Pulsed Electrodeposition and Properties of Nickel-Based Composite Coatings Modified with Graphene Oxide

Abstract

:1. Introduction

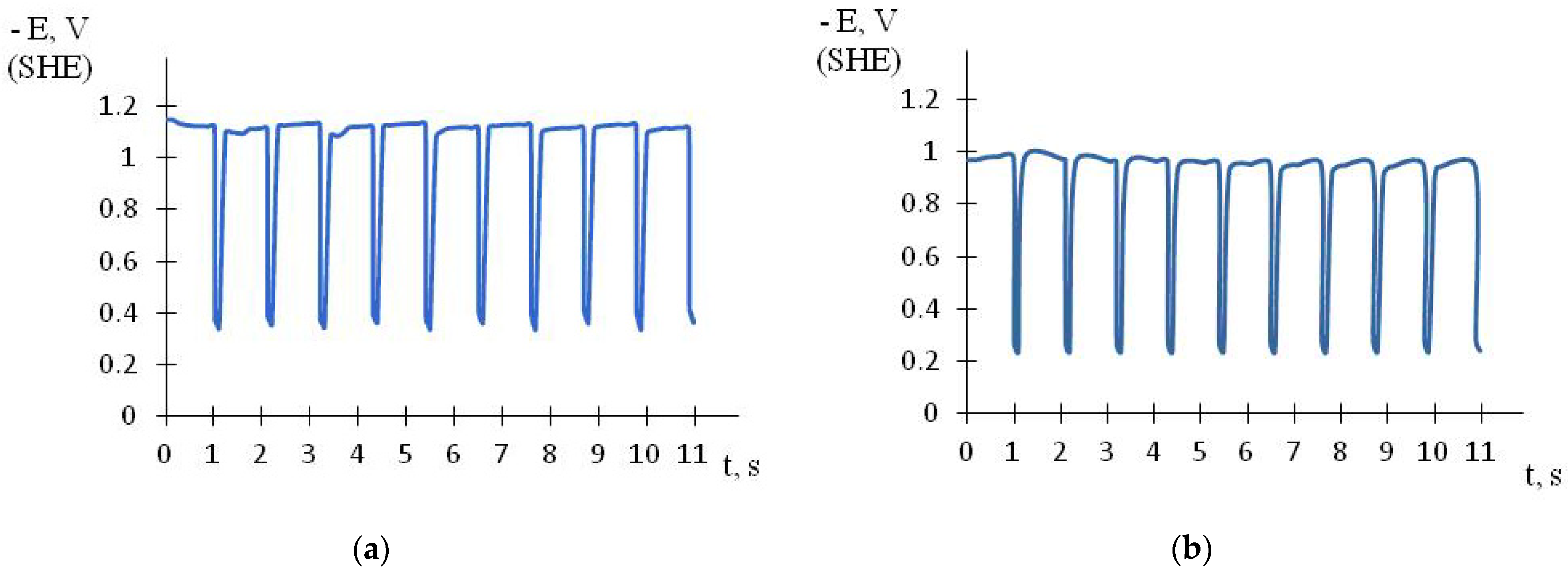

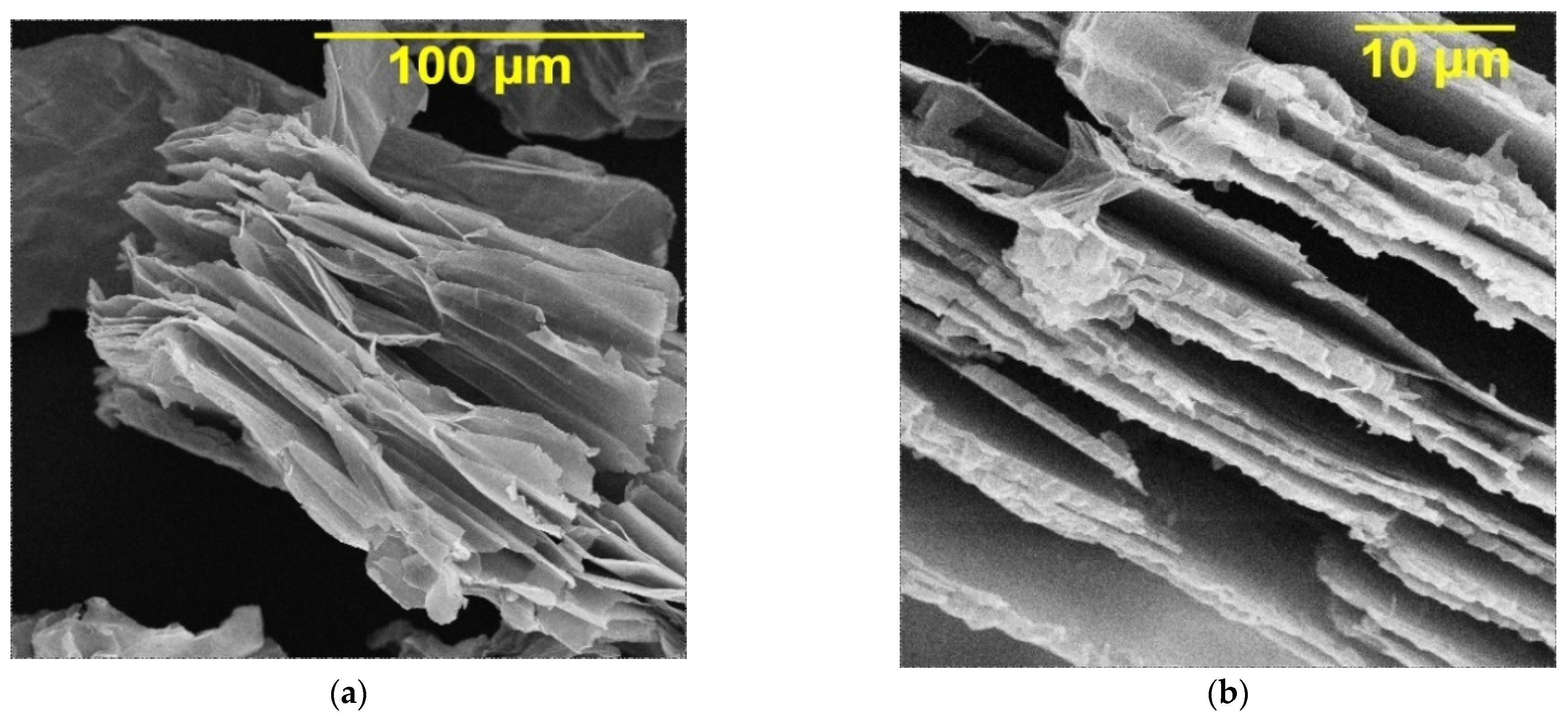

2. Materials and Methods

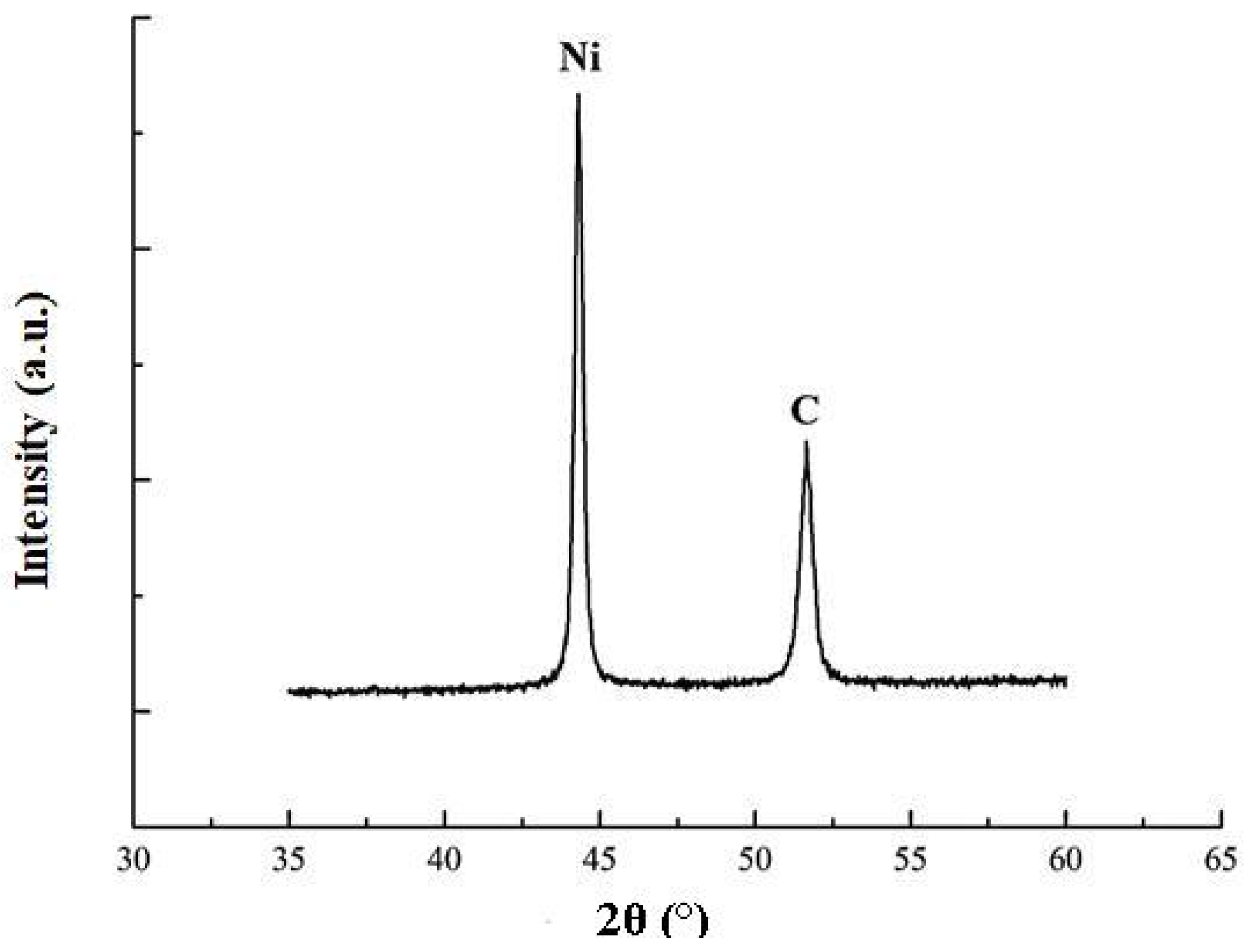

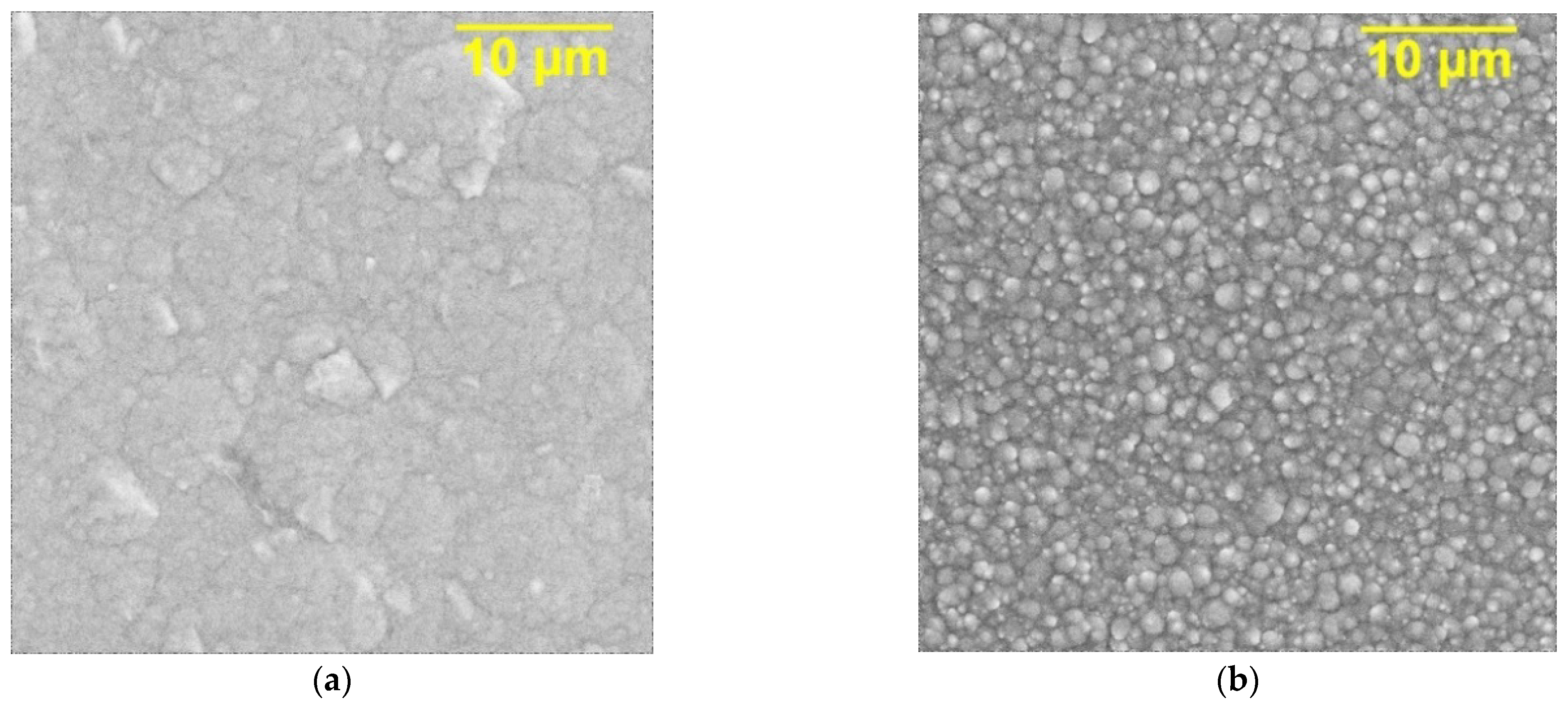

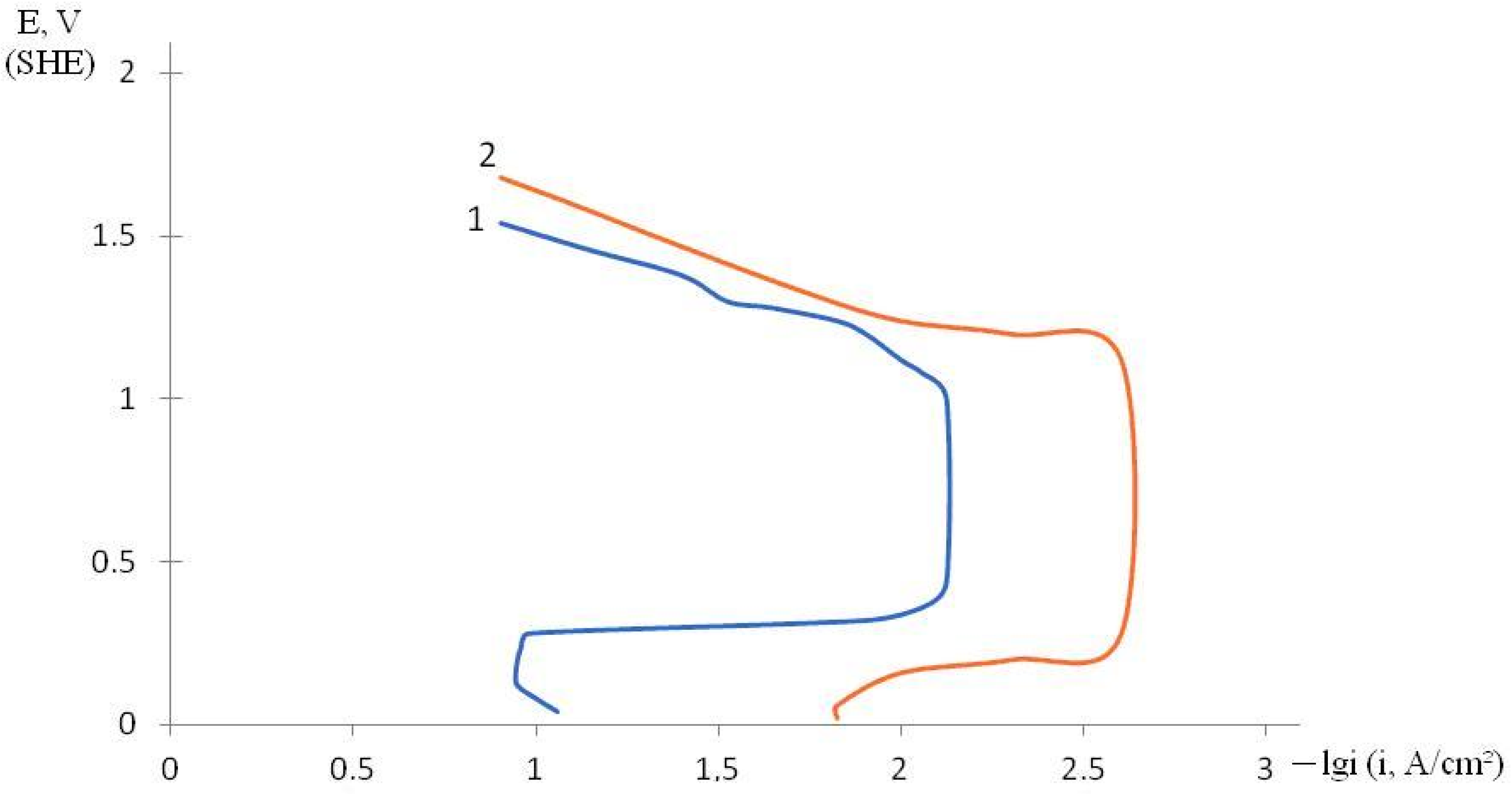

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Low, C.T.J.; Wills, R.G.A.; Walsh, F.C. Electrodeposition of composite coatings containing nanoparticles in a metal deposit. Surf. Coat. Technol. 2006, 201, 371–383. [Google Scholar] [CrossRef]

- Walsh, F.C. A review of the electrodeposition of metal matrix composite coatings by inclusion of particles in a metal layer: An established and diversifying technology. Trans. IMF 2014, 92, 83–98. [Google Scholar] [CrossRef] [Green Version]

- Tseluikin, V.N.; Koreshkova, A.A. Deposition of zinc-carbon nanotube composite coatings in the pulse-reverse mode. Russ. J. Appl. Chem. 2014, 87, 1251–1253. [Google Scholar] [CrossRef]

- Tseluikin, V.N.; Solov’ova, N.D.; Gun’kin, I.F. Electrodeposition of nickel-fullerene C60 composition coatings. Prot. Met. 2007, 43, 388–390. [Google Scholar] [CrossRef]

- Giannopoulos, F.; Chronopoulou, N.; Bai, J.; Zhao, H.; Pantelis, D.; Pavlatou, E.A.I.; Karatonis, A. Nickel/MWCNT-Al2O3 electrochemical co-deposition: Structural properties and mechanistics aspects. Electrochim. Acta 2016, 207, 76–86. [Google Scholar] [CrossRef]

- Hatipoglu, G.; Kartal, M.; Uysal, M.; Cetinkaya, T.; Akbulut, H. The effect of sliding speed on the wear behaviour of pulse electro co-deposited Ni/MWCNT nanocomposite coatings. Tribol. Int. 2016, 98, 59–73. [Google Scholar] [CrossRef]

- Mosallanejad, M.H.; Shafyei, A.; Akhavan, S. Simultaneous co-deposition of SiC and CNT into the Ni coating. Can. Metall. Q. 2016, 55, 147–155. [Google Scholar] [CrossRef]

- Tseluikin, V.N.; Chubenko, I.S.; Gun’kin, I.F.; Pankst’yanov, A.Y. Colloidal dispersion of fullerene C60 free of organic solvents. Russ. J. Appl. Chem. 2006, 79, 325–326. [Google Scholar] [CrossRef]

- Tseluikin, V.N. Electrodeposition and properties of composite coatings modified by fullerene C60. Prot. Met. Phys. Chem. Surf. 2017, 53, 433–436. [Google Scholar] [CrossRef]

- Makarova, I.; Dobryden, I.; Kharitonov, D.; Kasach, A.; Ryl, J.; Repo, E.; Vuorinen, E. Nickel-nanodiamond coatings electrodeposited from tartrate electrolyte at ambient temperature. Surf. Coat. Technol. 2019, 380, 125063. [Google Scholar] [CrossRef]

- Gyawali, G.; Joshi, B.; Tripathi, K.; Lee, S.W. Effect of ultrasonic nanocrystal surface modification on properties of electrodeposited Ni and Ni-SiC composite coatings. J. Mater. Eng. Perform. 2017, 26, 4462–4469. [Google Scholar] [CrossRef]

- Lanzutti, A.; Lekka, M.; de Leitenburg, C.; Fedrizzi, L. Effect of pulse current on wear behaviour of Ni matrix micro- and nano-SiC composite coatings at room and elevated temperature. Tribol. Int. 2019, 132, 50–61. [Google Scholar] [CrossRef]

- Legkaya, D.A.; Solov’eva, N.D.; Yakovlev, A.V. Physicomechanical properties of nickel coating deposited from sulfate nickel plating electrolyte using preliminary underpotential deposition. Russ. J. Appl. Chem. 2017, 90, 1454–1458. [Google Scholar] [CrossRef]

- Tseluikin, V.N.; Vasilenko, E.A. Electrodeposition and properties of composite coatings based on nickel. Russ. J. Appl. Chem. 2011, 84, 2005–2007. [Google Scholar]

- Nayana, O.; Venkatesha, T.V. Effect of ethyl vanillin of ZnNi alloy electrodeposition and its properties. Bull. Mater. Sci. 2014, 37, 1137–1146. [Google Scholar] [CrossRef] [Green Version]

- Torabinejad, V.; Aliofkhazraei, M.; Assareh, S.; Allahyarzadeh, M.H.; Sabour Rouhaghdam, A. Electrodeposition of Fe-Ni alloys compoosites, and nano coatings: A review. J. Alloys Compd. 2017, 691, 841–859. [Google Scholar] [CrossRef]

- Tseluikin, V.N.; Koreshkova, A.A. Pulsed Electrodeposition of Composite Coatings Based on Zinc–Nickel Alloy. Prot. Met. Phys. Chem. Surf. 2018, 54, 453–456. [Google Scholar] [CrossRef]

- Rahmani, H.; Aliofkhazraei, M.; Karimzadeh, A. Effect of frequency and duty cycle on corrosion and wear resistance of functionally graded Zn-Ni nanocomposite coating. Can. Metall. Q. 2018, 57, 99–108. [Google Scholar] [CrossRef]

- Beltowska-Lehmana, E.; Bigosa, A.; Indykab, P.; Chojnackaa, A.; Drewienkiewiczc, A.; Zimowskid, S.; Kotd, M.; Szczerbaa, M.J. Optimisation of the electrodeposition process of Ni-W/ZrO2 nanocomposites. J. Electroanal. Chem. 2018, 813, 39–51. [Google Scholar] [CrossRef]

- Yakovlev, A.V.; Yakovleva, E.V.; Tseluikin, V.N.; Krasnov, V.V.; Mostovoy, A.S.; Rakhmetulina, L.A.; Frolov, I.N. Electrochemical synthesis of multilayer graphene oxide by anodic oxidation of disperse graphite. Russ. J. Electrochem. 2019, 55, 1196–1202. [Google Scholar] [CrossRef]

- Chang, L.M.; Chen, D.; Liu, J.H.; Zhang, R.J. Effect of different plating modes on microstructure and corrosion resistance of Zn-Ni alloy coatings. J. Alloys Compd. 2009, 479, 489–493. [Google Scholar] [CrossRef]

- Pinate, S.; Leisner, P.; Zanella, C. Electrocodeposition of nano-SiC particles by pulse-reverse under an adapted waveform. J. Electrochem. Soc. 2019, 166, D804–D809. [Google Scholar] [CrossRef]

- Guglielmi, N. Kinetics of the deposition of inert particles from electrolytic bath. J. Electrochem. Soc. 1972, 119, 1009–1012. [Google Scholar] [CrossRef]

- Yang, F.; Kang, H.; Guo, E.; Li, R.; Chen, Z.; Zeng, Y. The role of nickel in mechanical perfopmance and corrosion behaviour of nickel-aluminium bronze in 3.5 wt.% NaCl solution. Corros. Sci. 2018, 139, 333–345. [Google Scholar] [CrossRef]

- Rekha, M.Y.; Srivastava, C. Microstructural evolution and corrosion behavior of Zn-Ni-graphene oxide composite coatings. Metall. Mater. Trans. A 2019, 50, 5896–5913. [Google Scholar] [CrossRef]

| Electrolyte Composition | Concentration, g/L | Deposition Parameters |

|---|---|---|

| NiSO4·7H2O | 220 | Temperature t = 45 °C |

| NiCl2·6H2O | 40 | Constant stirring |

| CH3COONa | 30 | Cathode current density |

| Graphene oxide | 10 | ic = 7, 8, 9, 10 A/dm2 |

| Cathode Current Density ic, A/dm2 | Ni | Ni–GO CECs |

|---|---|---|

| 7 | 0.465 | 0.338 |

| 8 | 0.661 | 0.472 |

| 9 | 0.945 | 0.673 |

| 10 | 1.477 | 0.986 |

| Cathode Current Density ic, A/dm2 | Ni | Ni–GO CECs |

|---|---|---|

| 7 | 1100 | 1528 |

| 8 | 1124 | 1573 |

| 9 | 1220 | 1695 |

| 10 | 1465 | 2028 |

| Cathode Current Density ic, A/dm2 | Ni | Ni–GO CECs |

|---|---|---|

| 7 | 0.574 | 0.410 |

| 8 | 0.492 | 0.328 |

| 9 | 0.390 | 0.267 |

| 10 | 0.185 | 0.123 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tseluikin, V.; Dzhumieva, A.; Tikhonov, D.; Yakovlev, A.; Strilets, A.; Tribis, A.; Lopukhova, M. Pulsed Electrodeposition and Properties of Nickel-Based Composite Coatings Modified with Graphene Oxide. Coatings 2022, 12, 656. https://doi.org/10.3390/coatings12050656

Tseluikin V, Dzhumieva A, Tikhonov D, Yakovlev A, Strilets A, Tribis A, Lopukhova M. Pulsed Electrodeposition and Properties of Nickel-Based Composite Coatings Modified with Graphene Oxide. Coatings. 2022; 12(5):656. https://doi.org/10.3390/coatings12050656

Chicago/Turabian StyleTseluikin, Vitaly, Asel Dzhumieva, Denis Tikhonov, Andrey Yakovlev, Anastasia Strilets, Alena Tribis, and Marina Lopukhova. 2022. "Pulsed Electrodeposition and Properties of Nickel-Based Composite Coatings Modified with Graphene Oxide" Coatings 12, no. 5: 656. https://doi.org/10.3390/coatings12050656