Enhancing the Corrosion Resistance of Low Pressure Cold Sprayed Metal Matrix Composite Coatings on AZ31B Mg Alloy through Friction Stir Processing

Abstract

:1. Introduction

2. Experimental Work

2.1. Manufacturing of MMC Coatings

2.2. Characterization of Materials

2.3. Electrochemical Experiment

- Reference as saturated calomel electrode (SCE),

- Counter as a platinum electrode,

- Working as MMC coatings.

3. Result and Discussion

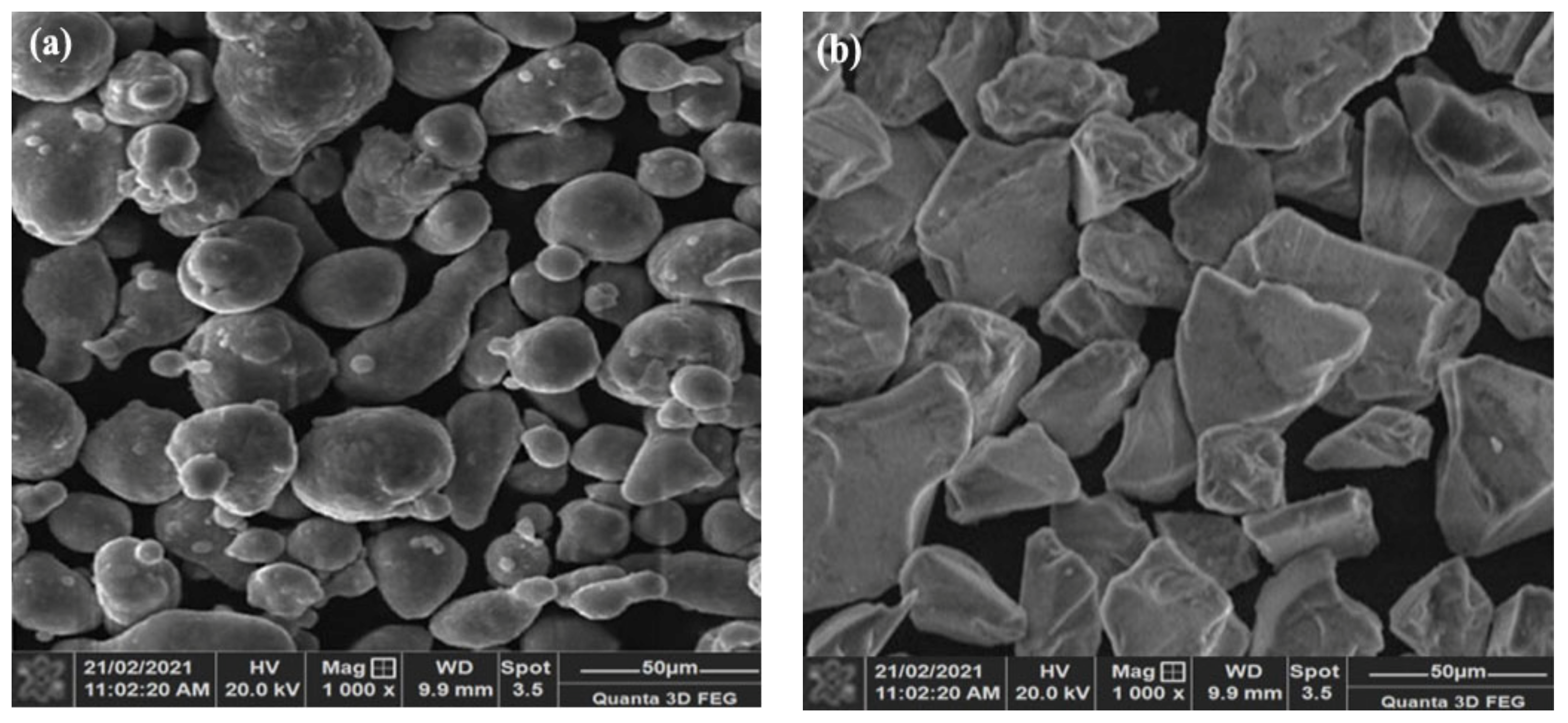

3.1. Coating Microstructure and Characterization

3.2. Microstructural Study

Refinement of Alumina Particles

3.3. Williamson–Hall Measurement

- k: Shape factor constant

- λ: X-ray wavelength

- d: Crystalline dimension

- ε: Lattice strain

- θ: Bragg angle

- ρ: Dislocation density

- b: Burgers vector

- B: Peak broadening width

| Samples | Crystalline Dimension (d) (nm) | Dislocation Density (ρ) (mm2) | Micro Strain (ε) (%) |

|---|---|---|---|

| LPC Sprayed | 192.3 | 2.04 × 1020 | 0.111 |

| 800 rpm (1st run of FSP) | 73.1 | 2.83 × 1019 | 0.038 |

| 800 rpm (2nd run FSP) | 97.3 | 2.28 × 1019 | 0.034 |

| 800 rpm (3rd run FSP) | 59.2 | 3.76 × 1019 | 0.042 |

3.4. Corrosion Performance and Morphology

3.5. Mechanism of Corrosion

4. Conclusions

- (i)

- The size of the alumina components could be decreased by utilizing FSP. Multiple runs of FSP improved the rate of scattering and separation of alumina particles due to the high stir motion created by FSP.

- (ii)

- The matrix phase (Al alloy) dislocation density and micro strain are lowered after the friction stir technique. The lower dislocation densities improve corrosion resistance. However, the dislocation density and micro strain were higher in the third run of FSP, which harmed corrosion resistance.

- (iii)

- Furthermore, the lower (1st and 2nd) runs of FSP can significantly improve the protection against corrosion of the LPCSed Al alloy/alumina coating, and the 2nd run of FSP provides outstanding resistance to corrosion. The enhanced surface state is the primary enhancement mechanism for the FSPed MMC coatings.

- (iv)

- The amalgamate action of the enhanced surface state and damaged interface of interior deposits would be accountable for the poor corrosion rate in the third run of the friction stir method.

- (v)

- Changes in the weight percentages of aluminium alloy and alumina powder, as well as post-treatments such as laser remelting and heat treatment techniques, could be investigated further. The samples’ corrosion performance must then be analyzed further using electrochemical impedance spectroscopy experiments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gangil, N.; Siddiquee, A.N.; Maheshwari, S. Aluminium based in-situ composite fabrication through friction stir processing: A review. J. Alloys Compd. 2017, 715, 91–104. [Google Scholar] [CrossRef]

- Ashokkumar, M.; Thirumalaikumarasamy, D.; Thirumal, P.; Barathiraja, R. Influences of Mechanical, Corrosion, erosion and tribological performance of cold sprayed Coatings A review. Mater. Today Proc. 2021, 46, 7581–7587. [Google Scholar] [CrossRef]

- Sharifitabar, M.; Sarani, A.; Khorshahian, S.; Afarani, M.S. Fabrication of 5052Al/Al2O3 nanoceramic particle reinforced composite via friction stir processing route. Mater. Des. 2011, 32, 4164–4172. [Google Scholar] [CrossRef]

- Pan, J.; Li, J.H.; Fukunaga, H.; Ning, X.G.; Ye, H.Q.; Yao, Z.K.; Yang, D.M. Microstructural study of the interface reaction between whiskers and aluminium. Compos. Sci. Technol. 1977, 57, 319–325. [Google Scholar] [CrossRef]

- Ramesh, C.; Pramod, S.; Keshavamurthy, R. A study on microstructure and mechanical properties of Al 6061–TiB2 in-situ composites. Mater. Sci. Eng. A 2011, 528, 4125–4132. [Google Scholar] [CrossRef]

- Kumar, A.V. Method of stir casting of aluminum metal matrix composites: A review. Mater. Today 2017, 4, 1140–1146. [Google Scholar]

- Chianeh, V.A.; Hosseni, H.R.M.; Nofar, N. Microstructural features and mechanical properties of Al-Al3Ti composite fabricated by in-situ powder metallurgy route. J. Alloys Compd. 2009, 473, 127–132. [Google Scholar] [CrossRef]

- Yan, D.-R.; Yang, Y.; Chu, Z.-H.; Chen, X.-G.; Dai, X.-R.; Wang, Y.-H.; Dong, Y.-C. In situ composite coatings prepared by complex reactive plasma spraying of Fe2O3-Al-Cr2O3 composite powders. Surf. Coat. Technol. 2017, 328, 94–101. [Google Scholar] [CrossRef]

- Mathanbabu, M.; Thirumalaikumarasamy, D.; Thirumal, P.; Ashokkumar, M. Study on thermal, mechanical, microstructural properties and failure analyses of lanthanum zirconate based thermal barrier coatings: A review. Mater. Today Proc. 2021, 46, 7948–7954. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gärtner, F.; Klassen, T. Cold spraying—A materials perspective. Acta. Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.; Kim, J. Microstructure of Kinetic Spray Coatings: A Review. J. Therm. Spray Technol. 2015, 24, 592–610. [Google Scholar] [CrossRef]

- Bashirzadeh, M.; Azarmi, F.; Leither, C.P.; Karami, G. Investigation on relationship between mechanical properties and mi-crostructural characteristics of metal matrix composites fabricated by cold spraying technique. Appl. Surf. Sci. 2013, 275, 208–216. [Google Scholar] [CrossRef]

- Yin, S.; Xie, Y.; Cizek, J.; Ekoi, E.J.; Hussain, T.; Dowling, D.P.; Lupoi, R. Advanced diamond- reinforced metal matrix com-posites via cold spray: Properties and deposition mechanism. Compos. Part B-Eng. 2017, 113, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Wang, Q.; Ye, R.; Ramachandran, C.S. Plasma electrolytic oxidation of cold spray kinetically metallized CNT-Al coating on AZ91-Mg alloy: Evaluation of mechanical and surficial characteristics. J. Alloys Compd. 2021, 892, 162094. [Google Scholar] [CrossRef]

- Yu, M.; Suo, X.K.; Li, W.Y.; Wang, Y.Y.; Liao, H.L. Microstructure, mechanical property and wear performance of cold sprayed Al5056/SiCp composite coatings: Effect of reinforcement content. Appl. Surf. Sci. 2014, 289, 188–196. [Google Scholar] [CrossRef]

- Yang, K.; Li, W.; Niu, P.; Yang, X.; Xu, Y. Cold sprayed AA2024/Al2O3 metal matrix composites improved by friction stir processing: Microstructure characterization, mechanical performance and strengthening mechanisms. J. Alloys Compd. 2018, 736, 115–123. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, S.M.; Moridi, A.; Guagliano, M. Critical review of corrosion protection by cold spray coatings. Surf. Eng. 2015, 31, 803–815. [Google Scholar] [CrossRef]

- Da Silva, F.S.; Bedoya, J.; Dosta, S.; Cinca, N.; Cano, I.; Guilemany, J.M.; Benedetti, A. Corrosion characteristics of cold gas spray coatings of reinforced aluminum deposited onto carbon steel. Corros. Sci. 2017, 114, 57–71. [Google Scholar] [CrossRef] [Green Version]

- Spencer, K.; Fabijanic, D.M.; Zhang, M.X. The use of Al-Al2O3 cold spray coatings to improve the surface properties of magnesium alloys. Surf. Coat. Technol. 2009, 204, 336–344. [Google Scholar] [CrossRef]

- Tao, Y.; Xiong, T.; Sun, C.; Jin, H.; Du, H.; Li, T. Effect of α-Al2O3 on the properties of cold sprayed Al/α-Al2O3 composite coatings on AZ91D magnesium alloy. Appl. Surf. Sci. 2009, 256, 261–266. [Google Scholar] [CrossRef]

- Koivuluoto, H.; Vuoristo, P. Effect of Ceramic Particles on Properties of Cold-Sprayed Ni-20Cr+Al2O3 Coatings. J. Therm. Spray Technol. 2009, 18, 555–562. [Google Scholar] [CrossRef]

- Wang, Y.; Normand, B.; Mary, N.; Yu, M.; Liao, H. Microstructure and corrosion behavior of cold sprayed SiCp/Al 5056 composite coatings. Surf. Coat. Technol. 2014, 251, 264–275. [Google Scholar] [CrossRef]

- Meydanoglu, O.; Jodoin, B.; Kayali, E.S. Microstructure, mechanical properties and corrosion performance of 7075 Al matrix ceramic particle reinforced composite coatings produced by the cold gas dynamic spraying process. Surf. Coat. Technol. 2013, 235, 108–116. [Google Scholar] [CrossRef]

- Irissou, E.; Legoux, J.-G.; Arsenault, B.; Moreau, C. Investigation of Al-Al2O3 Cold Spray Coating Formation and Properties. J. Therm. Spray Technol. 2007, 16, 661–668. [Google Scholar] [CrossRef]

- Rao, Y.; Wang, Q.; Oka, D.; Ramachandran, C.S. On the PEO treatment of cold sprayed 7075 aluminum alloy and its effects on mechanical, corrosion and dry sliding wear performances thereof. Surf. Coat. Technol. 2019, 383, 125271. [Google Scholar] [CrossRef]

- Rao, Y.; Wang, Q.; Chen, J.; Ramachandran, C.S. Abrasion, sliding wear, corrosion, and cavitation erosion characteristics of a duplex coating formed on AZ31 Mg alloy by sequential application of cold spray and plasma electrolytic oxidation techniques. Mater. Today Commun. 2020, 26, 101978. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Q.; Chen, G.; Ramachandran, C.S. Mechanical, tribological and corrosion physiognomies of CNT-Al metal matrix composite (MMC) coatings deposited by cold gas dynamic spray (CGDS) process. Surf. Coat. Technol. 2020, 403, 126380. [Google Scholar] [CrossRef]

- Luo, X.; Chidambaram-Seshadri, R.; Yang, G.J. Micro-nanostructured cermet coatings. In Advanced Nanomaterials and Coatings by Thermal Spray; Elsevier: Amsterdam, The Netherlands, 2019; pp. 61–117. [Google Scholar]

- Huang, R.; Sone, M.; Ma, W.; Fukanuma, H. The effects of heat treatment on the mechanical properties of cold-sprayed coatings. Surf. Coat. Technol. 2015, 261, 278–288. [Google Scholar] [CrossRef]

- Yang, K.; Li, W.; Guo, X.; Yang, X.; Xu, Y. Characterizations and anisotropy of cold-spraying additive-manufactured copper bulk. J. Mater. Sci. Technol. 2018, 34, 1570–1579. [Google Scholar] [CrossRef]

- Yang, K.; Li, W.; Huang, C.; Yang, X.; Xu, Y. Optimization of cold-sprayed AA2024/Al2O3 metal matrix composites via friction stir processing: Effect of rotation speeds. J. Mater. Sci. Technol. 2018, 34, 2167–2177. [Google Scholar] [CrossRef]

- Ma, Z. Friction Stir Processing Technology: A Review. Met. Mater. Trans. A 2008, 39, 642–658. [Google Scholar] [CrossRef]

- Mishra, R.; Ma, Z.; Charit, I. Friction stir processing: A novel technique for fabrication of surface composite. Mater. Sci. Eng. A 2003, 341, 307–310. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Marzbanrad, B.; Shah, L.; Jahed, H.; Gerlich, A. Friction-stir processing of a cold sprayed AA7075 coating layer on the AZ31B substrate: Structural homogeneity, microstructures and hardness. Surf. Coat. Technol. 2017, 331, 116–128. [Google Scholar] [CrossRef] [Green Version]

- Yang, C. A novel uncertainty-oriented regularization method for load identification. Mech. Syst. Signal Process. 2021, 158, 107774. [Google Scholar] [CrossRef]

- Yang, C.; Hou, X.; Chang, S. A synchronous placement and size-based multi-objective optimization method for heat dissipation design on antenna module of space solar power satellite. Sustain. Energy Technol. Assess. 2021, 45, 101183. [Google Scholar] [CrossRef]

- Yang, C.; Hou, X. Iterative two-layer thermal design strategy for step sandwich antenna of space solar power satellite using modified constrained multi-objective optimization. Aerosp. Sci. Technol. 2021, 118, 106987. [Google Scholar] [CrossRef]

- Hodder, K.; Izadi, H.; McDonald, A.; Gerlich, A. Fabrication of aluminum–alumina metal matrix composites via cold gas dynamic spraying at low pressure followed by friction stir processing. Mater. Sci. Eng. A 2012, 556, 114–121. [Google Scholar] [CrossRef]

- Huang, C.; Li, W.; Feng, Y.; Xie, Y.; Planche, M.-P.; Liao, H.; Montavon, G. Microstructural evolution and mechanical properties enhancement of a cold-sprayed Cu Zn alloy coating with friction stir processing. Mater. Charact. 2017, 125, 76–82. [Google Scholar] [CrossRef]

- Huang, C.; Li, W.; Feng, Y.; Xie, Y.; Planche, M.P.; Liao, H.; Montavon, G. Modification of a cold sprayed SiCp/Al5056 composite coating by friction stir processing. Surf. Coat. Technol. 2016, 296, 69–75. [Google Scholar] [CrossRef]

- Peat, T.; Galloway, A.; Toumpis, A.; Steel, R.; Zhu, W.; Iqbal, N. Enhanced erosion performance of cold spray co-deposited AISI316 MMCs modified by friction stir processing. Mater. Des. 2017, 120, 22–35. [Google Scholar] [CrossRef] [Green Version]

- Peat, T.; Galloway, A.; Toumpis, A.; McNutt, P.; Iqbal, N. The erosion performance of cold spray deposited metal matrix composite coatings with subsequent friction stir processing. Appl. Surf. Sci. 2017, 396, 1635–1648. [Google Scholar] [CrossRef] [Green Version]

- Pang, J.; Liu, F.; Liu, J.; Tan, M.-J.; Blackwood, D. Friction stir processing of aluminium alloy AA7075: Microstructure, surface chemistry and corrosion resistance. Corros. Sci. 2016, 106, 217–228. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Velonaki, Z.; Stergiou, C.I.; Kourkoulis, S.K. The effect of artificial ageing heat treatments on the corro-sion-induced hydrogen embrittlement of 2024 (Al-Cu) aluminium alloy. Corros. Sci. 2016, 102, 413–424. [Google Scholar] [CrossRef]

- Kumar, S.; Jyothirmayi, A.; Wasekar, N.; Joshi, S. Influence of annealing on mechanical and electrochemical properties of cold sprayed niobium coatings. Surf. Coat. Technol. 2016, 296, 124–135. [Google Scholar] [CrossRef]

- Xu, W.; Liu, J.; Zhu, H. Pitting corrosion of friction stir welded aluminum alloy thick plate in alkaline chloride solution. Electrochim. Acta 2010, 55, 2918–2923. [Google Scholar] [CrossRef]

- Tao, Y.; Xiong, T.; Sun, C.; Kong, L.; Cui, X.; Li, T.; Song, G.L. Microstructure and corrosion performance of a cold sprayed aluminium coating on AZ91D magnesium alloy. Corros. Sci. 2010, 52, 3191–3197. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, Z.H.; Li, X.B.; Huang, G.S.; Li, C.X.; Li, Y. Corrosion behavior of low pressure cold sprayed Zn-Ni composite coatings. J. Alloys Compd. 2017, 719, 194–202. [Google Scholar] [CrossRef]

- Ngai, S.; Ngai, T.; Vogel, F.; Story, W.; Thompson, G.B.; Brewer, L.N. Saltwater corrosion behavior of cold sprayed AA7075 aluminum alloy coatings. Corros. Sci. 2018, 130, 231–240. [Google Scholar] [CrossRef]

- Barouz, M.; Givi, M.K.B. Fabrication of in situ Cu/SiC composites using multipass friction stir processing: Evaluation of microstructural, porosity, mechanical and electrical behaviour. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1445–1453. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Parmar, V.; Changela, K.; Srinivas, B.; Sankar, M.M.; Mohanty, S.; Panigrahi, S.K.; Hariharan, K.; Kalyanasundaram, D. Relationship between Dislocation Density and Antibacterial Activity of Cryo-Rolled and Cold-Rolled Copper. Materials 2019, 12, 200. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Z.; Li, W.; Feng, Y.; Li, J.; Chao, Y. Global anisotropic response of friction stir welded 2024 aluminum sheets. Acta Mater. 2015, 92, 117–125. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enomoto, M.; Jogan, S. Microstructural evolution of 6063 aluminum during friction-stir welding. Met. Mater. Trans. A 1999, 30, 2429–2437. [Google Scholar] [CrossRef]

- Rahsepar, M.; Jarahimoghadam, H. The influence of multipass friction stir processing on the corrosion behavior and mechanical properties of zircon-reinforced Al metal matrix composites. Mater. Sci. Eng. A 2016, 671, 214–220. [Google Scholar] [CrossRef]

- Pandey, V.; Singh, J.K.; Chattopadhyay, K.; Srinivas, N.C.S.; Singh, V. Influence of ultrasonic shot peening on corrosion behavior of 7075 aluminum alloy. J. Alloys Compd. 2017, 723, 826–840. [Google Scholar] [CrossRef]

- Sattari, B.; Shamanian, M.; Ashrafi, A.; Salehi, M.; Salimijazi, F. Effect of number of passes on the corrosion behavior of Fe/Al surface composites produced by plasma spraying and friction stir processing. J. Mater. Process. Technol. 2017, 250, 35–44. [Google Scholar] [CrossRef]

- Niu, P.; Li, W.; Zhang, Z.; Wang, F.; Feng, Y.; Fu, M. Significant effect of oxide on mechanical properties of friction-stir-welded AA2024 joints. Sci. Technol. Weld. Join. 2016, 22, 66–70. [Google Scholar] [CrossRef]

| S. No | Parameters | Units | Ranges |

|---|---|---|---|

| 1 | Air pressure | bar | 12 |

| 2 | Air temperature | °C | 500 |

| 3 | Powder feed rate | g/min | 20 |

| 4 | Standoff distance | mm | 10 |

| Specimens | Current Densities | Potentials | ||||

|---|---|---|---|---|---|---|

| Icorr (A/cm2) | Corrosion (VSCE) | Pitting (VSCE) | Repassivation (VSCE) | Pitting– Corrosion (V) | Repassivation– Corrosion (V) | |

| LPC Sprayed | 1.31 × 10−6 | −0.575 | −0.483 | −0.762 | 0.092 | −0.187 |

| 800 rpm (1st run of FSP) | 1.40 × 10−7 | −0.612 | −0.517 | −0.780 | 0.095 | −0.168 |

| 800 rpm (2nd run FSP) | 1.21 × 10−7 | −0.636 | −0.510 | −0.781 | 0.126 | −0.145 |

| 800 rpm (3rd run FSP) | 1.33 × 10−6 | −0.594 | −0.504 | −0.777 | 0.090 | −0.183 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohankumar, A.; Duraisamy, T.; Chidambaramseshadri, R.; Pattabi, T.; Ranganathan, S.; Kaliyamoorthy, M.; Balachandran, G.; Sampathkumar, D.; Rajendran, P.R. Enhancing the Corrosion Resistance of Low Pressure Cold Sprayed Metal Matrix Composite Coatings on AZ31B Mg Alloy through Friction Stir Processing. Coatings 2022, 12, 135. https://doi.org/10.3390/coatings12020135

Mohankumar A, Duraisamy T, Chidambaramseshadri R, Pattabi T, Ranganathan S, Kaliyamoorthy M, Balachandran G, Sampathkumar D, Rajendran PR. Enhancing the Corrosion Resistance of Low Pressure Cold Sprayed Metal Matrix Composite Coatings on AZ31B Mg Alloy through Friction Stir Processing. Coatings. 2022; 12(2):135. https://doi.org/10.3390/coatings12020135

Chicago/Turabian StyleMohankumar, Ashokkumar, Thirumalaikumarasamy Duraisamy, Ramachandran Chidambaramseshadri, Thirumal Pattabi, Sathiyamoorthy Ranganathan, Murugan Kaliyamoorthy, Guruprasad Balachandran, Deepak Sampathkumar, and Pradeep Raj Rajendran. 2022. "Enhancing the Corrosion Resistance of Low Pressure Cold Sprayed Metal Matrix Composite Coatings on AZ31B Mg Alloy through Friction Stir Processing" Coatings 12, no. 2: 135. https://doi.org/10.3390/coatings12020135

APA StyleMohankumar, A., Duraisamy, T., Chidambaramseshadri, R., Pattabi, T., Ranganathan, S., Kaliyamoorthy, M., Balachandran, G., Sampathkumar, D., & Rajendran, P. R. (2022). Enhancing the Corrosion Resistance of Low Pressure Cold Sprayed Metal Matrix Composite Coatings on AZ31B Mg Alloy through Friction Stir Processing. Coatings, 12(2), 135. https://doi.org/10.3390/coatings12020135