1. Introduction

An electrochromic device (ECD) is a spectrally selective filter that changes the color of light passing through the device [

1]. It is an advanced thin-film optical element that can filter out specific wavelength ranges. In recent years, this technology has gradually been introduced to the market. Its applications can be found in reflective blinds [

2], variable reflection car rearview mirrors [

3], ophthalmic lenses [

4], electronic displays [

5], aircraft smart windows [

6], and military camouflage [

7]. As a promising energy-saving green technology [

8], ECD can regulate the sunlight and heat flow into the building, thereby reducing the air-conditioning utilization rate to achieve energy saving [

9,

10]. ECD refers to the optical change of the material and the phenomenon with electrochemical reaction under the applied voltage [

11,

12]. For advantages such as high contrast and low operating voltage, it is usually possible to use it for automobiles, and structural applications usually require long-term stability under climatic conditions. However, most ECDs made of hard materials are particularly due to color speed and long-term stability, mainly owing to the electrical and mechanical properties of flexible substrates.

When polyethylene terephthalate (PET) is selected as a flexible substrate, the corresponding optical properties or thermal properties must be acceptable. For example, thermal expansion coefficients must be small enough to adapt to higher or operating temperatures. On the other hand, the surface properties of PET substrates are suitable for the formation of surface films in transparent conductive oxide (TCO) applications. The current technology for transparent conductive oxide (TCO) requires a thin-film coating at high temperatures to obtain higher transparency and conductivity. Since flexible TCO substrates cannot be coated at high temperatures, these devices cannot reduce the sheet resistance. In this paper, we produced flexible ECDs on TCO with multiple layers. Compared to the glass-based ECD, the thickness of the TCO/ECD layer are controlled at room-temperature operation by sputtering powers, thus ascertaining their applications with flexibility, lightweight, portability, low cost, and easy process.

Indium tin oxide (ITO) is a well-known TCO that has been extensively studied due to its numerous applications. ITO thin films with high transparency (~90%) and low resistivity (<5 × 10

−4 Ω cm) in the visible spectrum are widely used as transparent electrodes [

13]. The ITO thin film can also provide high carrier concentration (10

18−10

21 cm

−3) and applicable mobility (25–50 cm

2/Vs) [

14]. According to a research paper [

15], adding additional metal impurities (Ag, Zn, Pt, Na, K, etc.) can improve the conductivity of the ITO film. The one possibility for the further improvement of the TCO electrodes is to use dielectric/metal/dielectric multilayer films, built-up by a thin metal (nano-Ag) layer, embedded between two dielectric layers. In addition, the multilayer (ITO/nano-Ag/ITO) transparent electrode can suppress the reflection of the metal layer and obtain a selective transparency effect in the visible region [

16].

For the conductive property, the change in resistivity (

ρ) of the ITO/nano-Ag/ITO multilayer films with increasing nano-Ag thickness can be explained using the following basic equation [

17]:

where

n is the number of charge carriers,

e is the charge of the carrier, and

μ is the mobility of the material. As the thickness of the nano-Ag layer increases, both values of

n and

μ also increase, which proves that the nano-Ag layer is the main conduction path for showing their electrical transportation [

17].

Tungsten oxide (WO

3) is the most widely studied cathode EC material, especially used for ECD. The color change of electrochromic WO

3 materials is directly related to the dual injection/extraction of electrons and ions, the principle of which is usually described by a simple redox reaction [

18]:

where M

+ can be either H

+ or a positive ion (such as Li

+, Na

+, K

+), e

− represents the electrons, and

x is a parameter with o <

x < l, which is a measure of both the e

− and cation concentration injected into the film. The color-changing property of M

xWO

3 films depends on the

x value and the process of ion insertion and e

− injection.

The EC mechanism of WO

3 can be explained by the “intervalence transfer theory”, according to the theory of charge transfer between valences proposed by Faughnan et al. [

19]. Under the presence of an electric field, M

+ and e

− are injected into the WO

3 film. It can be shown that the injected electrons are captured by W

6+ to form W

5+, while M

+ remains ionized at the interstitial sites of the WO

3 lattice. Because WO

3 combines with ions and electrons, it produces a compound tungsten bronze (M

xWO

3), thus W

5+ (A) and W

6+ (B) coexist in the colored state, and the electron absorbing the photon energy hv, in W

5+ (A) transition with W

6+ (B), can be described by the following equation [

20,

21]:

where A and B are two different lattice sites. The nano-Ag film thickness and critical optical transmittance parameters have a great influence on the ECD. The valence of these oxides is changed by an applied potential, leading to a change in the electronic distribution due to the ion migration of the EC multilayer [

22]. By changing the resistance of the multilayer TC films and the

ρ value of the single-layer electrode, the influence of the

ρ value on the change of the transmittance and the optical density difference of the coloring and fading of WO

3 was discussed. Using an R2R sputtering system for flexible ECD, in this study, we investigate the optical, electrical, structural, and surface properties of ITO/nano-Ag/ITO multilayer electrodes grown on PET substrates. From the measurements, it was found that the flexible ITO/nano-Ag/ITO electrodes grown by R2R sputtering exhibited lower higher transmittance and sheet resistance due to the presence of the nano-Ag film. Advantages of R2R technologies include their low-cost continuous process and compatibility with flexible surfaces.

Figure 1 shows a schematic diagram of an R2R sputtering system used in a continuous sputtering process. This R2R sputtering system is equipped with a wind roller, unwind roller, vacuum, heating, gas, orbital, three cathode guns, and a rectangular cathode gun for depositing ITO/nano-Ag/ITO flexible electrodes on PET substrates. In addition, the ITO/nano-Ag/ITO electrodes were prepared by continuous dual magnetron mid-frequency sputtering of the ITO layer and DC sputtering of the Ag layer at room temperature, respectively. The rolling speed of the flexible substrate is maintained by adjusting the speed of the motors for the unwinding and winding rollers, which are mounted under the unwinding rollers. Low-cost and bulk-manufactured ECDs can be achieved by depositing flexible electrodes using R2R sputtering techniques. In particular, the R2R-based constant fabrication processes of flexible ITO/nano-Ag/ITO electrodes are one of their advantages for mass and low-cost production [

23,

24]. The R2R system sputters at room temperature without any violent chemical reactions.

2. Experiments and Measurements

The PET substrates with a polymeric hard coating (PET-HC, Kimoto Tech Inc., Saitama, Japan) have 125-μm thickness and their transmittance is 88.03% throughout the visible spectrum. In order to improve adhesion between the ITO electrode and PET substrate, the surface pretreatment of PET substrate is irradiated by an Ar ion beam with 200 W DC pulse power to remove organic pollutants on the surface [

25]. The flexible PES substrate with a width of 250 mm and a length of 200 m was continuously passed above the ITO, Ag, and ITO targets by the motion of the unwinding and winding rollers during the R2R sputtering process. After the substrate surface treatment, the bottom ITO layer was deposited on a PET substrate using ITO targets composed of In

2O

3 (90% by weight) and SnO

2 (10% by weight) with a DC power of 2.5 kW and a working pressure of 1.3 × 10

−3 Torr, Ar/O

2 flow rate of 60/3 sccm, and a rolling speed of 0.5 m/min. During the R2R atomization method, the PET substrate is mechanically attached to the cooling drum to hold the substrate temperature below 20 °C. Subsequently, under the Ar flow of 60 sccm and the rolling speed of 1.0 m/min, the Ag intermediate layer was continuously sputtered onto the bottom ITO layer under the working pressure of 1.6 × 10

−3 Torr, and the thickness of nano-Ag was controlled by sputtering with different powers. The thickness of the Ag intermediate layer was controlled by the DC power supply of the 99% Ag target, which ranged from 0.05 to 0.30 kW. Then, the top ITO layer was continuously deposited on the Ag interlayer under the same conditions as the bottom ITO layer. In this study, the WO

3 thin film fabricated by a direct current (DC) magnetron sputtering system was directly prepared on ITO/nano-Ag/ITO-coated PET with a gas pressure of 4 × 10

−6 Torr. The DC sputtering system power was set to a range of 40–80 W. The gas flow rates for oxygen and argon were 10 sccm and 50 sccm, respectively.

The electrolyte was to ensure the ion transmission between the two electrodes of the ECD to balance the charge generated by the redox process. The electrolyte gel was obtained by mixing 1 M LiClO

4 in a propylene carbonate and 40 wt.% ethylene carbonate solution. Then, 8 wt.% of LiClO

4 and 30 wt.% of plasticizers were added to the liquid electrolyte and mixed with the polymer weight ratio of 2:1 to prepare a gel polymer electrolyte. The ECDs were fabricated by hot pressing the electrolyte gel sandwiched on the WO

3/ITO/nano-Ag/ITO/PET electrode and the ITO/nano-Ag/ITO/PET counter electrode with a scotch tape spacer at 50 °C. In order to prevent electrolyte leakage after the devices are assembled, the ECDs must be sealed with epoxy resin [

26].

For experimental measurement, the structural properties of the layers with different Ag DC power were analyzed by Rigaku X-ray diffraction (XRD, Siemens D5000, Munich, Germany) with the Ni-filtered Cu Kα radiation. In addition, the transmittance and reflectance of the layers were measured by a Shimadzu MPC-3100 UV/VIS/NIR spectrometer within a wavelength ranging from 190 to 2600 nm. The surface morphology of the layer is examined by a field-emission scanning electron microscope (FESEM, S-4800, Hitachi, Japan) with increasing Ag thickness. The working voltage, magnifying rate, and corresponding distance of FESEM parameters were set to 15 kV, 30~220 k, and 9.6~16 mm, respectively. The atomic force microscopy (AFM, NTMDT P47, Tempe, AZ, USA) was employed for examining the layer two-dimensional (2D) surface morphology and three-dimensional (3D) surface roughness image. The scan area was set as 1 × 1 μm2, and the scan rate was 3.459 Hz (512 samples). Film thickness was measured with an alpha-step-200 profile-meter supplied by Tencor. The sheet resistance of the sample was measured with a 4-point probe (Veeco, FPP-50000, Materials Development Corporation, Plainview, NY, USA), and the resistivity of the film was calculated. The transmission electron microscopy (TEM, FEI Tecnai™ G2 F-20, Hillsboro, OR, USA) of thin-film analysis was captured transmitting electron or elastic scattering electronic to formed imaging or making a diffraction pattern and then resolving the microstructure and crystal structure of thin samples.

3. Results and Discussion

The optical properties of the ITO/Nano-Ag/ITO multilayer Nano-Ag film are very important and are highly dependent on their thickness and deposition conditions. Prior to depositing the TCO-film electrodes, the TFCalc program (version 3.5) was used to simulate transparent properties in various nano-Ag thicknesses, from basic coatings to optimal multi-layer electrode designs. The exact shape of the spectrum can be determined by the thickness of the embedded nano-Ag layer.

Figure 2 shows the optical properties of the ITO/Nano-Ag/ITO multilayer Nano-Ag film are very important and are highly dependent on their thickness and deposition conditions. Prior to depositing the TCO-film electrodes, the TFCalc program (version 3.5) was used to simulate transparent properties in various nano-Ag thicknesses, from basic coatings to optimal multi-layer electrode designs. The exact shape of the spectrum can be determined by the thickness of the embedded nano-Ag layer.

Figure 2 shows the simulation results of light transmission of ITO/nano-Ag/ITO stacks on PET substrates with constant ITO film thickness (42 nm) and different nano-Ag layer thickness. When compared to a bare 84 nm-ITO film, the insertion of the nano-Ag layer between two ITO layers resulted in an increase in optical transmittance, particularly in the visible wavelength range of 400–800 nm. The anti-reflection (AR) effect is responsible for this noticeable improvement. The light–matter interaction principles of thin-film optics are used in this type of AR multilayer to produce a destructive interference of the light reflected at the upper and lower interfaces of the ITO/nano-Ag/ITO system [

27].

The ITO/nano-Ag/ITO multilayer had the highest average optical transmittance (T

avg) of 92.05 percent at a nano-Ag layer thickness of 6 nm. However, raising the nano-Ag thickness above 7 nm reduced light transmittance because the excessively thick Ag layer caused light scattering, particularly in the high wavelength area. We can acquire the optimal optical transmittance of the AR ITO/nano-Ag/ITO films by regulating the nano-Ag thickness [

16,

17] in a certain nano-Ag thickness area, which suggests that the optical transmittance of the ITO/nano-Ag/ITO multilayers can be increased. Simulation results in light transmission of ITO/nano-Ag/ITO stacks on PET substrates with constant ITO film thickness (42 nm) and different nano-Ag layer thickness. When compared to a bare 84 nm-ITO film, the insertion of the nano-Ag layer between two ITO layers resulted in an increase in optical transmittance, particularly in the visible wavelength range of 400–800 nm. The anti-reflection (AR) effect is responsible for this noticeable improvement. The light–matter interaction principles of thin-film optics are used in this type of AR multilayer to produce destructive interference of the light reflected at the upper and lower interfaces of the ITO/nano-Ag/ITO system [

27]. The ITO/nano-Ag/ITO multilayer had the highest T

avg of 92.05% at a nano-Ag layer thickness of 6 nm. However, raising the nano-Ag thickness above 7 nm reduced light transmittance because the excessively thick Ag layer caused light scattering, particularly in the high wavelength area. We can acquire the optimal optical transmittance of the AR ITO/nano-Ag/ITO films by regulating the nano-Ag thickness [

16,

17], in a certain nano-Ag thickness area, which suggests that the optical transmittance of the ITO/nano-Ag/ITO multilayers can be increased.

The main purpose of this study is to understand the deposition of transparent conductive oxide films on a PET substrate at room temperature for the optical and conductive properties of ECD.

Figure 3 plots the average optical transmittance (T

avg) spectrum of the continuously grown ITO (42 nm)/nano-Ag/ITO (42 nm) layers as different Ag cathode DC powers (0.05–0.30 kW). For comparison, we also prepared R2R sputtered bare 84-nm-thickness ITO layer on a flexible PET substrate under the optimized sputtering conditions. Without the nano-Ag layer, the bare ITO layer (84 nm thickness) has an average optical transmittance of 79.62%. It can be also seen that when the DC power of the Ag cathode was at 0.05 kW, the flexible ITO/nano-Ag/ITO electrode average optical transmittance was decreased to a low transmittance of 66.99%. At an Ag DC power of 0.2 kW, the flexible ITO/nano-Ag/ITO electrodes showed the highest average optical transmittance of 87.19% due to low light scattering. However, increasing the Ag DC power above 0.25 kW results in a decrease in light transmittance, especially in the high wavelength region, because of light scattering from the nano-Ag layer.

The results in

Figure 3 show that the insertion of a nano-Ag film between the ITO layers can increase the light transmittance, most obvious in the wavelength range of 400–800 nm. The differences in optical properties of ITO/nano-Ag/ITO multilayers with different sputtering powers can be explained by the scattering and absorption of the nano-Ag interlayer. Therefore, the optical transparency can be improved at a certain nano-Ag thickness (corresponding to DC Ag powers) on the ITO/nano-Ag/ITO structure, which can also be explained by the AR effect [

28]. In summary, the transmittance of the multilayer layers deposited by the R2R sputtering system is affected by nano-Ag layer thickness.

A grazing-incident-angle X-ray diffractometer is used to study the phase content and crystallinity of ITO/nano-Ag/ITO multilayer films prepared under different silver cathode DC power supplies, as shown in

Figure 4. After R2R is deposited, new peaks at 35.2°, 38.3°, and 50.9° appear in the XRD spectra, corresponding to the (400), (111), and (440) planes of the anatase phase of ITO/nano-Ag/ITO layers, which are indicative of a nano-crystal embedded amorphous structure. The as-deposited ITO film on PET is preferentially oriented along (400) and (440) crystallographic directions. As the Ag DC power increases from 0.05 kW to 0.30 kW, the nano-Ag films show peaks whose intensities vary with respect to the increased thickness. According to the XRD patterns, the ITO/nano-Ag/ITO multilayers prepared at Ag DC power of 0.2 kW show a preferred orientation along the Ag (111) crystal plane, while the ITO/nano-Ag/ITO multilayer films prepared at lower Ag DC power show a random orientation. However, with the increase of Ag DC power, the Ag (111) peak intensity also increases. On the other hand, the orientation of the 42-nm-thickness ITO (shown in

Figure 4) is relatively stable. The diffraction intensities per unit thickness of these crystal planes are a function of Ag DC power. In order to study the microstructure of the nano-Ag film and the interface between the Ag and ITO layers in detail, it can be examined by FESEM, as described in the following paragraphs.

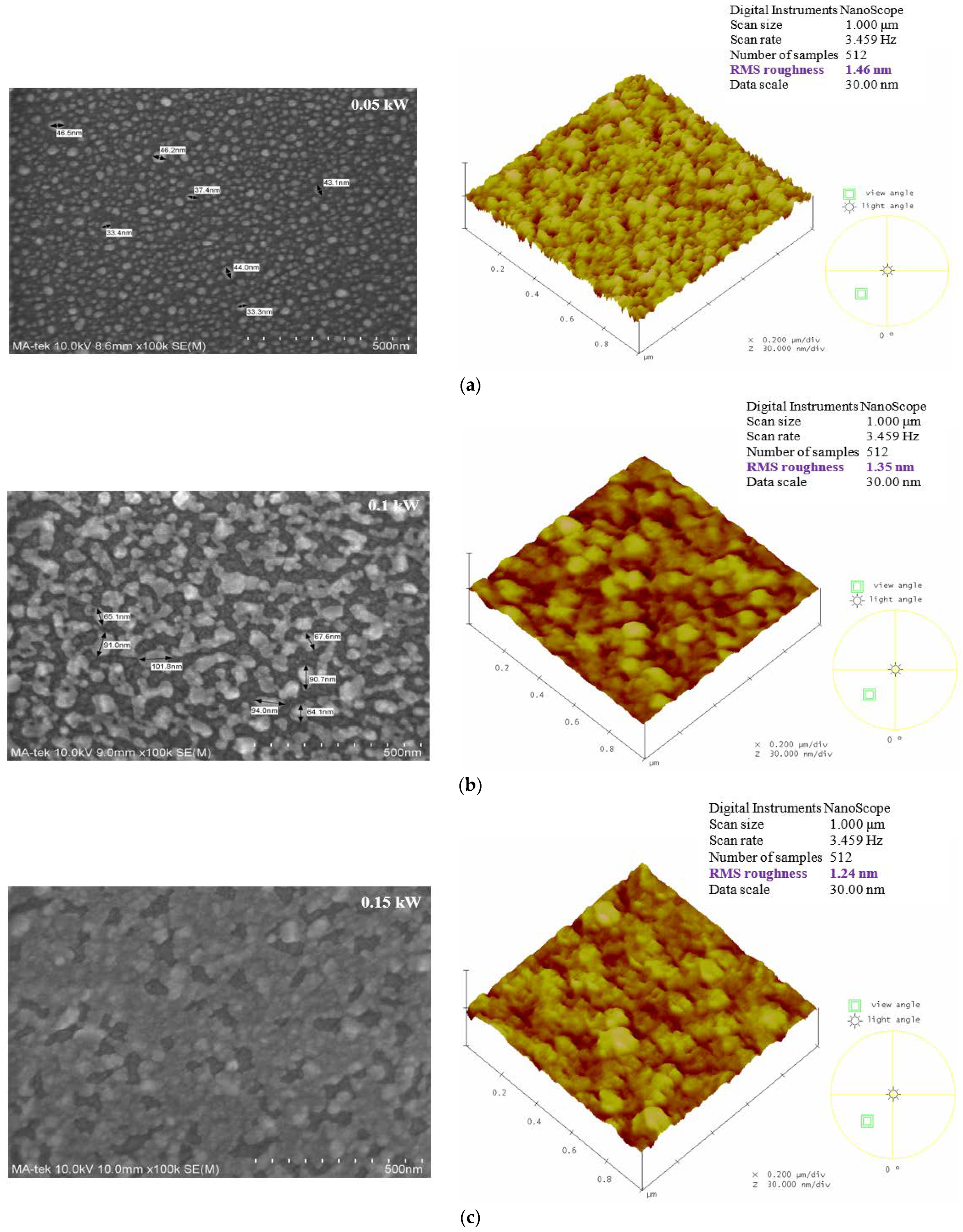

Figure 5a–f illustrates the FESEM surface morphology (left side) and AFM 3D images (right side) of the nano-Ag thin films sputtered on the surface of the ITO layer, with different Ag DC powers. The nature of the nanocrystalline is evident from the dimension of the domains exhibiting crystalline properties. Regardless of the thickness of the interlayer nano-Ag prepared by the R2R system in this study, the FESEM surface morphology shows that the film has no defects such as cracks, pinholes, or protrusions. It was observed that in the case of the nano-Ag layer, there was a significant difference in the surface morphology of the layers deposited on ITO with different Ag DC powers. The results in

Figure 5a–f show that the surface morphology is flat and dense. Increasing the Ag DC power leads to an increase in the nano-Ag stack thickness, leading to increased island coalescence, and eventually creating a continuous nano-Ag layer [

29]. Since the exact size and shape of the particles with Ag DC power above 0.15 kW cannot be clearly understood by FESEM, this study used data from AFM images to confirm.

Using 1 × 1 μm2 AFM scans of nano-Ag film on the ITO layer, the root mean square (RMS, Ra) roughness decreases smoothly first as the Ag DC power increases from 0.05 kW to 0.2 kW. Then, the Ra-value increases when the Ag DC power is at 0.25 kW and 0.3 kW. We achieve the optimal value of Ra (1.16 nm) at 0.2 kW DC power. The large Ra value of nano-Ag deposited on ITO can be attributed to the irregularly shaped grains on the surface. These results show that the variety of roughness is correlated to different Ag DC power.

Increasing the thickness of the nano-Ag film changes its shape from an island to a continuous film. As shown on the left side of

Figure 5a, a randomly connected Ag Island with an average particle size of 41 nm appears at 0.1 kW of Ag DC power. The surface of the ITO layer is not completely covered by the Ag layer due to the aggregation of Ag islands. In the case of 0.15 kW Ag DC power on the left side of

Figure 5b, a continuous nano-Ag film with an average particle size of 82 nm is formed on the surface of the ITO layer. However, the surface of the ITO layer is not yet covered. The nano-Ag sputtered with 0.2 kW of DC power completely covers the underlying ITO thin film, producing the smoothest surface as shown on the right side of the image in

Figure 5d. The optimum transmission of 0.2 kW Ag DC power may be due to the complete coverage of the lower ITO layer with the nano-Ag film. This is consistent with the XRD plot above in

Figure 4.

To explain the electrical properties of these electrodes, a parallel circuit model of ITO/nano-Ag/ITO has been modeled, as shown in the inset of

Figure 6.

Based on this model, the sheet (shunt in parallel) resistance (R

sh) of multilayers can be defined as

. For determining the optimal Ag DC power (nano-Ag thickness) on our developed TCO electrodes, we can evaluate the figure of merit (ϕ

TC) under the below equation [

30]:

where T is the transmittance in a specific wavelength range and R

sh is the sheet resistance of the flexible ITO/nano-Ag/ITO electrode. Therefore,

Figure 6 calculates the ϕ

TC value of the ITO/nano-Ag/ITO electrode as a function of Ag DC power using the average T value (in %) and the corresponding measured R

sh values (in Ω/□ adjusted at top). It was shown that the ϕ

TC value (in 10

−3 Ω

−1) of the flexible ITO/nano-Ag/ITO multilayer films increases with increasing Ag DC powers. At the initial stage of Ag growth in the low Ag DC-power region, random unconnected Ag islands would result in high sheet resistance and low average optical transmittance, leading to very low ϕ

TC values for the electrodes. However, the ϕ

TC value of the flexible ITO/nano-Ag/ITO electrode increased significantly with an increase in Ag DC power. When the Ag DC power was 0.2 kW (about 6 nm thickness), the flexible ITO/nano-Ag/ITO showed the highest ϕ

TC value (30.93 × 10

−3 Ω

−1), which could be attributed to very low R

sh and high T values. However, further increase in Ag DC power to a value above 0.2 kW actually resulted in a decrease in ϕ

TC value of the flexible ITO/nano-Ag/ITO electrodes, even though they had a low R

sh value, due to a rapid decrease in the T value. Therefore, to obtain the best ϕ

TC value, we chose flexible ITO/nano-Ag/ITO electrodes grown with this parameter to fabricate ECDs. The high ϕ

TC value of the flexible ITO/nano-Ag/ITO electrode shows that the R2R sputter-grown flexible ITO/nano-Ag/ITO electrode can be an electrode applied for flexible ECDs.

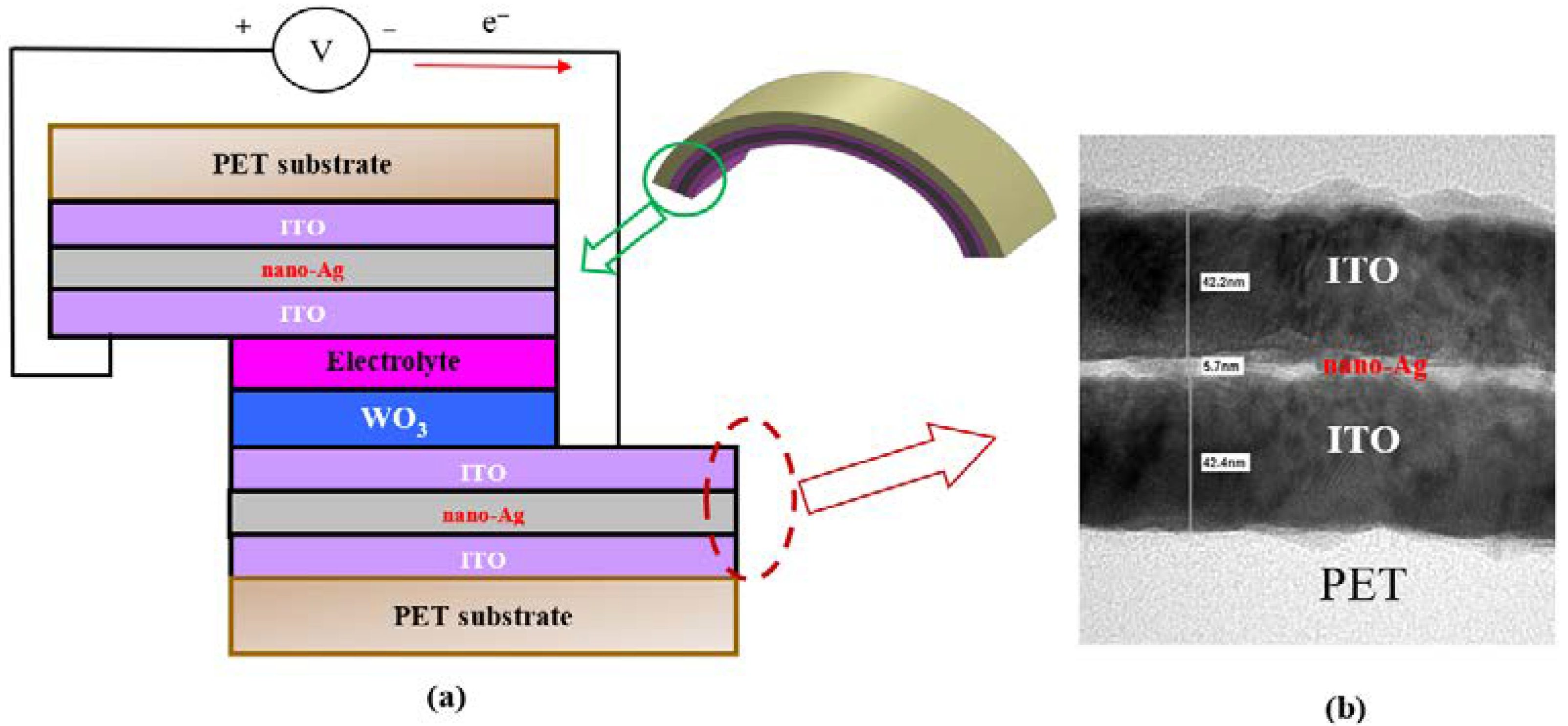

Figure 7a shows the schematic diagram of the ECD structure. The proposed ECD structure designed in this study consists of an electrolyte sandwiched in between a multilayer thin-film stack. The ECD is designed with a PET substrate multilayer structure and WO

3 as the color-changing material. The phenomenon of color changes when WO

3 material undergoes reversible oxidation or reduction reactions. Therefore, WO

3 film is used as the cathodic EC material film layer.

Figure 7b shows the cross-sectional TEM micrographs of the optimized ITO/nano-Ag/ITO multilayer electrode prepared via continuous R2R sputtering at an Ag DC power of 0.2 kW. The thickness of all films was carefully measured by cross-sectional TEM, and each film thickness of ITO, nano-Ag, and ITO layers were about 42.2 nm, 5.7 nm, and 42.4 nm, respectively. The TEM images clearly show nanocrystalline ITO/nano-Ag/ITO multilayer structures without interfacial reactions, and these thick interfaces between the layers indicate that all layers are physically stable. However, the nano-Ag film with a thickness of 5.7 nm grown under an Ag DC power of 0.2 kW showed a crystal structure with Ag (111)-preferred orientations consistent with the XRD results in

Figure 4.

In this study, the wavelength of the visible light spectrum of 400–800 nm was used as the wavelength for measuring the light transmittance of the film in the bleached and colored states. Transmittance was measured using a reflection spectroscope. By applying Lambert–Beer’s law, the range of visible and ultraviolet transmission can be characterized by the following equation [

31]:

where ∆T is a change of relative transmittance and T

b is the transmittance of the bleached state, T

c is the transmittance of the colored state, and ∆OD is a change of optical density. The optical density indicates the light absorption ability of electrochromic films. The change in film transmittance reflects the creation and attenuation of color centers during the insertion/extraction of a significant number of H

+ and e

−. When H

+ ions and electrons flow into the film through a cathode potential of +1.5 V (10 s) to −1.5 V (10 s), the colored state of the film becomes deep blue. The film is bleached as H

+, and by reversing the potential from −1.5 to +1.5 V, electrons flow out of the film.

Figure 8 shows the average light transmission spectra of WO

3 film at various thicknesses in the bleached and colored states within the visible wavelength. These WO

3 films exhibited a reversible color change from colorless to dark blue. The average optical transmittances in the colored states were about 38, 36, 23, 22 and 15% for the films deposited at different WO

3 thicknesses of 68, 122, 225, 320 and 425 nm, respectively. It is clearly shown that an increase in WO

3 thickness leads to a decrease in the colored state values since more oxygen vacancies can accommodate relatively more ions. Therefore, we can see that for the coloring efficiency of WO

3 material, the obtained value is correlated to the film thickness.

Another useful figure of merit for comparing the EC performance of films is color efficiency (CE). It is defined as ΔOD per unit of injection/extraction charge density at a particular wavelength [

32]. The measured CE values of the different WO

3-film thicknesses are also shown in the bottom-right of

Figure 8, in which one finding has the optimal CE of 79.30 cm

2/C (for 425 nm thickness) and the worst CE of 21.76 cm

2/C (for 68 nm thickness), both at the visible wavelength range of 400–800 nm. Comparing the CE values, the dramatic effect of adjusting the thickness of the WO3 film in improving the EC performance of the WO

3 film is noteworthy.

Figure 9 plots the ΔT and ∆OD values of the WO

3 film coating on the flexible ITO/nano-Ag/ITO electrodes as a function of WO

3 film thickness. We can obtain the transmittance change and optical density change increased rapidly with increasing WO

3 film thicknesses, which suggests that the electrons injected into the films with a larger crystallite size are more likely to exhibit free-electron behavior due to less grain boundary scattering [

33]. The maximum transmittance change value (44.18%) and optical density change value (0.59) of the WO

3 film coating are on the best figure of merit value (30.65 × 10

−3 Ω

−1) at 425 nm WO

3 thickness. Based on the experimental results described above, the WO

3 film is an optimum thickness, which offers a good coloring speed (∆OD) and high transmittance change (∆T) on ECD applications. In the meantime, the results from

Figure 8 show that there is a fairly good fit between the calculated ΔOD values and the measured CE values.