Water-Repellent Coatings on Corrosion Resistance by Femtosecond Laser Processing

Abstract

:1. Introduction

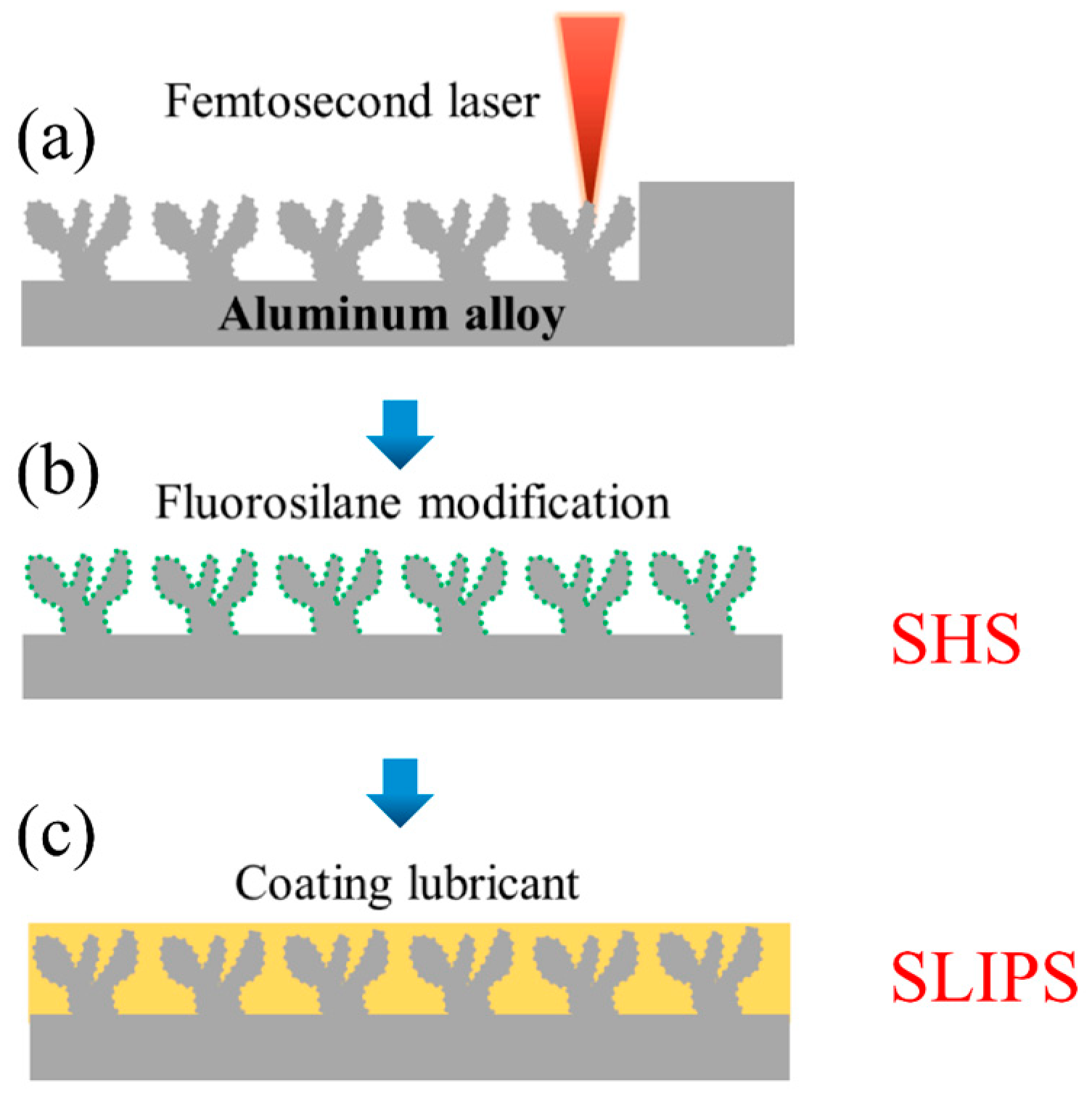

2. Materials and Methods

2.1. Femtosecond Laser Processing

2.2. Fabrication Water-Repellent Coatings

2.3. Morphology and Wettability

2.4. Electrochemical Measurements

3. Results and Discussion

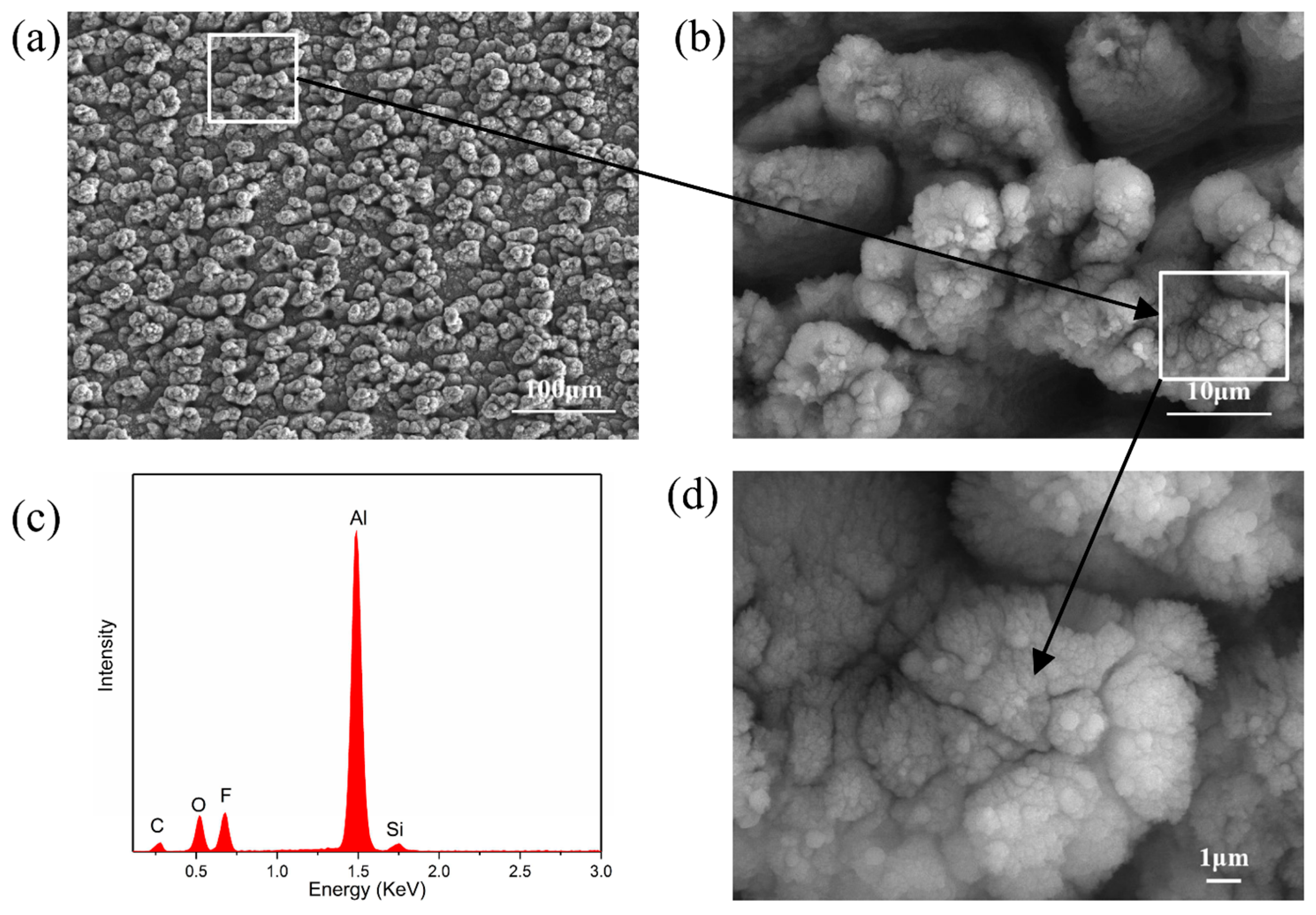

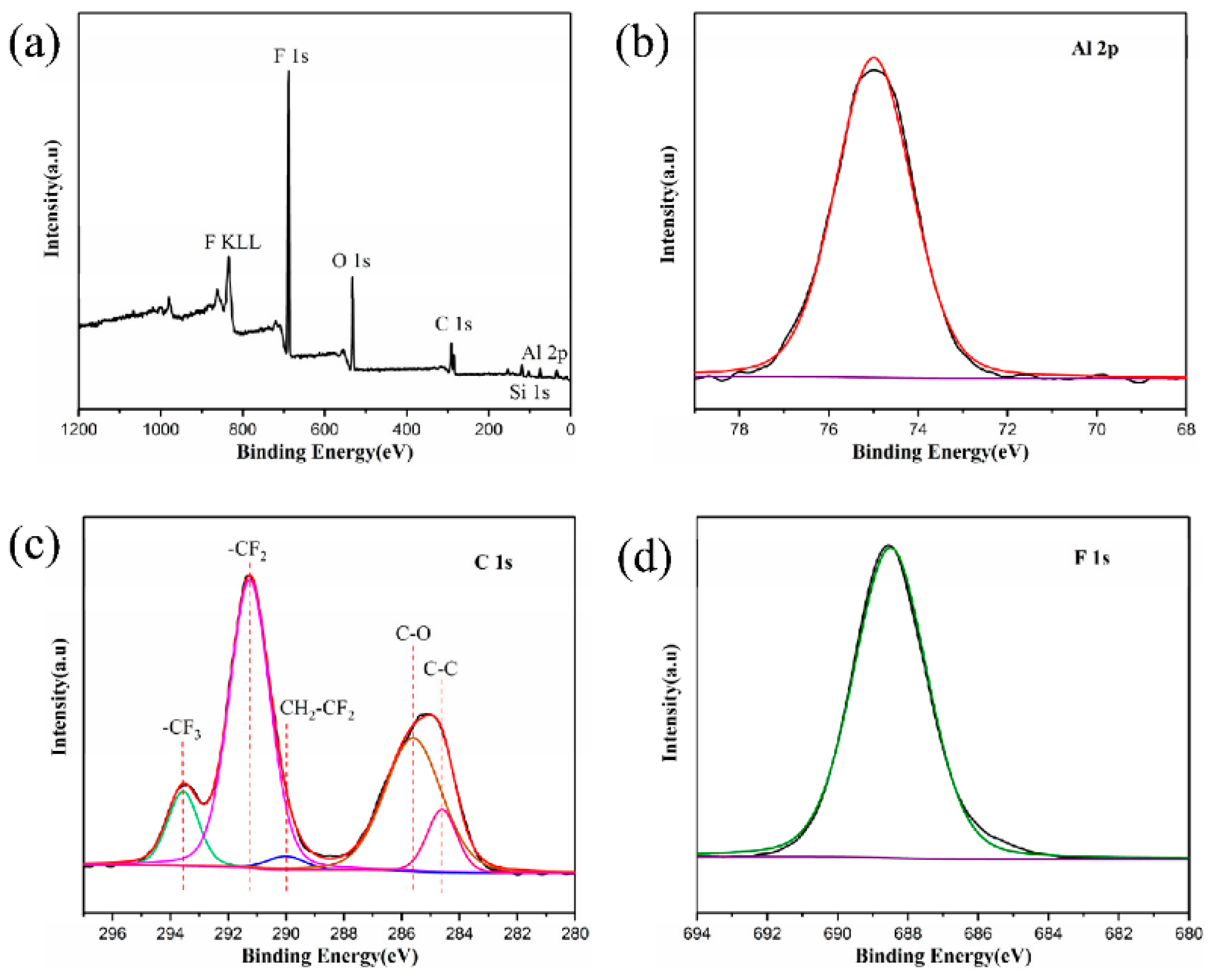

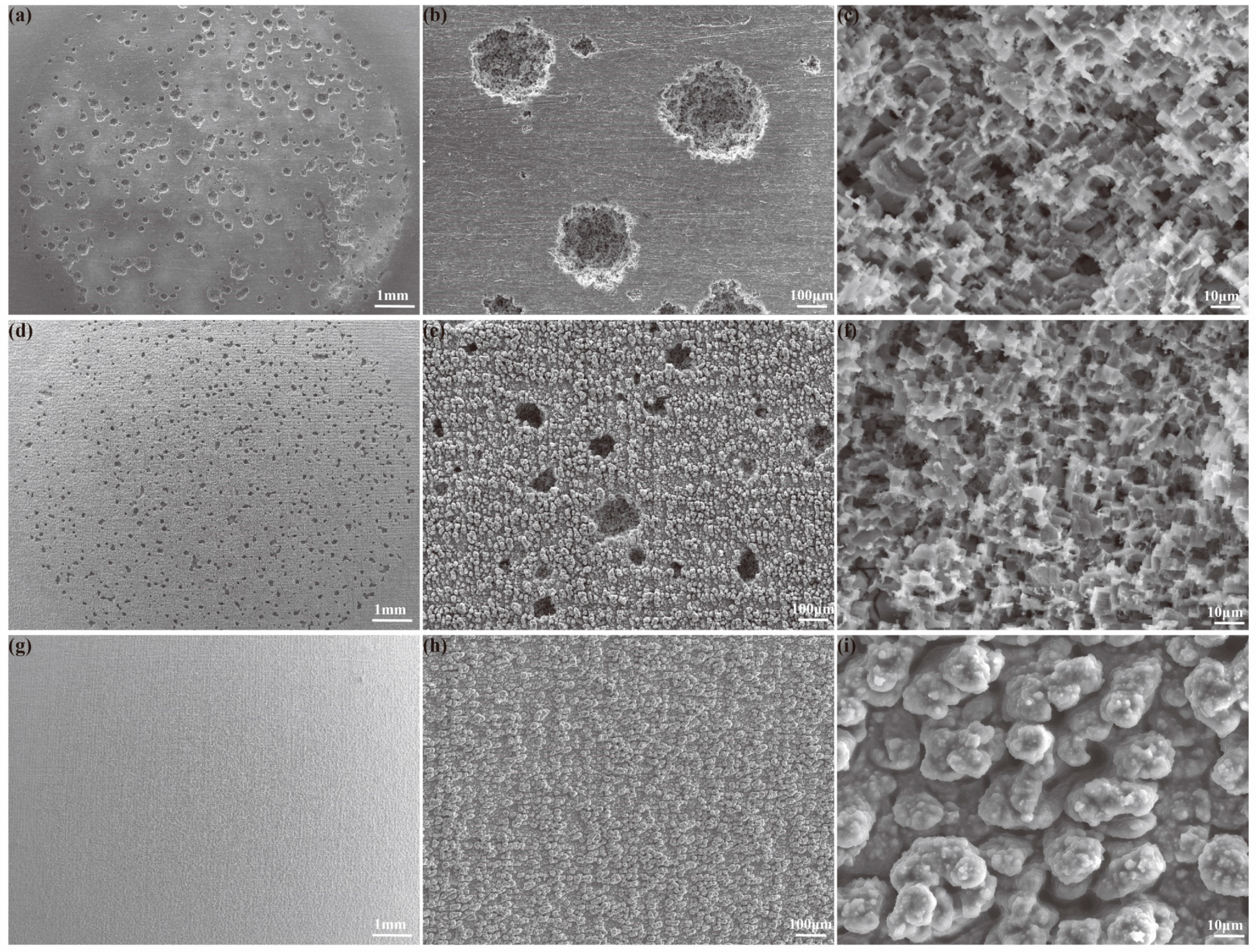

3.1. Morphology and Composition

3.2. Wettability

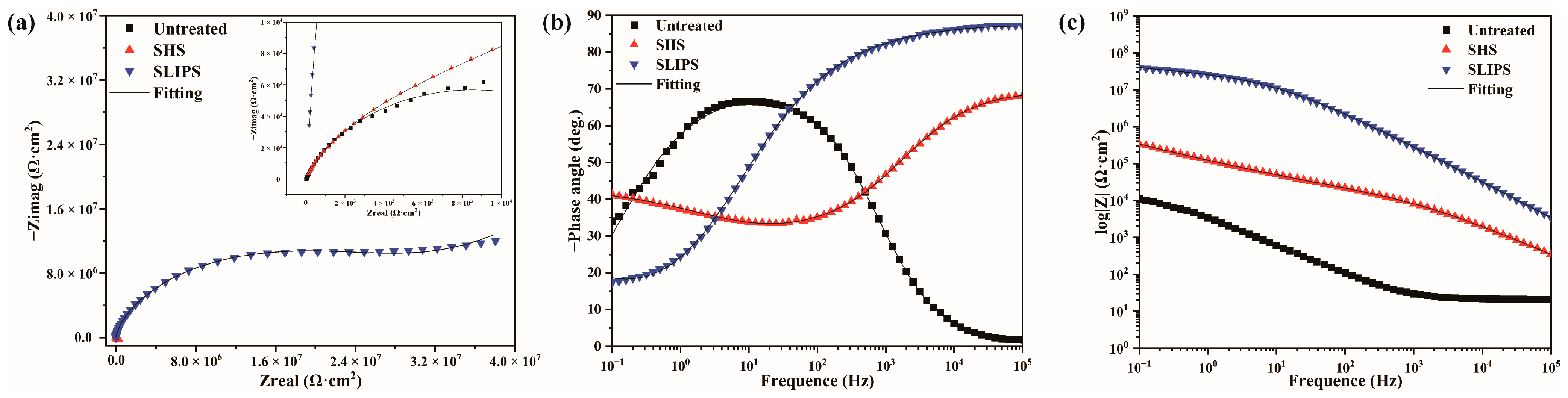

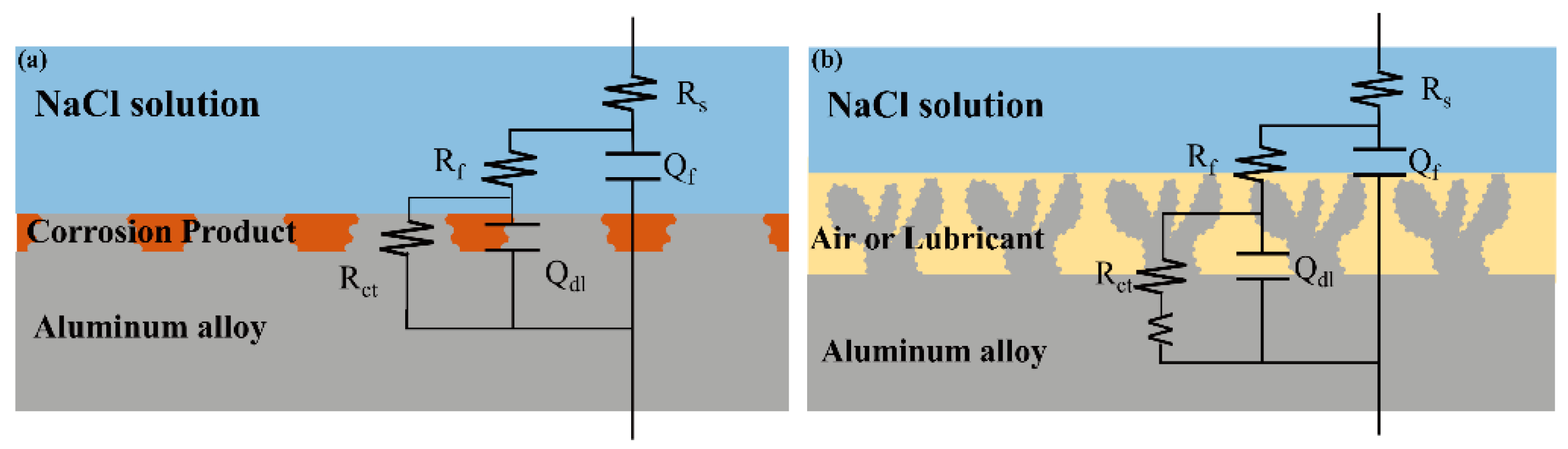

3.3. Corrosion Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sabel, C.F.; Victor, D.G. Governing global problems under uncertainty: Making bottom-up climate policy work. Clim. Change 2015, 144, 15–27. [Google Scholar] [CrossRef]

- Allachi, H.; Chaouket, F.; Draoui, K. Protection against corrosion in marine environments of AA6060 aluminium alloy by cerium chlorides. J. Alloys Compd. 2010, 491, 223–229. [Google Scholar] [CrossRef]

- Luo, G.; Xiao, H.; Li, S.; Wang, C.; Zhu, Q.; Song, L. Quasi-continuous-wave laser surface melting of aluminium alloy: Precipitate morphology, solute segregation and corrosion resistance. Corros. Sci. 2019, 152, 109–119. [Google Scholar] [CrossRef]

- Bandeira, R.M.; van Drunen, J.; de Souza Ferreira, F.A.; Rodrigues-Filho, U.P.; Tremiliosi-Filho, G. Chemically synthesized polyaniline/polyvinyl chloride blended coatings for the corrosion protection of AA7075 aluminum alloy. Corros. Sci. 2018, 139, 35–46. [Google Scholar] [CrossRef]

- Hikku, G.S.; Jeyasubramanian, K.; Venugopal, A.; Ghosh, R. Corrosion resistance behaviour of graphene/polyvinyl alcohol nanocomposite coating for aluminium-2219 alloy. J. Alloys Compd. 2017, 716, 259–269. [Google Scholar] [CrossRef]

- El-Etre, A.Y. Inhibition of aluminum corrosion using Opuntia extract. Corros. Sci. 2003, 45, 2485–2495. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, R.; Long, F.; Zhou, T.; Hu, W.; Liu, L. Durable superhydrophobic coating derived from hard-soft technology with enhanced anticorrosion performance. Corros. Sci. 2021, 193, 109889. [Google Scholar] [CrossRef]

- Xun, X.; Wan, Y.; Zhang, Q.; Gan, D.; Hu, J.; Luo, H. Low adhesion superhydrophobic AZ31B magnesium alloy surface with corrosion resistant and anti-bioadhesion properties. Appl. Surf. Sci. 2020, 505, 144566. [Google Scholar] [CrossRef]

- Mousavi, S.M.A.; Pitchumani, R. A study of corrosion on electrodeposited superhydrophobic copper surfaces. Corros. Sci. 2021, 186, 109420. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Y.; Hu, Z.; Zhang, X.; Wu, S.; Wang, R.; Zhu, Y. A novel electrodeposition route for fabrication of the superhydrophobic surface with unique self-cleaning, mechanical abrasion and corrosion resistance properties. Chem. Eng. J. 2016, 303, 37–47. [Google Scholar] [CrossRef]

- Liu, C.; Su, F.; Liang, J. Facile fabrication of a robust and corrosion resistant superhydrophobic aluminum alloy surface by a novel method. RSC Adv. 2014, 4, 55556–55564. [Google Scholar] [CrossRef]

- Latthe, S.S.; Terashima, C.; Nakata, K.; Sakai, M.; Fujishima, A. Development of sol–gel processed semi-transparent and self-cleaning superhydrophobic coatings. J. Mater. Chem. A 2014, 2, 5548–5553. [Google Scholar] [CrossRef]

- Wang, P.; Li, T.; Zhang, D. Fabrication of non-wetting surfaces on zinc surface as corrosion barrier. Corros. Sci. 2017, 128, 110–119. [Google Scholar] [CrossRef]

- Shen, P.; Uesawa, N.; Inasawa, S.; Yamaguchi, Y. Characterization of flowerlike silicon particles obtained from chemical etching: Visible fluorescence and superhydrophobicity. Langmuir 2010, 26, 13522–13527. [Google Scholar] [CrossRef]

- Trdan, U.; Hočevar, M.; Gregorčič, P. Transition from superhydrophilic to superhydrophobic state of laser textured stainless steel surface and its effect on corrosion resistance. Corros. Sci. 2017, 123, 21–26. [Google Scholar] [CrossRef] [Green Version]

- Radwan, A.B.; El-Hout, S.I.; Ibrahim, M.A.M.; Ismail, E.H.; Abdullah, A.M. Superior Corrosion and UV-Resistant Highly Porous Poly(vinylidene fluoride-co-hexafluoropropylene)/alumina Superhydrophobic Coating. ACS Appl. Polym. Mater. 2022, 4, 1358–1367. [Google Scholar] [CrossRef]

- Sarkar, M.K.; Bal, K.; He, F.; Fan, J. Design of an outstanding super-hydrophobic surface by electro-spinning. Appl. Surf. Sci. 2011, 257, 7003–7009. [Google Scholar] [CrossRef]

- Ma, Q.; Tong, Z.; Wang, W.; Dong, G. Fabricating robust and repairable superhydrophobic surface on carbon steel by nanosecond laser texturing for corrosion protection. Appl. Surf. Sci. 2018, 455, 748–757. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Direct femtosecond laser surface nano/microstructuring and its applications. Laser Photonics Rev. 2013, 7, 385–407. [Google Scholar] [CrossRef]

- Song, Y.; Wang, C.; Dong, X.; Yin, K.; Zhang, F.; Xie, Z.; Chu, D.; Duan, J. Controllable superhydrophobic aluminum surfaces with tunable adhesion fabricated by femtosecond laser. Opt. Laser Technol. 2018, 102, 25–31. [Google Scholar] [CrossRef]

- Rukosuyev, M.V.; Lee, J.; Cho, S.J.; Lim, G.; Jun, M.B.G. One-step fabrication of superhydrophobic hierarchical structures by femtosecond laser ablation. Appl. Surf. Sci. 2014, 313, 411–417. [Google Scholar] [CrossRef]

- Yuan, G.; Liu, Y.; Ngo, C.V.; Guo, C. Rapid fabrication of anti-corrosion and self-healing superhydrophobic aluminum surfaces through environmentally friendly femtosecond laser processing. Opt. Express 2020, 28, 35636–35650. [Google Scholar] [CrossRef]

- Wong, T.S.; Kang, S.H.; Tang, S.K.; Smythe, E.J.; Hatton, B.D.; Grinthal, A.; Aizenberg, J. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity. Nature 2011, 477, 443–447. [Google Scholar] [CrossRef] [PubMed]

- Kim, P.; Kreder, M.J.; Alvarenga, J.; Aizenberg, J. Hierarchical or not? Effect of the length scale and hierarchy of the surface roughness on omniphobicity of lubricant-infused substrates. Nano Lett. 2013, 13, 1793–1799. [Google Scholar] [CrossRef] [PubMed]

- Trdan, U.; Sano, T.; Klobčar, D.; Sano, Y.; Grum, J.; Šturm, R. Improvement of corrosion resistance of AA2024-T3 using femtosecond laser peening without protective and confining medium. Corros. Sci. 2018, 143, 46–55. [Google Scholar] [CrossRef]

- Ahmmed, K.M.T.; Grambow, C.; Kietzig, A.-M. Fabrication of micro/nano structures on metals by femtosecond laser micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef] [Green Version]

- Fan, P.; Bai, B.; Jin, G.; Zhang, H.; Zhong, M. Patternable fabrication of hyper-hierarchical metal surface structures for ultrabroadband antireflection and self-cleaning. Appl. Surf. Sci. 2018, 457, 991–999. [Google Scholar] [CrossRef]

- Saleema, N.; Sarkar, D.K.; Paynter, R.W.; Chen, X.G. Superhydrophobic aluminum alloy surfaces by a novel one-step process. ACS Appl Mater Interfaces 2010, 2, 2500–2502. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Lu, Z.; Zhang, D. Slippery liquid-infused porous surfaces fabricated on aluminum as a barrier to corrosion induced by sulfate reducing bacteria. Corros. Sci. 2015, 93, 159–166. [Google Scholar] [CrossRef]

- Lee, J.-M.; Kim, S.J.; Kim, J.W.; Kang, P.H.; Nho, Y.C.; Lee, Y.-S. A high resolution XPS study of sidewall functionalized MWCNTs by fluorination. J. Ind. Eng. Chem. 2009, 15, 66–71. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Brug, G.J.; Van Den Eeden, A.L.G.; Sluyters-Rehbach, M.; Sluyters, J.H. The analysis of electrode impedances complicated by the presence of a constant phase element. J. Electroanal. Chem. Interfacial Electrochem. 1984, 176, 275–295. [Google Scholar] [CrossRef]

- Zhang, X.-F.; Chen, Y.-Q.; Hu, J.-M. Robust superhydrophobic SiO2/polydimethylsiloxane films coated on mild steel for corrosion protection. Corros. Sci. 2020, 166, 108452. [Google Scholar] [CrossRef]

- Shi, H.; Han, E.-H.; Liu, F. Corrosion protection of aluminium alloy 2024-T3 in 0.05M NaCl by cerium cinnamate. Corros. Sci. 2011, 53, 2374–2384. [Google Scholar] [CrossRef]

| Sample | Ecorr (V vs. SCE) | Icorr (A/cm2) | Epit (V vs. SCE) | |

|---|---|---|---|---|

| Untreated (1 h) | −0.744 | 1.084 × 10−6 | / | / |

| SHS (1 h) | −1.06 | 1.06 × 10−7 | −0.332 | 90.22% |

| SLIPS (1 h) | −1.16 | 1.44 × 10−9 | −0.134 | 99.87% |

| Parameter | Untreated | SHS | SLIPS |

|---|---|---|---|

| Rs (Ω·cm2) | 21.03 | 15.65 | 14.7 |

| Yf (S·cm−2·sn) | 3.026 × 10−5 | 8.409 × 10−8 | 6.23 × 10−10 |

| nf | 0.8633 | 0.7806 | 0.9773 |

| Cf (F·cm−2) | 1.0934 × 10−5 | 1.17324 × 10−8 | 4.9616 × 10−10 |

| Rf (Ω·cm2) | 74.39 | 10780 | 88940 |

| Ydl (S·cm−2·sn) | 4.207 × 10−5 | 2.34 × 10−6 | 5.712 × 10−9 |

| ndl | 0.641 | 0.4649 | 0.5036 |

| Cdl (F·cm−2) | 3.54 × 10−5 | 3.99 × 10−7 | 1.22 × 10−9 |

| Rct (Ω·cm2) | 1.75 × 104 | 9.21 × 104 | 3.65 × 107 |

| Zw (Ω−1·s0.5·cm−2) | / | 1.44 × 10−6 | 8.98 × 10−8 |

| (%) | / | 80.99 | 99.95 |

| Sample | Ecorr (V vs. SCE) | Icorr (A/cm2) | Epit (V vs. SCE) | |

|---|---|---|---|---|

| Untreated (24 h) | −0.825 | 1.56 × 10−7 | −0.659 | / |

| SHS (24 h) | −1.02 | 2.97 × 10−8 | −0.455 | 80.96% |

| SLIPS (24 h) | −1.12 | 1.7 × 10−9 | −0.190 | 98.91% |

| Parameter | Untreated | SHS | SLIPS |

|---|---|---|---|

| Rs (Ω·cm2) | 18.49 | 25.51 | 18.16 |

| Yf (S·cm−2·sn) | 2.50 × 10−5 | 2.083 × 10−8 | 7.342 × 10−10 |

| nf | 0.8479 | 0.9553 | 0.9751 |

| Cf (F·cm−2) | 1.64 × 10−5 | 8.77 × 10−9 | 5.93 × 10−10 |

| Rf (Ω·cm2) | 3769 | 25.96 | 316700 |

| Ydl (S·cm−2·sn) | 6.51 × 10−6 | 1.49 × 10−10 | 5.712 × 10−9 |

| ndl | 0.5853 | 0.5065 | 1.008 × 10−10 |

| Cdl (F·cm−2) | 3.22 × 10−6 | 6.90 × 10−7 | 3.64 × 10−9 |

| Rct (Ω·cm2) | 5.69 × 104 | 3.04 × 105 | 3.702 × 107 |

| Zw (Ω−1·s0.5·cm−2) | / | 3.84 × 10−7 | 1.021 × 10−7 |

| (%) | / | 81.28 | 99.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Luo, G.; Cheng, M.; Song, L. Water-Repellent Coatings on Corrosion Resistance by Femtosecond Laser Processing. Coatings 2022, 12, 1736. https://doi.org/10.3390/coatings12111736

Zhao Z, Luo G, Cheng M, Song L. Water-Repellent Coatings on Corrosion Resistance by Femtosecond Laser Processing. Coatings. 2022; 12(11):1736. https://doi.org/10.3390/coatings12111736

Chicago/Turabian StyleZhao, Zexu, Guoyun Luo, Manping Cheng, and Lijun Song. 2022. "Water-Repellent Coatings on Corrosion Resistance by Femtosecond Laser Processing" Coatings 12, no. 11: 1736. https://doi.org/10.3390/coatings12111736

APA StyleZhao, Z., Luo, G., Cheng, M., & Song, L. (2022). Water-Repellent Coatings on Corrosion Resistance by Femtosecond Laser Processing. Coatings, 12(11), 1736. https://doi.org/10.3390/coatings12111736