Metastable Phase Formation, Microstructure, and Dielectric Properties in Plasma-Sprayed Alumina Ceramic Coatings

Abstract

1. Introduction

2. Experimental Procedure

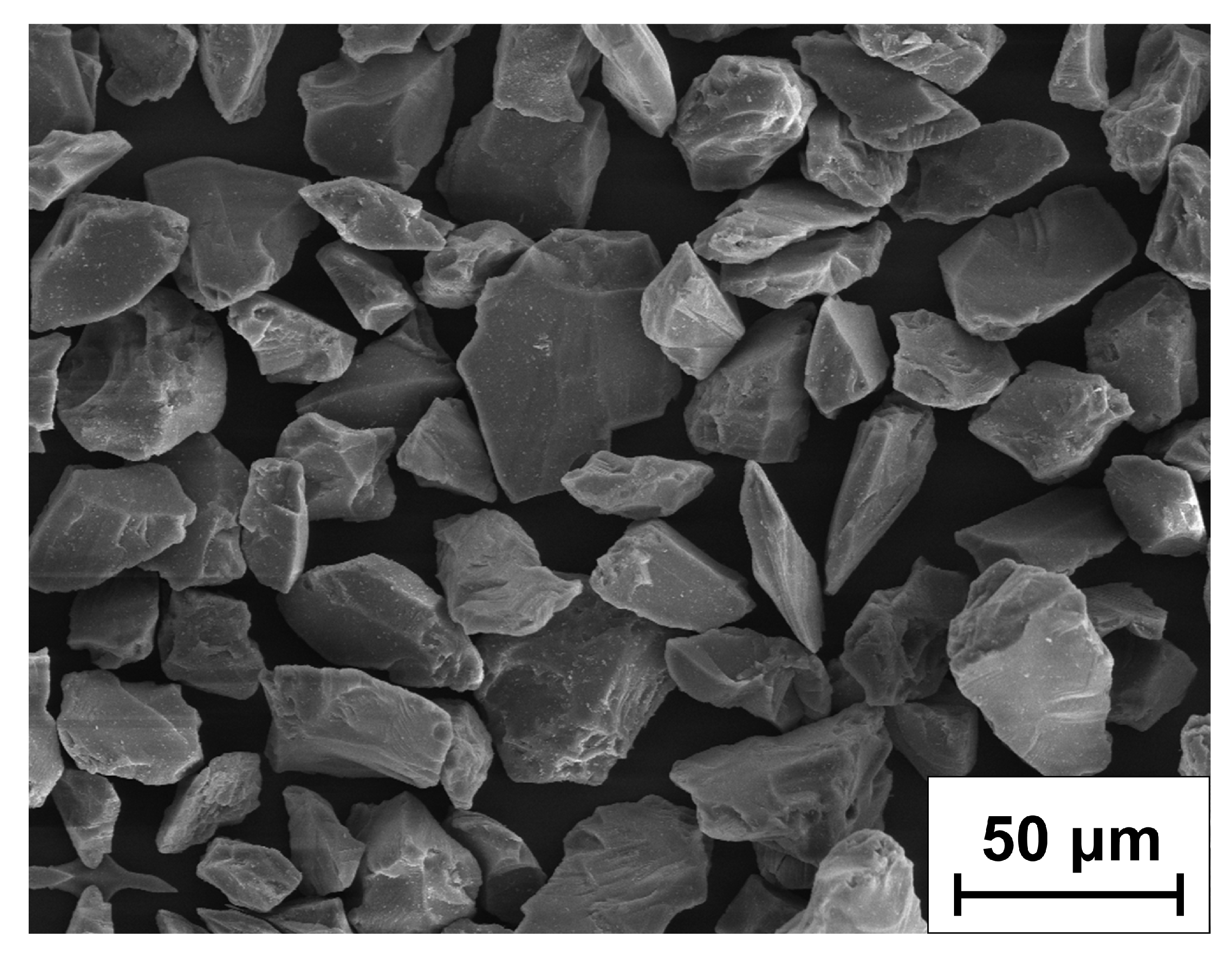

2.1. Materials and Atmospheric Plasma Spraying (APS) Process

2.2. Characterization

2.3. Dielectric Characterization

3. Results and Discussion

3.1. Microstructural Analysis

3.2. DC Resistivity

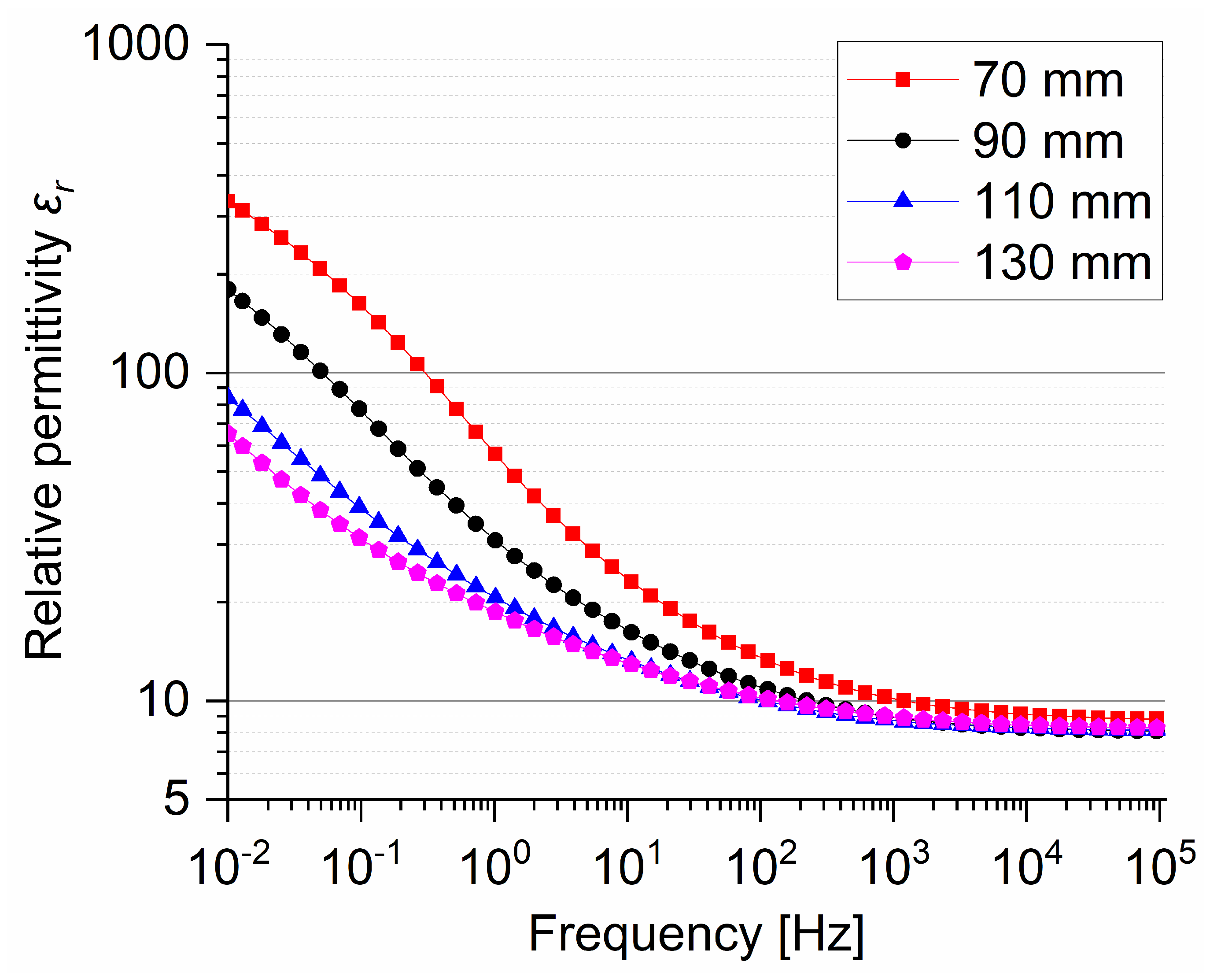

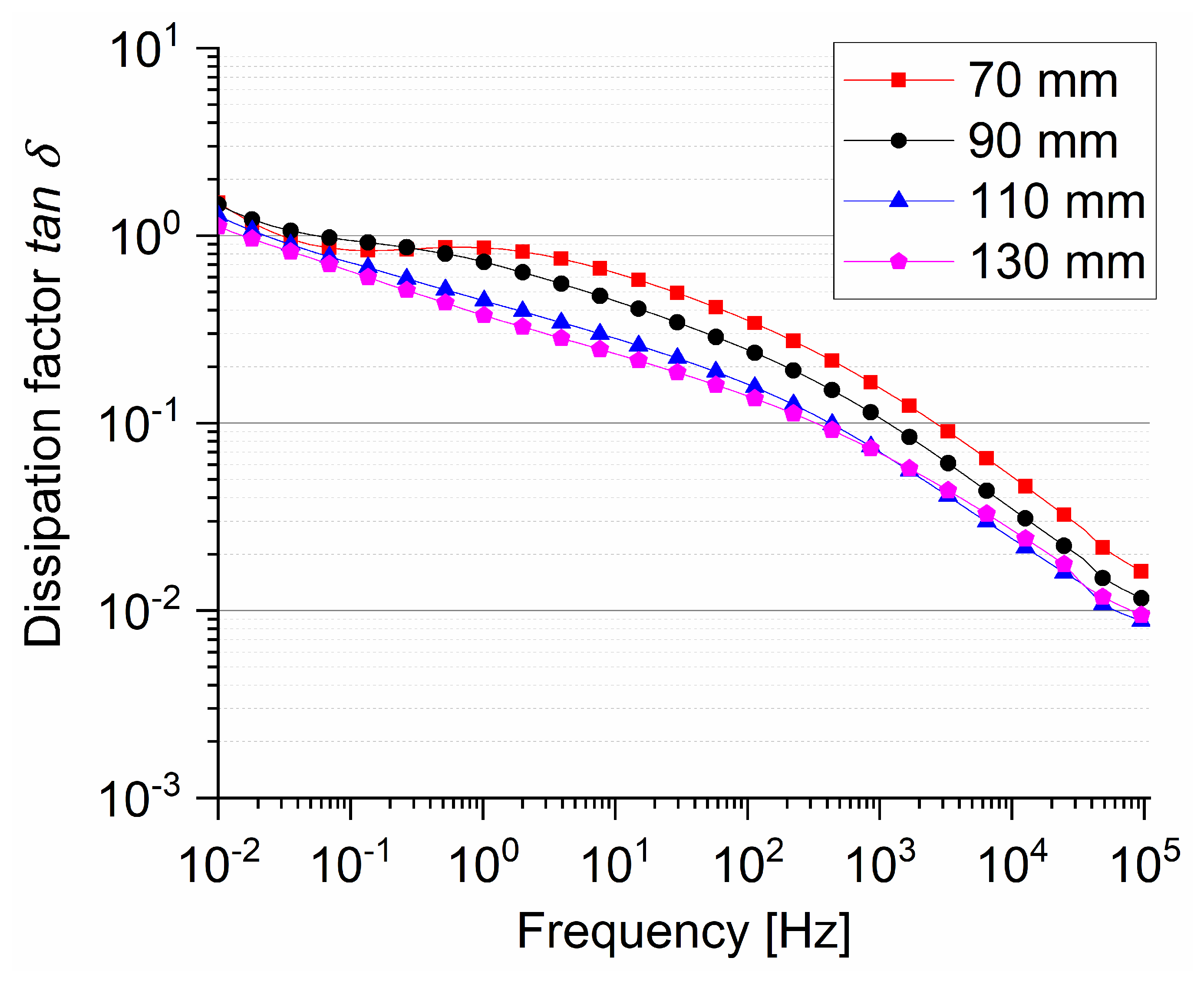

3.3. Relative Permittivity and Loss Factor

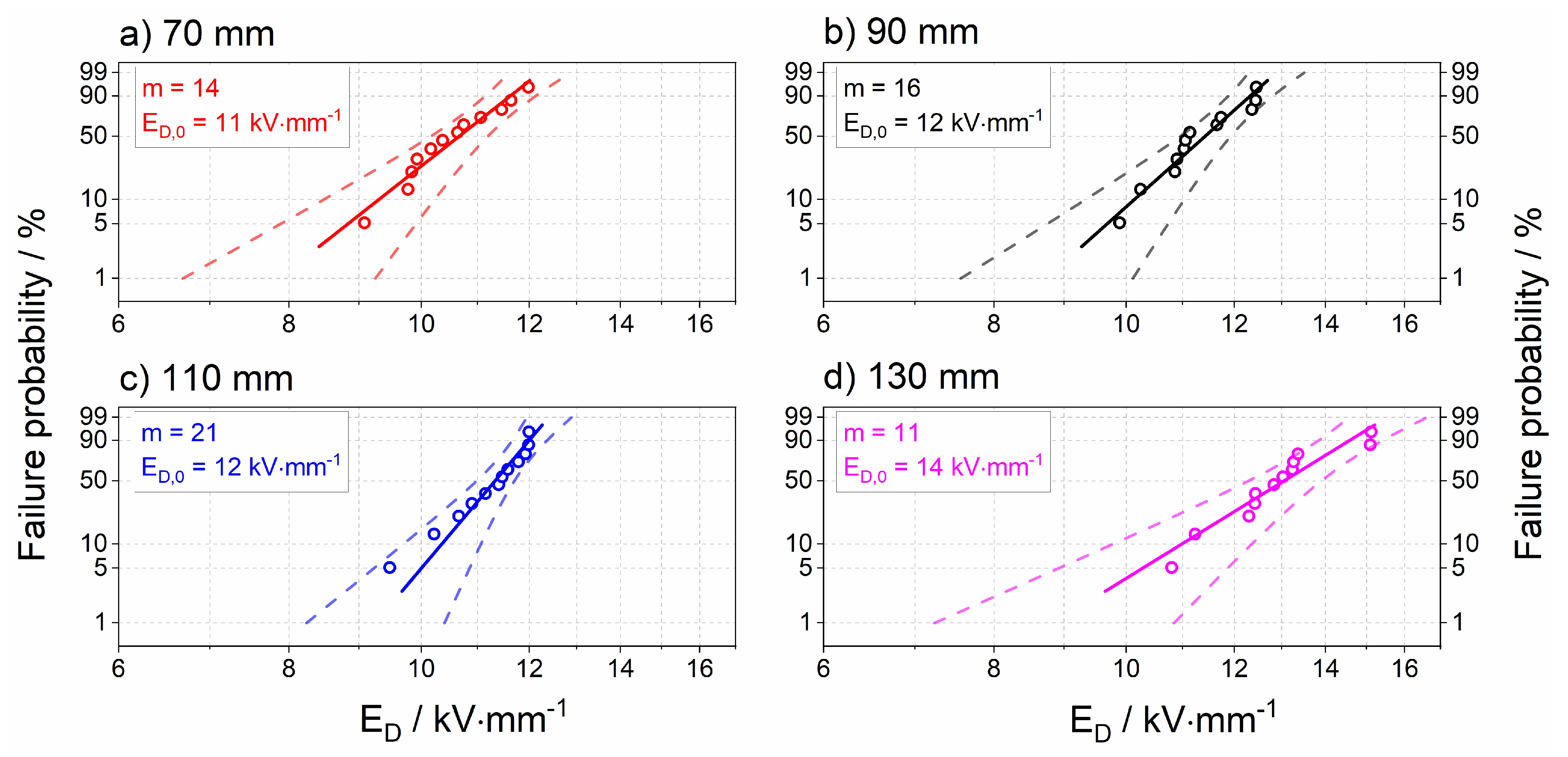

3.4. Dielectric Strength

4. Conclusions

- The amount of -AlO phase in the coatings increased at shorter spray distances due to a higher thermal energy. To date, there are no studies regarding the impact of -AlO on the dielectric properties of thermally sprayed coatings. From our measurements, it might be speculated that -AlO lowers the overall dielectric properties.

- In terms of microstructure, porosity was found to be lowest at the shortest spray distance of 70 mm. Nevertheless, the porosity of all coatings was in a similar range. The coating thickness decreased at longer spray distances due to lower deposition efficiency which results from a higher amount of cooling and deceleration of the particles.

- The higher thermal energy at shorter spray distances is expected to influence the defect density of the deposited coatings. Therefore, reducing the DC resistivity at shorter spray distances is associated with increased vertical crack density. It is assumed that vertical cracks can serve as conductive paths and reduce the resistance of the coating. This effect may be further intensified due to the moisture sensitivity of AlO coatings and the subsequent protonic conductivity mechanisms.

- Relative permittivity and loss factor are found to be influenced by the microstructure and phase composition at different spray distances. At low frequencies, both permittivity and loss tangent are increased. This can be attributed to either increasing interfacial polarization, the conductive microcracks, or a combination of both.

- Our results suggest that the dielectric strength tends to increase with larger spray distances. Previous studies have shown that increased porosity in thermally sprayed coatings decreases the dielectric strength. One possible explanation for the discrepancies we find in this trend could be due to the statistically non-significant differences in porosity, or the reduction in coating thickness at larger spray distances, which is reportedly beneficial for higher dielectric strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Takeuchi, J.; Yamasaki, R.; Harada, Y. Development of a Low-Pressure Plasma Sprayed Ceramic Coating on Electrostatic Chucks for Semiconductor Manufacturing Equipment. In Proceedings of the International Thermal Spray Conference, Essen, Germany, 4–6 March 2002; DVS Deutscher Verband für Schweißen: Dusseldorf, Germany, 2002; pp. 960–964. [Google Scholar] [CrossRef]

- Gao, J.; Duan, F.L.; Yu, C.; Meng, W.; Liu, L.; Ding, G.; Zhang, C.; Wang, Y. Electrical insulation of ceramic thin film on metallic aero-engine blade for high temperature sensor applications. Ceram. Int. 2016, 42, 19269–19275. [Google Scholar] [CrossRef]

- Varghese, P.; Vetrivendan, E.; Krishnan, R.; Mathews, T.; Ningshen, S. Plasma sprayed alumina-yttria composite ceramic coating for electrical insulation applications. Surf. Coat. Technol. 2021, 405, 126566. [Google Scholar] [CrossRef]

- Bajgiran, M.M.; Rad, M.R.; McDonald, A.; Moreau, C. Microstructure, phase and dielectric strength of thermally sprayed alumina layers in coating-based heating systems. Int. J. Appl. Ceram. Technol. 2021, 18, 1641–1656. [Google Scholar] [CrossRef]

- Ctibor, P.; Sedláček, J.; Neufuss, K. Influence of chemical composition on dielectric properties of Al2O3 and ZrO2 plasma deposits. Ceram. Int. 2003, 29, 527–532. [Google Scholar] [CrossRef]

- Caldararu, M.; Postole, G.; Hornoiu, C.; Bratan, V.; Dragan, M.; Ionescu, N.I. Electrical conductivity of γ-Al2O3 at atmospheric pressure under dehydrating/hydrating conditions. Appl. Surf. Sci. 2001, 181, 255–264. [Google Scholar] [CrossRef]

- Toma, F.L.; Berger, L.M.; Scheitz, S.; Langner, S.; Rödel, C.; Potthoff, A.; Sauchuk, V.; Kusnezoff, M. Comparison of the microstructural characteristics and electrical properties of thermally sprayed Al2O3 coatings from aqueous suspensions and feedstock powders. J. Therm. Spray Technol. 2012, 21, 480–488. [Google Scholar] [CrossRef]

- Kovarik, L.; Bowden, M.; Andersen, A.; Jaegers, N.R.; Washton, N.; Szanyi, J. Quantification of High-Temperature Transition Al2O3 and Their Phase Transformations. Angew. Chem. Int. Ed. 2020, 59, 21719–21727. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Xiong, X.; Gao, Y. The effect of the δ/γ phase on the dielectric properties of plasma sprayed Al2O3 coatings. J. Mater. Sci. Mater. Electron. 2017, 28, 12015–12020. [Google Scholar] [CrossRef]

- Li, Z.; Khuje, S.; Chivate, A.; Huang, Y.; Hu, Y.; An, L.; Shao, Z.; Wang, J.; Chang, S.; Ren, S. Printable Copper Sensor Electronics for High Temperature. ACS Appl. Electron. Mater. 2020, 2, 1867–1873. [Google Scholar] [CrossRef]

- Lührs, L.; Weissmüller, J. Nanoporous Copper-Nickel—Macroscopic bodies of a strong and deformable nanoporous base metal by dealloying. Scr. Mater. 2018, 155, 119–123. [Google Scholar] [CrossRef]

- Boccardi, S.; Ciampa, F.; Meo, M. Design and development of a heatsink for thermo-electric power harvesting in aerospace applications. Smart Mater. Struct. 2019, 28, 105057. [Google Scholar] [CrossRef]

- Hayashi, H.; Watanabe, M.; Inaba, H. Measurement of thermal expansion coefficient of LaCrO3. Thermochim. Acta 2000, 359, 77–85. [Google Scholar] [CrossRef]

- Kroeger, F.R.; Swenson, C.A. Absolute linear thermal-expansion measurements on copper and aluminum from 5 to 320 K. J. Appl. Phys. 1977, 48, 853–864. [Google Scholar] [CrossRef]

- Peter, R.; Petravic, M. Initial Stages of Oxide Formation on Copper Surfaces during Oxygen Bombardment at Room Temperature. J. Phys. Chem. C 2021, 125, 25290–25297. [Google Scholar] [CrossRef]

- ASTM E2109-01; Standard Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings. ASTM International: West Conshohocken, PA, USA, 2021.

- EN IEC 62631-3-4:2019; Dielectric and Resistive Properties of Solid Insulating Materials—Part 3–4: Determination of Resistive Properties (DC Methods). IEC International Electrotechnical Commission: Geneva, Switzerland, 2019.

- ASTM D149-20; Standard Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at Commercial Power Frequencies. ASTM International: West Conshohocken, PA, USA, 2020.

- Dissado, L.A. Theoretical basis for the statistics of dielectric breakdown. J. Phys. D Appl. Phys. 1990, 23, 1582–1591. [Google Scholar] [CrossRef]

- Vardelle, M.; Vardelle, A.; Fauchais, P. Spray parameters and particle behavior relationships during plasma spraying. J. Therm. Spray Technol. 1993, 2, 79–91. [Google Scholar] [CrossRef]

- Di Girolamo, G.; Brentari, A.; Blasi, C.; Serra, E. Microstructure and mechanical properties of plasma sprayed alumina-based coatings. Ceram. Int. 2014, 40, 12861–12867. [Google Scholar] [CrossRef]

- Bengtsson, P.; Johannesson, T. Characterization of microstructural defects in plasma-sprayed thermal barrier coatings. J. Therm. Spray Technol. 1995, 4, 245–251. [Google Scholar] [CrossRef]

- Ghara, T.; Bandyopadhyay, P.P. Mechanical Properties and Residual Stress Depth Profiles of Plasma Sprayed Ceramic Coatings Deposited Under Comparable Particle Temperature and Velocity. J. Therm. Spray Technol. 2022, 31, 1889–1905. [Google Scholar] [CrossRef]

- Valarezo, A.; Shinoda, K.; Sampath, S. Effect of Deposition Rate and Deposition Temperature on Residual Stress of HVOF-Sprayed Coatings. J. Therm. Spray Technol. 2020, 29, 1322–1338. [Google Scholar] [CrossRef]

- Shinde, S.V.; Sampath, S. Interplay between cracking and delamination in incrementally deposited plasma sprayed coatings. Acta Mater. 2021, 215, 117074. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Balasubramanian, V.; Rajendran, R. Developing empirical relationships to estimate porosity and microhardness of plasma-sprayed YSZ coatings. Ceram. Int. 2014, 40, 3171–3183. [Google Scholar] [CrossRef]

- Datta, S.; Pratihar, D.K.; Bandyopadhyay, P.P. Modeling of plasma spray coating process using statistical regression analysis. Int. J. Adv. Manuf. Technol. 2013, 65, 967–980. [Google Scholar] [CrossRef]

- Heintze, G.N.; Uematsu, S. Preparation and structures of plasma-sprayed γ- and α Al2O3 coatings. Surf. Coat. Technol. 1992, 50, 213–222. [Google Scholar] [CrossRef]

- McPherson, R. Formation of metastable phases in flame- and plasma-prepared alumina. J. Mater. Sci. 1973, 8, 851–858. [Google Scholar] [CrossRef]

- Stahr, C.C.; Saaro, S.; Berger, L.M.; Dubský, J.; Neufuss, K.; Herrmann, M. Dependence of the stabilization of α-Alumina on the spray process. J. Therm. Spray Technol. 2007, 16, 822–830. [Google Scholar] [CrossRef]

- Kovarik, L.; Bowden, M.; Genc, A.; Szanyi, J.; Peden, C.H.; Kwak, J.H. Structure of δ-alumina: Toward the atomic level understanding of transition alumina phases. J. Phys. Chem. C 2014, 118, 18051–18058. [Google Scholar] [CrossRef]

- Levin, I.; Brandon, D. Metastable alumina polymorphs: Crystal structures and transition sequences. J. Am. Ceram. Soc. 1998, 81, 1995–2012. [Google Scholar] [CrossRef]

- Penn, S.J.; Alford, N.M.N.; Templeton, A.; Wang, X.; Xu, M.; Reece, M.; Schrapel, K. Effect of porosity and grain size on the microwave dielectric properties of sintered alumina. J. Am. Ceram. Soc. 1997, 80, 1885–1888. [Google Scholar] [CrossRef]

- Rudolph, M.; Motylenko, M.; Rafaja, D. Structure model of γ-Al2O3 based on planar defects. IUCrJ 2019, 6, 116–127. [Google Scholar] [CrossRef]

- Lee, C.K.; Cho, E.; Lee, H.S.; Seol, K.S.; Han, S. Comparative study of electronic structures and dielectric properties of alumina polymorphs by first-principles methods. Phys. Rev. B Condens. Matter Mater. Phys. 2007, 76, 1–7. [Google Scholar] [CrossRef]

- Dragoo, A.L.; Diamond, J.J. Transitions in Vapor-Deposited Alumina from 300° to 1200 °C. J. Am. Ceram. Soc. 1967, 50, 568–574. [Google Scholar] [CrossRef]

- Kuechler, A. Hochspannungstechnik; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 978-3-642-11992-7. [Google Scholar]

- Swindeman, C.; Seals, R.; White, R.; Murray, W.; Cooper, M. An Investigation of the Electrical Behavior of Thermally-Sprayed Aluminum Oxide; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 1996. [Google Scholar] [CrossRef]

- Pawłowski, L. The relationship between structure and dielectric properties in plasma-sprayed alumina coatings. Surf. Coat. Technol. 1988, 35, 285–298. [Google Scholar] [CrossRef]

- Prudenziati, M. Development and the implementation of high-temperature reliable heaters in plasma spray technology. J. Therm. Spray Technol. 2008, 17, 234–243. [Google Scholar] [CrossRef]

- Beauvais, S.; Guipont, V.; Jeandin, M.; Juve, D.; Treheux, D.; Robisson, A.; Saenger, R. Influence of Defect Orientation on Electrical Insulating Properties of Plasma-Sprayed Alumina Coatings. J. Electroceram. 2005, 15, 65–74. [Google Scholar] [CrossRef]

- Ohmori, A.; Li, C.J.; Arata, Y. Influence of Plasma Spray Conditions on the Structure of Al2O3 Coatings (Surface Processing). Trans. JWRI 1990, 19, 259–270. [Google Scholar]

- Niittymäki, M.; Lahti, K.; Suhonen, T.; Metsäjoki, J. Effect of temperature and humidity on dielectric properties of thermally sprayed alumina coatings. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 908–918. [Google Scholar] [CrossRef]

- Fukatsu, N.; Kurita, N. Proton conduction in α-alumina and its application to hydrogen sensor for molten metals. Ionics 2007, 13, 183–194. [Google Scholar] [CrossRef]

- Samet, M.; Levchenko, V.; Boiteux, G.; Seytre, G.; Kallel, A.; Serghei, A. Electrode polarization vs. Maxwell-Wagner-Sillars interfacial polarization in dielectric spectra of materials: Characteristic frequencies and scaling laws. J. Chem. Phys. 2015, 142. [Google Scholar] [CrossRef]

- Malec, D.; Bley, V.; Talbi, F.; Lalam, F. Contribution to the understanding of the relationship between mechanical and dielectric strengths of Alumina. J. Eur. Ceram. Soc. 2010, 30, 3117–3123. [Google Scholar] [CrossRef]

- Niittymäki, M.; Lahti, K.; Suhonen, T.; Kanerva, U.; Metsäjoki, J. Influence of humidity and temperature on the dielectric properties of thermally sprayed ceramic MgAl2O4 coatings. In Proceedings of the 2014 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP 2014), Des Moines, IA, USA, 19–22 October 2014; pp. 94–97. [Google Scholar] [CrossRef]

- Niittymäki, M.; Suhonen, T.; Metsäjoki, J.; Lahti, K. DC Conduction and Breakdown Behavior of Thermally Sprayed Ceramic Coatings. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 499–510. [Google Scholar] [CrossRef]

| Particle Size Distribution (m) | |

|---|---|

| Dv(10) | 20.5 |

| Dv(50) | 33.3 |

| Dv(90) | 53.3 |

| Plasma Spray Parameters | |

|---|---|

| Plasma power (kW) | 35 |

| Primary gas Ar flow rate (Nlpm) | 30 |

| Secondary gas H flow rate (Nlpm) | 6 |

| Robot scanning velocity (mm/s) | 250 |

| Powder feed rate (g/min) | 40 |

| Spray distance (mm) | 130, 110, 90, 70 |

| Nozzle diameter (mm) | 6 |

| Sample | Thickness (µm) | Porosity (%) | Ṽeff (kV) | ED (kV/mm) | @ 50 Hz | tan @ 50 Hz | DC Resistivity (m) | Main Phase |

|---|---|---|---|---|---|---|---|---|

| 70 mm | 217 ± 11 | 5.4 ± 0.8 | 2.2 ± 0.2 | 10.5 ± 0.9 | 15.6 | 0.435 | 6.3 × | , , |

| 90 mm | 199 ± 17 | 5.7 ± 0.8 | 2.2 ± 0.2 | 11.3 ± 0.8 | 12.2 | 0.302 | 1.0 × | , , |

| 110 mm | 191 ± 12 | 6.4 ± 1.1 | 2.1 ± 0.1 | 11.2 ± 0.8 | 10.8 | 0.196 | 4.3 × | , |

| 130 mm | 183 ± 14 | 6.3 ± 0.9 | 2.1 ± 0.2 | 12.9 ± 1.3 | 10.9 | 0.166 | 6.3 × | , |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Junge, P.; Greinacher, M.; Kober, D.; Stargardt, P.; Rupprecht, C. Metastable Phase Formation, Microstructure, and Dielectric Properties in Plasma-Sprayed Alumina Ceramic Coatings. Coatings 2022, 12, 1847. https://doi.org/10.3390/coatings12121847

Junge P, Greinacher M, Kober D, Stargardt P, Rupprecht C. Metastable Phase Formation, Microstructure, and Dielectric Properties in Plasma-Sprayed Alumina Ceramic Coatings. Coatings. 2022; 12(12):1847. https://doi.org/10.3390/coatings12121847

Chicago/Turabian StyleJunge, Paul, Moritz Greinacher, Delf Kober, Patrick Stargardt, and Christian Rupprecht. 2022. "Metastable Phase Formation, Microstructure, and Dielectric Properties in Plasma-Sprayed Alumina Ceramic Coatings" Coatings 12, no. 12: 1847. https://doi.org/10.3390/coatings12121847

APA StyleJunge, P., Greinacher, M., Kober, D., Stargardt, P., & Rupprecht, C. (2022). Metastable Phase Formation, Microstructure, and Dielectric Properties in Plasma-Sprayed Alumina Ceramic Coatings. Coatings, 12(12), 1847. https://doi.org/10.3390/coatings12121847