Study on Using Microbubbles to Reduce Surface Damage of Mercury Target for Spallation Neutron Source

Abstract

:1. Introduction

2. Experimental Procedure

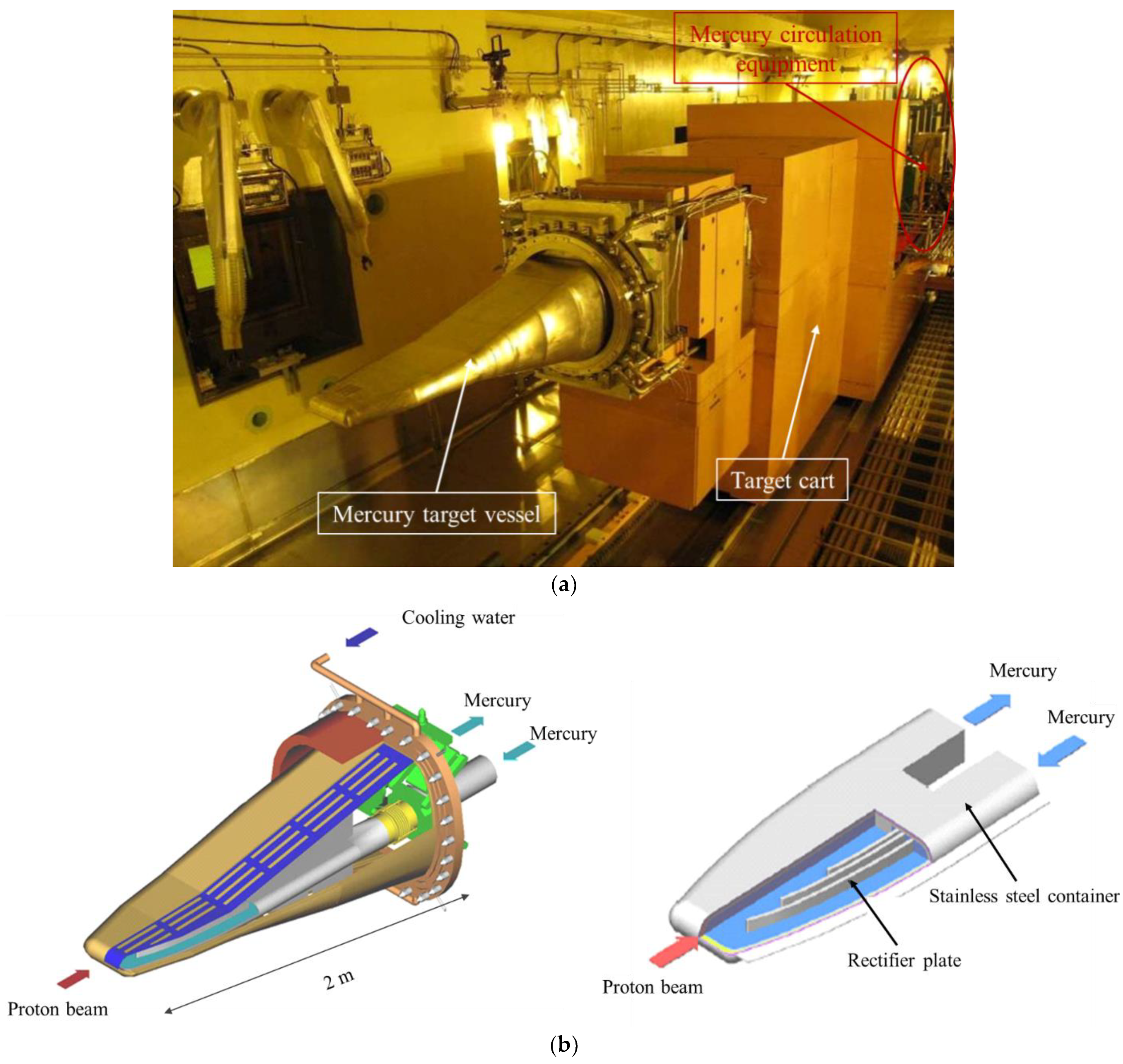

2.1. Mercury Target

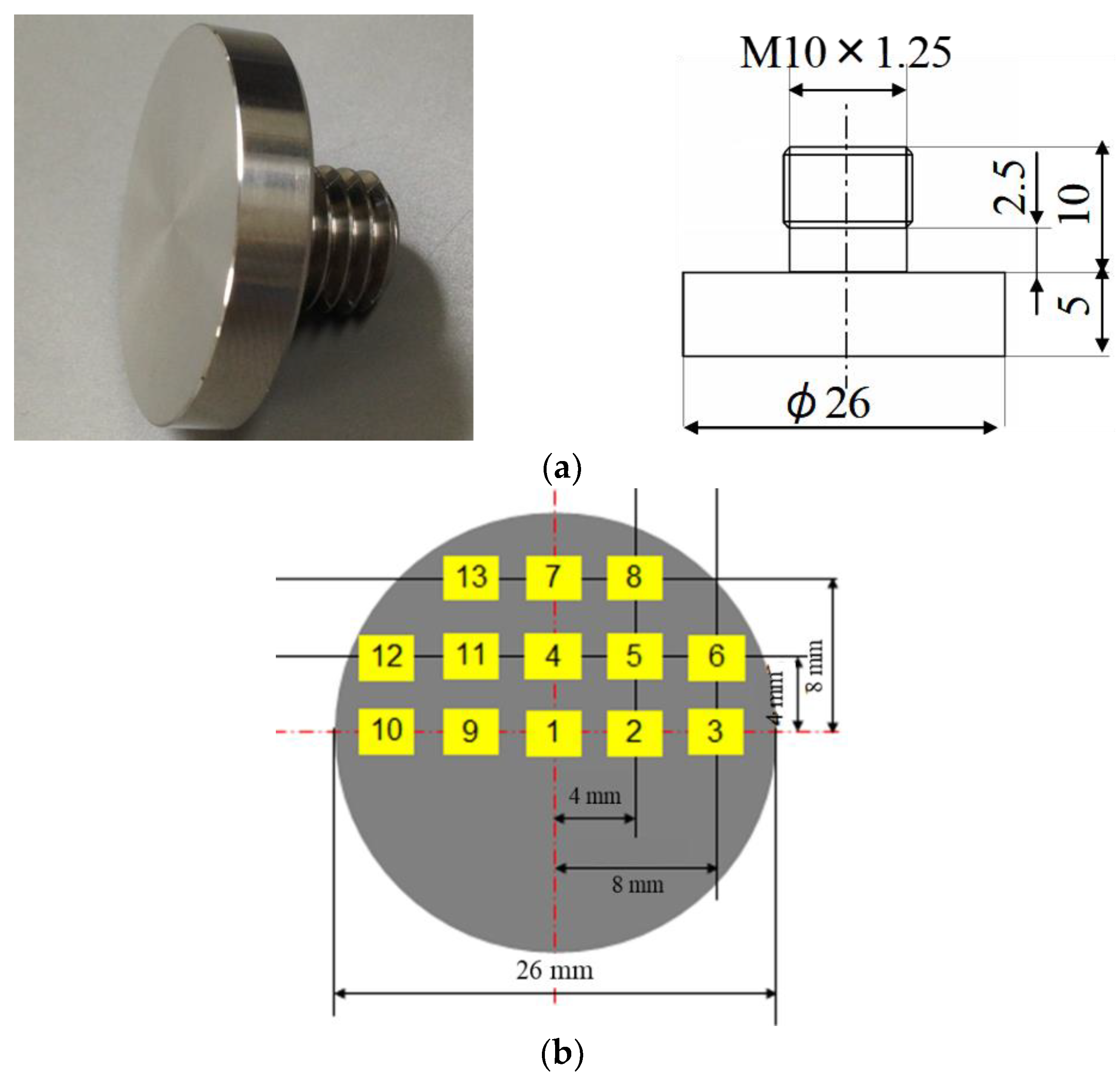

2.2. Experimental Specimen

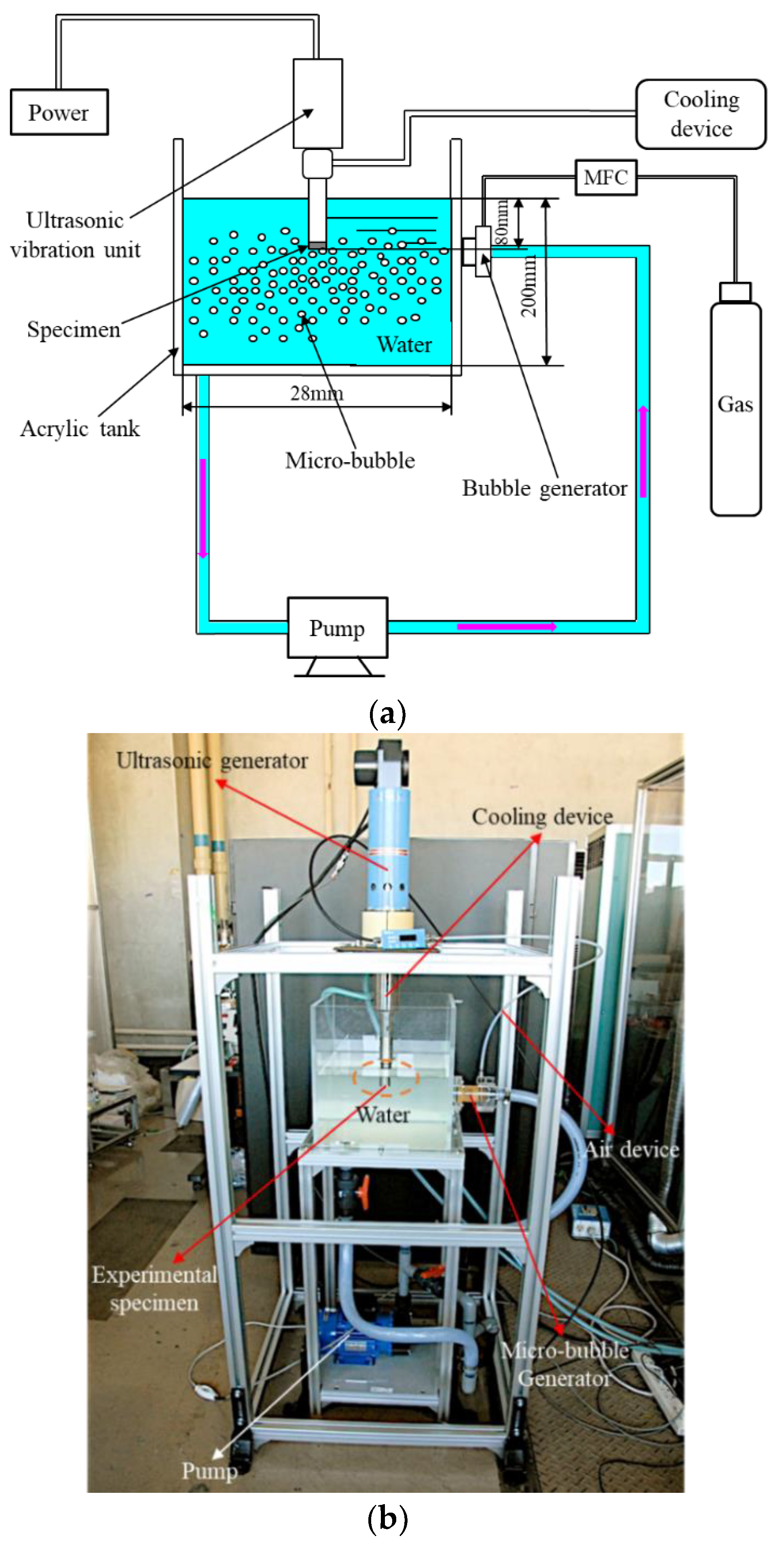

2.3. Experimental Setup and Experimental Proceed

2.4. Experimental Conditions

3. Results

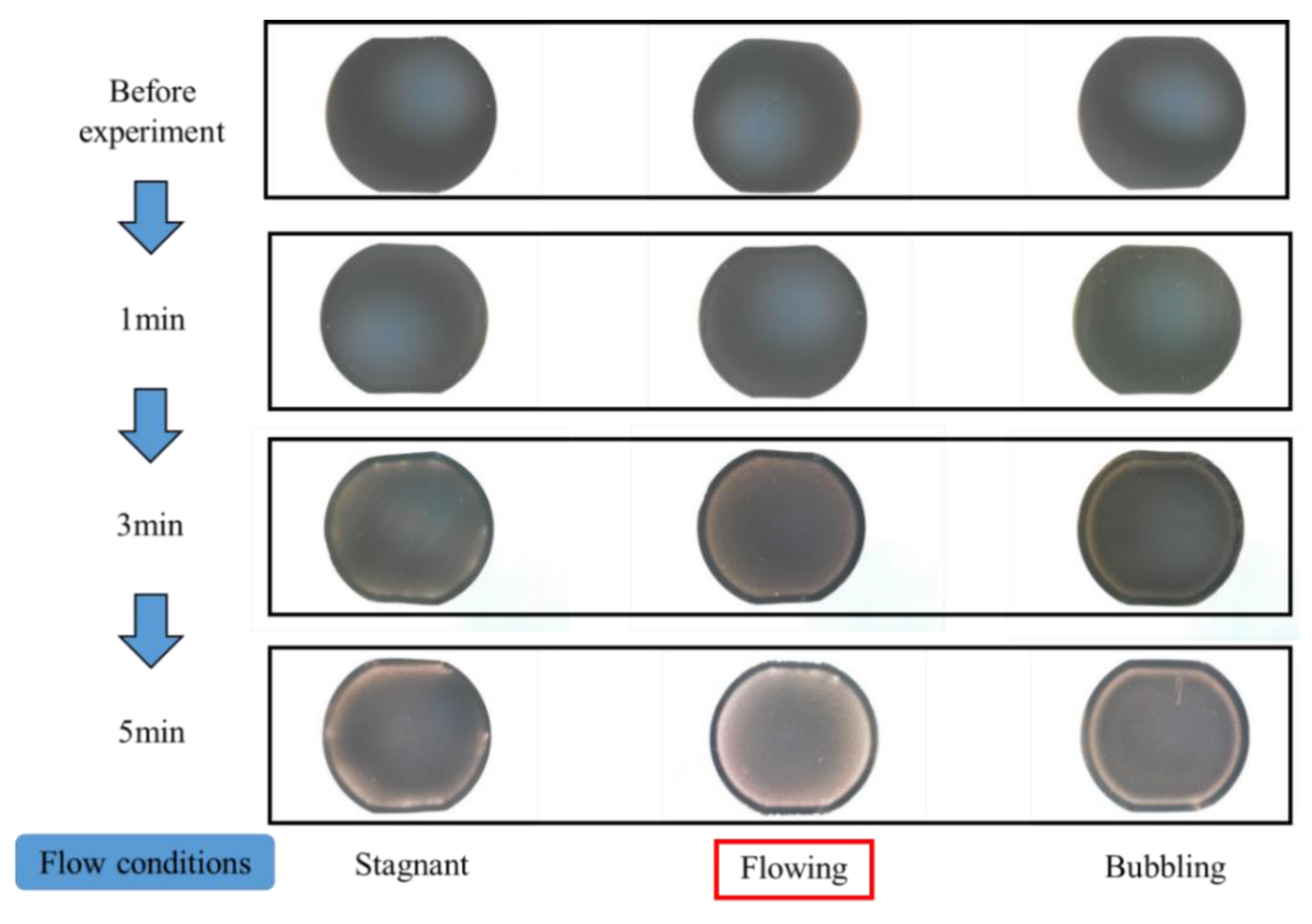

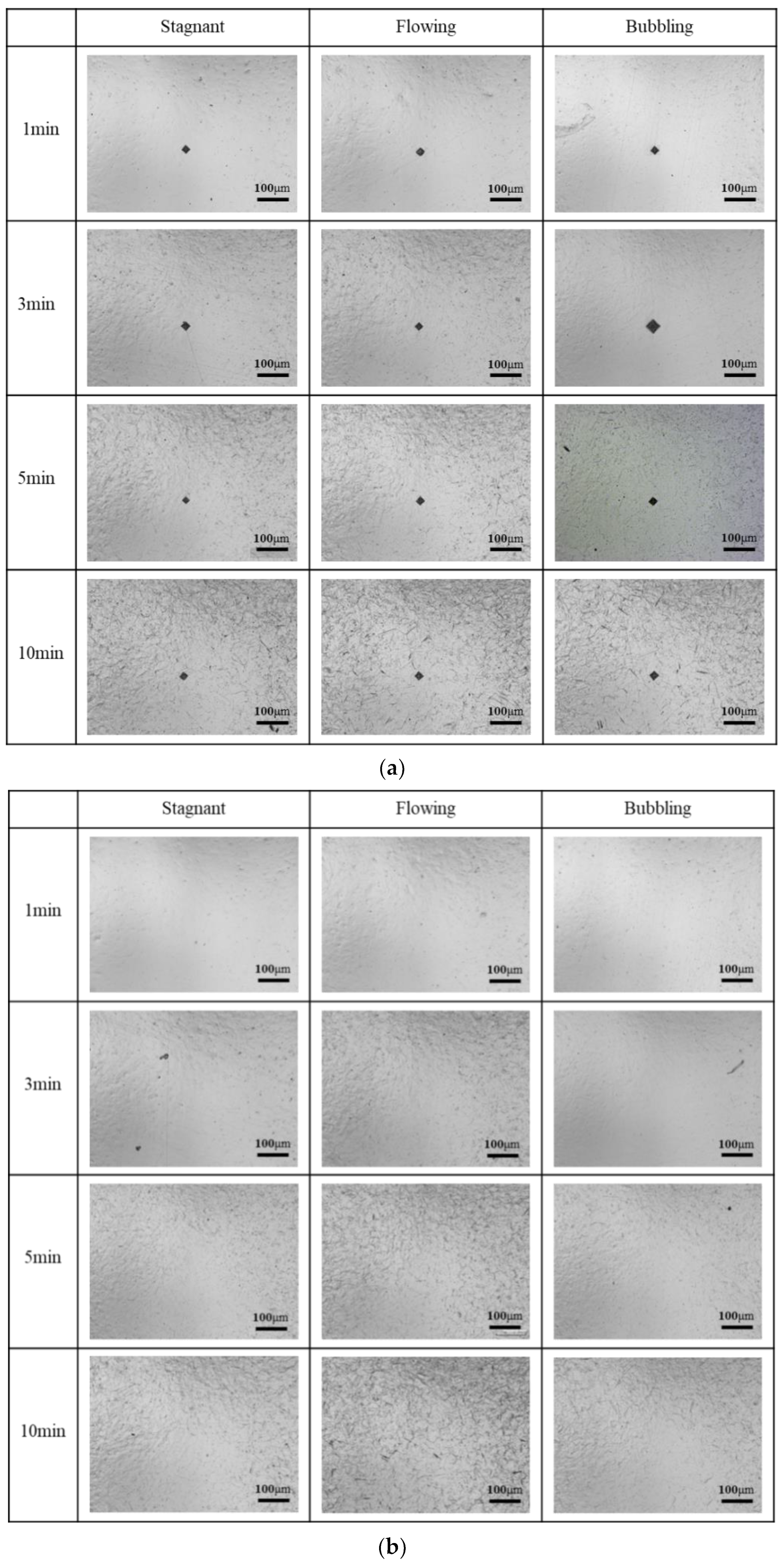

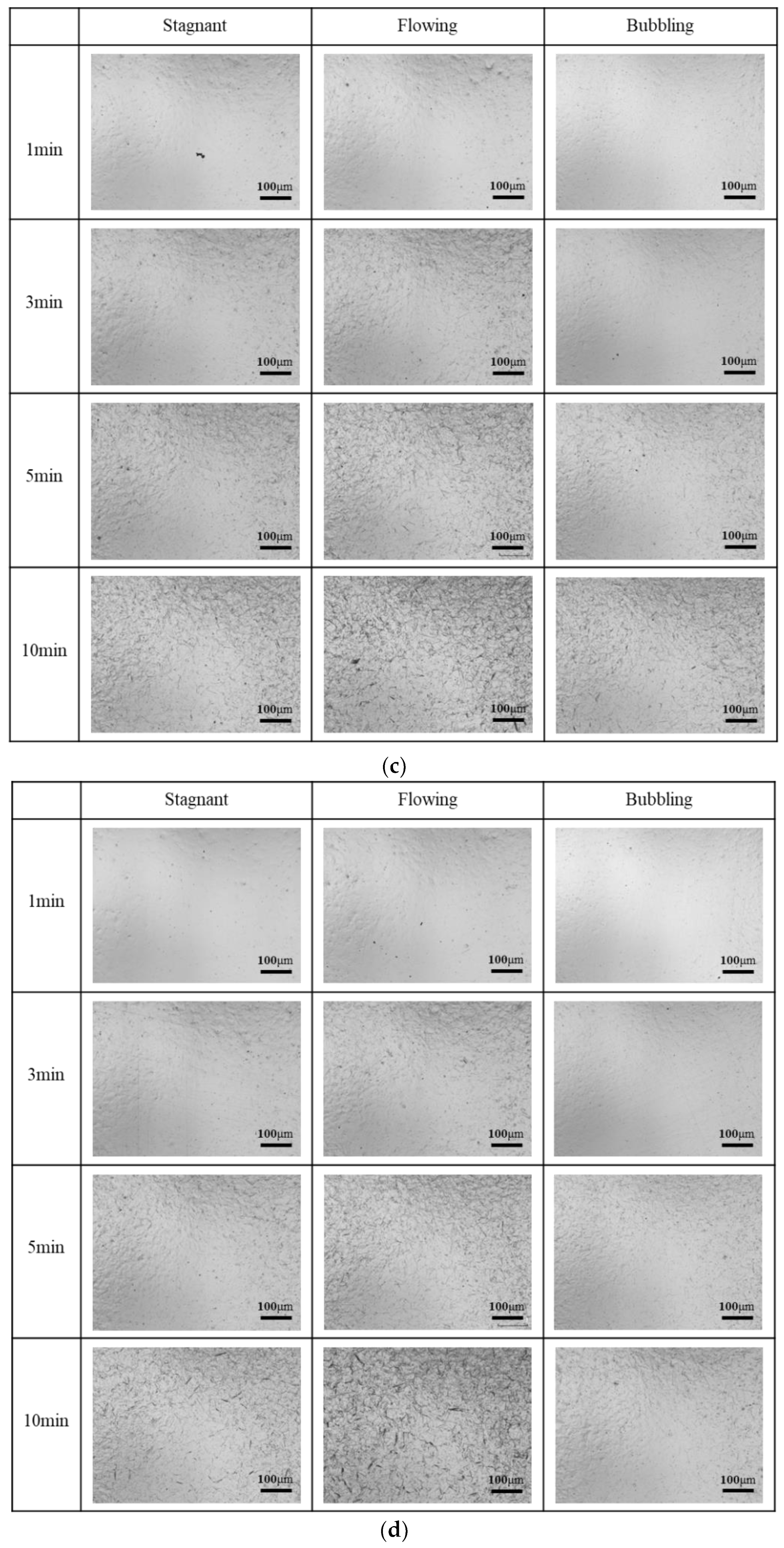

3.1. Surface Damage in Three Different Experimental Conditions

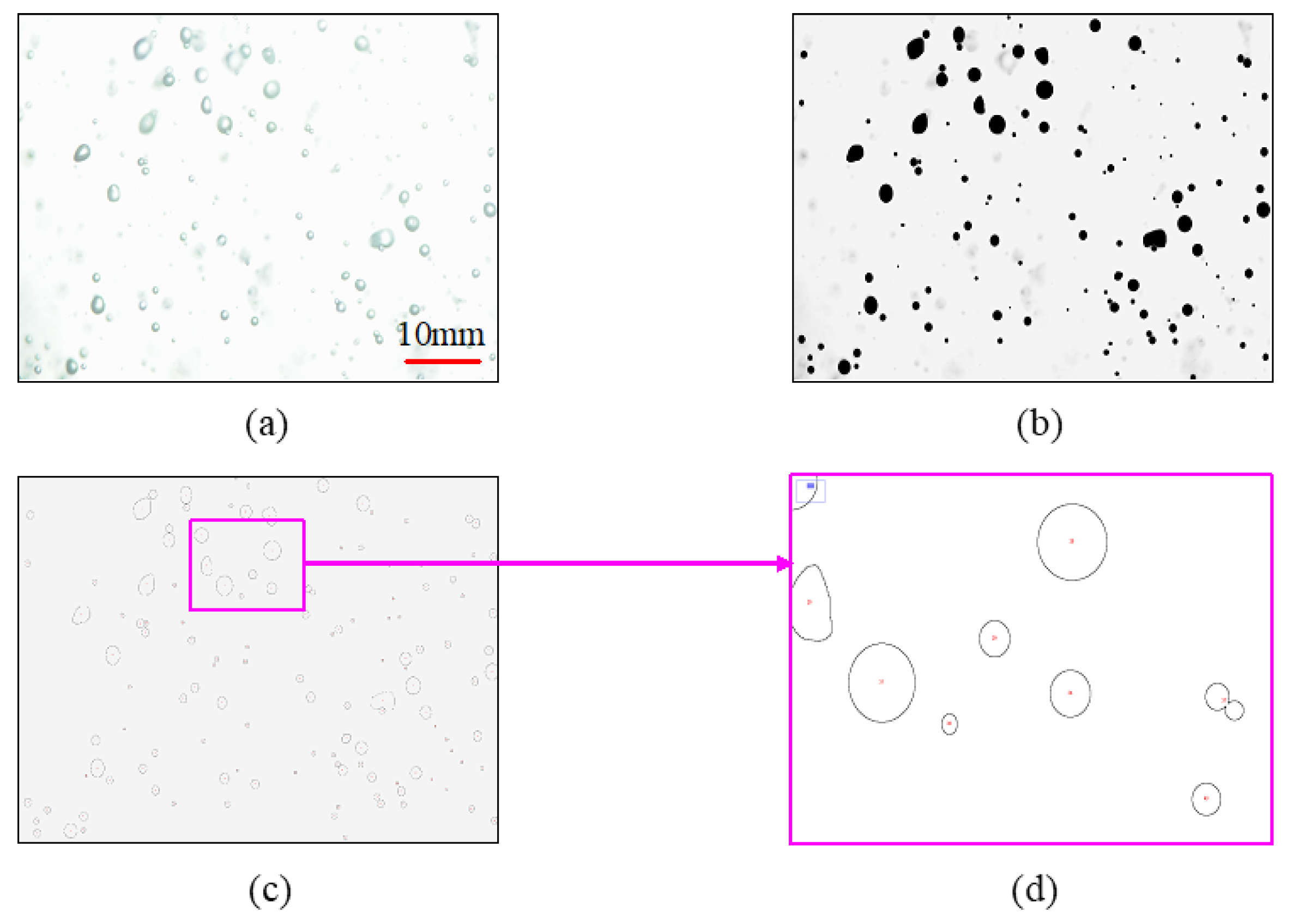

3.2. Investigations on the Amount and Size of Microbubbles

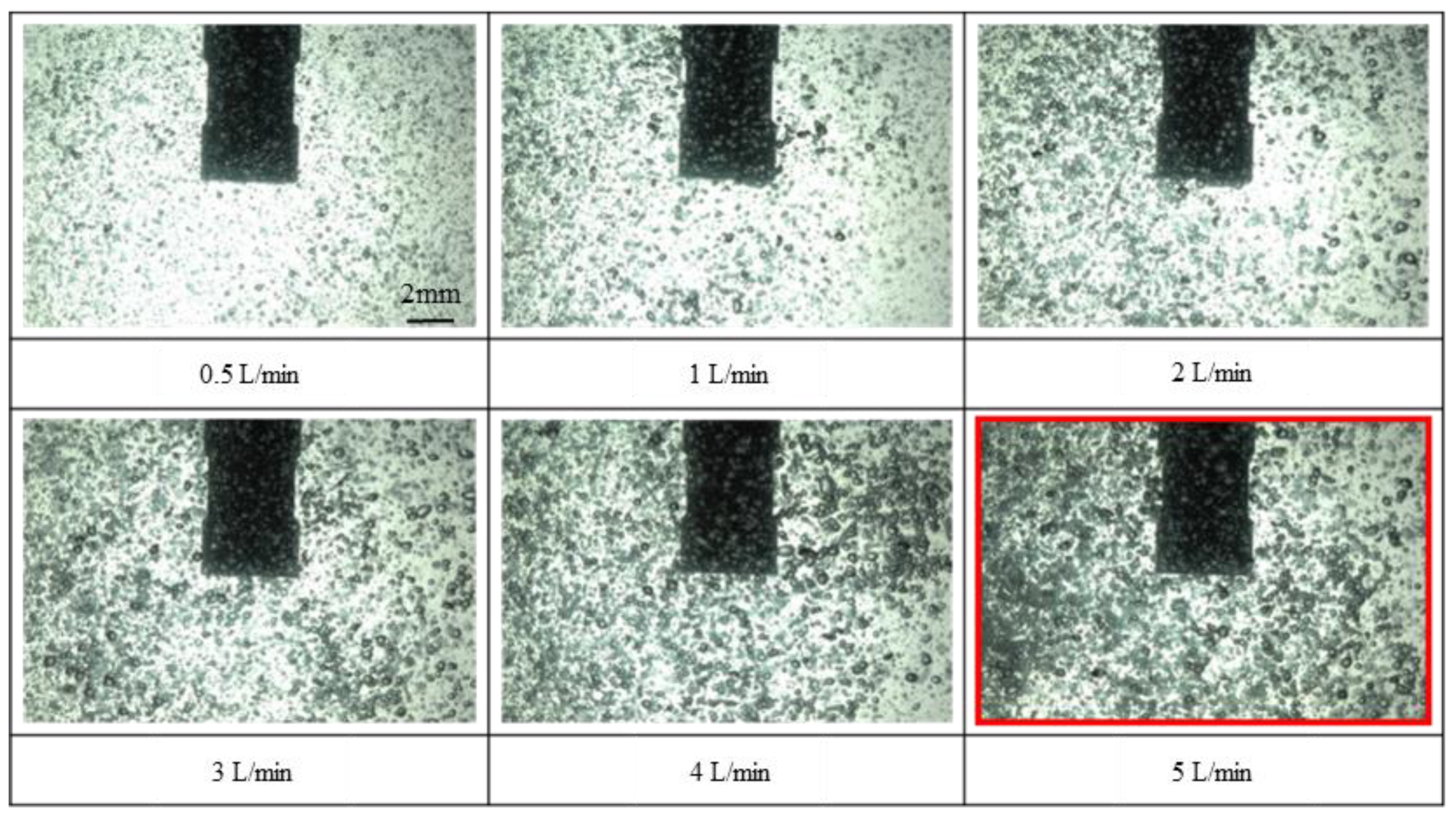

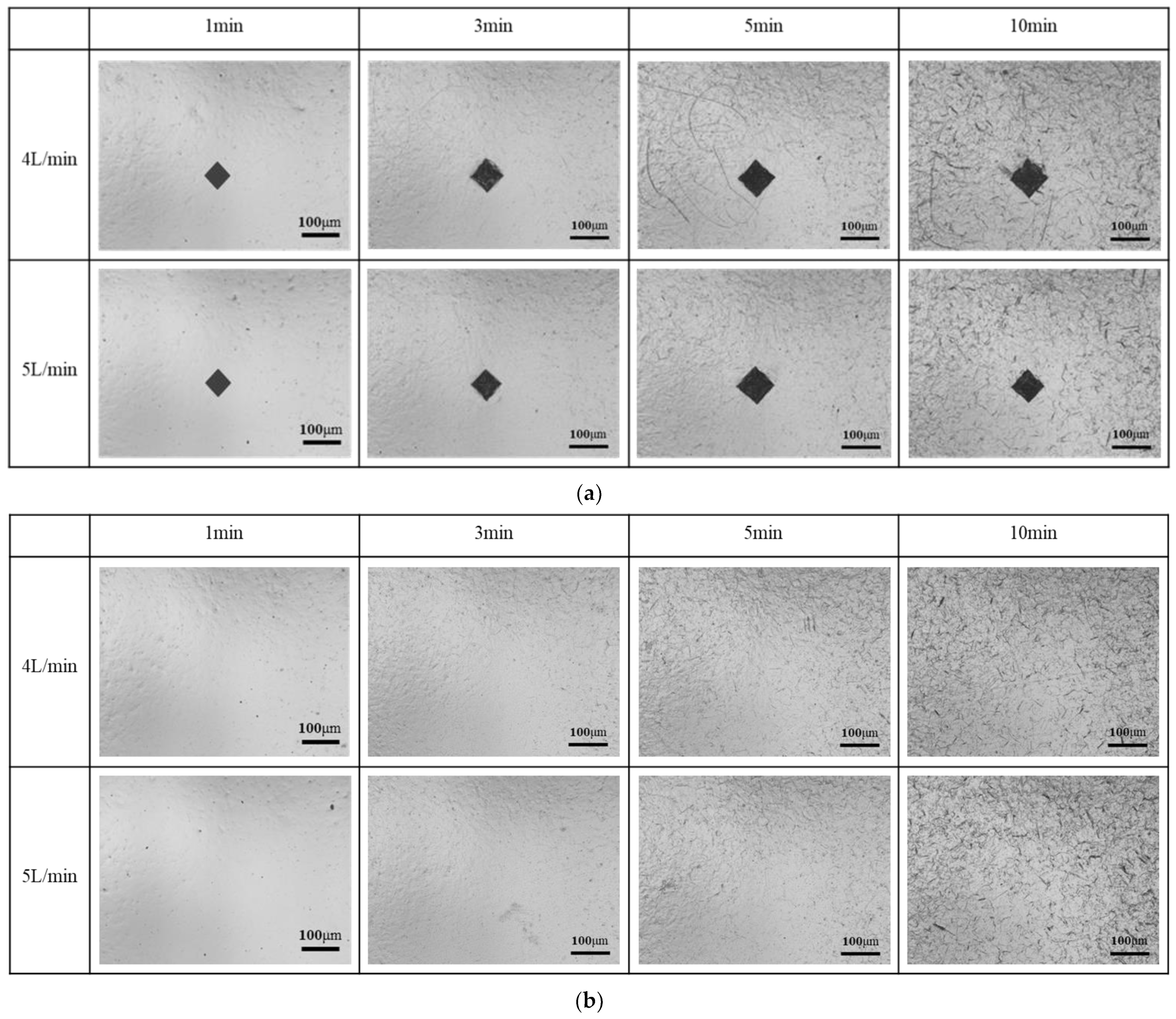

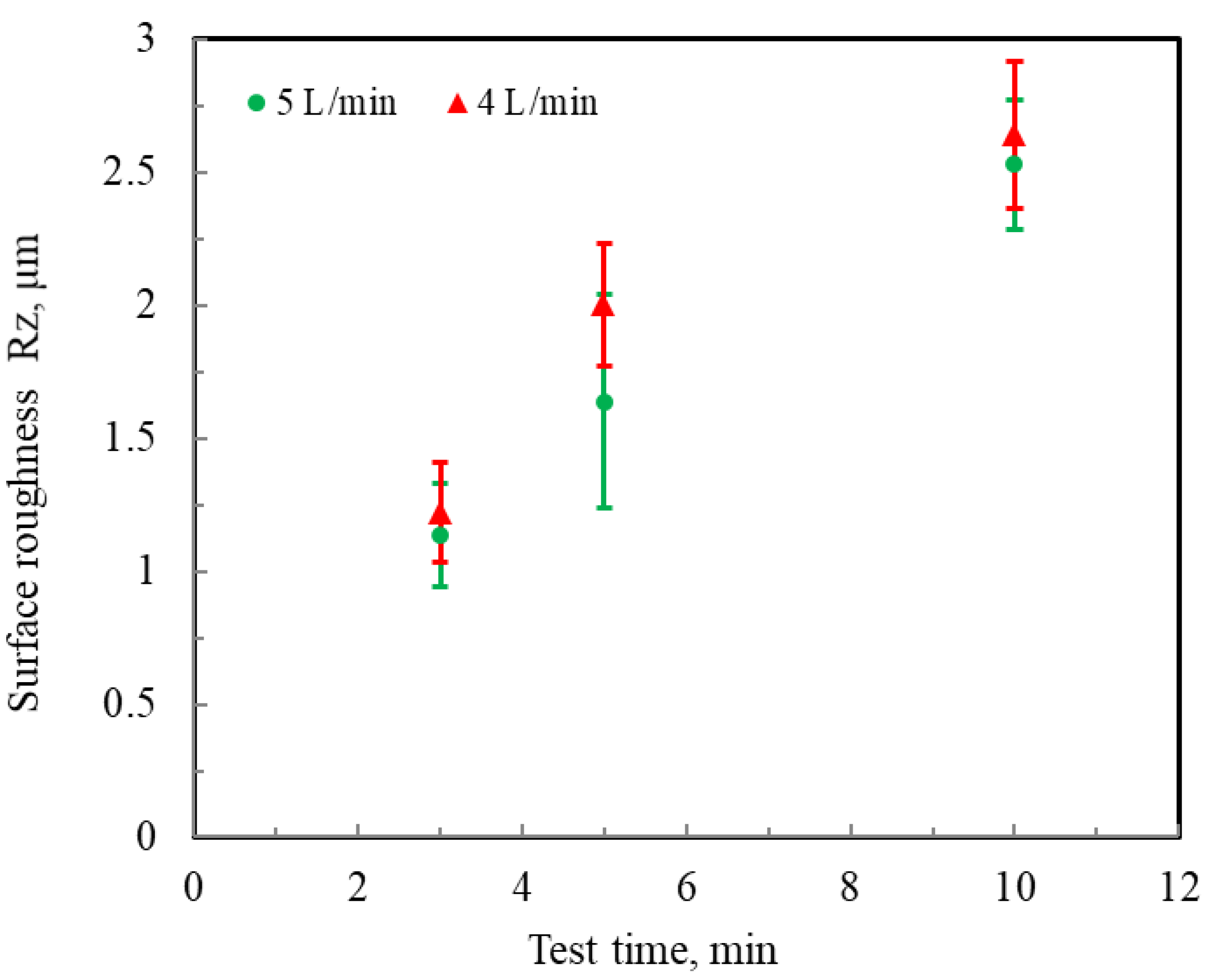

3.3. Effect of Flow Rate on the Surface Damage

4. Discussion

5. Conclusions

- It was confirmed that the method of microbubble injection was able to mitigate damage on the specimen surface by comparing the images of surface damage and surface roughness.

- The distribution of microbubbles and the number of microbubbles with different sizes of diameters were investigated. The number of microbubbles increased with an increase in air-flow rate.

- The effect of flow rate on the surface damage was also investigated by the images of surface damage and surface roughness at a 4 and 5 L/min air-flow rate.

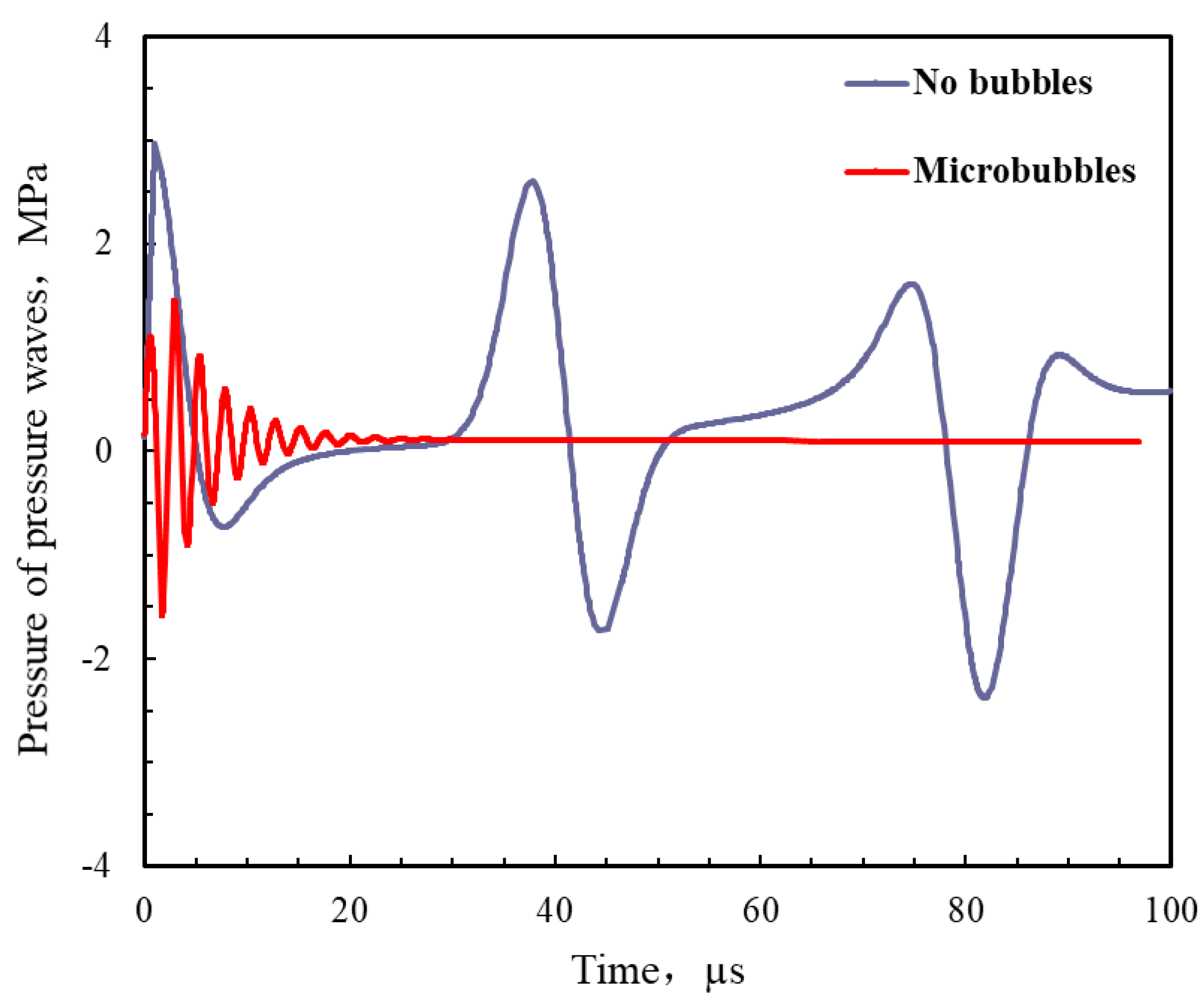

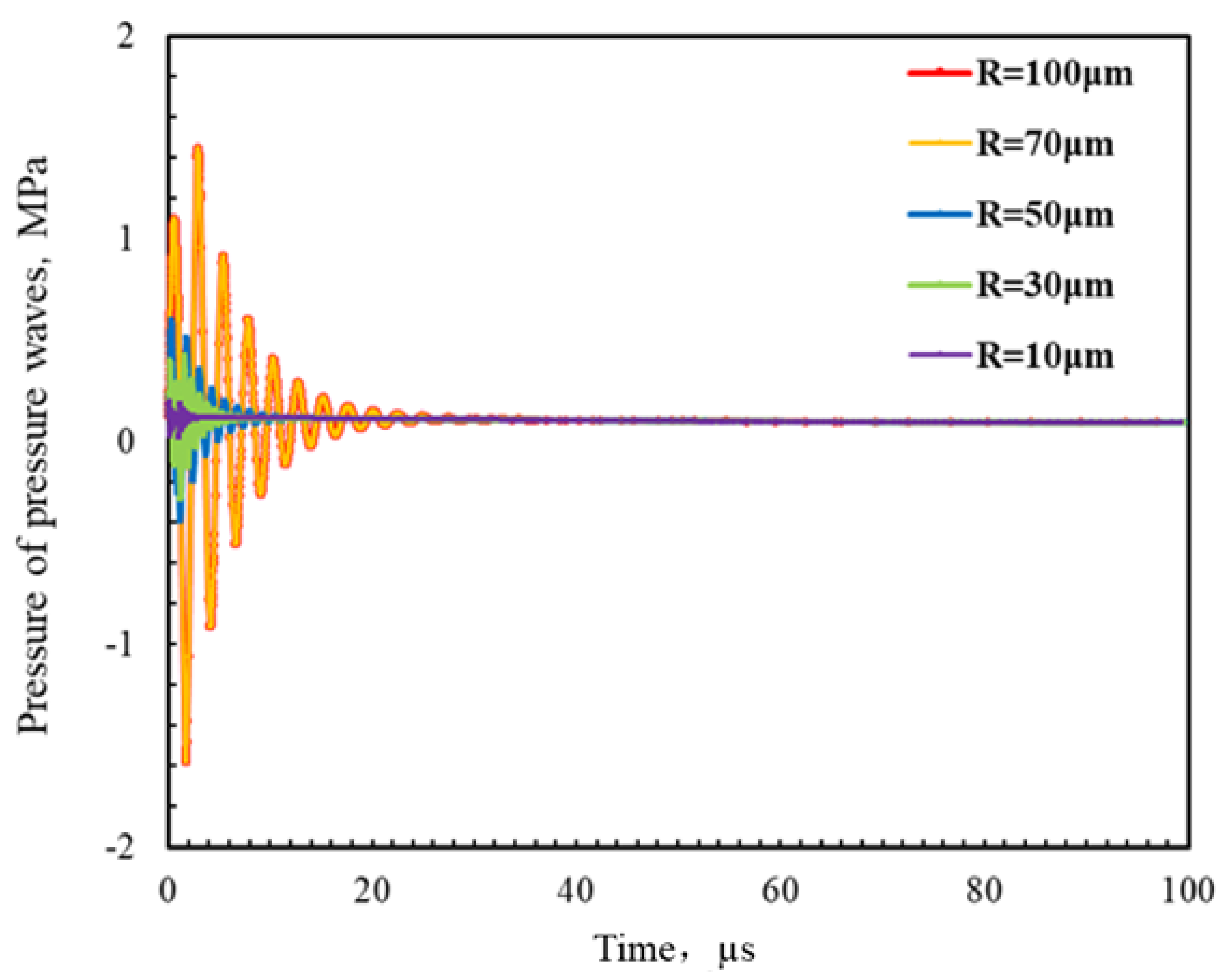

- A numerical simulation code was developed to investigate the effect of dispersed microbubbles surrounding the specimen surface on microsecond-scale pressure waves. The results showed that microbubble injections could effectively suppress microsecond-scale pressure waves, and the pressure amplitude of the pressure waves was markedly reduced by the smaller microbubbles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Futakawa, M.; Haga, K.; Wakui, T.; Kogawa, H.; Naoe, T. Development of the Hg target in the J-PARC neutron source. Nucl. Instrum. Methods Phys. Res. Sect. A 2009, 600, 18–21. [Google Scholar] [CrossRef]

- Takada, H.; Haga, K.; Teshigawara, M.; Aso, T.; Meigo, S.; Kogawa, H.; Naoe, T.; Wakui, T.; Ooi, M.; Harada, M.; et al. Materials and Life Science Experimental Facility at the Japan Proton Accelerator Research Complex I: Pulsed Spallation Neutron Source. Qnant. Beam Sci. 2017, 1, 8. [Google Scholar] [CrossRef] [Green Version]

- Haines, J.; McManamy, T.; Gabriel, T.; Battle, R.; Chipley, K.; Crabtree, J.; Jacobs, L.; Lousteau, D.; Rennich, M.; Riemer, B. Spallation neutron source target station design, development, and commissioning. Nucl. Instrum. Methods Phys. Res. A 2014, 764, 94–115. [Google Scholar] [CrossRef]

- Futakawa, M.; Kogawa, H.; Hasegawa, S.; Naoe, T.; Ida, M.; Haga, K. Mitigation technologies for damage induced by pressure waves in high-power mercury spallation neutron sources (II)-Bubbling effect to reduce pressure wave. J. Nucl. Sci. Technol. 2008, 45, 1041–1048. [Google Scholar] [CrossRef]

- Naoe, T.; Wakui, T.; Kinoshita, H.; Kogawa, H.; Haga, K.; Harada, M.; Takada, H.; Futakawa, M. Cavitation damage in double-walled mercury target vessel. J. Nucl. Mater. 2018, 506, 35–42. [Google Scholar] [CrossRef]

- Naoe, T.; Kogawa, H.; Wakui, T.; Haga, K.; Teshigawara, M.; Kinoshita, H.; Takada, H.; Futakawa, M. Cavitation damage prediction for the JSNS mercury target vessel. J. Nucl. Mater. 2016, 468, 313–320. [Google Scholar] [CrossRef] [Green Version]

- Futakawa, M.; Naoe, T.; Kogawa, H.; Teshigawara, M.; Ikeda, Y. Effects of pitting damage on fatigue limit and lifetime in mercury target. J. Nucl. Mater. 2006, 356, 168–177. [Google Scholar] [CrossRef]

- McClintock, D.; Riemer, B.; Ferguson, P.; Carroll, A.; Dayton, M. Initial observations of cavitation-induced erosion of liquid metal spallation target vessels at the Spallation Neutron Source. J. Nucl. Mater. 2012, 431, 147–159. [Google Scholar] [CrossRef]

- Riemer, B.; Wendel, M.; Felde, D.; Sangrey, R.; Abdou, A.; West, D.; Shea, T.; Hasegawa, S.; Kogawa, H.; Naoe, T.; et al. Small gas bubble experiment for mitigation of cavitation damage and pressure waves in short-pulse mercury spallation targets. J. Nucl. Mater. 2014, 450, 192–203. [Google Scholar] [CrossRef]

- McClintock, D.; Liu, Y.; Bruce, D.; Winder, D.; Schwartz, R.; Kyte, M.; Blokland, W.; Sangrey, R.; Carroll, T.; Long, C.; et al. Small-bubble gas injection to mitigate cavitation-induced erosion damage and reduce strain in target vessels at the Spallation Neutron Source. Mater. Des. 2022, 221, 110937. [Google Scholar] [CrossRef]

- Riemer, B.; Haines, J.; Wendel, M.; Bauer, G.; Futakawa, M.; Hasegawa, S.; Kogawa, H. Cavitation damage experiments for mercury spallation targets at the LANSCE–WNR in 2005. J. Nucl. Mater. 2008, 377, 162–173. [Google Scholar] [CrossRef]

- Riemer, B.; McClintock, D.; Kaminskas, S.; Abdou, A. Correlation between simulations and cavitation-induced erosion damage in Spallation Neutron Source target modules after operation. J. Nucl. Mater. 2014, 450, 183–191. [Google Scholar] [CrossRef]

- Hasegawa, S.; Naoe, T.; Futakawa, M. Solubility of helium in mercury for bubbling technology of the spallation neutron mercury target. J. Nucl. Mater. 2010, 398, 189–192. [Google Scholar] [CrossRef]

- Kogawa, H.; Haga, K.; Wakui, T.; Futakawa, M. Development on mercury pump for JSNS. Nucl. Instrum. Methods Phys. Res. A 2009, 600, 97–99. [Google Scholar] [CrossRef]

- Vevera, B.; McClintock, D.; Hyers, J.; Riemer, B. Characterization of irradiated AISI 316L stainless steel disks removed from the Spallation Neutron Source. J. Nucl. Mater. 2014, 450, 147–162. [Google Scholar] [CrossRef]

- Kogawa, H.; Naoe, T.; Kyotoh, H.; Haga, K.; Kinoshita, H.; Futakawa, M. Development of microbubble generator for suppression of pressure waves in mercury target of spallation source. J. Nucl. Sci. Technol. 2015, 52, 1461–1469. [Google Scholar] [CrossRef]

- Kogawa, H.; Naoe, T.; Futakawa, M.; Haga, K.; Wakui, T.; Harada, M.; Takada, H. Mitigation technologies for damage induced by pressure waves in high-power mercury spallation neutron sources (IV)–measurement of pressure wave response and microbubble effect on mitigation in mercury target at J-PARC. J. Nucl. Sci. Technol. 2017, 54, 733–741. [Google Scholar] [CrossRef]

| Specimen | SUS316 Button Shape, 26 mm in Diameter and 5 mm in Thickness |

|---|---|

| Vibration frequency | 20 kHz |

| Flowing rate of water | 75 L/min |

| Flowing rate of air | 4 L/min & 5 L/min |

| Working conditions | Stagnant water |

| Flowing water | |

| Bubbling water | |

| Test time | 1, 3, 5, 10 min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Lin, F.; Yang, Y.; Xue, Y.; Fu, Y.; Hang, W.; Zou, S. Study on Using Microbubbles to Reduce Surface Damage of Mercury Target for Spallation Neutron Source. Coatings 2022, 12, 1960. https://doi.org/10.3390/coatings12121960

Sun X, Lin F, Yang Y, Xue Y, Fu Y, Hang W, Zou S. Study on Using Microbubbles to Reduce Surface Damage of Mercury Target for Spallation Neutron Source. Coatings. 2022; 12(12):1960. https://doi.org/10.3390/coatings12121960

Chicago/Turabian StyleSun, Xu, Fuzhong Lin, Yanzhen Yang, Yuan Xue, Yongjian Fu, Wei Hang, and Shiqing Zou. 2022. "Study on Using Microbubbles to Reduce Surface Damage of Mercury Target for Spallation Neutron Source" Coatings 12, no. 12: 1960. https://doi.org/10.3390/coatings12121960

APA StyleSun, X., Lin, F., Yang, Y., Xue, Y., Fu, Y., Hang, W., & Zou, S. (2022). Study on Using Microbubbles to Reduce Surface Damage of Mercury Target for Spallation Neutron Source. Coatings, 12(12), 1960. https://doi.org/10.3390/coatings12121960