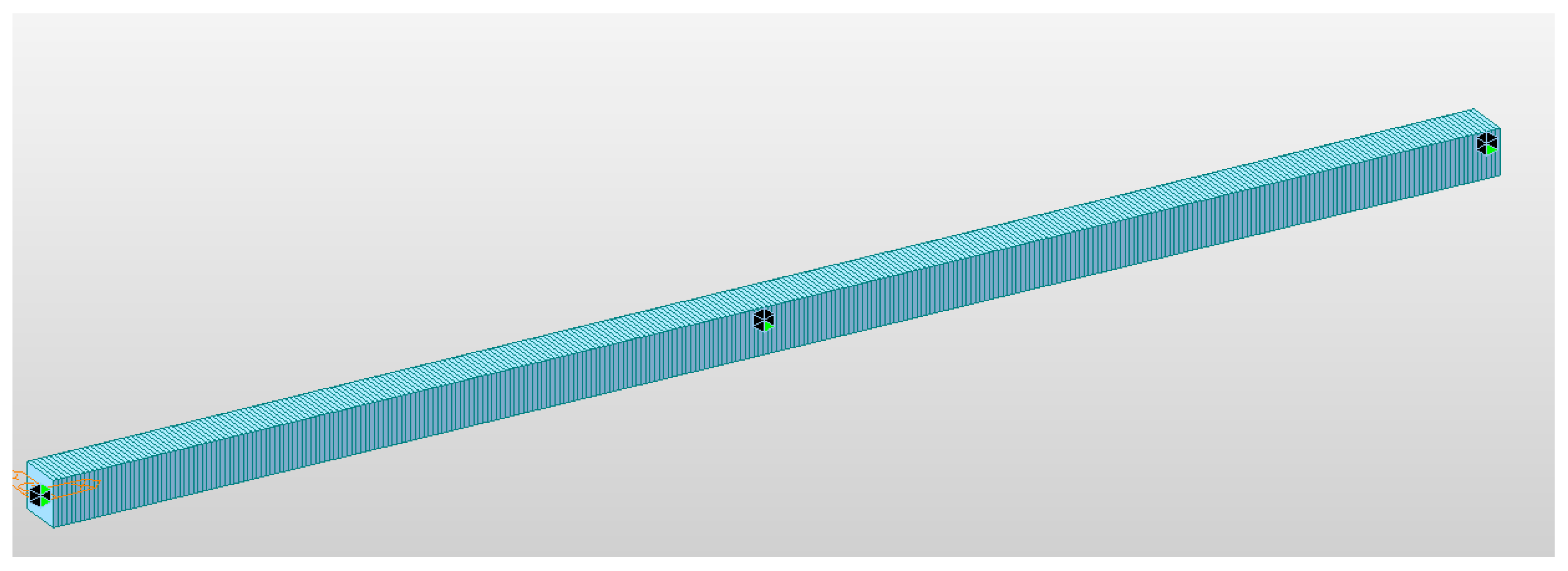

4.1. Test Plan

4.2. Testing Equipment

4.3. Identification of Damage Location by Deflection Influence Line and Its First and Second Derivatives

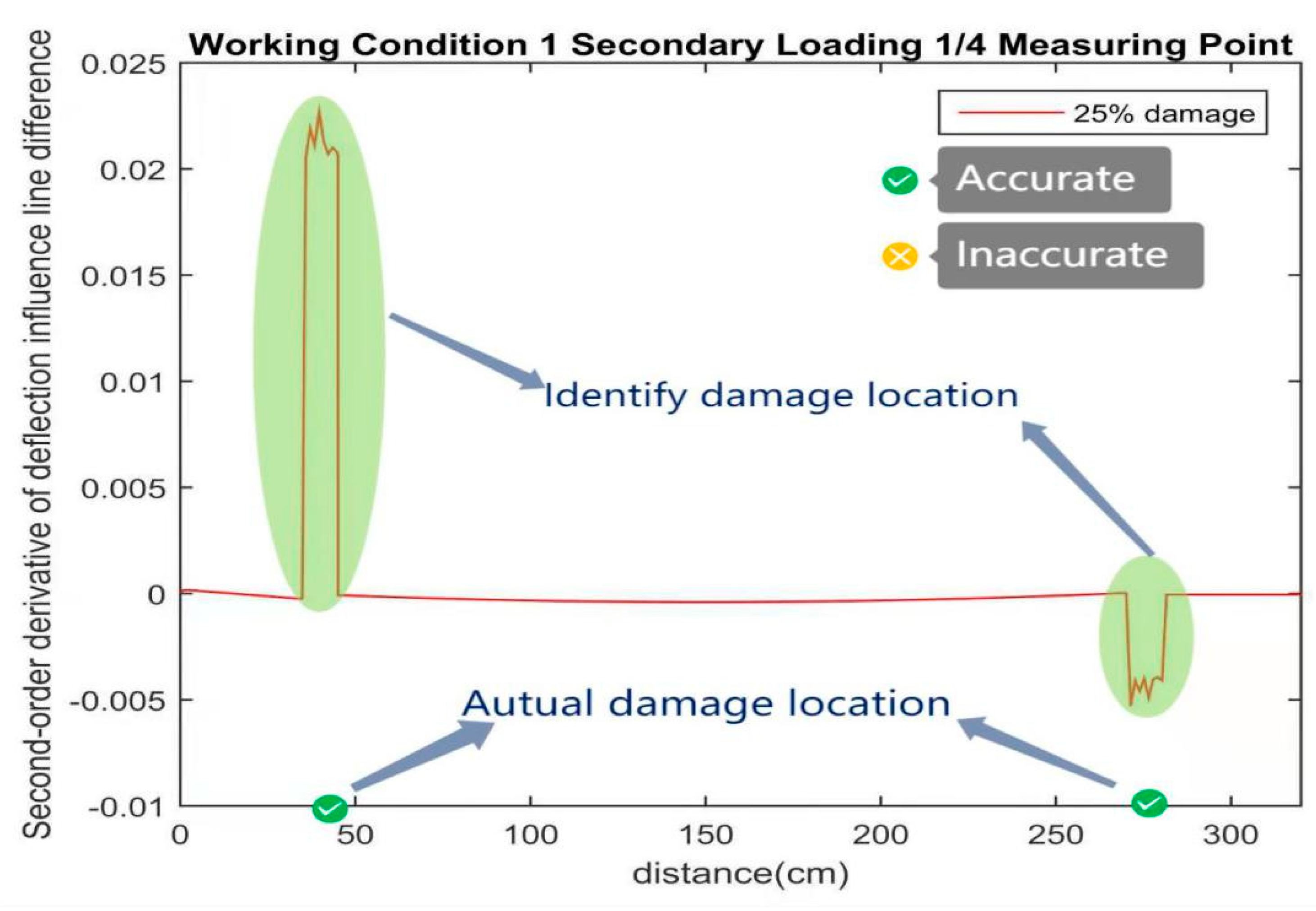

4.4. Identification of Damage Location by Deflection Influence Line Difference and Its First and Second Derivatives

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Alampalli, S.; Ettouney, M.M.; Agrawal, A.K. Structural health monitoring for bridge maintenance. Bridge Struct. 2005, 1, 345–354. [Google Scholar] [CrossRef]

- Fujino, Y.; Siringoringo, D.M.; Ikeda, Y.; Nagayama, T.; Mizutani, T. Research and Implementations of Structural Monitoring for Bridges and Buildings in Japan. Engineering 2019, 5, 1093–1119. [Google Scholar] [CrossRef]

- An, Y.; Chatzi, E.; Sim, S.-H.; Laflamme, S.; Blachowski, B.; Ou, J. Recent progress and future trends on damage identification methods for bridge structures. Struct. Control. Health Monit. 2019, 26, e2416. [Google Scholar] [CrossRef]

- Zhou, Y.; Di, S.; Xiang, C.; Li, W.; Wang, L. Damage identification in simply supported bridge based on rotational-angle influence lines method. Trans. Tianjin Univ. 2018, 24, 587–601. [Google Scholar] [CrossRef]

- Deng, L.; Wang, W.; Yu, Y. State-of-the-art review on the causes and mechanisms of bridge collapse. J. Perform. Constr. Facil. 2016, 30, 04015005. [Google Scholar] [CrossRef]

- Gehl, P.; D′Ayala, D. Development of Bayesian Networks for the multi-hazard fragility assessment of bridge systems. Struct. Saf. 2016, 60, 37–46. [Google Scholar] [CrossRef]

- Xu, F.Y.; Zhang, M.J.; Wang, L.; Zhang, J.R. Recent highway bridge collapses in China: Review and discussion. J. Perform. Constr. Facil. 2016, 30, 04016030. [Google Scholar] [CrossRef]

- Acar, E.; Izgi, A.; Serenbay, S.K. Note on Jakimovski-Leviatan Operators Preserving e–x. Appl. Math. Nonlinear Sci. 2019, 4, 543–550. [Google Scholar] [CrossRef] [Green Version]

- Sahin, R.; Yagcı, O. Fractional calculus of the extended hypergeometric function. Appl. Math. Nonlinear Sci. 2020, 5, 369–384. [Google Scholar] [CrossRef]

- Tan, J.-S.; Elbaz, K.; Wang, Z.-F.; Shen, J.S.; Chen, J. Lessons learnt from bridge collapse: A view of sustainable management. Sustainability 2020, 12, 1205. [Google Scholar] [CrossRef] [Green Version]

- Gidaris, I.; Padgett, J.E.; Barbosa, A.R.; Chen, S.; Cox, D.; Webb, B.; Cerato, A. Multiple-hazard fragility and restoration models of highway bridges for regional risk and resilience assessment in the United States: State-of-the-art review. J. Struct. Eng. 2017, 143, 04016188. [Google Scholar] [CrossRef]

- Omar, T.; Nehdi, M.L. Condition assessment of reinforced concrete bridges: Current practice and research challenges. Infrastructures 2018, 3, 36. [Google Scholar] [CrossRef] [Green Version]

- Sun, L.; Shang, Z.; Xia, Y.; Bhowmick, S.; Nagarajaiah, S. Review of bridge structural health monitoring aided by big data and artificial intelligence: From condition assessment to damage detection. J. Struct. Eng. 2020, 146, 04020073. [Google Scholar] [CrossRef]

- Shokravi, H.; Shokravi, H.; Bakhary, N.; Heidarrezaei, M.; Rahimian Koloor, S.S.; Petrů, M. Application of the subspace-based methods in health monitoring of civil structures: A systematic review and meta-analysis. Appl. Sci. 2020, 10, 3607. [Google Scholar] [CrossRef]

- Shang, Z.; Sun, L.; Xia, Y.; Zhang, W. Vibration-based damage detection for bridges by deep convolutional denoising autoencoder. Struct. Health Monit. 2020, 1475921720942836. [Google Scholar] [CrossRef]

- Wang, T.B. Damper performance requirements for improving durability of bridge structures. Bridge Construction. 2016, 46, 29–34. [Google Scholar]

- Kang, X.N. Preliminary Study on Damage Identification Method of Bridge Structure Based on Deflection Influence Line. Ph.D. Thesis, Chongqing Jiaotong University, Chongqing, China, 2008. [Google Scholar]

- Liu, Y.S. Study on Damage Identification of Simply Supported Beam Bridge Based on Deflection Difference Influence Line. Ph.D. Thesis, Lanzhou University of Technology, Lanzhou, China, 2009. [Google Scholar]

- Jia, Y. Research on Structural Damage Identification of Continuous Beam Bridge Based on Deflection Influence Line. Ph.D. Thesis, Guangzhou University, Guangzhou, China, 2014. [Google Scholar]

- Bautista-De Castro, Á.; Sánchez-Aparicio, L.J.; Ramos, L.F.; Sena-Cruz, J.; González-Aguilera, D. Integrating geomatic approaches, Operational Modal Analysis, advanced numerical and updating methods to evaluate the current safety conditions of the historical Bôco Bridge. Constr. Build. Mater. 2018, 158, 961–984. [Google Scholar] [CrossRef]

- Neild, S.A.; Williams, M.S.; McFadden, P.D. Nonlinear vibration characteristics of damaged concrete beams. J. Struct. Eng. 2003, 129, 260–268. [Google Scholar] [CrossRef]

- Unger, J.F.; Teughels, A.; De Roeck, G. System identification and damage detection of a prestressed concrete beam. J. Struct. Eng. 2006, 132, 1691–1698. [Google Scholar] [CrossRef]

- Zhang, R.F.; Zhang, X.M.; Qi, C.X. Application of the Influence Line on the Bridge Testing. Adv. Mater. Res. 2012, 594, 1586–1589. [Google Scholar] [CrossRef]

- Kato, M.; Shimada, S. Vibration of PC bridge during failure process. J. Struct. Eng. 1986, 112, 1692–1703. [Google Scholar] [CrossRef]

- Sassu, M.; Giresini, L.; Puppio, M.L. Failure scenarios of small bridges in case of extreme rainstorms. Sustain. Resilient Infrastruct. 2017, 2, 108–116. [Google Scholar] [CrossRef]

- Croce, P.; Marsili, F.; Klawonn, F.; Formichi, P.; Landi, F. Evaluation of statistical parameters of concrete strength from secondary experimental test data. Constr. Build. Mater. 2018, 163, 343–359. [Google Scholar] [CrossRef]

- Wang, F.L.; Chan, T.H.T.; Thambiratnam, D.P.; Tan, A.C.C. Damage diagnosis for complex steel truss bridges using multi-layer genetic algorithm. J. Civ. Struct. Health Monit. 2013, 3, 117–127. [Google Scholar] [CrossRef] [Green Version]

- Zheng, W.; Shen, J.; Wang, J. Improved computational framework for efficient bayesian probabilistic inference of damage in truss structures based on vibration measurements. Transp. Res. Rec. 2014, 2460, 117–127. [Google Scholar] [CrossRef]

- Behmanesh, I.; Moaveni, B. Probabilistic identification of simulated damage on the Dowling Hall footbridge through Bayesian finite element model updating. Struct. Control. Health Monit. 2015, 22, 463–483. [Google Scholar] [CrossRef]

- Nair, K.K.; Kiremidjian, A.S.; Law, K.H. Time series-based damage detection and localization algorithm with application to the ASCE benchmark structure. J. Sound Vib. 2006, 291, 349–368. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, J.; Liu, J.; Nasir, M.S.; Zhu, J.; Li, S.; Liang, J.; Yan, W. Smart Formaldehyde Detection Enabled by Metal Organic Framework-Derived Doped Electrospun Hollow Nanofibers. Sensor Actuat B-Chem. 2020, 326, 128819. [Google Scholar] [CrossRef]

- Zhou, S.; Bao, Y.; Li, H. Structural Damage Identification Based on Substructure Sensitivity and l1 Sparse Regularization; International Society for Optics and Photonics: Washington, WA, USA, 2013; p. 86923N. [Google Scholar]

- Zhang, Q.C.; Sun, Q.S. Damage detection of self-anchored suspension bridge based on neural network model and genetic-simulated annealing algorithm. Adv. Mater. Res. 2011, 243, 1963–1967. [Google Scholar] [CrossRef]

| Damage Location | 35–45 cm and 275–285 cm | ||||

|---|---|---|---|---|---|

| Work condition No. | Work condition No.1-1 | Work condition No.1-2 | Work condition No.1-3 | Work condition No.1-4 | Work condition No.1-5 |

| Number of injuries | 2 | 2 | 2 | 2 | 2 |

| Degree of damage | 0 | 10% | 20% | 30% | 50% |

| Damage Location | 35–45 cm and 75–85 cm | ||||

|---|---|---|---|---|---|

| Work condition No. | Work condition 2-1 | Work condition 2-2 | Work condition 2-3 | Work condition 2-4 | Work condition 2-5 |

| Number of injuries | 2 | 2 | 2 | 2 | 2 |

| Degree of damage | 0 | 10% | 20% | 30% | 50% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Xie, Q.; Li, G.; Liu, Y. Multi-Damage Identification of Multi-Span Bridges Based on Influence Lines. Coatings 2021, 11, 905. https://doi.org/10.3390/coatings11080905

Zhang Y, Xie Q, Li G, Liu Y. Multi-Damage Identification of Multi-Span Bridges Based on Influence Lines. Coatings. 2021; 11(8):905. https://doi.org/10.3390/coatings11080905

Chicago/Turabian StyleZhang, Yunkai, Qingli Xie, Guohua Li, and Yali Liu. 2021. "Multi-Damage Identification of Multi-Span Bridges Based on Influence Lines" Coatings 11, no. 8: 905. https://doi.org/10.3390/coatings11080905