Photoresist Microlens Arrays Fabricated by Nanoimprint Technique to Improve the Photoelectric Conversion Efficiency of Solar Cells

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Design of MLAs Mask

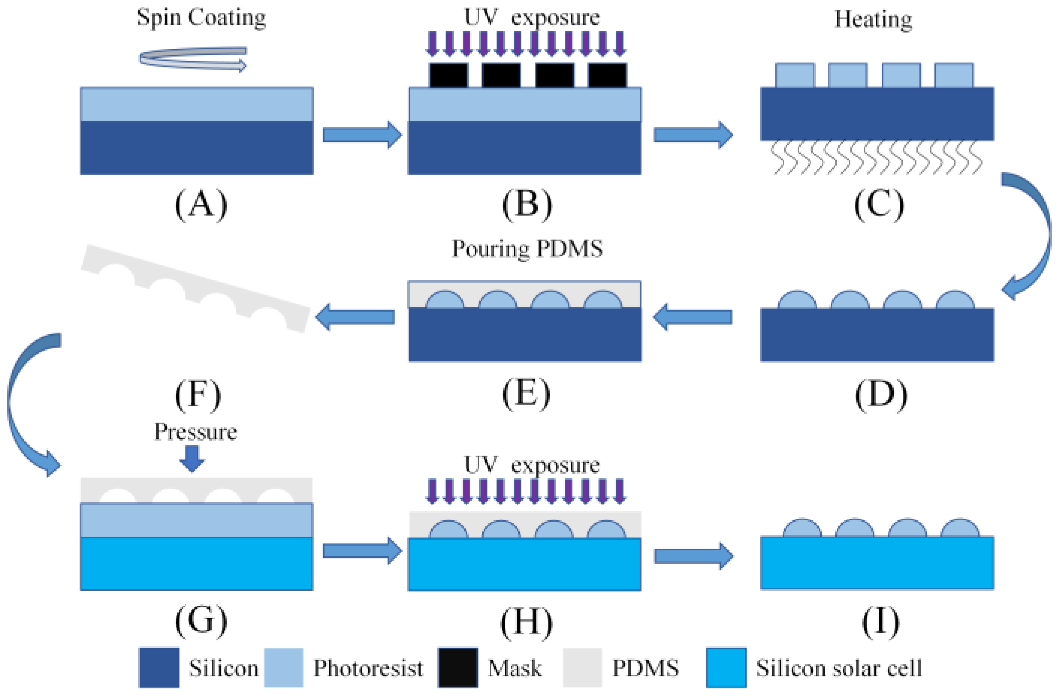

2.2. Fabrication Process of Photoresist Film MLAs on Silicon Solar Cells

2.3. Preparation of Original MLAs Mold

2.4. Fabrication of Photoresist Film MLAs on Silicon Solar Cells

2.5. Characterizations

3. Results

3.1. Optical Properties of The Photoresist Films

3.2. The Optical Transmittance of Photoresist Film MLAs

3.3. The Surface Topography of Photoresist Film MLAs

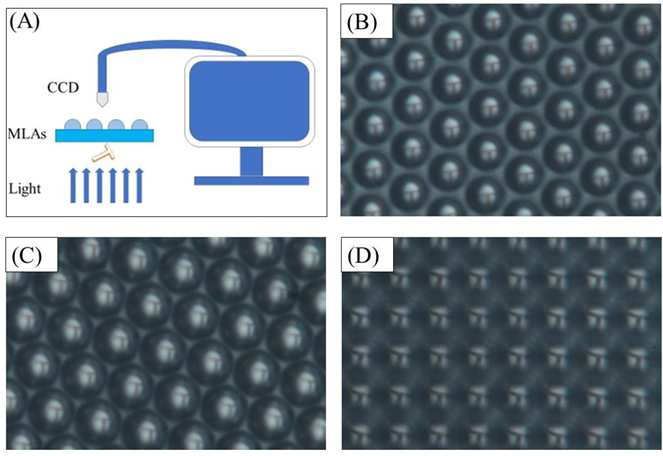

3.4. Optical Imaging Capabilities of Photoresist Film MLAs

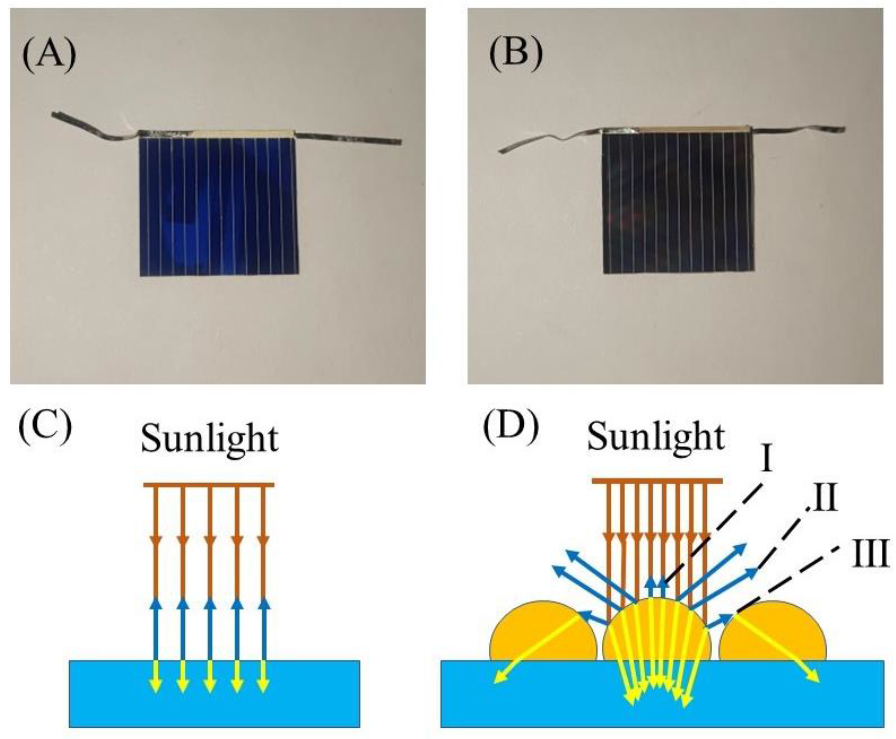

3.5. The Transport Mechanism of Sunlight on Silicon Solar Cells

3.6. Photovoltaic Properties of These Solar Cells

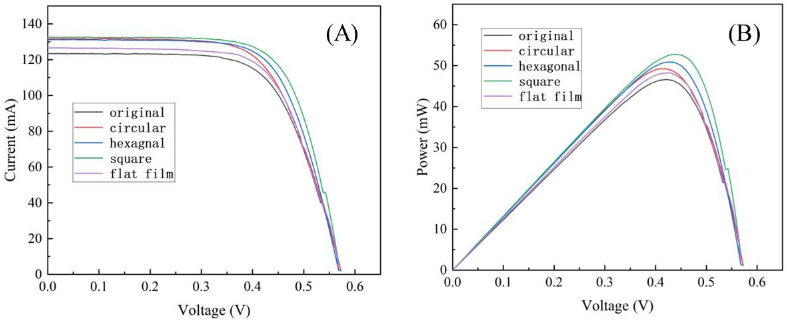

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hossain, M.K.; Gazi, A.R.; Md, A.A.; Mirza, H.K.R.; Mohammad, H.A.; Khan, M.I.; Shahadat, H.; Sapan, K.S.; Jalal, M.I.E.; El-Denglawey, A. Current Applications and Future Potential of Rare Earth Oxides in Sustainable Nuclear, Radiation, and Energy Devices: A Review. ACS Appl. Electron. Mater. 2022, 4, 3327–3353. [Google Scholar] [CrossRef]

- Zhong, S.; Shen, W. Quasi-omnidirectional crystalline silicon solar cells. J. Phys. D Appl. Phys. 2020, 53, 483001. [Google Scholar] [CrossRef]

- Obaid, S.; Lu, L. Highly Efficient microscale gallium arsenide solar cell arrays as optogenetic power options. IEEE Photonics J. 2019, 11, 8400108. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, F.; Yu, H. Self-healing perovskite solar cells. Sol. Energy 2020, 209, 408–414. [Google Scholar] [CrossRef]

- Wali, Q.; Iftikhar, F.J.; Khan, M.E.; Ullah, A.; Lqbal, Y.; Jose, R. Advances in stability of perovskite solar cells. Org. Electron. 2020, 78, 105590. [Google Scholar] [CrossRef]

- Bencherif, H.; Mwddour, F.; Elshorbagy, M.H.; Hossain, M.K.; Cuadrado, A.; Abdi, M.A.; Bendib, T.; Kouda, S.; Alda, J. Performance enhancement of (FAPbI3)1−x(MAPbBr3)x perovskite solar cell with an optimized design. Micro. Nanostruct. 2022, 171, 207403. [Google Scholar] [CrossRef]

- Javed, A.H.; Shahzad, N.; Khan, M.A.; Ayub, M.; Lqbal, N.; Hassan, M.; Hussain, N.; Rameel, M.I.; Shahzad, M.I. Effect of ZnO nanostructures on the performance of dye sensitized solar cells. Sol. Energy 2021, 230, 492–500. [Google Scholar] [CrossRef]

- Son, H.J.; Hong, K.K.; Ju, B.K.; Kim, S.H. Oxidation-resistant Cu-Based metallisation for Si solar cells. Energy Sci. Eng. 2022, 10, 1264–1271. [Google Scholar] [CrossRef]

- Lu, L.; Adel, N.; Wang, K.; Du, M.Y.; Liu, S.Z. Perovskite Quantum Dots in solar Cells. Adv. Sci. 2022, 9, 2104577. [Google Scholar] [CrossRef]

- Hsu, C.H.; Zhang, X.Y.; Zhao, M.J.; Lin, H.J.; Zhu, W.Z.; Lien, S.Y. Silicon Heterojunction Solar Cells with p-Type Silicon Carbon Window Layer. Crystals 2019, 9, 402. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.J.; Yao, Y.; Xiao, S.Q.; Gu, X.F. Review of status developments of high-Efficiency crystalline silicon solar cells. J. Phys. D Appl. Phys. 2018, 51, 123001. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, T.R.; Wang, C.B.; Yu, T.T.; Wang, J.; Xu, Z.P. Enhanced electro-Optical properties of TiO2 Nanocone Arrays for ultrathin GaAs Solar cells. Opt. Commun. 2019, 452, 281–285. [Google Scholar] [CrossRef]

- Chen, W.H.; Cabarrocas, P.R.I. Rational design of nanowire solar cells: From single nanowire to nanowire arrays. Nanotechnology 2019, 30, 194002. [Google Scholar] [CrossRef]

- Adibzadeh, F.; Olyaee, S. Nanostructure back reflector for enhancing the performance of InP nanowire array solar cells. Opt. Quant. Electron. 2022, 54, 303. [Google Scholar] [CrossRef]

- Wei, P.K.; Hao, Z.W.; Yang, Y.; Liu, L. Hollow NiSe2 nanospheres grown on graphene with unconventional dual-Vacancies in dye-Sensitized solar cells. Appl. Surf. Sci. 2021, 553, 149567. [Google Scholar] [CrossRef]

- Tang, H.B.; Liu, Y.P.; Chen, Q.S.; Wang, Y.; Chen, W.; Wu, J.T.; Zhao, Y.; Du, X.L. Optical Design of Inverted Pyramid Textured PERC Solar Cells. ACS Appl. Electron. Mater. 2019, 1, 2684–2691. [Google Scholar] [CrossRef]

- Sun, P.; Qu, G.P.; Hu, Q.K.; Ma, Y.C.; Liu, H.S.; Xu, Z.X.; Huang, Z.F. Highly Efficient Large-Area Flexible Perovskite Solar Cells Containing Tin Oxide Vertical Nanopillars without Oxygen Vacancies. ACS Appl. Energ. Mater. 2022, 5, 3568–3577. [Google Scholar] [CrossRef]

- Gao, Z.L.; Lin, G.L.; Chen, Y.C. Moth-eye nanostructure PDMS films for reducing reflection and retaining flexibility in ultra-thin c-Si solar cells. Sol. Energy 2020, 205, 275–281. [Google Scholar] [CrossRef]

- Huang, Z.S.; Wang, B. Thin-Film Solar Cells by Silicon-Based Nano-Pyramid Arrays. Adv. Theor. Simul. 2022, 5, 2100586. [Google Scholar] [CrossRef]

- Osama, M.A.; Amal, A.; Muhamad, Z.M.; Ben, F.S.; Qian, C.; Andrew, G.T.; Nigel, W.H.; Wang, X.L.; Patrick, H.; Janet, J.; et al. High efficiency semitransparent perovskite solar cells containing 2D nanopore arrays deposited in a single step. J. Mater. Chem. A 2022, 10, 10227–10241. [Google Scholar]

- Shi, J.; Huang, Y.S.; Peng, L.N.; Ni, Z.J.; Zhang, D.W. Grating/microlens arrays fabricated by hot-melting, self-Assembly and replication. Opt. Mater. 2020, 104, 109733. [Google Scholar] [CrossRef]

- Baek, S.; Kim, K.; Sung, Y.; Jung, P.; Ju, S.; Kim, W.; Kim, S.J.; Hong, S.H.; Lee, H. Solution-processable multi-color printing using UV nanoimprint lithography. Nanotechnology 2020, 31, 125301. [Google Scholar] [CrossRef] [PubMed]

| MLAs Shape | Diameter/Side Length (μm) | Space (μm) |

|---|---|---|

| Circular | 15 | 3 |

| Square | 15 | 3 |

| Hexagonal | 15 | 3 |

| Solar Cell with or without MLA | VOC (mV) | JSC (mA cm2) | Fill Actor (%) | Efficiency (%) |

|---|---|---|---|---|

| Reference | 570.0 | 30.85 | 65.93 | 11.53 |

| Circular | 574.5 | 32.93 | 65.08 | 12.31 |

| Hexagonal | 569.4 | 32.81 | 68.12 | 12.73 |

| Square | 566.6 | 33.13 | 70.25 | 13.19 |

| Flat film | 559.2 | 31.64 | 68.39 | 12.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Lv, L.; Zhang, X.; Hu, F. Photoresist Microlens Arrays Fabricated by Nanoimprint Technique to Improve the Photoelectric Conversion Efficiency of Solar Cells. Coatings 2022, 12, 1812. https://doi.org/10.3390/coatings12121812

Zhang X, Lv L, Zhang X, Hu F. Photoresist Microlens Arrays Fabricated by Nanoimprint Technique to Improve the Photoelectric Conversion Efficiency of Solar Cells. Coatings. 2022; 12(12):1812. https://doi.org/10.3390/coatings12121812

Chicago/Turabian StyleZhang, Xuehua, Liangwei Lv, Xinwen Zhang, and Fangren Hu. 2022. "Photoresist Microlens Arrays Fabricated by Nanoimprint Technique to Improve the Photoelectric Conversion Efficiency of Solar Cells" Coatings 12, no. 12: 1812. https://doi.org/10.3390/coatings12121812