Performance of Polyvinyl Alcohol/Bagasse Fibre Foamed Composites as Cushion Packaging Materials

Abstract

:1. Introduction

2. Experiments

2.1. Experimental Materials

2.2. Experimental Apparatus

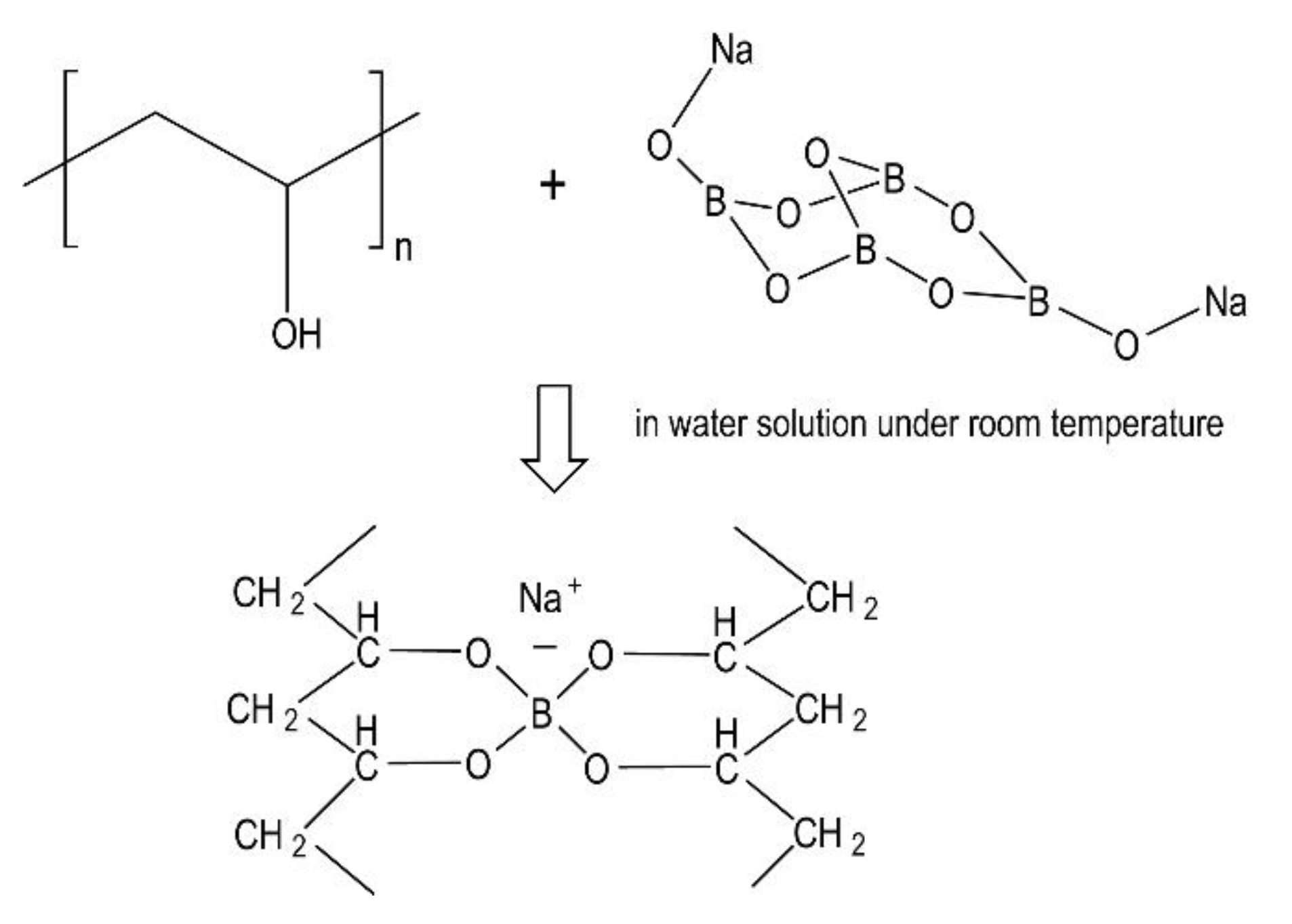

2.3. Specimen Preparation

2.4. Testing and Characterization

2.4.1. Static Compression Properties

2.4.2. Yield Strength and Young’s Modulus

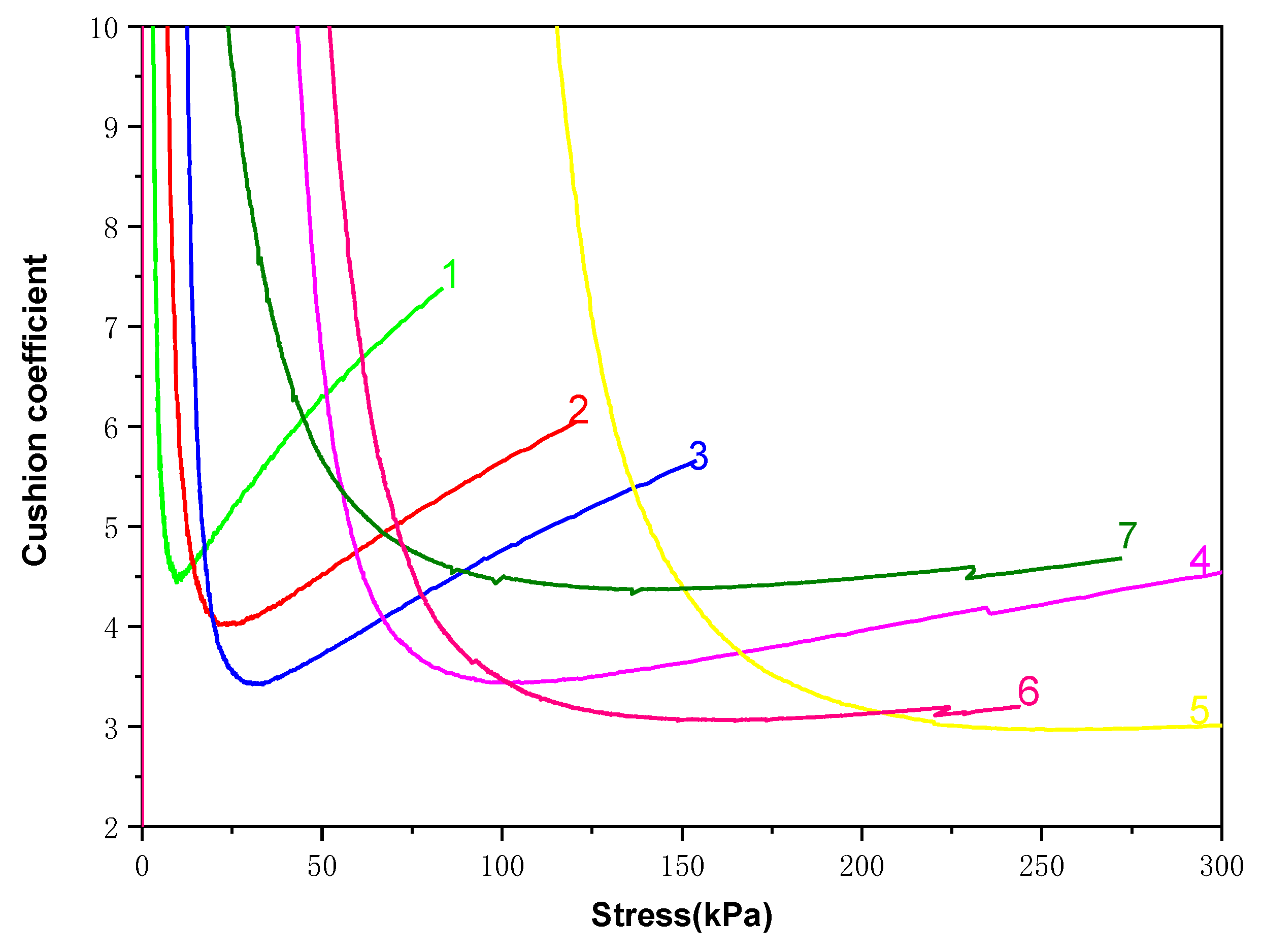

2.4.3. Cushion Coefficient

2.4.4. SEM Analysis

3. Result and Analysis

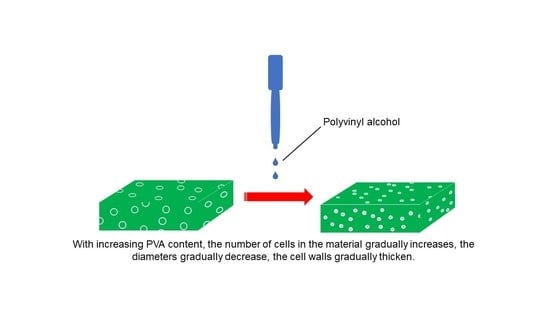

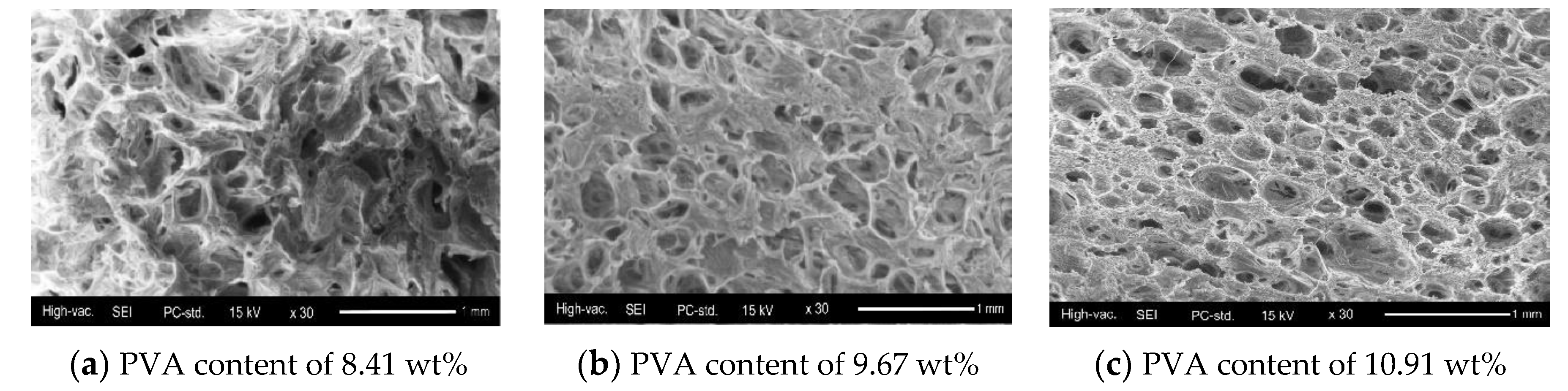

3.1. Effect of PVA Content on Material Properties

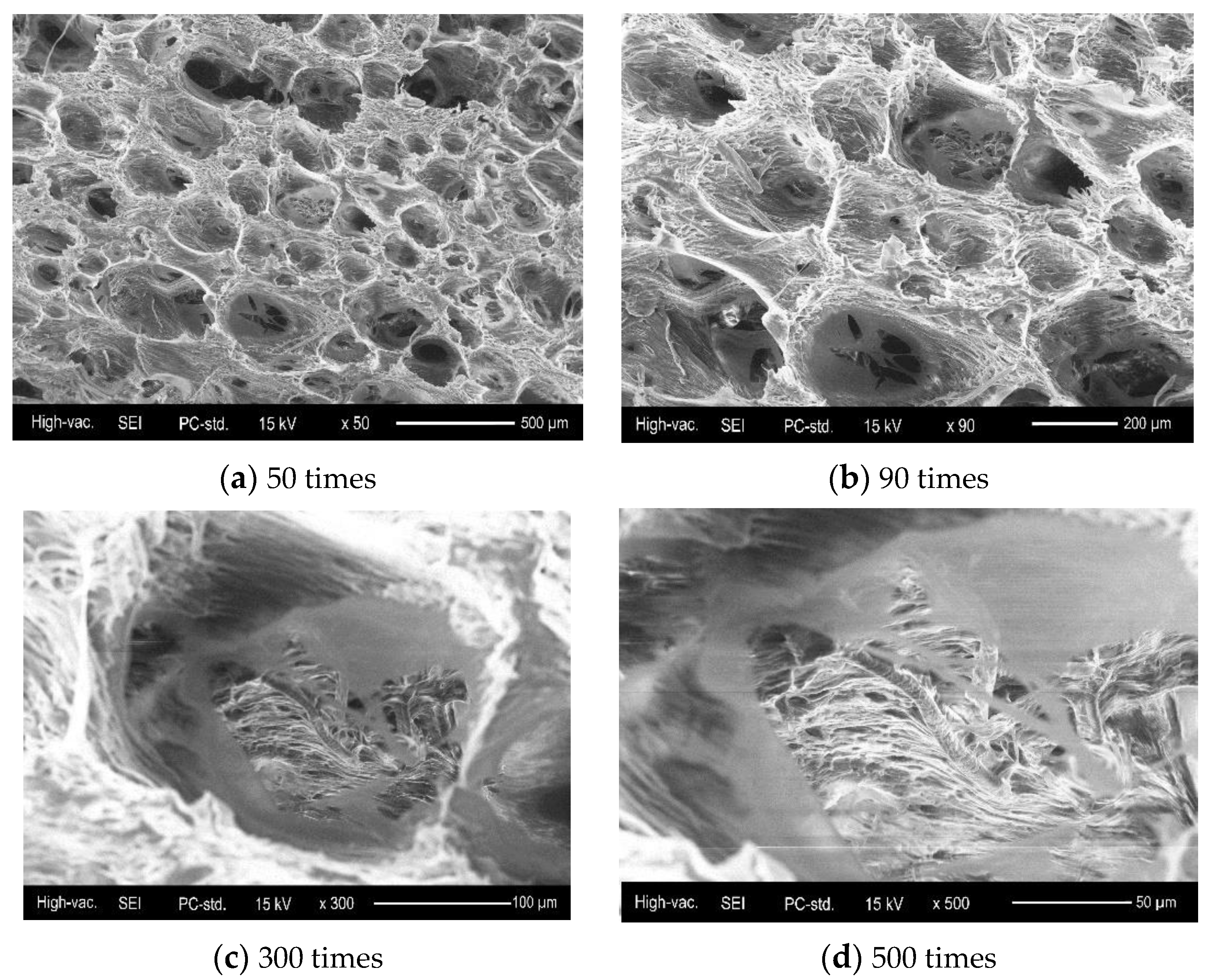

3.1.1. SEM Analysis

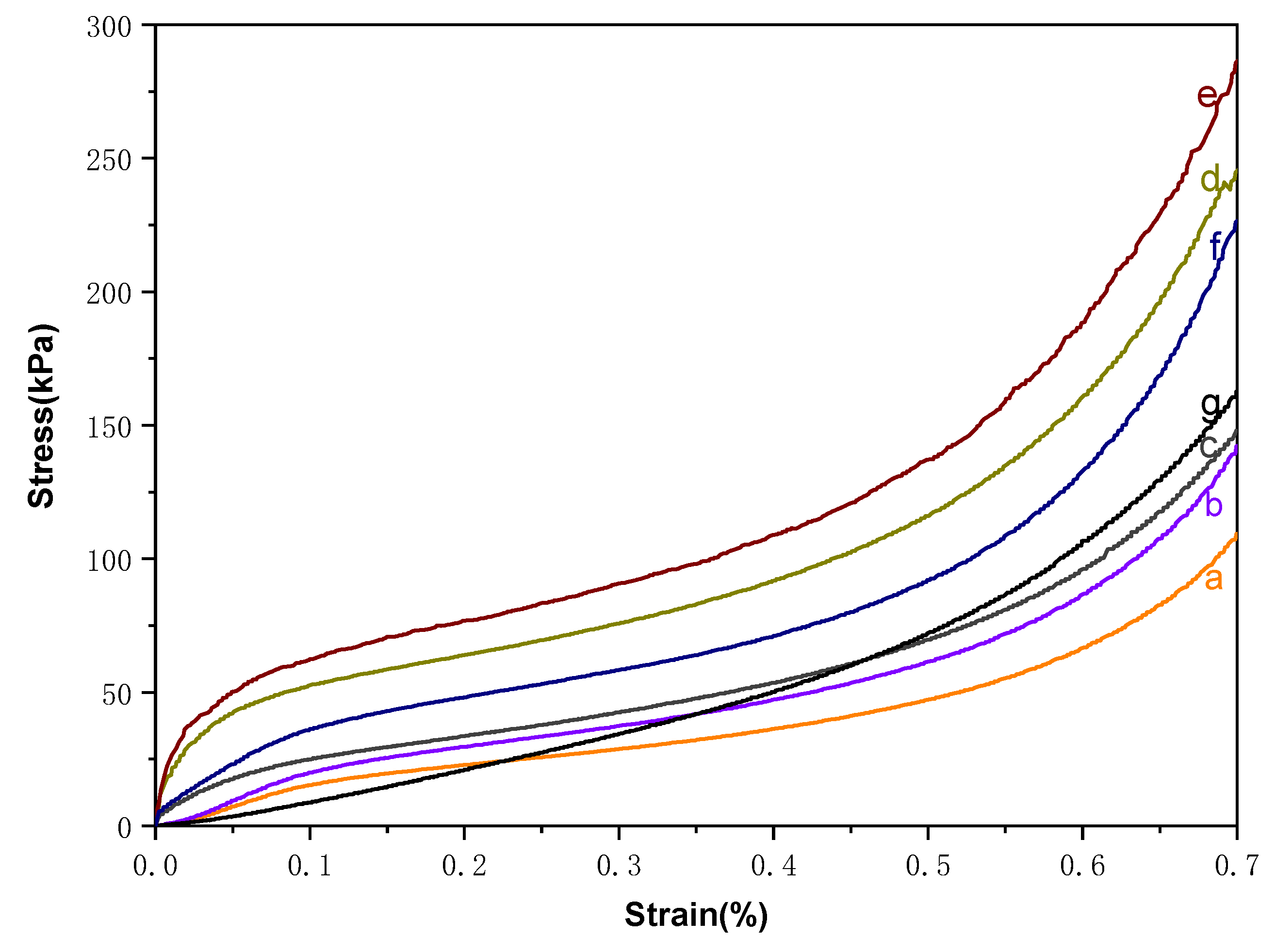

3.1.2. Stress and Strain Curve Analysis

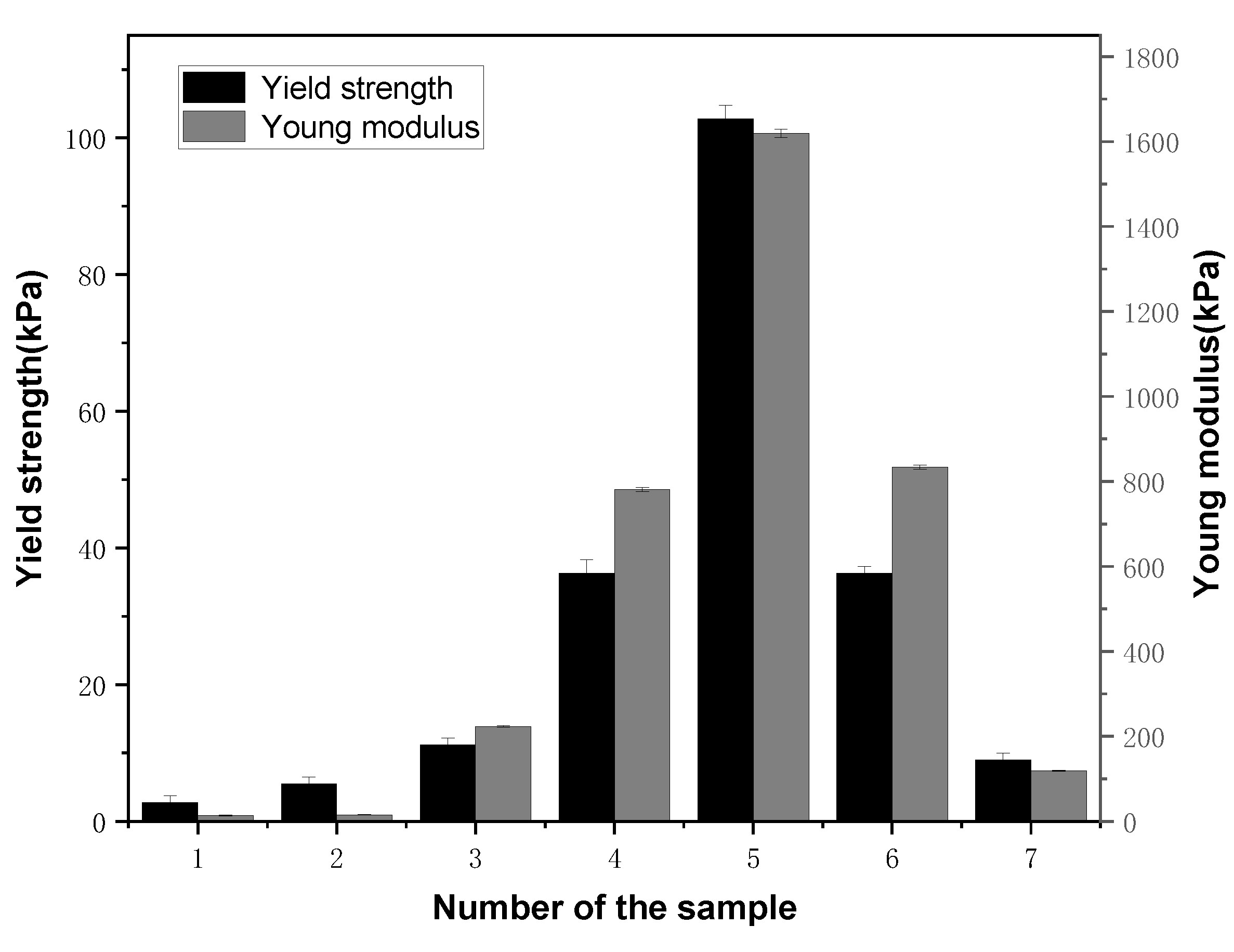

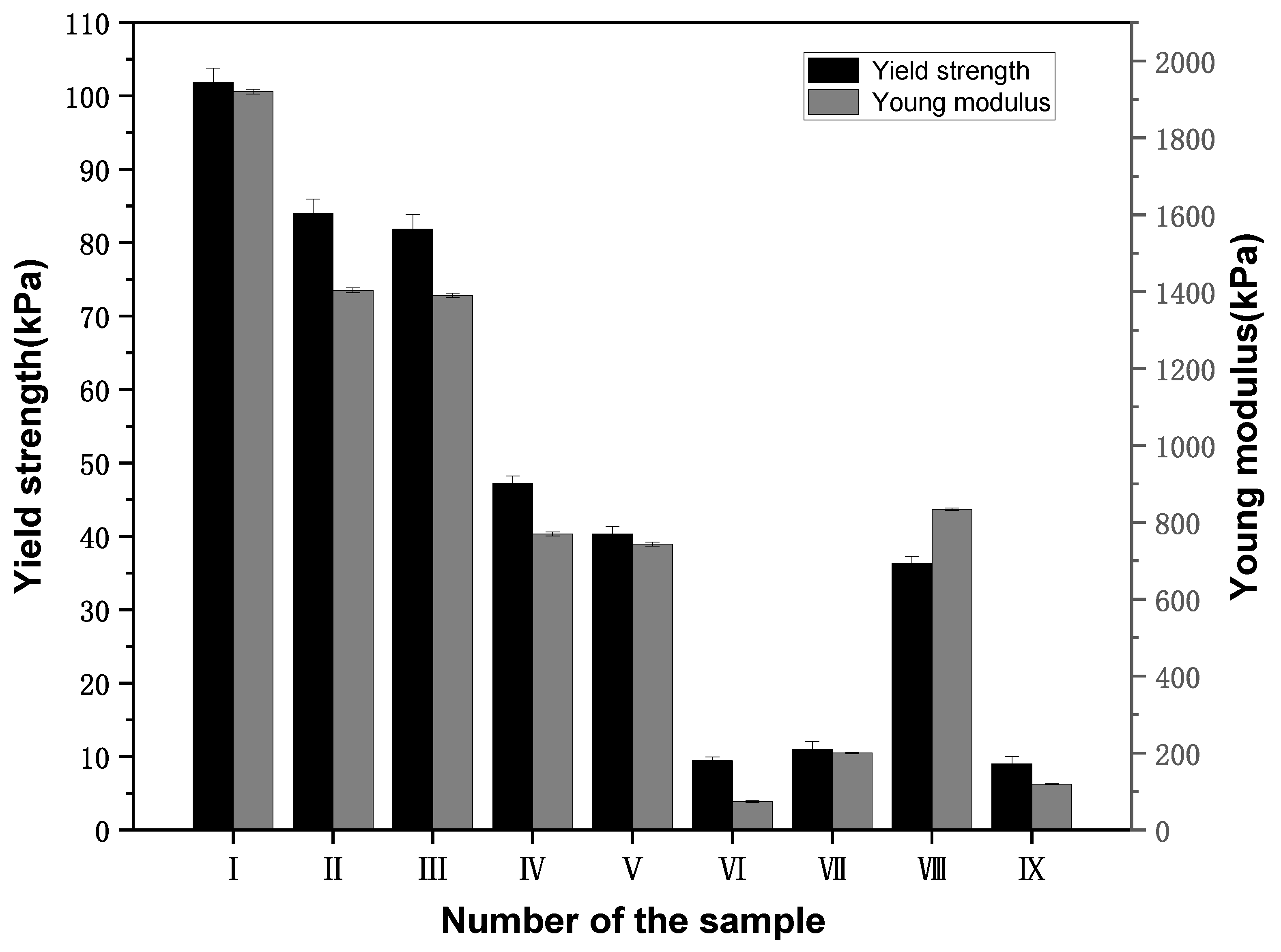

3.1.3. Analysis of Yield Strength and Young’s Modulus

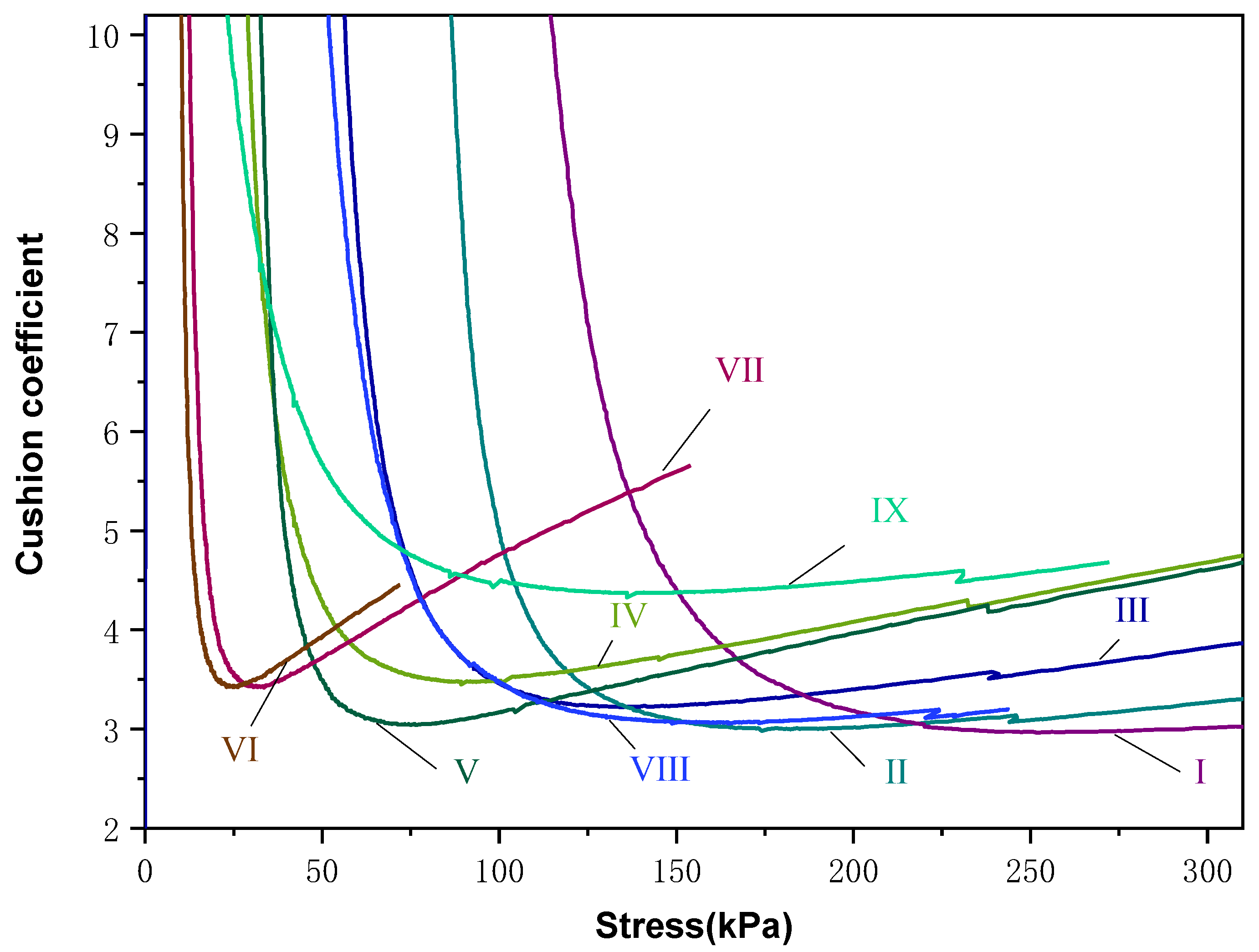

3.1.4. Cushion Coefficient Analysis

3.2. Effect of Sodium Tetraborate Content on the Mechanical Properties of Materials

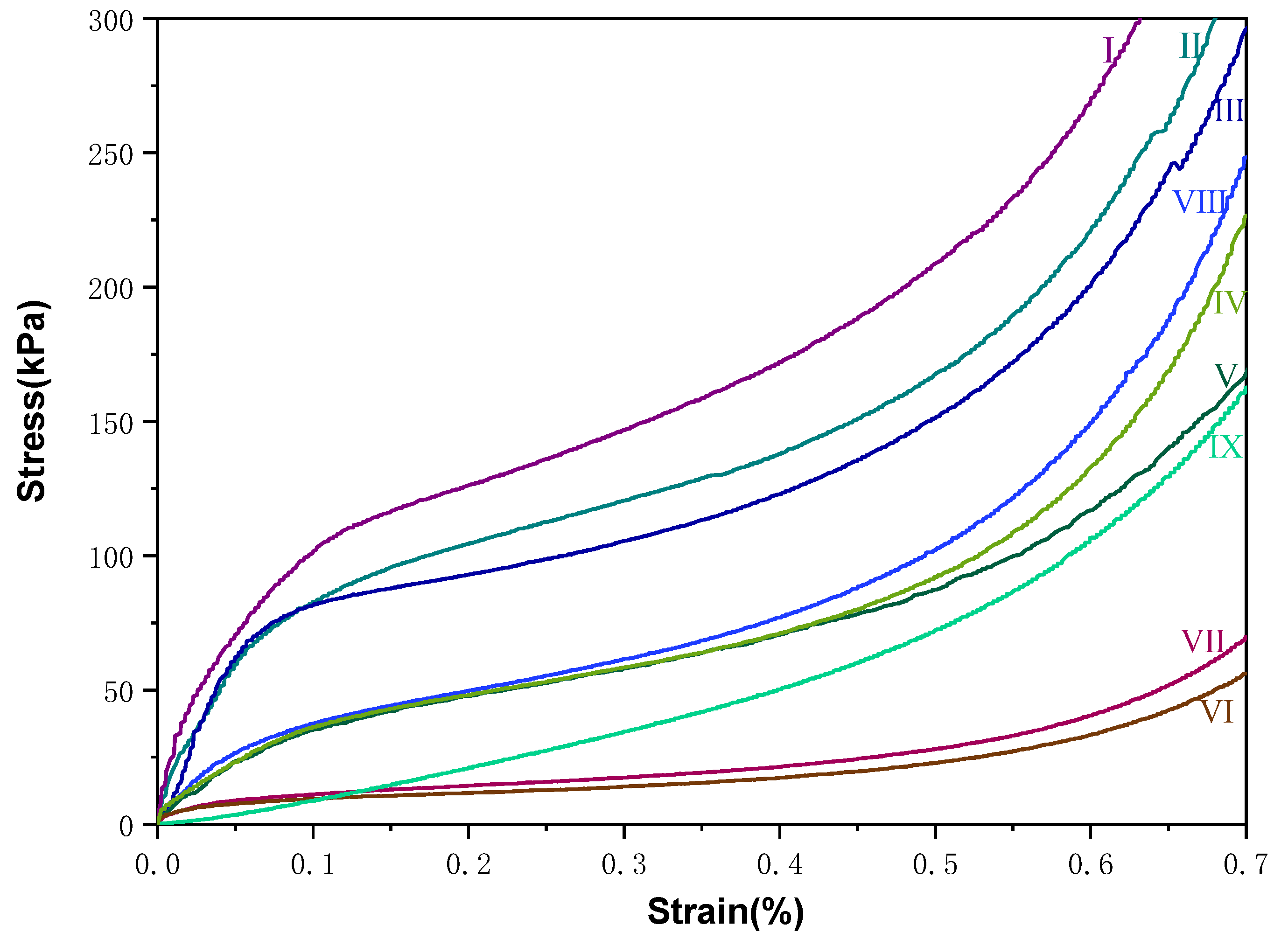

3.3. Effect of Water Content on the Mechanical Properties of Materials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, Z.; Dong, W.; Xiaomin, J. Research on the reduction design of fragile product cushion packaging under the green development concept. IOP Conf. Ser. Earth Environ. Sci. 2021, 657, 012057. [Google Scholar] [CrossRef]

- Chen, Q.; Du, X.; Chen, G. Preparation of Modified Montmorillonite—Plant Fiber Composite Foam Materials. Materials 2019, 12, 420. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Yang, X.; Xiu, H.; Dong, H.; Song, T.; Ma, F.; Feng, P.; Zhang, X.; Kozliak, E.; Ji, Y. Structure and performance control of plant fiber based foam material by fibrillation via refining treatment. Ind. Crop. Prod. 2019, 128, 186–193. [Google Scholar] [CrossRef]

- Duarte, I.; Banhart, J. A study of aluminium foam formation—kinetics and microstructure. Acta Mater. 2000, 48, 2349–2362. [Google Scholar] [CrossRef]

- Movahedi, N.; Linul, E.; Marsavina, L. The Temperature effect on the compressive behavior of closed-cell aluminum-alloy foams. J. Mater. Eng. Perform. 2018, 27, 99–108. [Google Scholar] [CrossRef]

- Movahedi, N.; Murch, G.E.; Belova, I.V.; Fiedler, T. Effect of heat treatment on the compressive behavior of zinc alloy ZA27 syntactic foam. Materials 2019, 12, 792. [Google Scholar] [CrossRef] [Green Version]

- Orbulov, I.N. Metal matrix composite syntactic foams for light-weight structural materials. In Encyclopedia of Materials: Composites; Brabazon, D., Ed.; Elsevier: Oxford, UK, 2021; pp. 781–797. [Google Scholar]

- Liu, J.; Ren, B.; Zhang, S.; Lu, Y.; Chen, Y.; Wang, L.; Yang, J.; Huang, Y. Hierarchical ceramic foams with 3D interconnected network architecture for superior high-temperature particulate matter capture. ACS Appl. Mater. Interfaces 2019, 11, 40585–40591. [Google Scholar] [CrossRef]

- Semerci, T.; Innocentini, M.D.D.M.; Marsola, G.A.; Lasso, P.R.O.; Soraru, G.D.; Vakifahmetoglu, C. Hot air permeable preceramic polymer derived reticulated ceramic foams. ACS Appl. Polym. Mater. 2020, 2, 4118–4126. [Google Scholar] [CrossRef]

- Li, F.; Guan, K.; Liu, P.; Li, G.; Li, J. Ingredient of Biomass packaging material and compare study on cushion properties. Int. J. Polym. Sci. 2014, 2014, 146509. [Google Scholar] [CrossRef]

- Kaisangsri, N.; Kerdchoechuen, O.; Laohakunjit, N. Characterization of cassava starch based foam blended with plant proteins, kraft fiber, and palm oil. Carbohydr. Polym. 2014, 110, 70–77. [Google Scholar] [CrossRef]

- Xingyun, Z.; Lingqing, Z.; Yuping, E.; Jiajun, W. Preparation of laminaria japonica foamed cushioning material and the research on its properties. J. Zhejiang Sci.-Technol. Univ. 2015, 33, 781–787. [Google Scholar]

- Aboura, Z.; Talbi, N.; Allaoui, S.; Benzeggagh, M. Elastic behavior of corrugated cardboard: Experiments and modeling. Compos. Struct. 2004, 63, 53–62. [Google Scholar] [CrossRef] [Green Version]

- Allaoui, S.; Aboura, Z.; Benzeggagh, M. Effects of the environmental conditions on the mechanical behaviour of the corrugated cardboard. Compos. Sci. Technol. 2009, 69, 104–110. [Google Scholar] [CrossRef]

- Shenghua, Z. Discussion on the background, present condition, and craft of foaming vegetable fiber material. Packag. Eng. 2007, 11, 239–242. [Google Scholar]

- Hongwei, J.; Xin, G.; Yuhua, G.; Dandan, W. Preparation and properties of bagasse cushioning materials. Funct. Mater. 2015, 46, 19101–19105. [Google Scholar]

- Guangsheng, Z.; Ruizhen, L.; Liangjie, Z.; Lei, C.; Cong, M. Performance and preparation of foamed waste paper pulp reinforced starch-based composites. Funct. Mater. 2012, 43, 3054–3057. [Google Scholar]

- Gang, L.; Fangyi, L.; Kaikai, G.; Peng, L.; Yu, L.; Xiujie, J.; Jianfeng, L. Preparation and properties of biomass cushion packaging material. Funct. Mater. 2013, 44, 1969–1973. [Google Scholar]

- Allen, M.Y. Development of MLFB made from Micro-wood fiber. Wood Process. Mach. 2006, 5, 36–37. [Google Scholar]

- Yan, M. Exploring the processing technology for low density boards with micro wood fiber. Wood Ind. 2006, 4, 19–21. [Google Scholar]

- Lisheng, X.; Yingjun, L. Research on the manufacturing method and process of low-density fiber formed body. China For. Prod. Ind. 2005, 32, 20–23. [Google Scholar] [CrossRef]

- Lawton, J.W.; Shogren, R.L.; Tiefenbacher, K.F. Effect of batter solids and starch type on the structure of baked starch foams. Cereal Chem. J. 1999, 76, 682–687. [Google Scholar] [CrossRef]

- Shogren, R.; Lawton, J.; Tiefenbacher, K. Baked starch foams: Starch modifications and additives improve process parameters, structure and properties. Ind. Crop. Prod. 2002, 16, 69–79. [Google Scholar] [CrossRef]

- Shibata, S.; Cao, Y.; Fukumoto, I. Effect of bagasse fiber on the flexural properties of biodegradable composites. Polym. Compos. 2005, 26, 689–694. [Google Scholar] [CrossRef]

- Verma, D.; Gope, P.; Maheshwari, M.K.; Sharma, R. Bagasse-fiber composites—A review. J. Mater. Environ. Sci. 2012, 3, 1079–1092. [Google Scholar]

- Gowda, T.M.; Naidu, A.; Chhaya, R. Some mechanical properties of untreated jute fabric-reinforced polyester composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 277–284. [Google Scholar] [CrossRef]

- Ray, D.; Sarkar, B.K.; Rana, A.K.; Bose, N.R. Effect of alkali treated jute fibres on composite properties. Bull. Mater. Sci. 2001, 24, 129–135. [Google Scholar] [CrossRef]

- Gassan, J. A study of fibre and interface parameters affecting the fatigue behaviour of natural fibre composites. Compos. Part A Appl. Sci. Manuf. 2002, 33, 369–374. [Google Scholar] [CrossRef]

- Keller, A. Compounding and mechanical properties of biodegradable hemp fibre composites. Compos. Sci. Technol. 2003, 63, 1307–1316. [Google Scholar] [CrossRef]

- Bai, J.; Li, Y.; Yang, S.; Du, J.; Wang, S.; Zheng, J.; Wang, Y.; Yang, Q.; Chen, X.; Jing, X. A simple and effective route for the preparation of poly(vinylalcohol) (PVA) nanofibers containing gold nanoparticles by electrospinning method. Solid State Commun. 2007, 141, 292–295. [Google Scholar] [CrossRef]

- Rachipudi, P.; Kariduraganavar, M.; Kittur, A.; Sajjan, A. Synthesis and characterization of sulfonated-poly(vinyl alcohol) membranes for the pervaporation dehydration of isopropanol. J. Membr. Sci. 2011, 383, 224–234. [Google Scholar] [CrossRef]

- Song, T.; Tanpichai, S.; Oksman, K. Cross-linked polyvinyl alcohol (PVA) foams reinforced with cellulose nanocrystals (CNCs). Cellulose 2016, 23, 1925–1938. [Google Scholar] [CrossRef]

- Ding, F.F.; Zhang, M.; Dong-Cai, Y.U. Research Progress in Influencing Factors on Comprehensive Performance of Plant Fiber Composite Material. Packag. Eng. 2009, 11. [Google Scholar] [CrossRef]

- Liguo, W.; Yueting, Z.; Shaohua, H. Recent Research and Development of Poly(vinyl alcohol) Hydrogels. J. Donghua Univ. Nat. Sci. 2001, 6, 114–118. [Google Scholar]

| Specimens | PVA (g) | Fibre (g) | Water (g) | Sodium Tetraborate (g) | Nucleating Agent (g) |

|---|---|---|---|---|---|

| 1: PVA of 7.11 wt% | 5 | 5 | 60 | 0.06 | 0.3 |

| 2: PVA of 8.41 wt% | 6 | 5 | 60 | 0.06 | 0.3 |

| 3: PVA of 9.67 wt% | 7 | 5 | 60 | 0.06 | 0.3 |

| 4: PVA of 10.91 wt% | 8 | 5 | 60 | 0.06 | 0.3 |

| 5: PVA of 12.10 wt% | 9 | 5 | 60 | 0.06 | 0.3 |

| Specimens | Sodium Tetraborate (g) | PVA (g) | Fibre (g) | Water (g) | Nucleating Agent (g) |

|---|---|---|---|---|---|

| a: sodium tetraborate of 0 wt% | 0 | 8 | 5 | 60 | 0.3 |

| b: sodium tetraborate of 0.027 wt% | 0.02 | 8 | 5 | 60 | 0.3 |

| c: sodium tetraborate of 0.055 wt% | 0.04 | 8 | 5 | 60 | 0.3 |

| d: sodium tetraborate of 0.082 wt% | 0.06 | 8 | 5 | 60 | 0.3 |

| e: sodium tetraborate of 0.109 wt% | 0.08 | 8 | 5 | 60 | 0.3 |

| Specimens | Water (g) | PVA (g) | Fibre (g) | Sodium Tetraborate (g) | Nucleating Agent (g) |

|---|---|---|---|---|---|

| I: Water of 80.19 wt% | 54 | 8 | 5 | 0.04 | 0.3 |

| II: Water of 80.76 wt% | 56 | 8 | 5 | 0.04 | 0.3 |

| III: Water of 81.30 wt% | 58 | 8 | 5 | 0.04 | 0.3 |

| IV: Water of 81.81 wt% | 60 | 8 | 5 | 0.04 | 0.3 |

| V: Water of 82.29 wt% | 62 | 8 | 5 | 0.04 | 0.3 |

| VI: Water of 82.75 wt% | 64 | 8 | 5 | 0.04 | 0.3 |

| VII: Water of 83.19 wt% | 66 | 8 | 5 | 0.04 | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Huang, X.; Wang, S.; Wang, D.; Guo, H. Performance of Polyvinyl Alcohol/Bagasse Fibre Foamed Composites as Cushion Packaging Materials. Coatings 2021, 11, 1094. https://doi.org/10.3390/coatings11091094

Liu B, Huang X, Wang S, Wang D, Guo H. Performance of Polyvinyl Alcohol/Bagasse Fibre Foamed Composites as Cushion Packaging Materials. Coatings. 2021; 11(9):1094. https://doi.org/10.3390/coatings11091094

Chicago/Turabian StyleLiu, Baodong, Xinjie Huang, Shuo Wang, Dongmei Wang, and Hongge Guo. 2021. "Performance of Polyvinyl Alcohol/Bagasse Fibre Foamed Composites as Cushion Packaging Materials" Coatings 11, no. 9: 1094. https://doi.org/10.3390/coatings11091094

APA StyleLiu, B., Huang, X., Wang, S., Wang, D., & Guo, H. (2021). Performance of Polyvinyl Alcohol/Bagasse Fibre Foamed Composites as Cushion Packaging Materials. Coatings, 11(9), 1094. https://doi.org/10.3390/coatings11091094