Effectiveness of Bio-Waste-Derived Carbon Doping on De-Icing Performance of an Electrically Resistant Concrete

Abstract

:1. Introduction

2. Materials and Methods

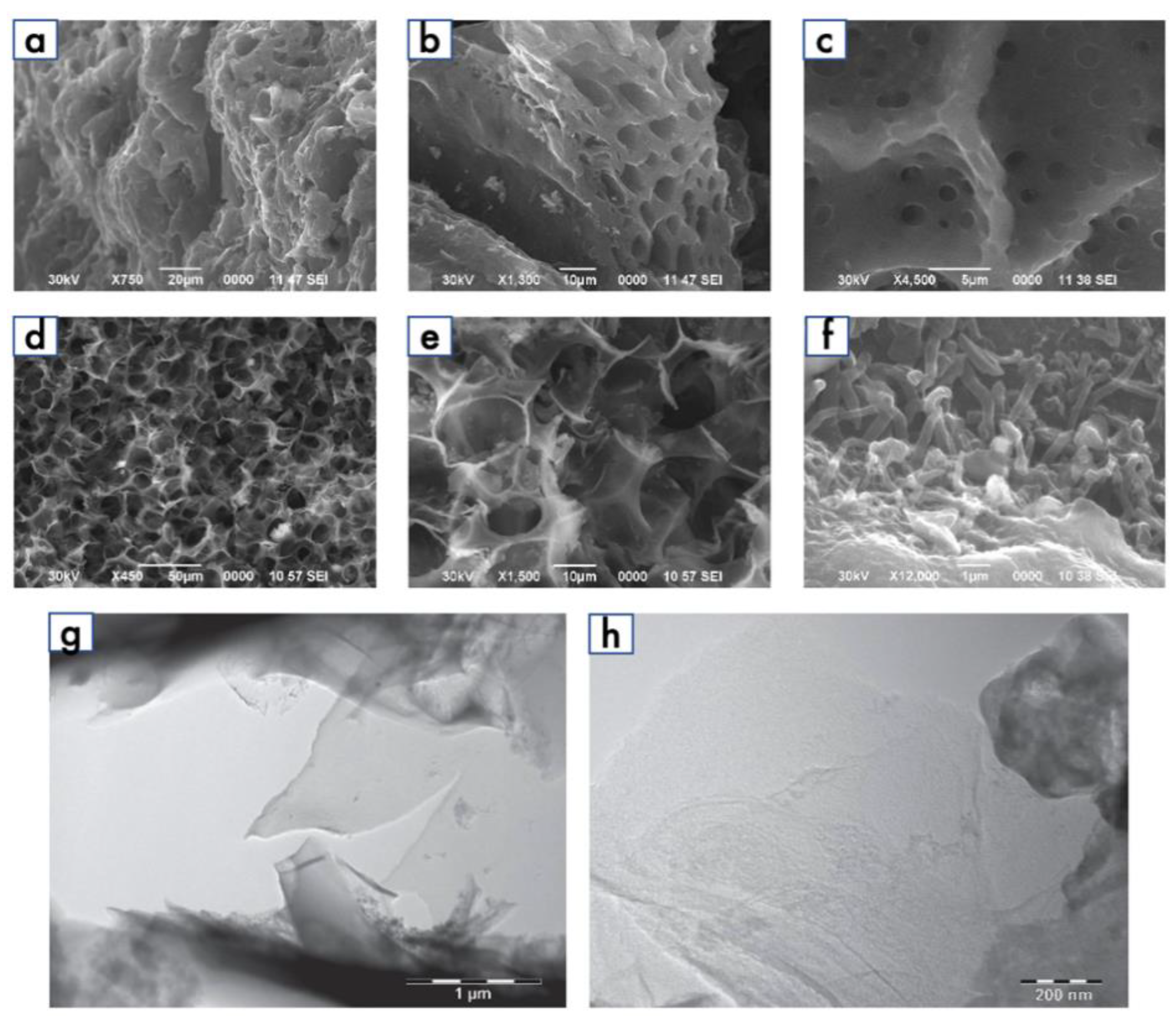

2.1. Synthesis of Graphene-like Porous Carbon from Biological Waste

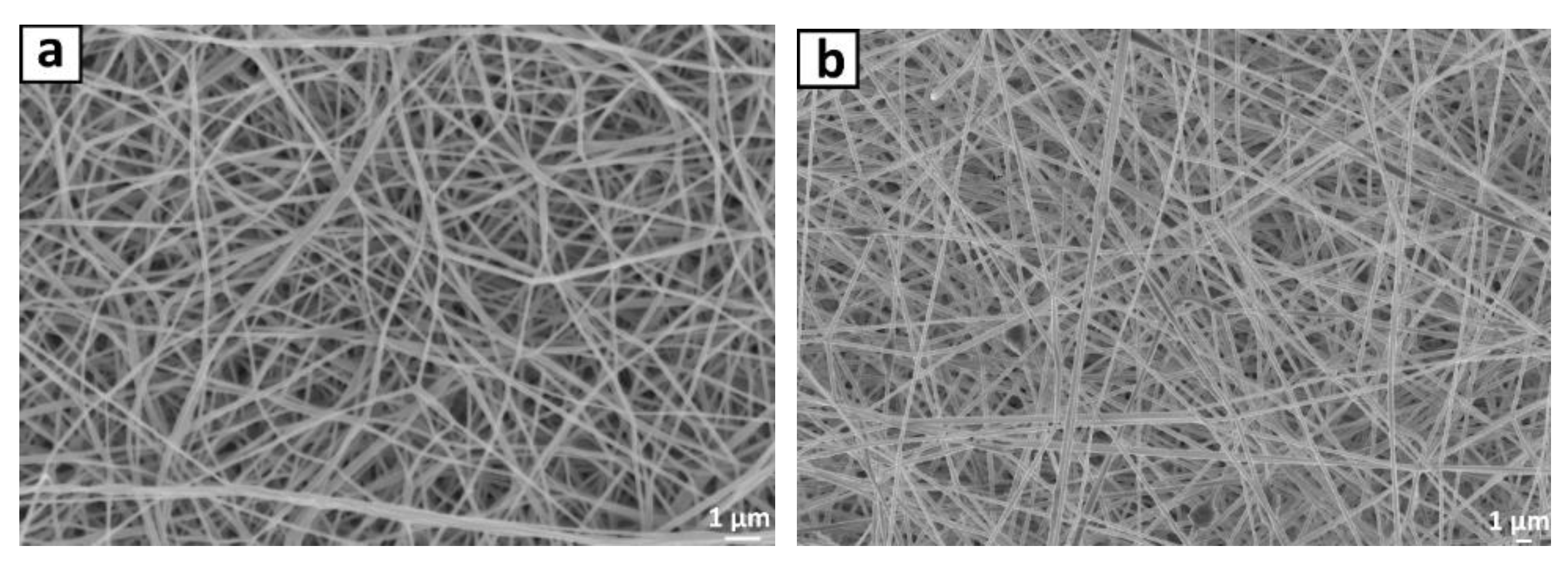

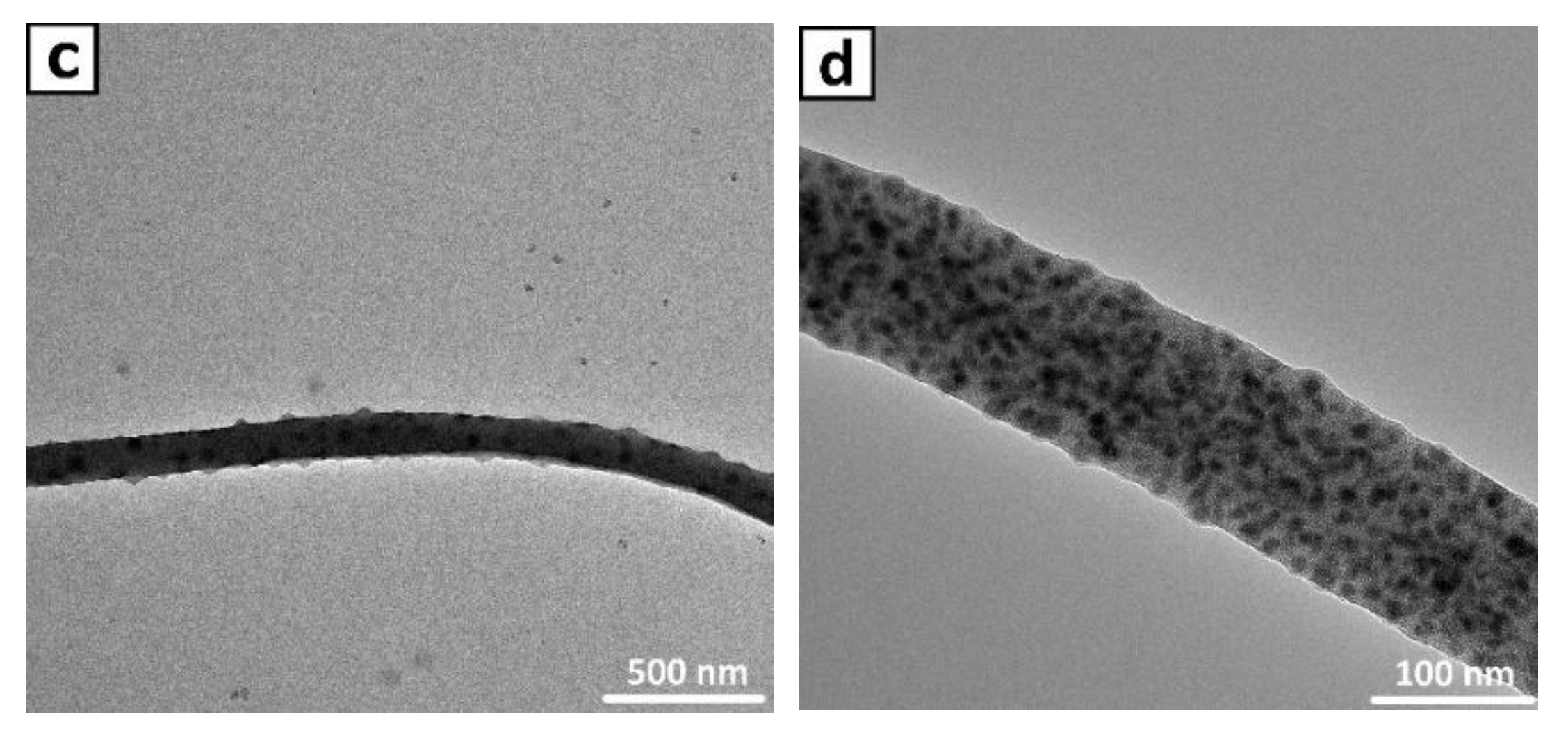

2.2. Electrospinning of CNF/GLC Composite

2.3. Preparation of the Concrete Filled with CNF/GLC Composite

2.4. Characterization

2.5. Electrical Conductivity and Heating Performance Tests

3. Results and Discussion

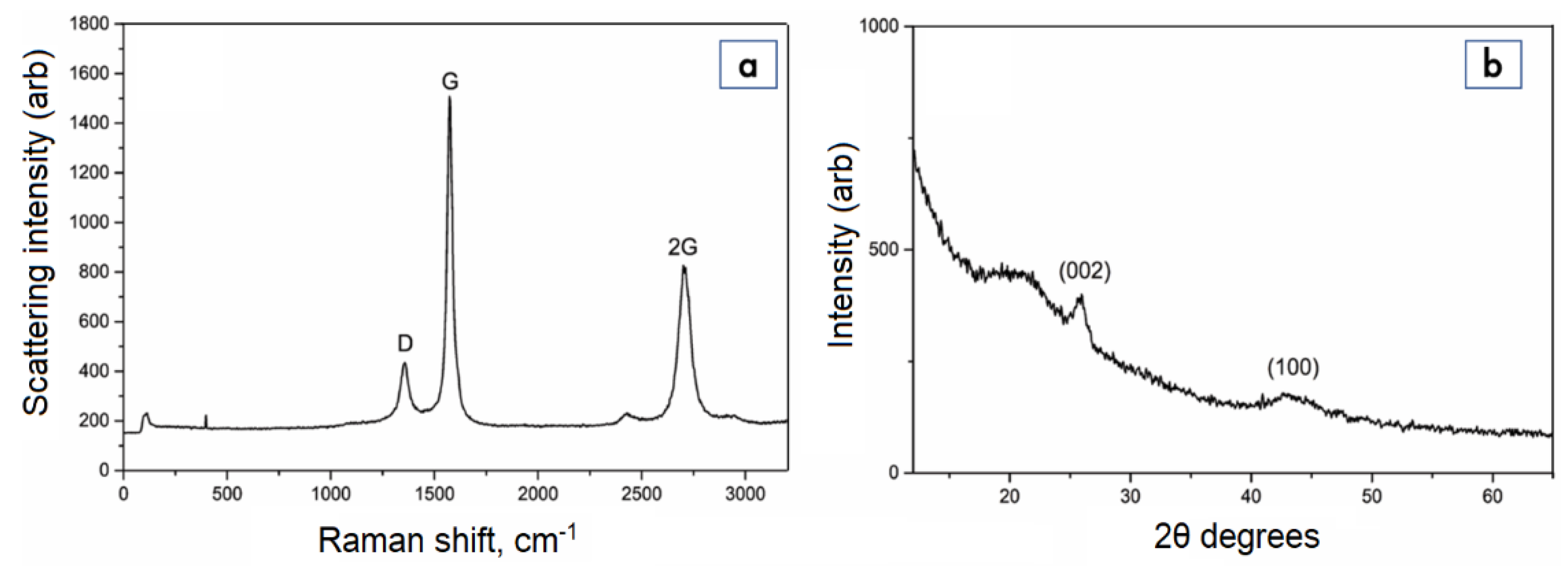

3.1. CNF, GLC, and CNF/GLC Composite Characterization

3.2. Investigation of the Concrete Unfilled and Filled with CNFs, GLC, and CNF/GLC

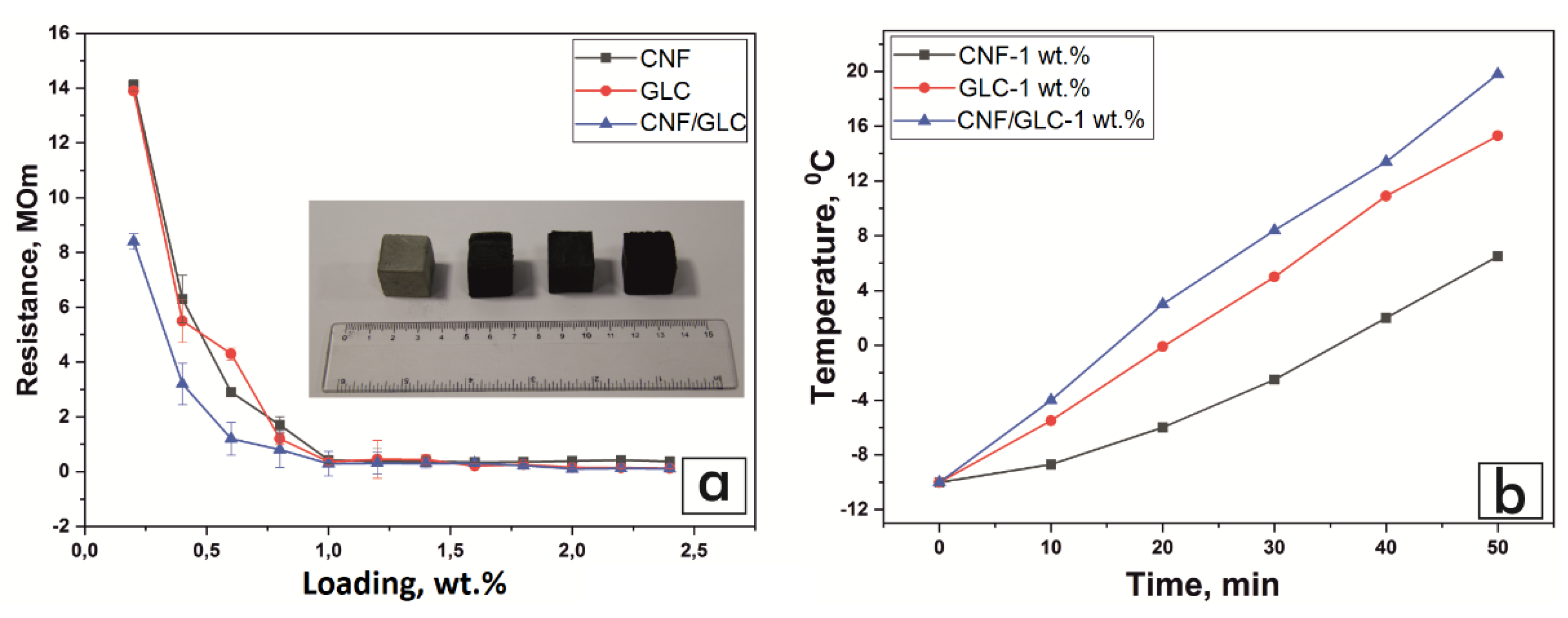

3.2.1. Electrical Resistance Tests

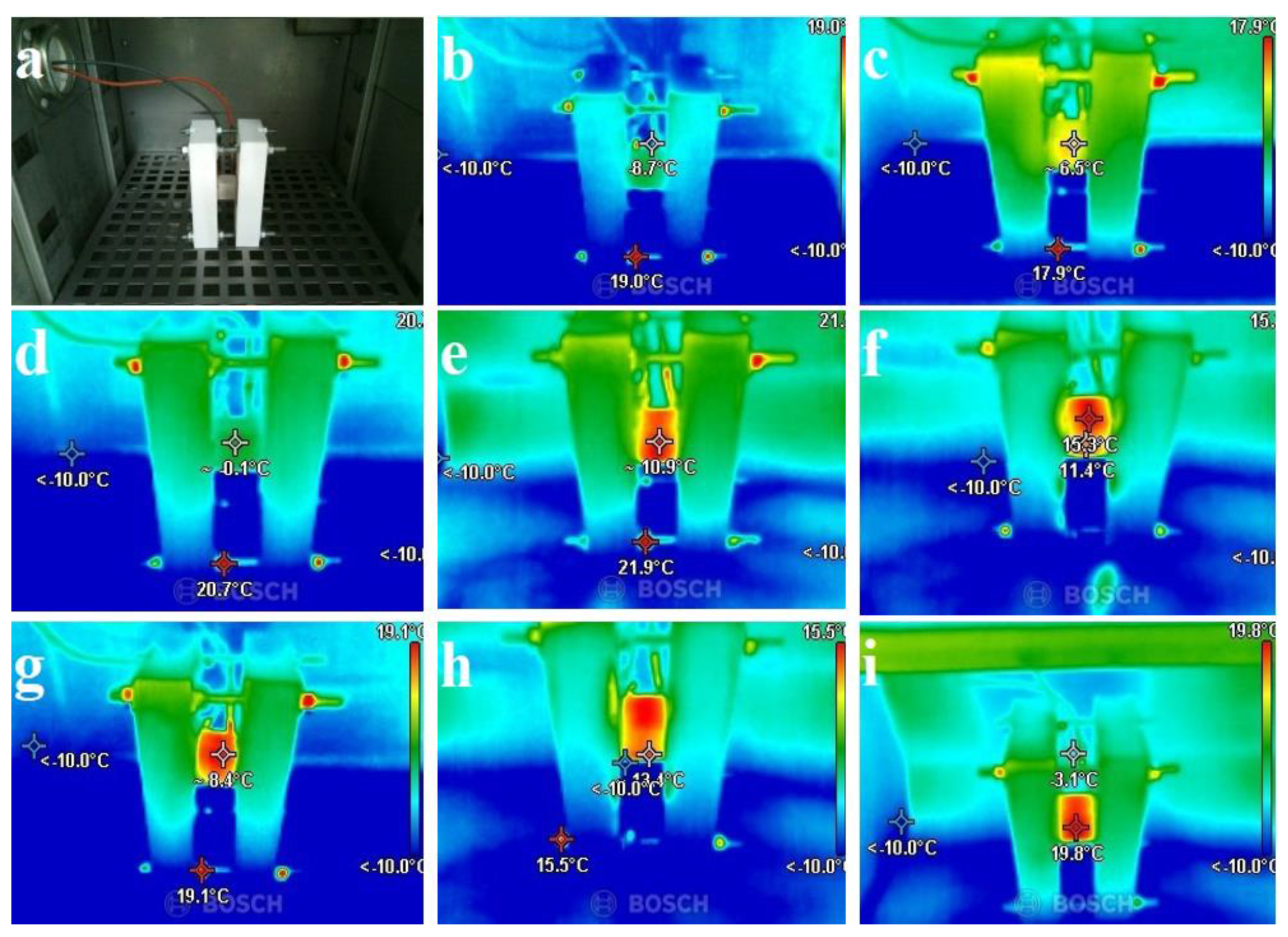

3.2.2. Heat Performance Tests

3.2.3. Mechanical and Hydrophobic Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, L.; Yang, Q.; Yang, X.; Liu, Z.; Song, Q. Numerical Investigation of Heat Transfer Performance of Graphene-Doped Anti-/Deicing Component. Therm. Sci. Eng. Prog. 2022, 28, 101098. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Liu, Z.; Song, Q.; Liu, C. Effect of Graphene Oxide Doping on Anti-/Deicing Performance of Shape Memory Epoxy Resin. Mater. Today Commun. 2022, 30, 103025. [Google Scholar] [CrossRef]

- Wang, B.; Yu, P.; Yang, Q.; Jing, Z.; Wang, W.; Li, P.; Tong, X.; Lin, F.; Wang, D.; Lio, G.E.; et al. Upcycling of Biomass Waste into Photothermal Superhydrophobic Coating for Efficient Anti-Icing and Deicing. Mater. Today Phys. 2022, 24, 100683. [Google Scholar] [CrossRef]

- Kenzhebayeva, A.; Bakbolat, B.; Sultanov, F.; Daulbayev, C.; Mansurov, Z. A Mini-Review on Recent Developments in Anti-Icing Methods. Polymers 2021, 13, 4149. [Google Scholar] [CrossRef]

- Bakr, A.R.; Fu, G.Y.; Hedeen, D. Water Quality Impacts of Bridge Stormwater Runoff from Scupper Drains on Receiving Waters: A Review. Sci. Total Environ. 2020, 726, 138068. [Google Scholar] [CrossRef]

- Novotny, E.V.; Murphy, D.; Stefan, H.G. Increase of Urban Lake Salinity by Road Deicing Salt. Sci. Total Environ. 2008, 406, 131–144. [Google Scholar] [CrossRef]

- Sanzo, D.; Hecnar, S.J. Effects of Road De-Icing Salt (NaCl) on Larval Wood Frogs (Rana Sylvatica). Environ. Pollut. 2006, 140, 247–256. [Google Scholar] [CrossRef]

- Kayama, M.; Quoreshi, A.M.; Kitaoka, S.; Kitahashi, Y.; Sakamoto, Y.; Maruyama, Y.; Kitao, M.; Koike, T. Effects of Deicing Salt on the Vitality and Health of Two Spruce Species, Picea Abies Karst., and Picea Glehnii Masters Planted along Roadsides in Northern Japan. Environ. Pollut. 2003, 124, 127–137. [Google Scholar] [CrossRef]

- Rivett, M.O.; Cuthbert, M.O.; Gamble, R.; Connon, L.E.; Pearson, A.; Shepley, M.G.; Davis, J. Highway Deicing Salt Dynamic Runoff to Surface Water and Subsequent Infiltration to Groundwater during Severe UK Winters. Sci. Total Environ. 2016, 565, 324–338. [Google Scholar] [CrossRef] [Green Version]

- Alamayreh, M.I.; Alahmer, A.; Younes, M.B.; Bazlamit, S.M. Pre-Cooling Concrete System in Massive Concrete Production: Energy Analysis and Refrigerant Replacement. Energies 2022, 15, 1129. [Google Scholar] [CrossRef]

- Li, P.; Li, W.; Sun, Z.; Shen, L.; Sheng, D. Development of Sustainable Concrete Incorporating Seawater: A Critical Review on Cement Hydration, Microstructure and Mechanical Strength. Cem. Concr. Compos. 2021, 121, 104100. [Google Scholar] [CrossRef]

- Shishegaran, A.; Daneshpajoh, F.; Taghavizade, H.; Mirvalad, S. Developing Conductive Concrete Containing Wire Rope and Steel Powder Wastes for Route Deicing. Constr. Build. Mater. 2020, 232, 117184. [Google Scholar] [CrossRef]

- Gao, J.; Guo, H.; Wang, X.; Wang, P.; Wei, Y.; Wang, Z.; Huang, Y.; Yang, B. Microwave Deicing for Asphalt Mixture Containing Steel Wool Fibers. J. Clean. Prod. 2019, 206, 1110–1122. [Google Scholar] [CrossRef]

- Dong, W.; Huang, Y.; Lehane, B.; Aslani, F.; Ma, G. Mechanical and Electrical Properties of Concrete Incorporating an Iron-Particle Contained Nano-Graphite by-Product. Constr. Build. Mater. 2021, 270, 121377. [Google Scholar] [CrossRef]

- Chen, L.; Ren, J.; Zhang, Y.; Liu, Z.; Xu, F.; Cheng, J. Microstructure Simulation and Heat Transfer Optimization for Graphene Oxide Doped Anti-/Deicing Composites. Compos. Sci. Technol. 2021, 213, 108901. [Google Scholar] [CrossRef]

- Sultanov, F.; Bakbolat, B.; Daulbaev, C.; Urazgalieva, A.; Azizov, Z.; Mansurov, Z.; Tulepov, M.; Pei, S.S. Sorptive Activity and Hydrophobic Behavior of Aerogels Based on Reduced Graphene Oxide and Carbon Nanotubes. J. Eng. Phys. Thermophys. 2017, 90, 826–830. [Google Scholar] [CrossRef]

- Lu, S.; Bai, E.; Xu, J.; Chen, J. Research on Electromagnetic Properties and Microwave Deicing Performance of Carbon Fiber Modified Concrete. Constr. Build. Mater. 2021, 286, 122868. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, X.; Wang, Y.; Luo, S. Engineering Properties and Microwave Heating Induced Ice-Melting Performance of Asphalt Mixture with Activated Carbon Powder Filler. Constr. Build. Mater. 2019, 197, 50–62. [Google Scholar] [CrossRef]

- Atamanov, M.; Amrousse, R.; Jandosov, J.; Hori, K.; Kerimkulova, A.; Chenchik, D.; Kolesnikov, B. Combustion Characteristics of HAN-Based Green Propellant Assisted with Nanoporous Active Carbons. Eurasian Chem.-Technol. J. 2017, 19, 215. [Google Scholar] [CrossRef] [Green Version]

- Daulbayev, C.; Sultanov, F.; Korobeinyk, A.V.; Yeleuov, M.; Taurbekov, A.; Bakbolat, B.; Umirzakov, A.; Baimenov, A.; Daulbayev, O. Effect of Graphene Oxide/Hydroxyapatite Nanocomposite on Osteogenic Differentiation and Antimicrobial Activity. Surf. Interfaces 2022, 28, 101683. [Google Scholar] [CrossRef]

- Yeleuov, M.; Seidl, C.; Temirgaliyeva, T.; Taurbekov, A.; Prikhodko, N.; Lesbayev, B.; Sultanov, F.; Daulbayev, C.; Kumekov, S. Modified Activated Graphene-Based Carbon Electrodes from Rice Husk for Supercapacitor Applications. Energies 2020, 13, 4943. [Google Scholar] [CrossRef]

- Yeleuov, M.; Daulbayev, C.; Taurbekov, A.; Abdisattar, A.; Ebrahim, R.; Kumekov, S.; Prikhodko, N.; Lesbayev, B.; Batyrzhan, K. Synthesis of Graphene-like Porous Carbon from Biomass for Electrochemical Energy Storage Applications. Diam. Relat. Mater. 2021, 119, 108560. [Google Scholar] [CrossRef]

- Ming, Y.; Duan, Y.; Zhang, S.; Zhu, Y.; Wang, B. Self-Heating 3D Printed Continuous Carbon Fiber/Epoxy Mesh and Its Application in Wind Turbine Deicing. Polym. Test. 2020, 82, 106309. [Google Scholar] [CrossRef]

- Pan, L.; Liu, Z.; kızıltaş, O.; Zhong, L.; Pang, X.; Wang, F.; Zhu, Y.; Ma, W.; Lv, Y. Carbon Fiber/Poly Ether Ether Ketone Composites Modified with Graphene for Electro-Thermal Deicing Applications. Compos. Sci. Technol. 2020, 192, 108117. [Google Scholar] [CrossRef]

- Sassani, A.; Arabzadeh, A.; Ceylan, H.; Kim, S.; Sadati, S.M.S.; Gopalakrishnan, K.; Taylor, P.C.; Abdualla, H. Carbon Fiber-Based Electrically Conductive Concrete for Salt-Free Deicing of Pavements. J. Clean. Prod. 2018, 203, 799–809. [Google Scholar] [CrossRef]

- Rhee, I.; Lee, J.-S.; Kim, J.H.; Kim, Y.A. Thermal Performance, Freeze-and-Thaw Resistance, and Bond Strength of Cement Mortar Using Rice Husk-Derived Graphene. Constr. Build. Mater. 2017, 146, 350–359. [Google Scholar] [CrossRef]

- Daulbayev, C.; Sultanov, F.; Korobeinyk, A.V.; Yeleuov, M.; Azat, S.; Bakbolat, B.; Umirzakov, A.; Mansurov, Z. Bio-Waste-Derived Few-Layered Graphene/SrTiO3/PAN as Efficient Photocatalytic System for Water Splitting. Appl. Surf. Sci. 2021, 549, 149176. [Google Scholar] [CrossRef]

- Amiri, M.; Golmohammadi, F. Biomass Derived Hierarchical 3D Graphene Framework for High Performance Energy Storage Devices. J. Electroanal. Chem. 2019, 849, 113388. [Google Scholar] [CrossRef]

- Singh, N.; Sharma, M.; Mondal, D.; Maru, D.A.; Rathod, M.R.; Sequeira, R.A.; Chudasama, N.A.; Prasad, K. Seaweed Biomass Derived Bio Solvents for the Large Scale Production of Few Layered Graphene Nanosheets from Graphite. Mater. Sci. Energy Technol. 2021, 4, 100–106. [Google Scholar] [CrossRef]

- Prikhod’ko, N.G.; Mansurov, Z.A.; Auelkhankyzy, M.; Lesbaev, B.T.; Nazhipkyzy, M.; Smagulova, G.T. Flame Synthesis of Graphene Layers at Low Pressure. Russ. J. Phys. Chem. B 2015, 9, 743–747. [Google Scholar] [CrossRef]

- Ferrari, A.C. Raman Spectroscopy of Graphene and Graphite: Disorder, Electron–Phonon Coupling, Doping and Nonadiabatic Effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Stobinski, L.; Lesiak, B.; Malolepszy, A.; Mazurkiewicz, M.; Mierzwa, B.; Zemek, J.; Jiricek, P.; Bieloshapka, I. Graphene Oxide and Reduced Graphene Oxide Studied by the XRD, TEM and Electron Spectroscopy Methods. J. Electron. Spectrosc. Relat. Phenom. 2014, 195, 145–154. [Google Scholar] [CrossRef]

- Wu, S.; Mo, L.; Shui, Z.; Chen, Z. Investigation of the Conductivity of Asphalt Concrete Containing Conductive Fillers. Carbon 2005, 43, 1358–1363. [Google Scholar] [CrossRef]

- AlShareedah, O.; Nassiri, S. Spherical Discrete Element Model for Estimating the Hydraulic Conductivity and Pore Clogging of Pervious Concrete. Constr. Build. Mater. 2021, 305, 124749. [Google Scholar] [CrossRef]

- Shen, L.; Yao, X.; Zhu, D.; Alkayem, N.F.; Cao, M.; Ren, Q. A Thermal Cracking Pattern-Based Multiscale Homogenization Method for Effective Thermal Conductivity of Steel Fiber Reinforced Concrete after High Temperature. Int. J. Heat Mass Transf. 2021, 180, 121732. [Google Scholar] [CrossRef]

- Dehghanpour, H.; Yilmaz, K.; Ipek, M. Evaluation of Recycled Nano Carbon Black and Waste Erosion Wires in Electrically Conductive Concretes. Constr. Build. Mater. 2019, 221, 109–121. [Google Scholar] [CrossRef]

- Zhu, X.; Bai, Y.; Chen, X.; Tian, Z.; Ning, Y. Evaluation and Prediction on Abrasion Resistance of Hydraulic Concrete after Exposure to Different Freeze-Thaw Cycles. Constr. Build. Mater. 2022, 316, 126055. [Google Scholar] [CrossRef]

- Saidmurodov, S.S.; Jacobsen, S.; Hendriks, M.A.N.; Shamsutdinova, G. An Evaluation of the Ice Melting during Concrete-Ice Abrasion Experiment. Case Stud. Therm. Eng. 2022, 35, 102088. [Google Scholar] [CrossRef]

- Wang, C.; Fu, H.; Ma, W.; Zhang, Z.; Ji, X.; Han, X. Combination Design and Performance Evaluation of Conductive Bonding Layer for Asphalt Pavement Active Deicing. Constr. Build. Mater. 2020, 263, 121037. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Y.; Liu, W.; Yan, D. Microwave Heating and Deicing Efficiency for Asphalt Concrete with SiC–Fe3O4 Microwave Enhanced Functional Layer. J. Clean. Prod. 2022, 332, 130111. [Google Scholar] [CrossRef]

- Rao, R.; Fu, J.; Chan, Y.; Tuan, C.Y.; Liu, C. Steel Fiber Confined Graphite Concrete for Pavement Deicing. Compos. Part B Eng. 2018, 155, 187–196. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, Z.; Wang, S.; Zheng, J.; Che, G. Concrete Pavement Deicing with Carbon Fiber Heating Wires. Cold Reg. Sci. Technol. 2011, 65, 413–420. [Google Scholar] [CrossRef]

- Liu, J.; Xu, J.; Huang, H.; Chen, H. Microwave Deicing Efficiency and Dielectric Property of Road Concrete Modified Using Different Wave Absorbing Material. Cold Reg. Sci. Technol. 2020, 174, 103064. [Google Scholar] [CrossRef]

| Equipment | Manifacturer/Model | Specifications |

|---|---|---|

| Digital multimeter | Total (TMT47503) | Non-contact voltage detection; DC Voltage: 600 mV/6 V/60 V/600 V/1000 V ± (0.5% + 3); Resistance: 600 Ω/6 kΩ/60 kΩ/600 kΩ/6 MΩ ± (0.8% + 3). |

| Thermal camera | Bosch GTC 400 C | Measurement range: 10 °C to + 400 °C; Measurement accuracy of IR: ±3.0 °C; Resolution: 0.1 °C; Focus distance—minimum: 0.3 m. |

| No. | CNF | GLC | CNF/GLC Composite | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Content, wt.% | Resistance, MΩ | Power, W | Content, wt.% | Resistance, MΩ | Power, W | Content, wt.% | Resistance, MΩ | Power, W | |

| 1 | 0.2 | 14.1 ± 0.2 | 7.09 | 0.2 | 13.9 ± 0.14 | 7.19 | 0.2 | 8.4 ± 0.29 | 11.9 |

| 2 | 0.4 | 6.3 ± 0.87 | 15.87 | 0.4 | 5.5 ± 0.78 | 18.18 | 0.4 | 3.2 ± 0.76 | 31.25 |

| 3 | 0.6 | 2.9 ± 0.15 | 34.48 | 0.6 | 4.3 ± 0.22 | 23.26 | 0.6 | 1.2 ± 0.6 | 83.33 |

| 4 | 0.8 | 1.7 ± 0.3 | 58.82 | 0.8 | 1.2 ± 0.21 | 83.33 | 0.8 | 0.8 ± 0.065 | 125 |

| 5 | 1 | 0.42 ± 0.12 | 238.1 | 1 | 0.36 ± 0.12 | 277.78 | 1 | 0.29 ± 0.045 | 344.83 |

| 6 | 1.2 | 0.38 ± 0.046 | 263.16 | 1.2 | 0.45 ± 0.069 | 222.22 | 1.2 | 0.31 ± 0.04 | 322.58 |

| 7 | 1.4 | 0.381 ± 0.17 | 262.47 | 1.4 | 0.44 ± 0.17 | 227.27 | 1.4 | 0.3 ± 0.17 | 333.33 |

| 8 | 1.6 | 0.34 ± 0.01 | 294.12 | 1.6 | 0.21 ± 0.096 | 476.19 | 1.6 | 0.31 ± 0.1 | 322.58 |

| 9 | 1.8 | 0.35 ± 0.021 | 285.71 | 1.8 | 0.26 ± 0.078 | 384.62 | 1.8 | 0.22 ± 0.02 | 454.55 |

| 10 | 2 | 0.39 ± 0.019 | 256.41 | 2 | 0.15 ± 0.042 | 666,67 | 2 | 0.1 ± 0.019 | 1000 |

| 11 | 2.2 | 0.42 ± 0.084 | 238.1 | 2.2 | 0.14 ± 0.035 | 714.29 | 2,2 | 0.12 ± 0.09 | 833.33 |

| 12 | 2.4 | 0.37 ± 0.014 | 270.27 | 2.4 | 0.12 ± 0.017 | 833.33 | 2.4 | 0.11 ± 0.041 | 909.09 |

| CNF | GLC | CNF/GLC composite | |||||||

| Content, wt.% | Resistance, MΩ | Power, W | Content, wt.% | Resistance, MΩ | Power, W | Content, wt.% | Resistance, MΩ | Power, W | |

| 0.2 | 14.1 ± 0.2 | 7.09 | 0.2 | 13.9 ± 0.14 | 7.19 | 0.2 | 8.4 ± 0.29 | 11.9 | |

| 0.4 | 6.3 ± 0.87 | 15.87 | 0.4 | 5.5 ± 0.78 | 18.18 | 0.4 | 3.2 ± 0.76 | 31.25 | |

| 0.6 | 2.9 ± 0.15 | 34.48 | 0.6 | 4.3 ± 0.22 | 23.26 | 0.6 | 1.2 ± 0.6 | 83.33 | |

| 0.8 | 1.7 ± 0.3 | 58.82 | 0.8 | 1.2 ± 0.21 | 83.33 | 0.8 | 0.8 ± 0.065 | 125 | |

| 1 | 0.42 ± 0.12 | 238.1 | 1 | 0.36 ± 0.12 | 277.78 | 1 | 0.29 ± 0.045 | 344.83 | |

| 1.2 | 0.38 ± 0.046 | 263.16 | 1.2 | 0.45 ± 0.069 | 222.22 | 1.2 | 0.31 ± 0.04 | 322.58 | |

| 1.4 | 0.381 ± 0.17 | 262.47 | 1.4 | 0.44 ± 0.17 | 227.27 | 1.4 | 0.3 ± 0.17 | 333.33 | |

| 1.6 | 0.34 ± 0.01 | 294.12 | 1.6 | 0.21 ± 0.096 | 476.19 | 1.6 | 0.31 ± 0.1 | 322.58 | |

| 1.8 | 0.35 ± 0.021 | 285.71 | 1.8 | 0.26 ± 0.078 | 384.62 | 1.8 | 0.22 ± 0.02 | 454.55 | |

| 2 | 0.39 ± 0.019 | 256.41 | 2 | 0.15 ± 0.042 | 666.67 | 2 | 0.1 ± 0.019 | 1000 | |

| 2.2 | 0.42 ± 0.084 | 238.1 | 2.2 | 0.14 ± 0.035 | 714.29 | 2.2 | 0.12 ± 0.09 | 833.33 | |

| 2.4 | 0.37 ± 0.014 | 270.27 | 2.4 | 0.12 ± 0.017 | 833.33 | 2.4 | 0.11 ± 0.041 | 909.09 | |

| Material Composition | Applied De-Icing Approach | Characteristics of the De-Icing Process | Ref. |

|---|---|---|---|

| Carbon fiber conductive bonding layer | Electrothermal | At the constant temperature of −5 °C, the surface temperature of the pavement could reach above 0 °C after the conductive bonding layer was electrified for 100 min under 36 V voltage | [39] |

| SiC-Fe3O4 | Microwave | The ice-thawing time of microwave-enhanced functional layer with −15 °C initial temperature was 46 s. It was increased about 1.7 times in contrast to −5 °C. | [40] |

| Carbon fiber | Microwave | The results show that carbon fiber-modified concrete has the highest heating rate, with a value of 1.680 °C/s, which is 4.46 times higher than that of pristine concrete. | [17] |

| Steel fiber confined graphite | Electrothermal | The average surface power density of the ramps was between 200 W/m2 and 300 W/m2, which is adequate for melting ice in winter environment. | [41] |

| Carbon fiber heating wires | Electrothermal | A heating experiment on concrete slabs with carbon fiber heating wires was conducted in a refrigerator at −25 °C. It is shown that with an input power of 1134 W/m2, the temperature on the slab’s surface rises above 0 °C after 2.5 h at an approximate rate of 0.17 °C/min. | [42] |

| Iron black, silicon carbon, and graphite | Microwave | The enhancements of the three absorbing materials ranked from high to low are in the following order: graphite, iron black, and silicon carbon. | [43] |

| Carbon fibers/graphene-like porous carbon composite (CNF/GLC) | Electrothermal | Modified concrete was heated to +19.8 °C at low voltage (10 V). | This article |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bakbolat, B.; Daulbayev, C.; Sultanov, F.; Taurbekov, A.; Tolynbekov, A.; Yeleuov, M.; Korobeinyk, A.V.; Mansurov, Z. Effectiveness of Bio-Waste-Derived Carbon Doping on De-Icing Performance of an Electrically Resistant Concrete. Coatings 2022, 12, 1629. https://doi.org/10.3390/coatings12111629

Bakbolat B, Daulbayev C, Sultanov F, Taurbekov A, Tolynbekov A, Yeleuov M, Korobeinyk AV, Mansurov Z. Effectiveness of Bio-Waste-Derived Carbon Doping on De-Icing Performance of an Electrically Resistant Concrete. Coatings. 2022; 12(11):1629. https://doi.org/10.3390/coatings12111629

Chicago/Turabian StyleBakbolat, Baglan, Chingis Daulbayev, Fail Sultanov, Azamat Taurbekov, Aidos Tolynbekov, Mukhtar Yeleuov, Alina V. Korobeinyk, and Zulkhair Mansurov. 2022. "Effectiveness of Bio-Waste-Derived Carbon Doping on De-Icing Performance of an Electrically Resistant Concrete" Coatings 12, no. 11: 1629. https://doi.org/10.3390/coatings12111629

APA StyleBakbolat, B., Daulbayev, C., Sultanov, F., Taurbekov, A., Tolynbekov, A., Yeleuov, M., Korobeinyk, A. V., & Mansurov, Z. (2022). Effectiveness of Bio-Waste-Derived Carbon Doping on De-Icing Performance of an Electrically Resistant Concrete. Coatings, 12(11), 1629. https://doi.org/10.3390/coatings12111629