Microstructure and Electric Properties of Bi2O3-Doped (K0.5Na0.5)NbO3 Lead-Free Ceramics

Abstract

:1. Introduction

2. Materials and Methods

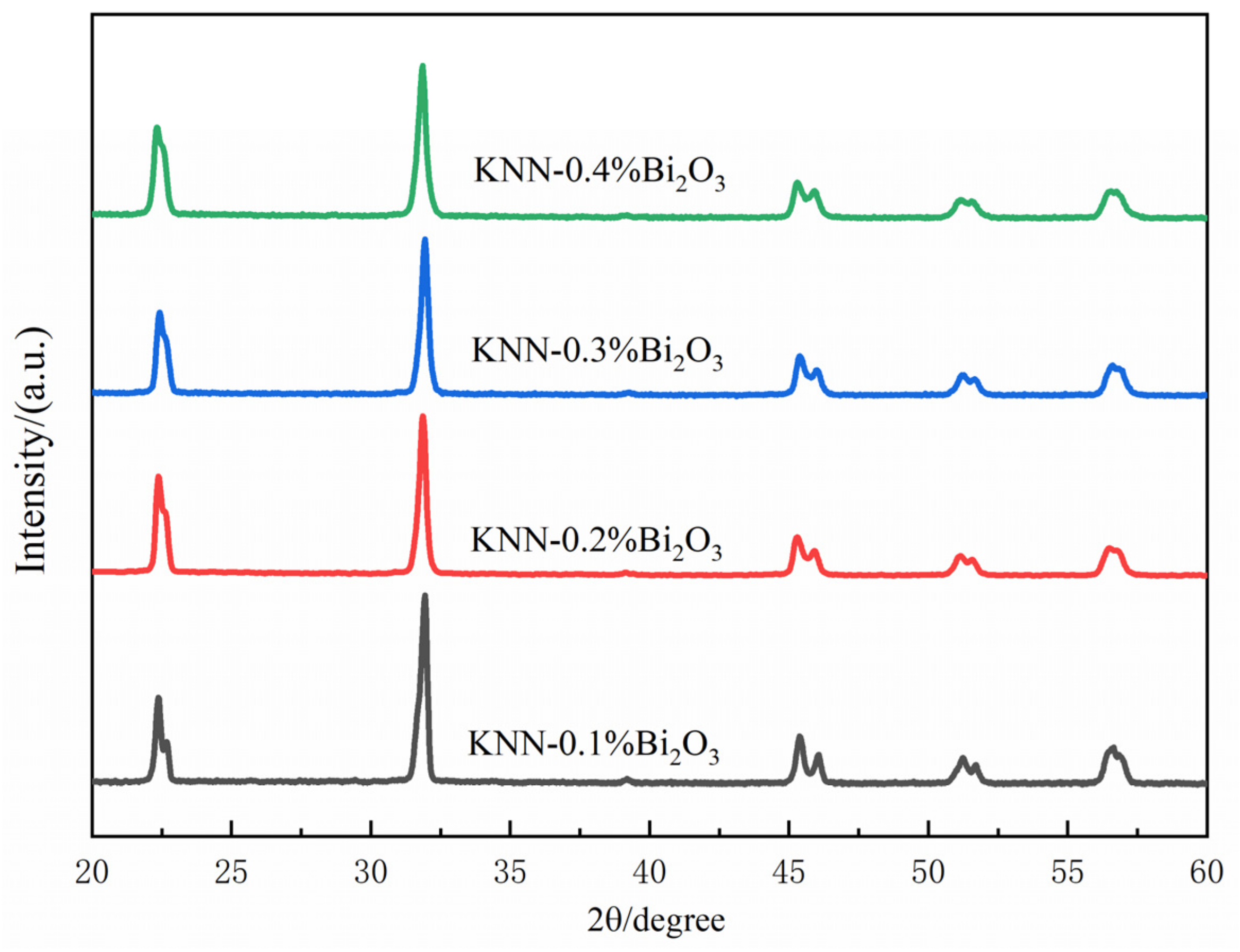

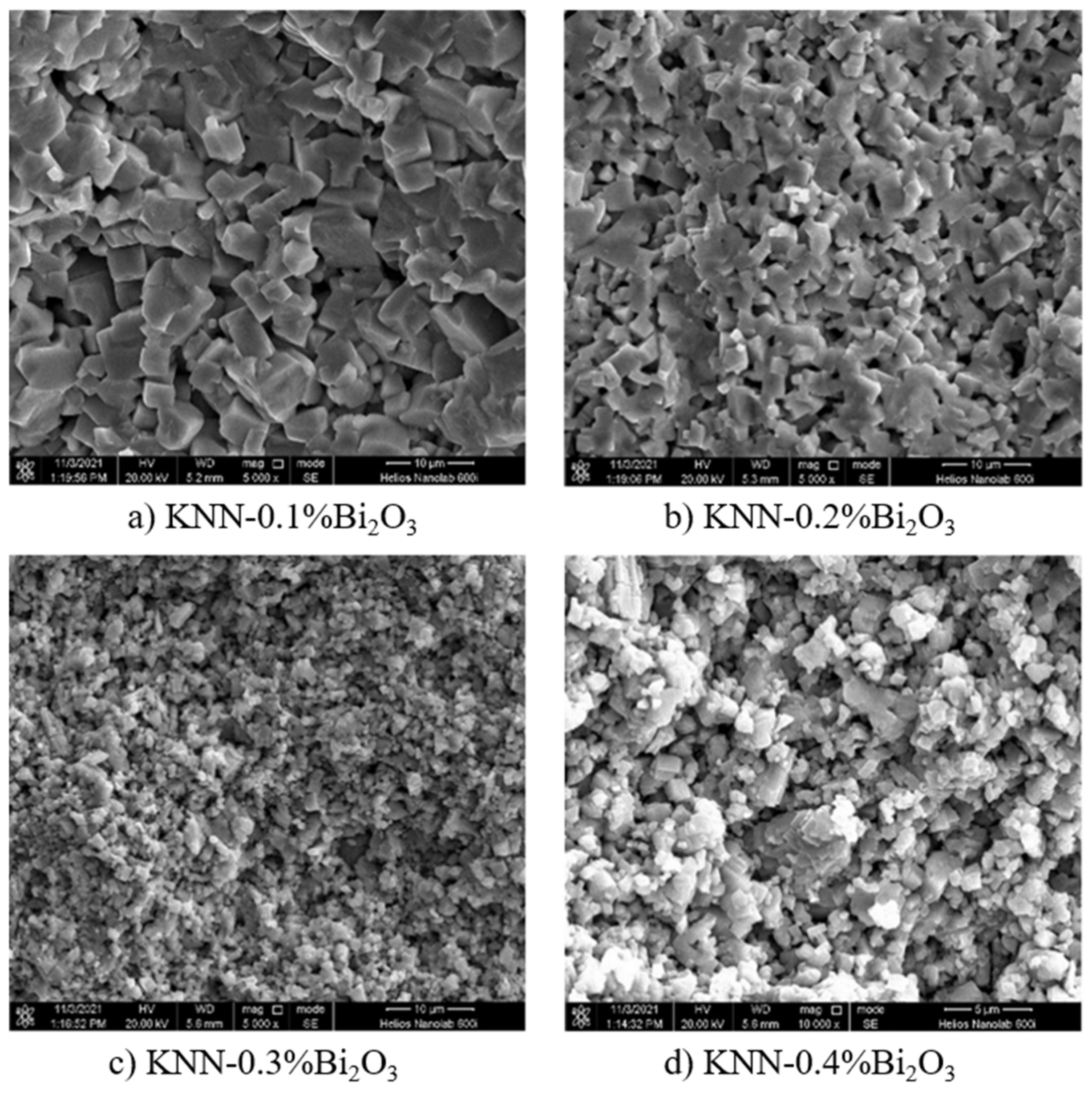

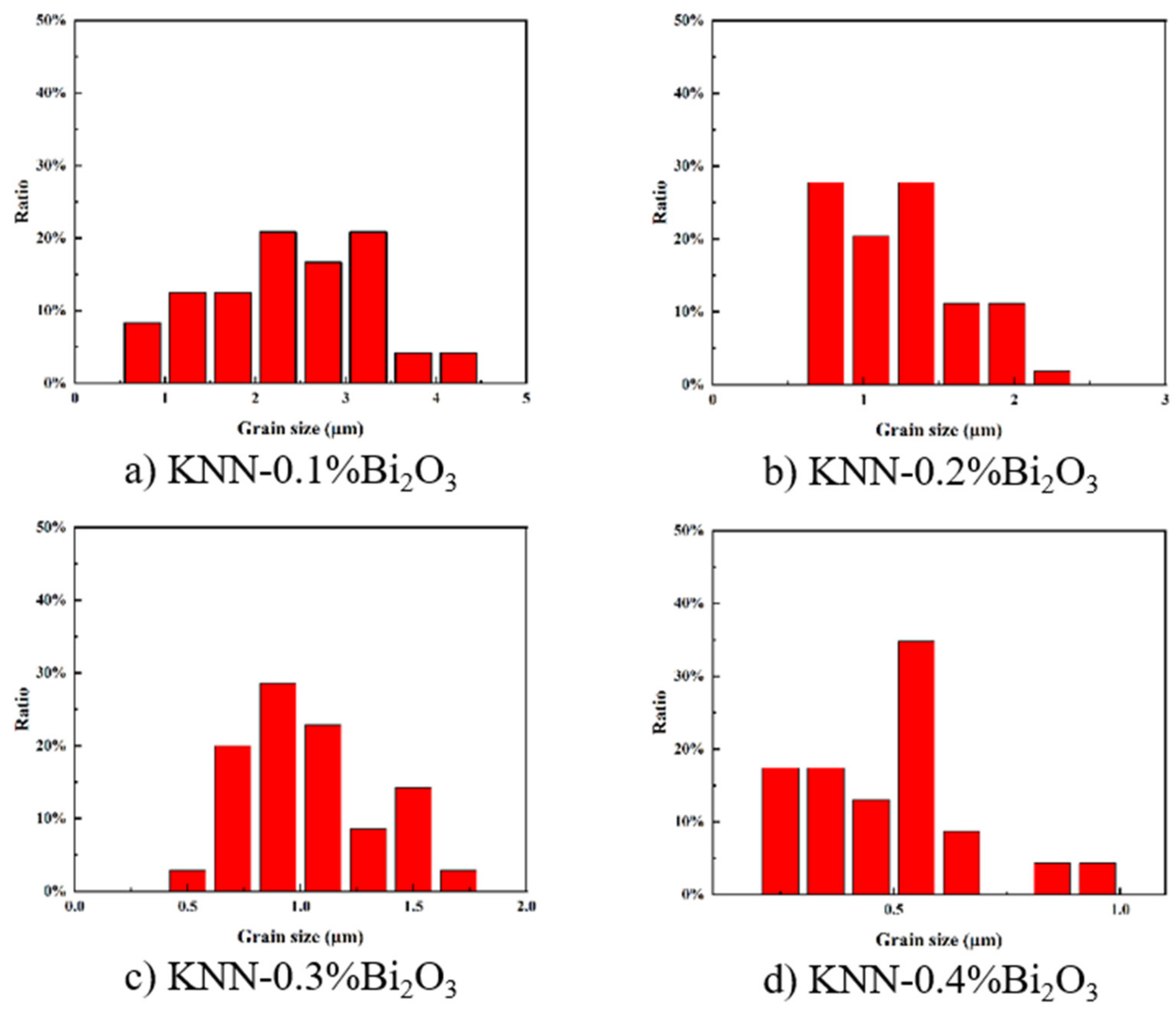

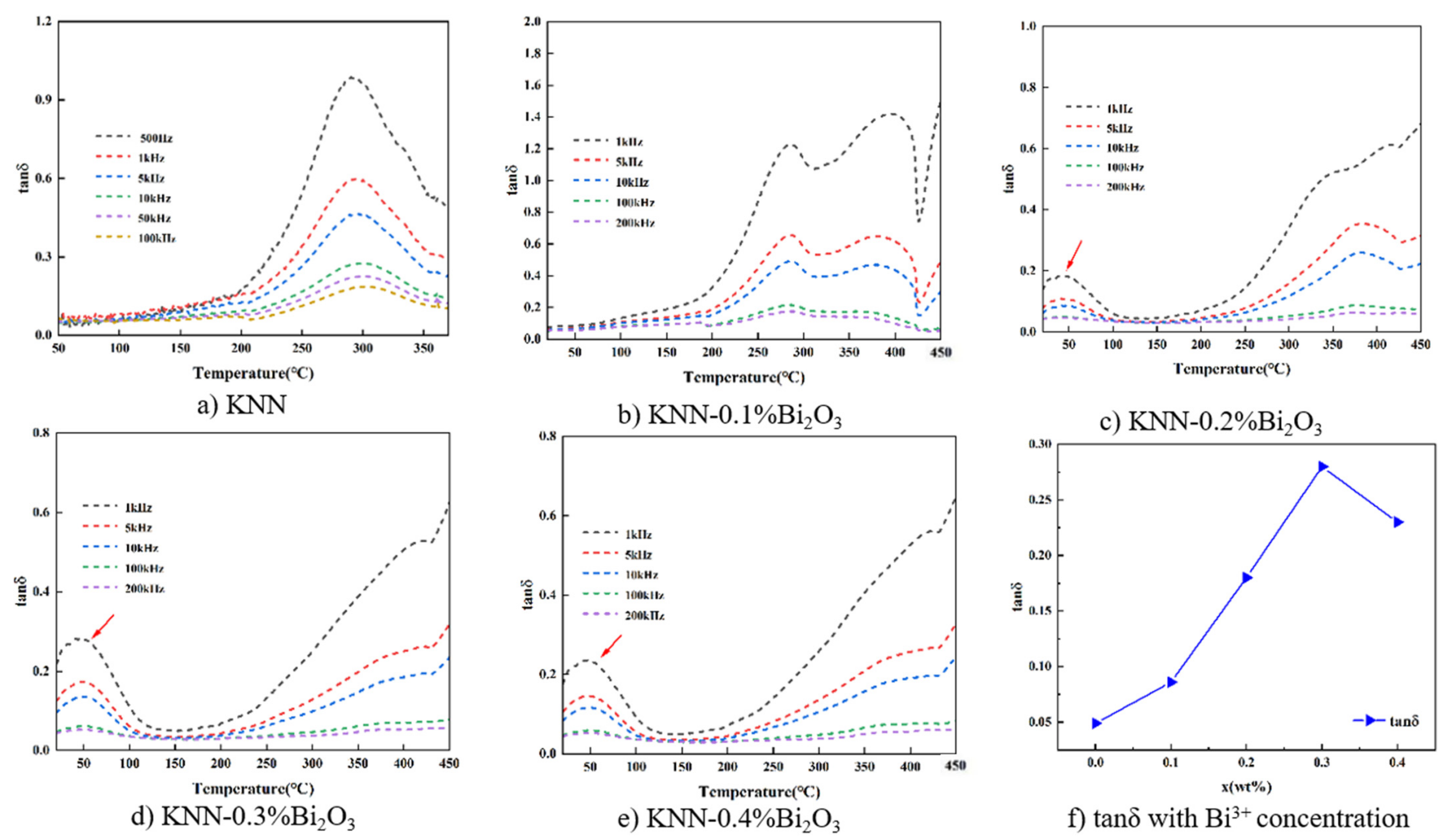

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Egerton, L.; Dillon, D.M. Piezoelectric and dielectric properties of ceramics in the system potassium-sodium niobate. J. Am. Ceram. Soc. 2010, 42, 438–442. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Zhang, J.; Yao, W.; Liu, D.; He, G. Remarkably strong piezoelectricity, rhombohedral-orthorhombic-tetragonal phase coexistence and domain structure of (K,Na)(Nb,Sb)O3-(Bi,Na)ZrO3-BaZrO3 ceramics. J. Alloy. Compd. 2019, 820, 153411. [Google Scholar] [CrossRef]

- Wang, J.; Luo, L. Probing the diffusion behavior of polymorphic phase transition in K0.5Na0.5NbO3 ferroelectric ceramics by Eu3+ photoluminescence. J. Appl. Phys. 2018, 123, 144102.1–144102.7. [Google Scholar] [CrossRef]

- Xu, K.; Li, J.; Lv, X.; Wu, J.; Zhang, X.; Xiao, D.; Zhu, J. Superior piezoelectric properties in potassium-sodium niobate lead-free ceramics. Adv. Mater. 2016, 28, 8519–8523. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y.; Zhang, J.L.; Yao, W.; Lu, C.; Zhang, S. Domain configuration and thermal stability of (K0.48Na0.52)(Nb0.96Sb0.04)O3-Bi0.50(Na0.82K0.18)0.50ZrO3 piezoceramics with high d33 coefficient. ACS Appl. Mater. Interfaces 2016, 8, 7257–7265. [Google Scholar] [CrossRef] [PubMed]

- Li, J.F.; Wang, K.; Zhu, F.Y.; Cheng, L.Q.; Yao, F.Z. (K,Na)NbO3-based lead-free piezoceramics: Fundamental aspects, processing technologies and remaining challenge. J. Am. Ceram. Soc. 2013, 96, 3677–3696. [Google Scholar] [CrossRef]

- Dai, Y.J.; Zhang, X.W.; Chen, K.P. Morphotropic phase boundary and electrical properties of K1-xNaxNbO3 lead-free ceramics. Appl. Phys. Lett. 2009, 94, 042905. [Google Scholar] [CrossRef]

- Wu, J.; Xiao, D.; Zhu, J. Potassium-Sodium Niobate Lead-Free Piezoelectric Materials: Past, Present, and Future of Phase Boundaries. Chem. Rev. 2015, 115, 2559–2595. [Google Scholar] [CrossRef]

- Guo, Y.; Kakimoto, K.I.; Ohsato, H. Phase transitional behavior and piezoelectric properties of (Na(0.5)K(0.5))NbO3-LiNbO3 ceramics. Appl. Phys. Lett. 2004, 85, 4121–4123. [Google Scholar] [CrossRef]

- Dai, Y.; Zhang, X.; Zhou, G. Phase transitional behavior in K0.5Na0.5NbO3-LiTaO3 ceramics. Appl. Phys. Lett. 2007, 90, 262903. [Google Scholar] [CrossRef]

- Wang, K.; Yao, F.Z.; Jo, W.; Gobeljic, D.; Shvartsman, V.V.; Lupascu, D.C.; Li, J.F.; Redl, J. Temperature-Insensitive (K,Na)NbO3-based lead-free Piezoactuator Ceramics. Adv. Funct. Mater. 2013, 23, 4079–4086. [Google Scholar] [CrossRef]

- Du, H.L.; Zhou, W.C.; Luo, F.; Zhu, D.M.; Pei, Z.B. Structure and electrical properties’ investigation of (K0.5Na0.5)NbO3-(Bi0.5Na0.5)TiO3 lead-free piezoelectric ceramics. J. Phys. D Appl. Phys. 2008, 41, 085416. [Google Scholar] [CrossRef]

- Hong, T.; Wu, J.; Zheng, T.; Wang, X.; Lou, X. New (1-x)K0.45Na0.55Nb0.96Sb0.04O3-xBi0.5Na0.5HfO3 lead-free ceramics: Phase boundary and their electrical properties. J. Appl. Phys. 2015, 118, 044102. [Google Scholar]

- Cheng, X.; Wu, J.; Lou, X.; Wang, X.; Wang, X.; Xiao, D.; Zhu, J. Achieving both giant d33 and high Tc in patassium-sodium niobate ternary system. ACS. Appl. Mater. Inter. 2014, 6, 750–756. [Google Scholar] [CrossRef]

- Cheng, X.; Wu, J.; Wang, X.; Zhang, B.; Lou, X.; Wang, X.; Xiao, D.; Zhu, J. Mediating the contradiction of d33 and TC in potassium-sodium niobate lead-free piezoceramics. ACS Appl. Mater. Interfaces 2013, 5, 10409–10417. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Liu, H.; Fan, L.; Ren, Y.; Chen, J. Structural origin of size effect on piezoelectric performance of Pb(Zr,Ti)O3. Ceram. Int. 2020, 47, 5256–5264. [Google Scholar] [CrossRef]

- Huang, X.; Li, W.; Zeng, J.; Zheng, L.; Men, Z.; Li, G. The grain size effect in dielectric diffusion and electrical conduction of PZnTe-PZT ceramics. Physica B 2019, 560, 16–22. [Google Scholar] [CrossRef]

- Yu, H.; Wang, X.; Jian, F.; Li, L. Grain size effect on piezoelectric and ferroelectric properties of BaTiO3 ceramics. J. Eur. Ceram. Soc. 2014, 34, 1445–1448. [Google Scholar]

- Kakimoto, K.I.; Kaneko, R.; Kagomiya, I. Grain size controlled (Li,Na,K)NbO3 ceramics using powder source classified by centrifugal separator. Jpn. J. Appl. Phys. 2013, 51, 09LD06. [Google Scholar] [CrossRef]

- Wang, X.; Yu, H.; Zhao, P.; Liu, X.; Wei, T.; Zhang, Q.; Wang, X. Optimizing the grain size and grain boundary morphology of (K,Na)NbO3-based ceramics: Paving the way for ultrahigh energy storage capacitors. J. Mater. 2021, 7, 780–789. [Google Scholar] [CrossRef]

- Wang, C.; Chen, J.; Shen, L.; Rui, J.; Hou, Y. Particle size effect on the electrical properties of spark-plasma-sintered relaxor potassium sodium niobate ceramic. J. Ceram. Sci. Technol. 2017, 8, 255–258. [Google Scholar]

- Cha, J.M.; Lee, J.W.; Bae, B.; Yong, J.J.; Yoon, C.B. Synthesis and characterization of MnO2 added (Na0.475K0.475Li0.05) (Nb0.9Ta0.05Sb0.05)O3 lead-free piezoelectric ceramics. J. Korean Ceram. Soc. 2020, 57, 440–446. [Google Scholar] [CrossRef]

- Ar, A.; Spa, C.; Ym, A.; Gth, A.; Jjc, A.; Bdh, A.; Khc, B.; Sn, D.; Cwa, A. An easy approach to obtain large piezoelectric constant in high-quality transparent ceramics by normal sintering process in modified potassium sodium niobate ceramics. J. Eur. Ceram. Soc. 2020, 40, 2989–2995. [Google Scholar]

- Wang, X.; Tang, X.; Kwok, K.; Chan, H.; Choy, C.L. Effect of excess Bi2O3 on the electrical properties and microstructure of (Bi1/2Na1/2)TiO3 ceramics. Appl. Phys. A 2005, 80, 1071–1075. [Google Scholar] [CrossRef]

- Li, S.; Fu, J.; Zuo, R. Middle-low temperature sintering and piezoelectric properties of CuO and Bi2O3 doped PMS-PZT based ceramics for ultrasonic motors. Ceram Int. 2021, 47, 20117–20125. [Google Scholar] [CrossRef]

- Yang, W.; Li, P.; Wu, S.; Li, F.; Shen, B.; Zhai, W. A study on the relationship between grain size and electrical properties in (K,Na)NbO3-Based lead-free piezoelectric ceramics. Adv. Electron. Mater. 2019, 5, 1900570. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.; Thong, H.; Lu, J.; Li, J.; Gong, W.; Wang, K. Grain size effect on piezoelectric performance in perovskite-based piezoceramics. Acta Phys. Sin. 2020, 69, 217704. [Google Scholar] [CrossRef]

- Bah, M.; Podor, R.; Retoux, R.; Delorme, F.; Nadaud, K.; Giovannelli, F.; Monot-Laffez, I.; Ayral, A. Real-Time Capturing of Microscale Events Controlling the Sintering of Lead-Free Piezoelectric Potassium-Sodium Niobate. Small 2022, 2106825. [Google Scholar] [CrossRef]

- Cahn, J.W. The impurity-drag effect in grain boundary motion. Acta Metall. 1962, 10, 789–798. [Google Scholar] [CrossRef]

| x (wt%) | 0.1 | 0.2 | 0.3 |

| a(Å) | 3.9655 | 3.9801 | 3.9700 |

| b(Å) | 5.7482 | 5.6841 | 5.6846 |

| c(Å) | 5.6344 | 5.7130 | 5.7064 |

| x (wt%) | 0.1 | 0.2 | 0.3 | 0.4 |

| kp | 0.474 | 0.276 | 0.478 | 0.270 |

| kt | 0.306 | 0.166 | 0.140 | 0.145 |

| d33(pC/N) | 121 | 81 | 80 | 82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wang, J.; Wu, F.; Ma, H.; Ma, T.; Tian, Y.; Liu, D.; Yang, B. Microstructure and Electric Properties of Bi2O3-Doped (K0.5Na0.5)NbO3 Lead-Free Ceramics. Coatings 2022, 12, 526. https://doi.org/10.3390/coatings12040526

Li J, Wang J, Wu F, Ma H, Ma T, Tian Y, Liu D, Yang B. Microstructure and Electric Properties of Bi2O3-Doped (K0.5Na0.5)NbO3 Lead-Free Ceramics. Coatings. 2022; 12(4):526. https://doi.org/10.3390/coatings12040526

Chicago/Turabian StyleLi, Jiaqi, Junjun Wang, Fengmin Wu, Hui Ma, Tianyi Ma, Yu Tian, Danqing Liu, and Bin Yang. 2022. "Microstructure and Electric Properties of Bi2O3-Doped (K0.5Na0.5)NbO3 Lead-Free Ceramics" Coatings 12, no. 4: 526. https://doi.org/10.3390/coatings12040526

APA StyleLi, J., Wang, J., Wu, F., Ma, H., Ma, T., Tian, Y., Liu, D., & Yang, B. (2022). Microstructure and Electric Properties of Bi2O3-Doped (K0.5Na0.5)NbO3 Lead-Free Ceramics. Coatings, 12(4), 526. https://doi.org/10.3390/coatings12040526