Phase Control Growth of InAs Nanowires by Using Bi Surfactant

Abstract

:1. Introduction

2. Materials and Methods

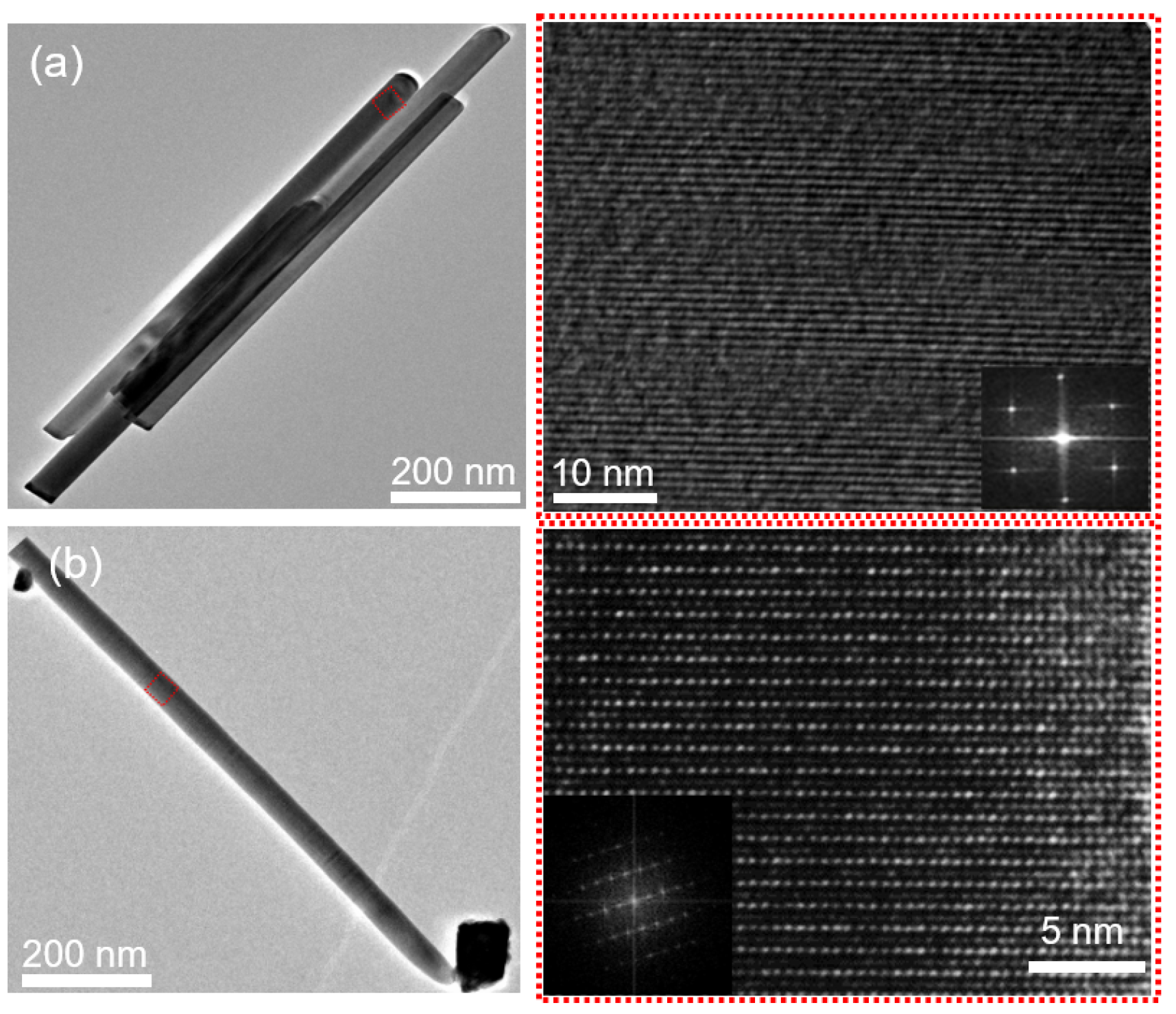

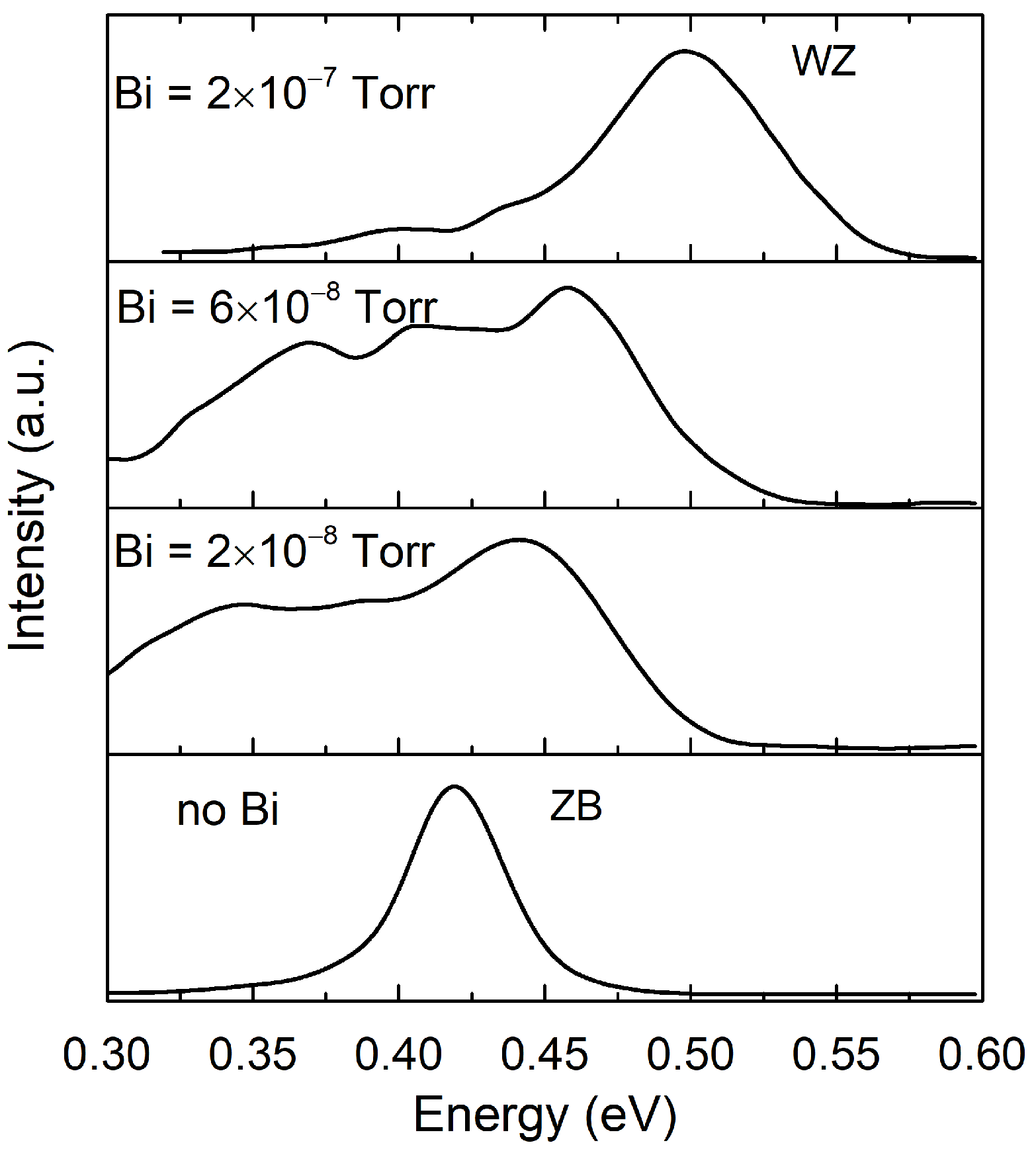

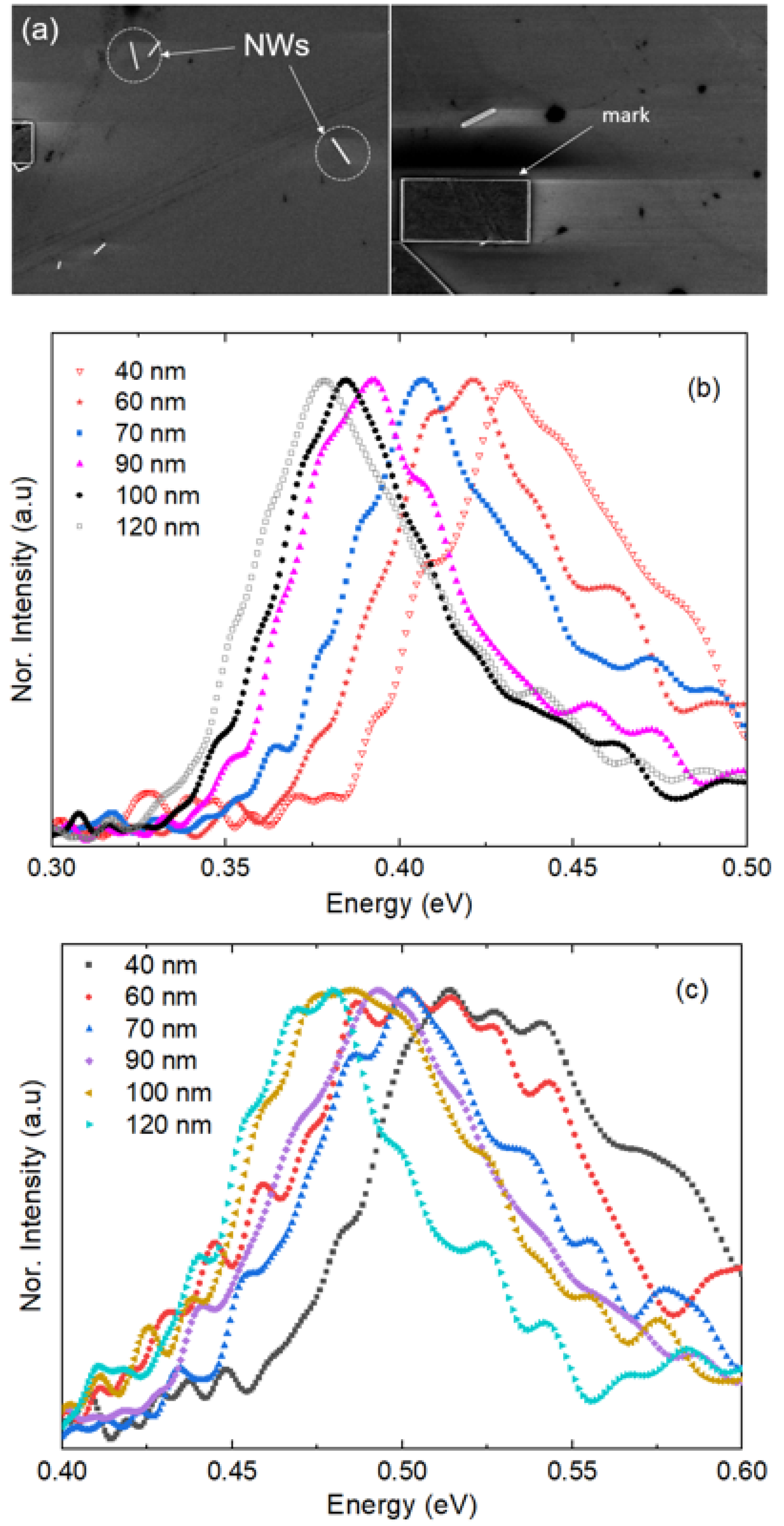

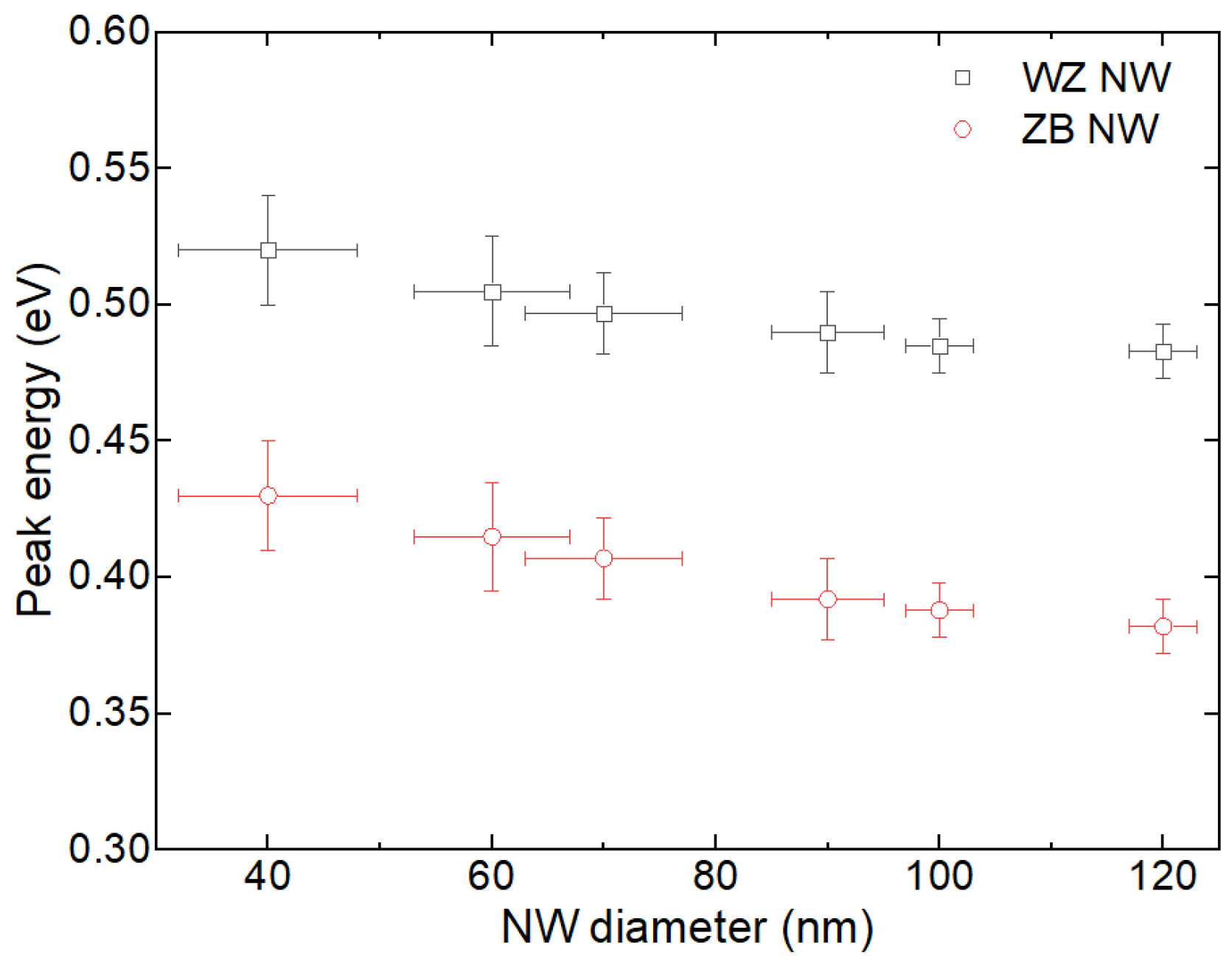

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, P.; Yan, R.; Fardy, M. Semiconductor nanowire: What’s next? Nano Lett. 2010, 10, 1529–1536. [Google Scholar] [CrossRef] [PubMed]

- Tomioka, K.; Motohisa, J.; Hara, S.; Fukui, T. Control of InAs nanowire growth directions on Si. Nano Lett. 2008, 8, 3475–3480. [Google Scholar] [CrossRef] [PubMed]

- Offermans, P.; Crego-Calama, M.; Brongersma, S.H. Gas detection with vertical InAs nanowire arrays. Nano Lett. 2010, 10, 2412–2415. [Google Scholar] [CrossRef] [PubMed]

- Mingo, N. Thermoelectric figure of merit and maximum power factor in III-V semiconductor nanowires. Appl. Phys. Lett. 2004, 84, 2652–2654. [Google Scholar] [CrossRef]

- Koskinen, T.; Khayrudinov, V.; Emadi, F.; Jiang, H.; Haggren, T.; Lipsanen, H.; Tittonen, I. Thermoelectric Characteristics of InAs Nanowire Networks Directly Grown on Flexible Plastic Substrates. ACS Appl. Energy Mater. 2021, 4, 14727–14734. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Yue, L.; Liang, D.; Chen, X.; Li, Y.; Lu, P.; Shao, J.; Wang, S. Novel dilute bismide, epitaxy, physical properties and device application. Crystals 2017, 7, 63. [Google Scholar] [CrossRef]

- Töpfer, T.; Petrov, K.P.; Mine, Y.; Jundt, D.; Curl, R.F.; Tittel, F.K. Room-temperature mid-infrared laser sensor for trace gas detection. Appl. Opt. 1997, 36, 8042–8049. [Google Scholar] [CrossRef]

- Du, J.; Liang, D.; Tang, H.; Gao, X.P. InAs nanowire transistors as gas sensor and the response mechanism. Nano Lett. 2009, 9, 4348–4351. [Google Scholar] [CrossRef]

- Muhiyudin, M.; Hutson, D.; Gibson, D.; Waddell, E.; Song, S.; Ahmadzadeh, S. Miniaturised Infrared Spectrophotometer for Low Power Consumption Multi-Gas Sensing. Sensors 2020, 20, 3843. [Google Scholar] [CrossRef]

- Sun, M.; Leong, E.; Chin, A.; Ning, C.Z.; Cirlin, G.; Samsonenko, Y.B.; Dubrovskii, V.; Chuang, L.; Chang-Hasnain, C. Photoluminescence properties of InAs nanowires grown on GaAs and Si substrates. Nanotechnology 2010, 21, 335705. [Google Scholar] [CrossRef]

- Sumikura, H.; Zhang, G.; Takiguchi, M.; Takemura, N.; Shinya, A.; Gotoh, H.; Notomi, M. Mid-infrared lasing of single wurtzite InAs nanowire. Nano Lett. 2019, 19, 8059–8065. [Google Scholar] [CrossRef] [PubMed]

- Joyce, H.J.; Wong-Leung, J.; Gao, Q.; Tan, H.H.; Jagadish, C. Phase perfection in zinc blende and wurtzite III-V nanowires using basic growth parameters. Nano Lett. 2010, 10, 908–915. [Google Scholar] [CrossRef] [PubMed]

- Dayeh, S.A.; Susac, D.; Kavanagh, K.L.; Yu, E.T.; Wang, D. Structural and Room-Temperature Transport Properties of Zinc Blende and Wurtzite InAs Nanowires. Adv. Funct. Mater. 2009, 19, 2102–2108. [Google Scholar] [CrossRef]

- Koblmüller, G.; Hertenberger, S.; Vizbaras, K.; Bichler, M.; Bao, F.; Zhang, J.; Abstreiter, G. Self-induced growth of vertical free-standing InAs nanowires on Si (111) by molecular beam epitaxy. Nanotechnology 2010, 21, 365602. [Google Scholar] [CrossRef]

- Johansson, J.; Dick, K.A.; Caroff, P.; Messing, M.E.; Bolinsson, J.; Deppert, K.; Samuelson, L. Diameter dependence of the wurtzite- zinc blende transition in InAs nanowires. J. Phys. Chem. C 2010, 114, 3837–3842. [Google Scholar] [CrossRef]

- Rota, M.B.; Ameruddin, A.S.; Fonseka, H.A.; Gao, Q.; Mura, F.; Polimeni, A.; Miriametro, A.; Tan, H.H.; Jagadish, C.; Capizzi, M. Bandgap energy of wurtzite InAs nanowires. Nano Lett. 2016, 16, 5197–5203. [Google Scholar] [CrossRef]

- Biermanns, A.; Dimakis, E.; Davydok, A.; Sasaki, T.; Geelhaar, L.; Takahasi, M.; Pietsch, U. Role of liquid indium in the structural purity of wurtzite InAs nanowires that grow on Si (111). Nano Lett. 2014, 14, 6878–6883. [Google Scholar] [CrossRef]

- Möller, M.; de Lima, M., Jr.; Cantarero, A.; Chiaramonte, T.; Cotta, M.; Iikawa, F. Optical emission of InAs nanowires. Nanotechnology 2012, 23, 375704. [Google Scholar] [CrossRef]

- Tixier, S.; Adamcyk, M.; Young, E.; Schmid, J.; Tiedje, T. Surfactant enhanced growth of GaNAs and InGaNAs using bismuth. J. Cryst. Growth 2003, 251, 449–454. [Google Scholar] [CrossRef]

- Lewis, R.B.; Corfdir, P.; Li, H.; Herranz, J.; Pfüller, C.; Brandt, O.; Geelhaar, L. Quantum dot self-assembly driven by a surfactant-induced morphological instability. Phys. Rev. Lett. 2017, 119, 086101. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Zhang, Z.; Chen, P.; Shi, S.; Yao, L.; Zhou, C.; Zhou, X.; Zou, J.; Lu, W. Bismuth-induced phase control of GaAs nanowires grown by molecular beam epitaxy. Appl. Phys. Lett. 2014, 105, 162102. [Google Scholar] [CrossRef] [Green Version]

- Ishikawa, F.; Akamatsu, Y.; Watanabe, K.; Uesugi, F.; Asahina, S.; Jahn, U.; Shimomura, S. Metamorphic GaAs/GaAsBi heterostructured nanowires. Nano Lett. 2015, 15, 7265–7272. [Google Scholar] [CrossRef] [PubMed]

- Fan, D.; Zeng, Z.; Dorogan, V.G.; Hirono, Y.; Li, C.; Mazur, Y.I.; Yu, S.Q.; Johnson, S.R.; Wang, Z.M.; Salamo, G.J. Bismuth surfactant mediated growth of InAs quantum dots by molecular beam epitaxy. J. Mater. Sci. Mater. Electron. 2013, 24, 1635–1639. [Google Scholar] [CrossRef]

- Wang, L.; Pan, W.; Chen, X.; Wu, X.; Shao, J.; Wang, S. Influence of Bi on morphology and optical properties of InAs QDs. Opt. Mater. Express 2017, 7, 4249–4257. [Google Scholar] [CrossRef]

- Webster, P.T.; Schaefer, S.T.; Steenbergen, E.H.; Johnson, S.R. Optical quality in strain-balanced InAs/InAsSb superlattices grown with and without Bi surfactant. In Proceedings of the Quantum Sensing and Nano Electronics and Photonics XV. International Society for Optics and Photonics, San Francisco, CA, USA, 28 January–2 February 2018; Volume 10540, p. 105401E. [Google Scholar]

- Alghamdi, H.; Alhassni, A.; Alhassan, S.; Almunyif, A.; Klekovkin, A.V.; Trunkin, I.N.; Vasiliev, A.L.; Galeti, H.V.; Gobato, Y.G.; Kazakov, I.P.; et al. Effect of bismuth surfactant on the structural, morphological and optical properties of self-assembled InGaAs quantum dots grown by Molecular Beam Epitaxy on GaAs (001) substrates. J. Alloys Compd. 2022, 164015. [Google Scholar] [CrossRef]

- Bao, J.; Bell, D.C.; Capasso, F.; Erdman, N.; Wei, D.; Fröberg, L.; Mårtensson, T.; Samuelson, L. Nanowire-Induced Wurtzite InAs Thin Film on Zinc-Blende InAs Substrate. Adv. Mater. 2009, 21, 3654–3658. [Google Scholar] [CrossRef]

- Koblmüller, G.; Vizbaras, K.; Hertenberger, S.; Bolte, S.; Rudolph, D.; Becker, J.; Döblinger, M.; Amann, M.C.; Finley, J.; Abstreiter, G. Diameter dependent optical emission properties of InAs nanowires grown on Si. Appl. Phys. Lett. 2012, 101, 053103. [Google Scholar] [CrossRef]

- Sun, M.; Joyce, H.J.; Gao, Q.; Tan, H.; Jagadish, C.; Ning, C.Z. Removal of surface states and recovery of band-edge emission in InAs nanowires through surface passivation. Nano Lett. 2012, 12, 3378–3384. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saleem, S.; Maryam, A.; Fatima, K.; Noor, H.; Javed, F.; Asghar, M. Phase Control Growth of InAs Nanowires by Using Bi Surfactant. Coatings 2022, 12, 250. https://doi.org/10.3390/coatings12020250

Saleem S, Maryam A, Fatima K, Noor H, Javed F, Asghar M. Phase Control Growth of InAs Nanowires by Using Bi Surfactant. Coatings. 2022; 12(2):250. https://doi.org/10.3390/coatings12020250

Chicago/Turabian StyleSaleem, Samra, Ammara Maryam, Kaneez Fatima, Hadia Noor, Fatima Javed, and Muhammad Asghar. 2022. "Phase Control Growth of InAs Nanowires by Using Bi Surfactant" Coatings 12, no. 2: 250. https://doi.org/10.3390/coatings12020250

APA StyleSaleem, S., Maryam, A., Fatima, K., Noor, H., Javed, F., & Asghar, M. (2022). Phase Control Growth of InAs Nanowires by Using Bi Surfactant. Coatings, 12(2), 250. https://doi.org/10.3390/coatings12020250