Effect of Substrate Temperature on the Properties of RF Magnetron Sputtered p-CuInOx Thin Films for Transparent Heterojunction Devices

Abstract

:1. Introduction

2. Experimental Details

2.1. Deposition of Copper Indium Oxide Thin Films with Substrate Heating

2.2. Morphological and Optical Studies of Copper Indium Oxide Thin Films

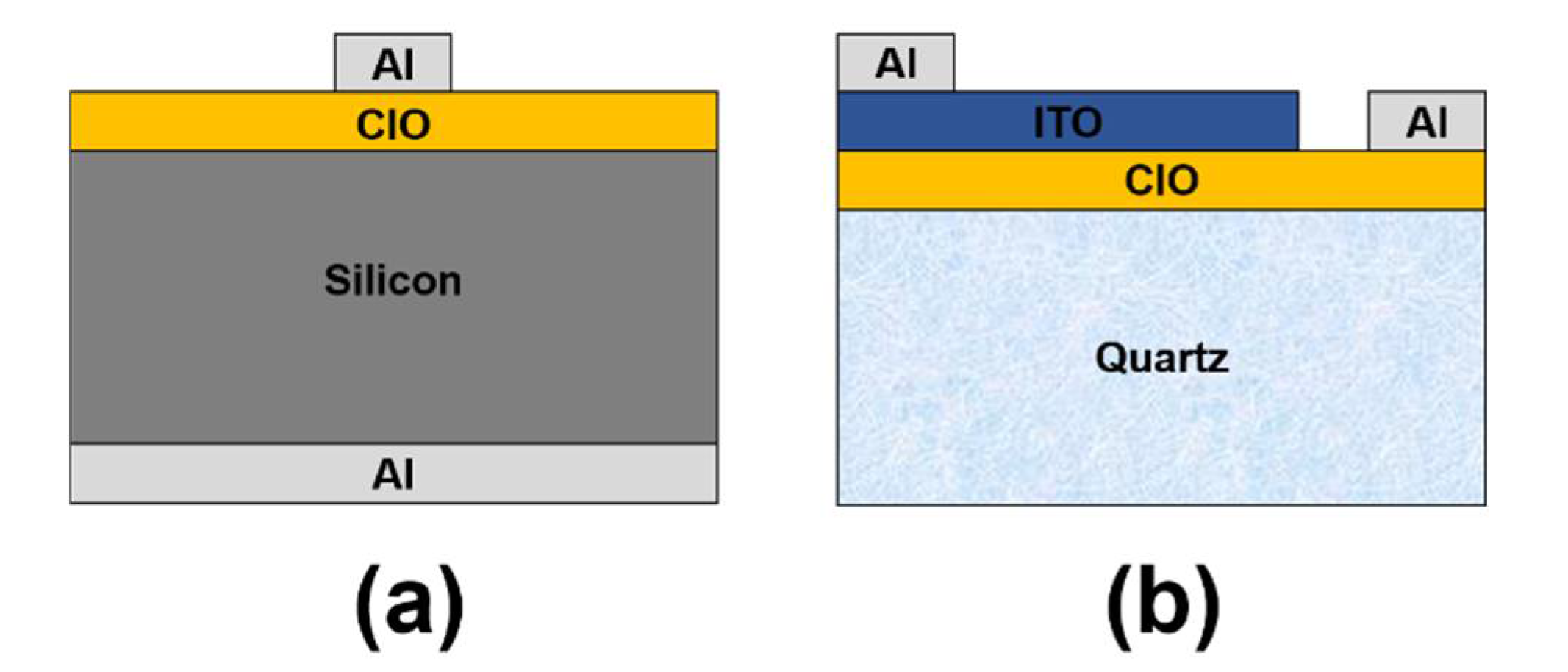

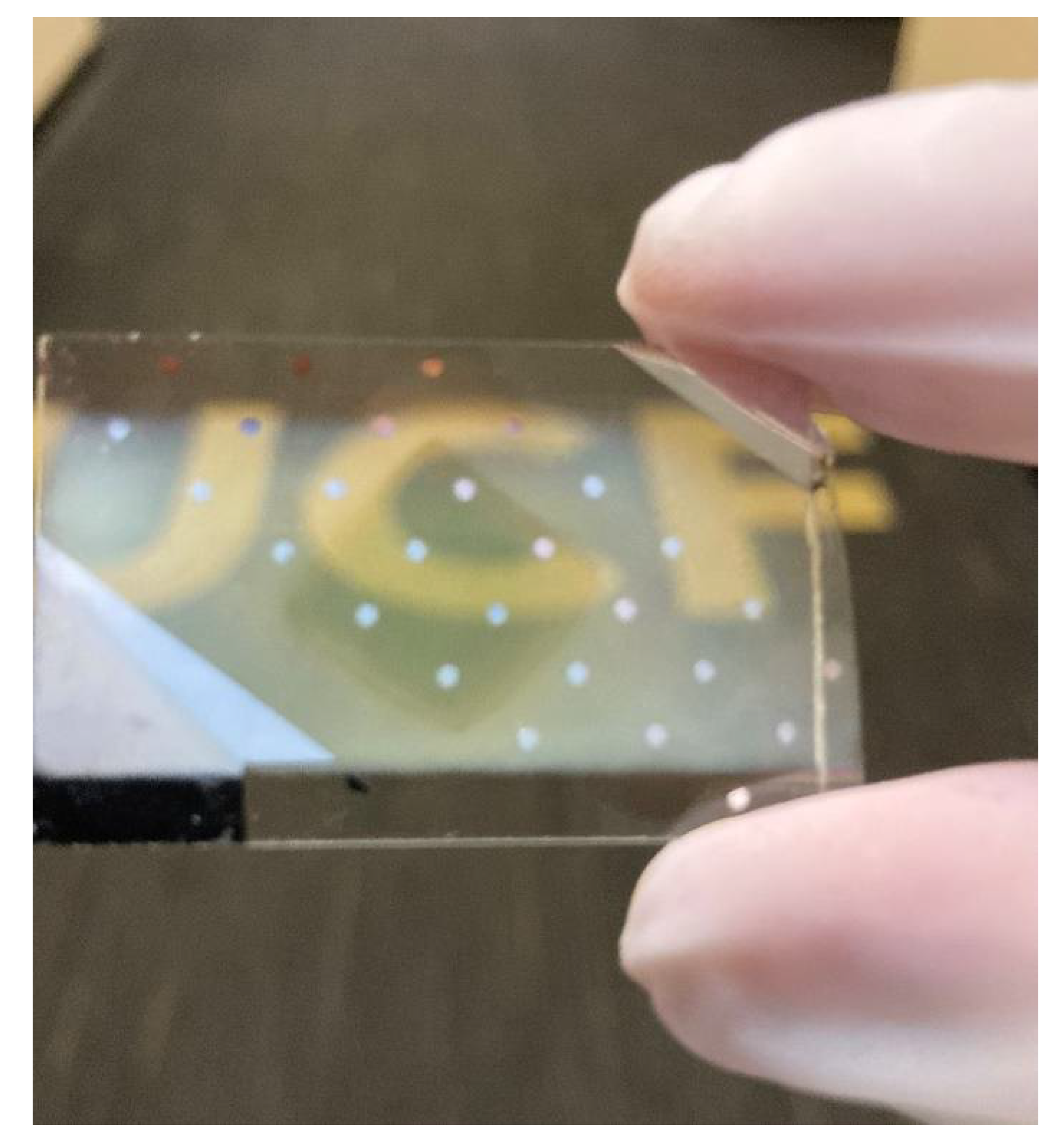

2.3. Fabrication of CuInOx Heterojunctions and Electrical Studies

3. Results and Discussions

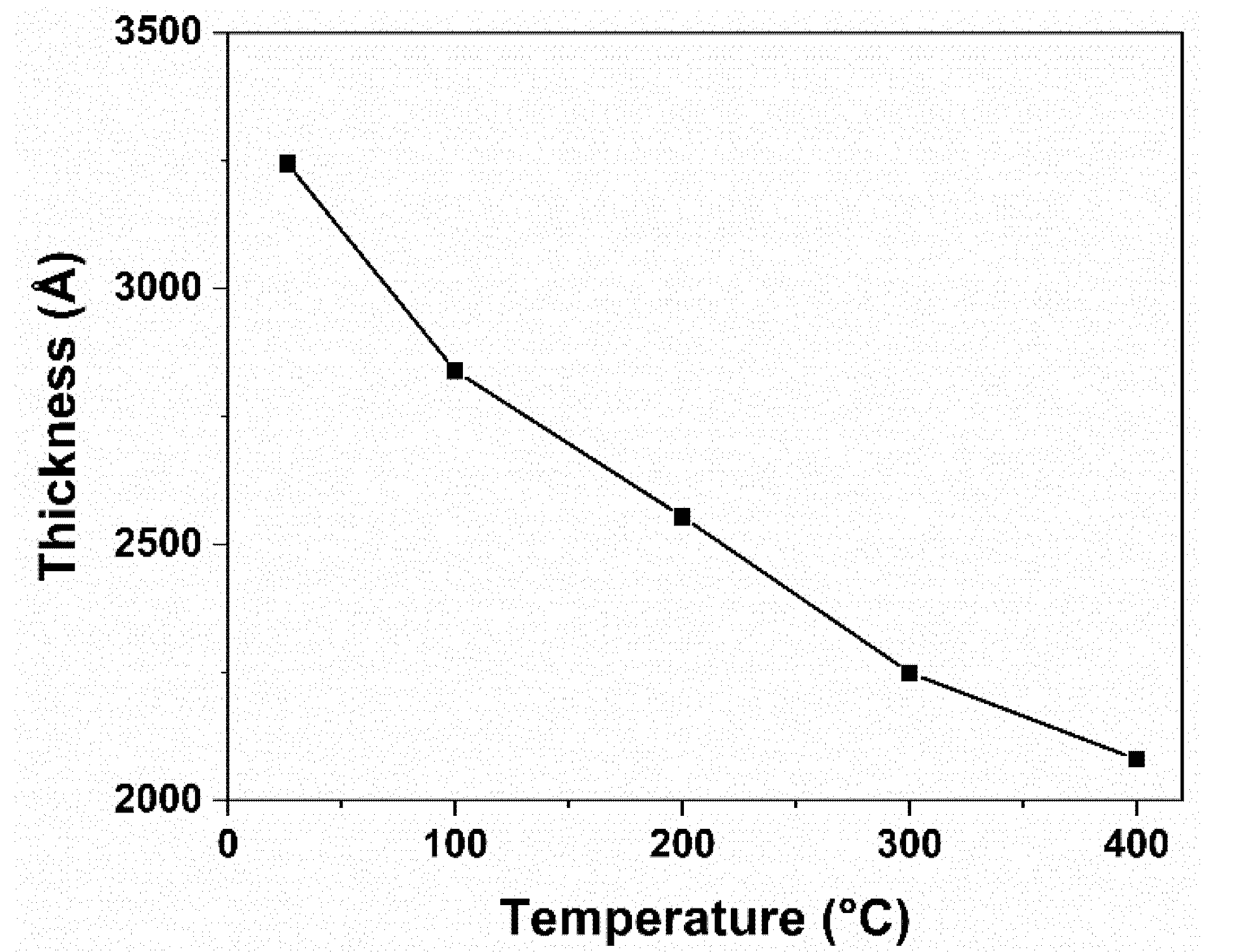

3.1. Deposition and Morphological Studies

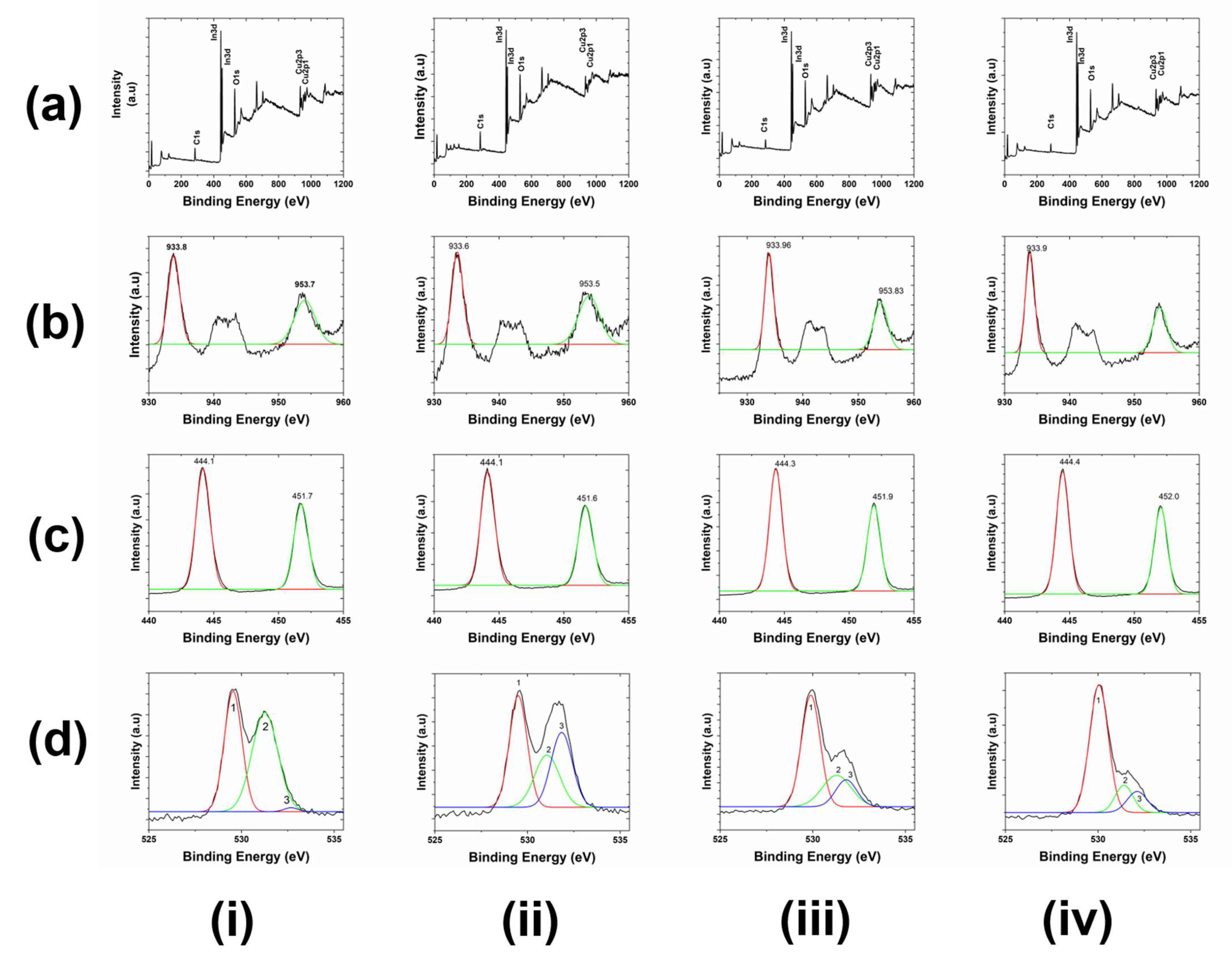

3.2. XPS Analysis

3.3. Optical Analysis and Bandgap

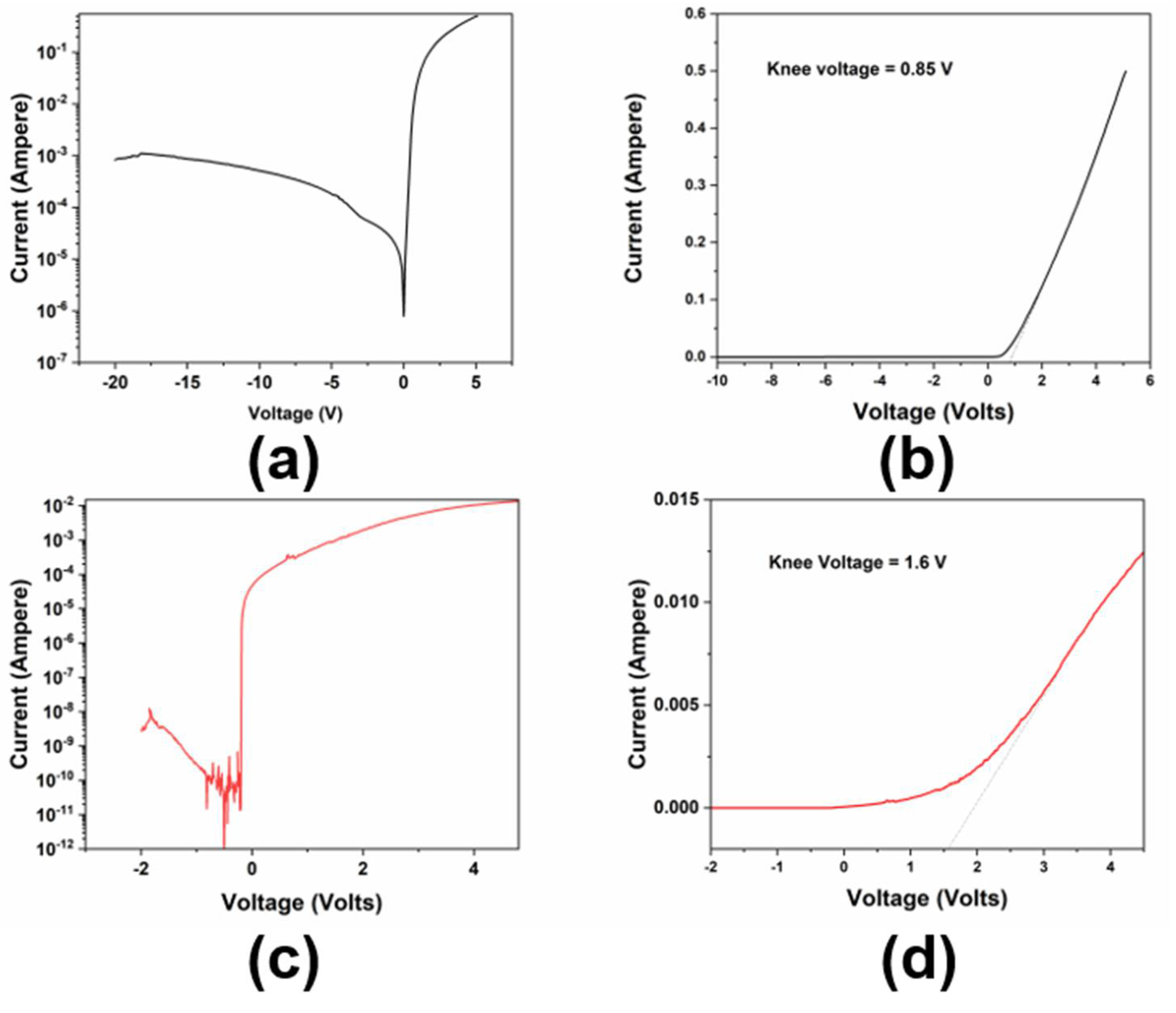

3.4. Electrical Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ginley, D.S.; Bright, C. Transparent conducting oxides. MRS Bull. 2000, 25, 15–18. [Google Scholar] [CrossRef]

- Fortunato, E.; Ginley, D.; Hosono, H.; Paine, D.C. Transparent conducting oxides for photovoltaics. MRS Bull. 2007, 32, 242–247. [Google Scholar] [CrossRef] [Green Version]

- Ye, F.; Cai, X.M.; Dai, F.P.; Zhang, D.P.; Fan, P.; Liu, L.J. Transparent Conductive Cu-In-O Thin Films Deposited by Reactive DC Magnetron Sputtering with Different Targets. In Advanced Materials Research; Trans Tech Publications Ltd.: Kapellweg, Switzerland, 2011. [Google Scholar]

- Lewis, B.G.; Paine, D.C. Applications and processing of transparent conducting oxides. MRS Bull. 2000, 25, 22–27. [Google Scholar] [CrossRef]

- Szyszka, B.; Loebmann, P.; Georg, A.; May, C.; Elsaesser, C. Development of new transparent conductors and device applications utilizing a multidisciplinary approach. Thin Solid Film. 2010, 518, 3109–3114. [Google Scholar] [CrossRef]

- Sundaram, K.; Khan, A. Characterization and optimization of zinc oxide films by rf magnetron sputtering. Thin Solid Film. 1997, 295, 87–91. [Google Scholar] [CrossRef]

- Shantheyanda, B.P.; Todi, V.O.; Sundaram, K.B.; Vijayakumar, A.; Oladeji, I. Compositional study of vacuum annealed Al doped ZnO thin films obtained by RF magnetron sputtering. J. Vac. Sci. Technol. A Vac. Surf. Film. 2011, 29, 051514. [Google Scholar] [CrossRef]

- Sundaram, K.B.; Bhagavat, G.K. Chemical vapour deposition of tin oxide films and their electrical properties. J. Phys. D Appl. Phys. 1981, 14, 333. [Google Scholar] [CrossRef]

- Sundaram, K.B.; Bhagavat, G.K. Low temperature synthesis wide optical band gap Al and (Al, Na) co-doped ZnO thin films. Appl. Surf. Sci. 2011, 257, 2341–2345. [Google Scholar]

- Banerjee, A.; Chattopadhyay, K. Recent developments in the emerging field of crystalline p-type transparent conducting oxide thin films. Prog. Cryst. Growth Charact. Mater. 2005, 50, 52–105. [Google Scholar] [CrossRef]

- Sheng, S.; Fang, G.; Li, C.; Xu, S.; Zhao, X. p-Type transparent conducting oxides. Phys. Status Solidi 2006, 203, 1891–1900. [Google Scholar] [CrossRef]

- Saikumar, A.K.; Sundaresh, S.; Nehate, S.D.; Sundaram, K.B. Properties of RF Magnetron-Sputtered Copper Gallium Oxide (CuGa2O4) Thin Films. Coatings 2021, 11, 921. [Google Scholar] [CrossRef]

- Skaria, G.; Kumar Saikumar, A.; Shivprasad, A.D.; Sundaram, K.B. Annealing Studies of Copper Indium Oxide (Cu2In2O5) Thin Films Prepared by RF Magnetron Sputtering. Coatings 2021, 11, 1290. [Google Scholar] [CrossRef]

- Su, C.-Y.; Mishra, D.K.; Chiu, C.-Y.; Ting, J.-M. Effects of Cu2S sintering aid on the formation of CuInS2 coatings from single crystal Cu2In2O5 nanoparticles. Surf. Coat. Technol. 2013, 231, 517–520. [Google Scholar] [CrossRef]

- Su, C.-Y.; Chiu, C.-Y.; Chang, C.-H.; Ting, J.-M. Synthesis of Cu2In2O5 and CuInGaO4 nanoparticles. Thin Solid Film. 2013, 531, 42–48. [Google Scholar] [CrossRef]

- Nair, B.; Rahman, H.; Shaji, S.; Okram, G.; Sharma, V.; Philip, R.R. Calcium incorporated copper indium oxide thin films-a promising candidate for transparent electronic applications. Thin Solid Film. 2020, 693, 137673. [Google Scholar] [CrossRef]

- Sundaresh, S.; Nehate, S.D.; Sundaram, K.B. Electrical and optical studies of reactively sputtered indium oxide thin films. ECS J. Solid State Sci. Technol. 2021, 10, 065016. [Google Scholar] [CrossRef]

- Saikumar, A.K.; Sundaresh, S.; Nehate, S.D.; Sundaram, K.B. Preparation and Characterization of Radio Frequency Sputtered Delafossite p-type Copper Gallium Oxide (p-CuGaO2) Thin Films. ECS J. Solid State Sci. Technol. 2022, 11, 023005. [Google Scholar] [CrossRef]

- Ray, S.; Banerjee, R.; Basu, N.; Batabyal, A.K.; Barua, A.K. Properties of tin doped indium oxide thin films prepared by magnetron sputtering. J. Appl. Phys. 1983, 54, 3497–3501. [Google Scholar] [CrossRef]

- Sundaram, K.B.; Garside, B.K. Properties of ZnO films reactively RE sputtered using a Zn target. J. Phys. D Appl. Phys. 1984, 17, 147. [Google Scholar] [CrossRef]

- Singh, M.; Singh, V.N.; Mehta, B.R. Synthesis and properties of nanocrystalline copper indium oxide thin films deposited by RF magnetron sputtering. J. Nanosci. Nanotechnol. 2008, 8, 3889–3894. [Google Scholar] [CrossRef]

- Ohyama, M.; Kozuka, H.; Yoko, T. Sol-gel preparation of transparent and conductive aluminum-doped zinc oxide films with highly preferential crystal orientation. J. Am. Ceram. Soc. 1998, 81, 1622–1632. [Google Scholar] [CrossRef]

- Sundaram, K.B.; Bhagavat, G.K. Optical absorption studies on tin oxide films. J. Phys. D Appl. Phys. 1981, 14, 921. [Google Scholar] [CrossRef]

- Yanagi, H.; Ueda, K.; Ohta, H.; Orita, M.; Hirano, M.; Hosono, H. Fabrication of all oxide transparent p–n homojunction using bipolar CuInO2 semiconducting oxide with delafossite structure. Solid State Commun. 2001, 121, 15–17. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skaria, G.; Kundu, A.; Sundaram, K.B. Effect of Substrate Temperature on the Properties of RF Magnetron Sputtered p-CuInOx Thin Films for Transparent Heterojunction Devices. Coatings 2022, 12, 500. https://doi.org/10.3390/coatings12040500

Skaria G, Kundu A, Sundaram KB. Effect of Substrate Temperature on the Properties of RF Magnetron Sputtered p-CuInOx Thin Films for Transparent Heterojunction Devices. Coatings. 2022; 12(4):500. https://doi.org/10.3390/coatings12040500

Chicago/Turabian StyleSkaria, Giji, Avra Kundu, and Kalpathy B. Sundaram. 2022. "Effect of Substrate Temperature on the Properties of RF Magnetron Sputtered p-CuInOx Thin Films for Transparent Heterojunction Devices" Coatings 12, no. 4: 500. https://doi.org/10.3390/coatings12040500

APA StyleSkaria, G., Kundu, A., & Sundaram, K. B. (2022). Effect of Substrate Temperature on the Properties of RF Magnetron Sputtered p-CuInOx Thin Films for Transparent Heterojunction Devices. Coatings, 12(4), 500. https://doi.org/10.3390/coatings12040500