Investigations on the Influence of Subsequent Electron Beam (EB) Remelting on the Microstructure of an Aluminium Nitride Layer Formed on an Aluminium Substrate (Part II)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Surface Treatment Technologies and Parameters

2.3. Characterization Methods

3. Results and Discussion

3.1. Initial Plasma Nitrided State (PN)

3.2. Influence of the AlN Layer Thickness on the Subsequent Electron Beam Remelting Process (PN + EBR)

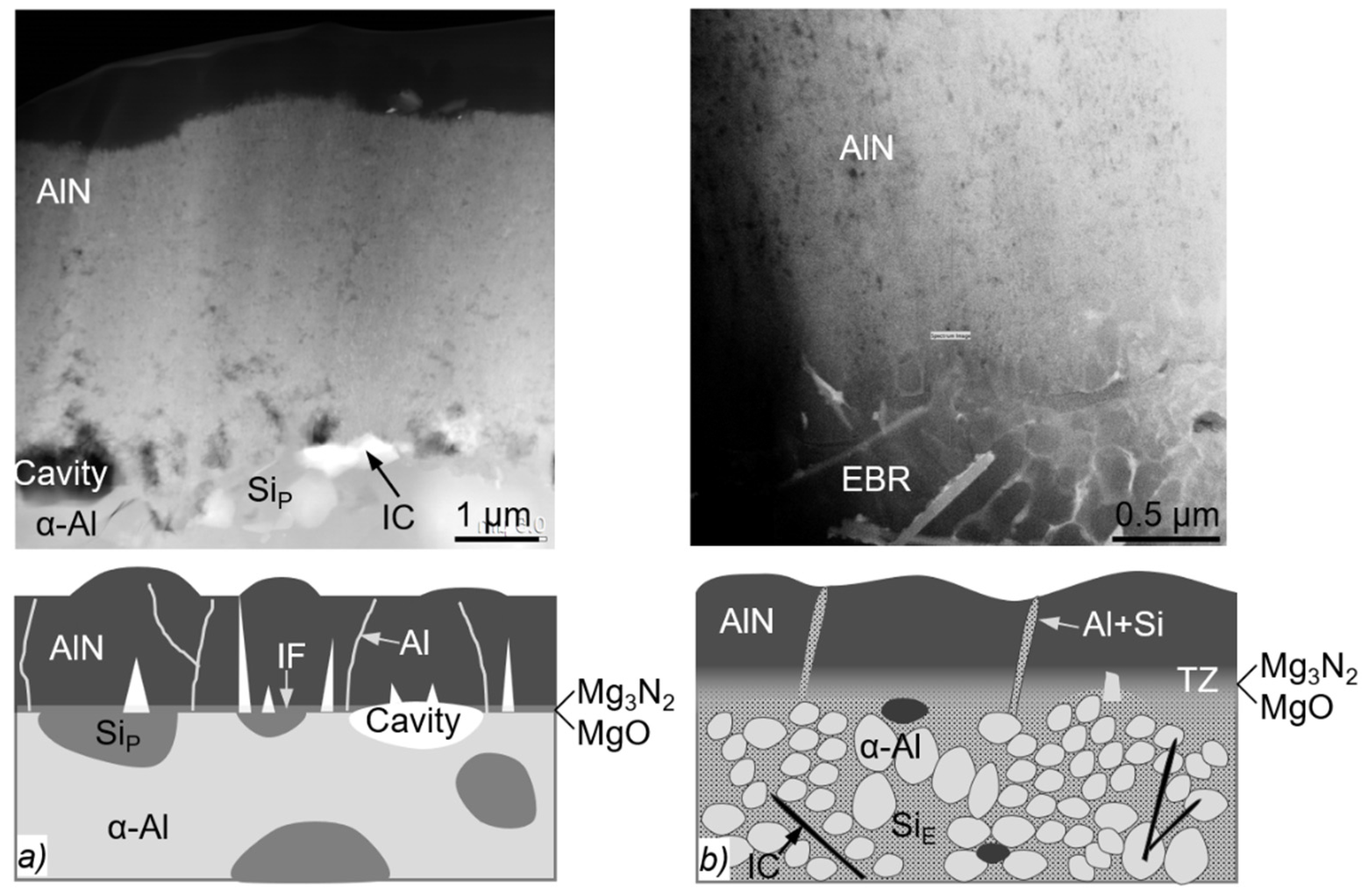

3.3. High-Resolution Analysis of the Single and Duplex Treatment

3.3.1. Single Treatment: Electron Beam Remelting (EBR)

3.3.2. Duplex Treatment: Plasma Nitriding + Electron Beam Remelting (PN + EBR)

3.3.3. Characterization of Layer Hardness

3.4. Model Conception for the Formation of the Interface after EB Remelting

4. Conclusions

- (1)

- EBR of the Al substrates beneath the AlN layer led to the formation of a fine dendric Al matrix microstructure with different intermetallic compounds.

- (2)

- In addition to an increase in hardness in the remelted layer, the special innovation of the technology lies in the fact that it was also possible to eliminate (i.e., to “fill”) both the cavities underneath the AlN layer resulting from outward diffusion of the Al and the small gaps between the AlN rods. As a result, a homogeneous transition zone was generated that exhibited continuous bonding of the AlN layer to the substrate.

- (3)

- Despite the high temperature during the EBR, the transition zone exhibited both AlN and Mg3N2. Furthermore, large amounts of MgO were detected in a polycrystalline structure with a preferential orientation. In the lower (transition zone) as well as in the middle part of the AlN layer, additional Al and Si were detected, the radial intensity distribution peaks of which were strongly broadened and washed out. This was obviously due to the fine cellular dendritic solidification of the Al melt.

- (4)

- The subsequent remelting led to homogenisation of the hardness values in the nitride layer.

- (5)

- Due to movement of the melt pool, the surface was structured with a relatively regular pattern and defects, both within and below the AlN layer, were filled with Al melt. It is expected that both should have beneficial effects on the material’s wear behaviour. The research on this matter has not yet been completed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Spies, H.-J.; Dalke, A. Nitriding of Aluminum and its Alloys. In ASM Handbook, Heat Treating of Nonferrous Alloys; Totten, G.E., Ed.; ASM International: Materials Park, OH, USA, 2016; Volume 4E, pp. 302–307. [Google Scholar] [CrossRef]

- Telbizova, T.; Parascandola, S.; Kreissig, U.; Günzel, R.; Möller, W. Mechanism of diffusional transport during ion nitriding of aluminium. Appl. Phys. Lett. 2000, 76, 1404–1406. [Google Scholar] [CrossRef]

- Spies, H.-J. Stand und Entwicklung des Nitrierens von Aluminium- und Titanlegierungen. HTM J. Heat Treat. Mater. 2000, 55, 141–150. [Google Scholar] [CrossRef]

- Buchwalder, A.; Dalke, A.; Spies, H.-J.; Zenker, R. Plasma nitriding of spray-formed aluminium alloys. Adv. Eng. Mater. 2012, 13, 970–975. [Google Scholar] [CrossRef]

- Reinhold, B.; Naumann, J.; Spies, H.-J. Einfluss von Zusammensetzung und Bauteilgeometrie auf das Nitrierverhalten von Aluminiumlegierungen. HTM J. Heat Treat. Mater. 1998, 53, 329–336. [Google Scholar] [CrossRef]

- Reinhold, B. Untersuchungen zum Einfluss des Sauerstoffpartialdrucks beim Plasmanitrieren von Aluminiumlegierungen und chromlegierten Stählen. Ph.D. Thesis, TU Bergakademie Freiberg, Freiberg, Germany, 2004. [Google Scholar]

- Buchwalder, A.; Spies, H.-J.; Zenker, R.; Dalke, A.; Krug, P. Plasmanitrieren von sprühkompaktierten Al-Legierungen. HTM J. Heat Treat. Mater. 2011, 66, 240–247. [Google Scholar] [CrossRef]

- Dalke, A. Beitrag zur kombinierten Randschichtbehandlung von Aluminiumlegierungen: Elektronenstrahlumschmelzlegieren mit Fe-Basis-Zusatzstoffen und Plasmanitrieren. Ph.D. Thesis, TU Bergakademie Freiberg, Freiberg, Germany, 2016. [Google Scholar]

- Hegelmann, E.; Jung, A.; Buchwalder, A.; Zenker, R. Investigation of electron beam surface remelting of plasma nitrided spray-formed hypereutectic Al-Si alloy. In Proceedings of the 26th DTZ Jihlava, Jihlava, Czech Republic, 21–23 November 2017. [Google Scholar]

- Jung, A.; Buchwalder, A.; Hegelmann, E.; Hengst, P.; Zenker, R. Surface engineering of spray-formed aluminium-silicon alloys by plasma nitriding and subsequent electron beam remelting. Surf. Coat. Technol. 2018, 335, 166–172. [Google Scholar] [CrossRef]

- Hegelmann, E.; Jung, A.; Hengst, P.; Zenker, R.; Buchwalder, A. Investigations regarding electron beam surface remelting of plasma nitrided spray-formed hypereutectic Al-Si alloy. Adv. Eng. Mater. 2018, 20, 1800244. [Google Scholar] [CrossRef]

- Meletis, E.I.; Yan, S. Formation of aluminum nitride by intensified plasma ion nitriding. J. Vac. Sci. Technol. A 1991, 9, 2279–2284. [Google Scholar] [CrossRef]

- Grumbt, G. Beitrag zum Elektronenstrahl-Randschichthärten in Kombination mit einer PVD-Hartstoffbeschichtung. Ph.D. Thesis, TU Bergakademie Freiberg, Freiberg, Germany, 2018. [Google Scholar]

- Schultz, H. Elektronenstrahlschweißen; DVS-Verlag: Düsseldorf, Germany, 1989. [Google Scholar]

- Jones, H. Rapid Solidfication of Metals and Alloys; The Institution of Metallurgists: London, UK, 1982. [Google Scholar]

- Furrer, P.; Warlimont, H. Gefüge und Eigenschaften von Aluminiumlegierungen nach rascher Erstarrung. Z. Met. 1971, 62, 12–20. [Google Scholar] [CrossRef]

- Gaffet, E.; Pellitier, J.M.; Bonnet-Jobez, S. Laser surface alloying of Ni film on Al-based alloy. Acta Metal 1989, 12, 3205–3215. [Google Scholar] [CrossRef]

- Buchwalder, A. Beitrag zur Flüssigphasen-Randschichtbehandlung von Bauteilen aus Aluminiumwerkstoffen Mittels Elektronenstrahl. Ph.D. Thesis, TU Bergakademie Freiberg, Freiberg, Germany, 2007. [Google Scholar]

- Gyenot, M. Randschichtlegieren von Aluminium AlSi8Cu3 mit Silizium Mittels Diodenlaser. Ph.D. Thesis, University of Bremen, Bremen, Germany, 2003. [Google Scholar]

- Zenker, R.; Buchwalder, A.; Klemm, M. Neue Entwlicklungen auf dem Gebiet der thermischen Elektronenstrahl-Randschichtbehandlung von Aluminium-Legierungen. HTM J. Heat Treat. Mater. 2009, 4, 208–214. [Google Scholar] [CrossRef]

- Buchwalder, A.; Böcker, J.; Hegelmann, E.; Klemm, V. Investigations on the Microstructure of an Aluminium Nitride Layer and Its Interface with the Aluminium Substrate (Part I). Coatings 2022, 12, 618. [Google Scholar] [CrossRef]

- BDG-Richlinie: Bestimmung des Dendritenarm-abstandes für Gusstücke aus Aluminium-Gusslegierungen. P220. 2011. Available online: https://www.guss.de/fileadmin/user_upload/richtlinien/bdg-richtlinie_p_220.pdf (accessed on 29 March 2022).

- Zhang, J.; Fan, Z.; Wang, Y.-Q.; Zhou, B.-L. Microstructure and mechanical properties of in situ Al-Mg2Si composites. Mater. Sci. Technol. 2000, 16, 913–918. [Google Scholar] [CrossRef]

- Krug, P.; Sinha, G. Metallische Verbundwerkstoffe; Kainer, K.U., Ed.; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003. [Google Scholar]

- Dalke, A.; Buchwalder, A.; Spies, H.-J.; Biermann, H.; Zenker, R. EB Surface Alloying and Plasma Nitriding of Different Al Alloys. Mater. Sci. Forum 2011, 690, 91–94. [Google Scholar] [CrossRef]

- Dalke, A.; Buchwalder, A.; Spies, H.-J.; Zenker, R. Influence of process control on nitride layer formation of spray formed Al alloys during dc pulse plasma nitriding. In Proceedings of the IFHTSE 2014, München, Germany, 12–15 May 2014. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buchwalder, A.; Böcker, J.; Hegelmann, E.; Jung, A.; Michler, M.; Klemm, V. Investigations on the Influence of Subsequent Electron Beam (EB) Remelting on the Microstructure of an Aluminium Nitride Layer Formed on an Aluminium Substrate (Part II). Coatings 2022, 12, 650. https://doi.org/10.3390/coatings12050650

Buchwalder A, Böcker J, Hegelmann E, Jung A, Michler M, Klemm V. Investigations on the Influence of Subsequent Electron Beam (EB) Remelting on the Microstructure of an Aluminium Nitride Layer Formed on an Aluminium Substrate (Part II). Coatings. 2022; 12(5):650. https://doi.org/10.3390/coatings12050650

Chicago/Turabian StyleBuchwalder, Anja, Jan Böcker, Eugen Hegelmann, Anne Jung, Martin Michler, and Volker Klemm. 2022. "Investigations on the Influence of Subsequent Electron Beam (EB) Remelting on the Microstructure of an Aluminium Nitride Layer Formed on an Aluminium Substrate (Part II)" Coatings 12, no. 5: 650. https://doi.org/10.3390/coatings12050650