Sandwich Structure to Enhance the Mechanical and Electrochemical Performance of TaN/(Ta/Ti)/TiN Multilayer Films Prepared by Multi-Arc Ion Plating

Abstract

:1. Introduction

2. Experimental Details

2.1. Film Preparation and Characterization

2.2. Mechanical Tests

2.3. Tribological and Adhesive Test

2.4. Electrochemical Corrosion Test

3. Results and Discussion

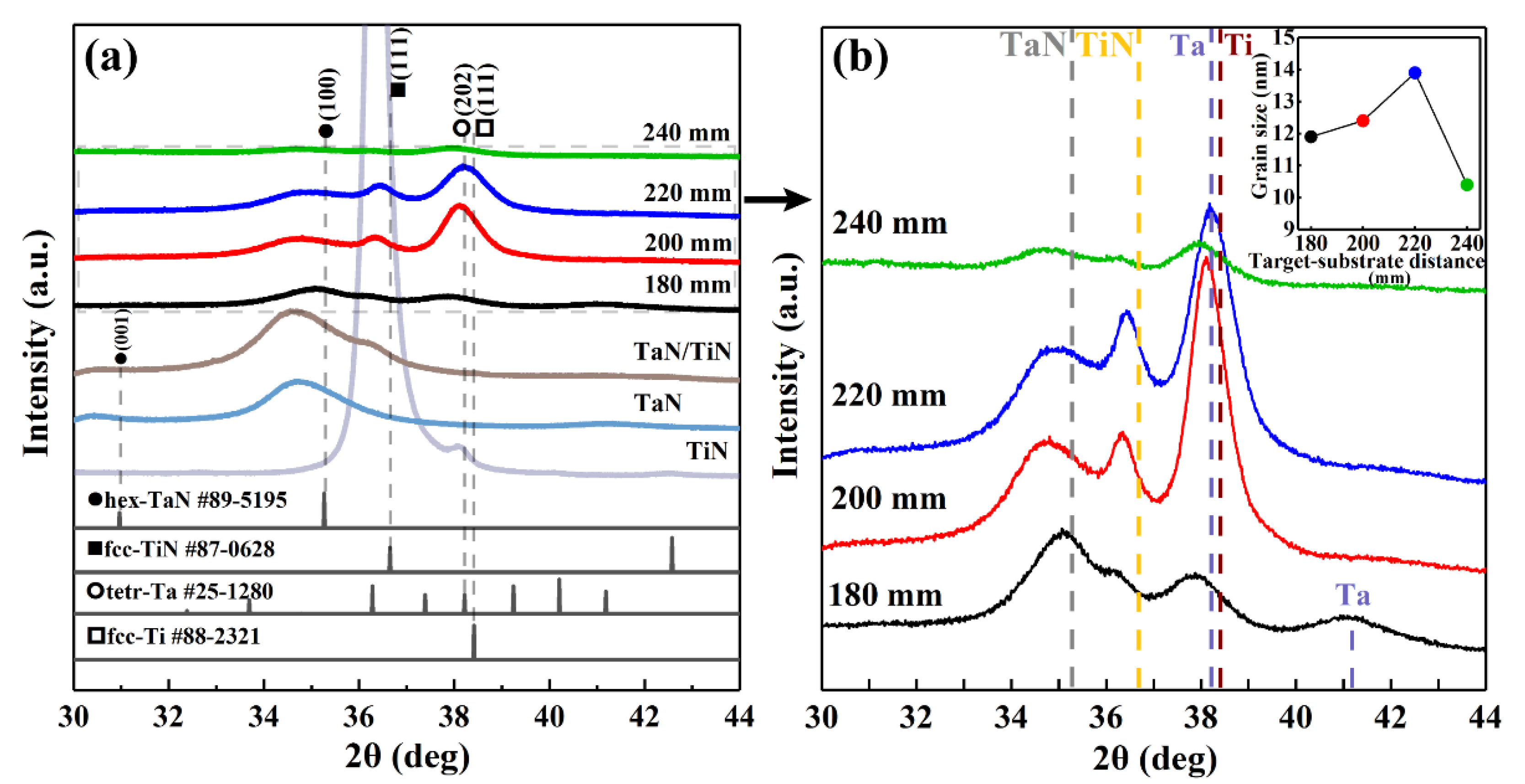

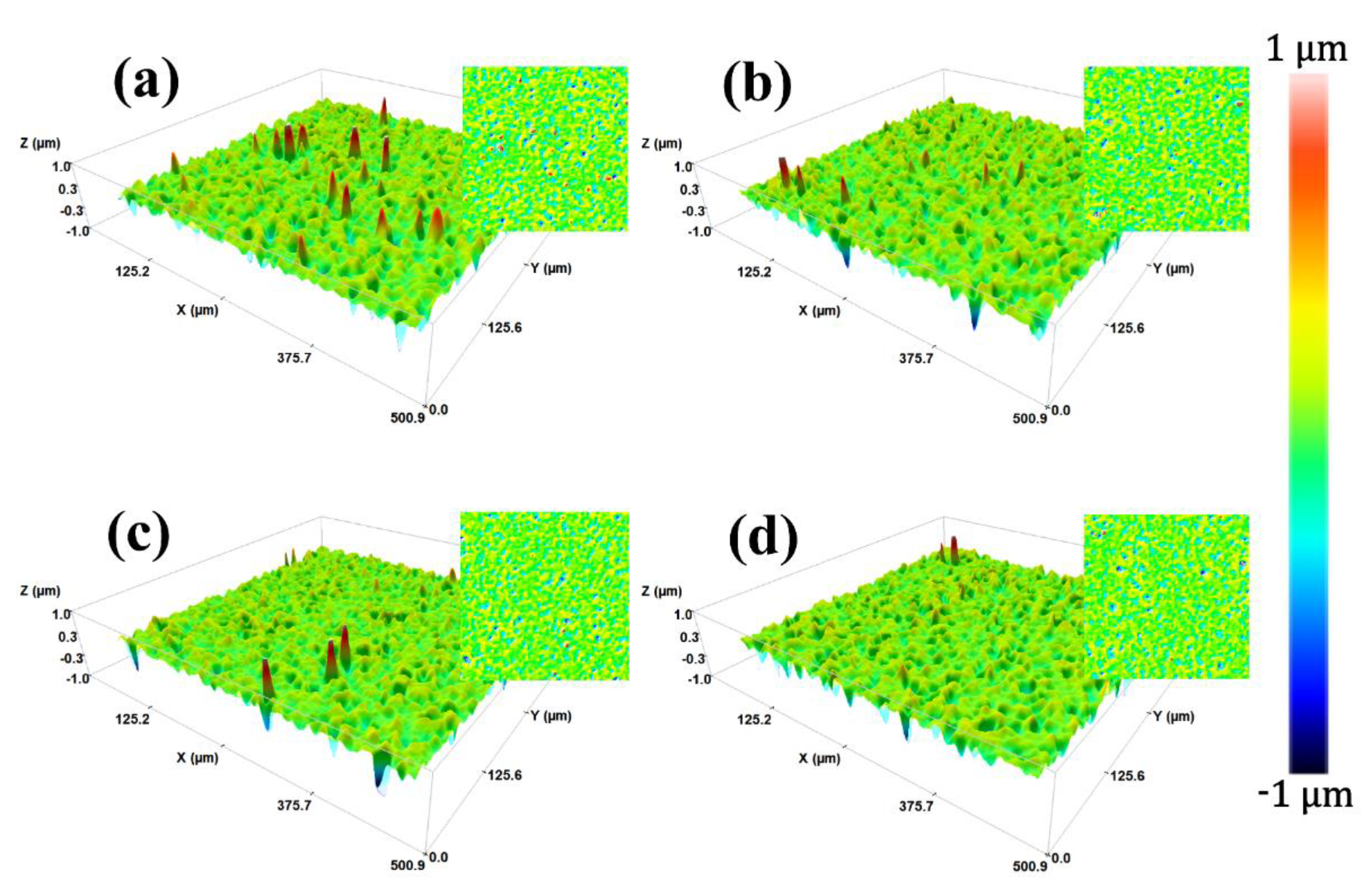

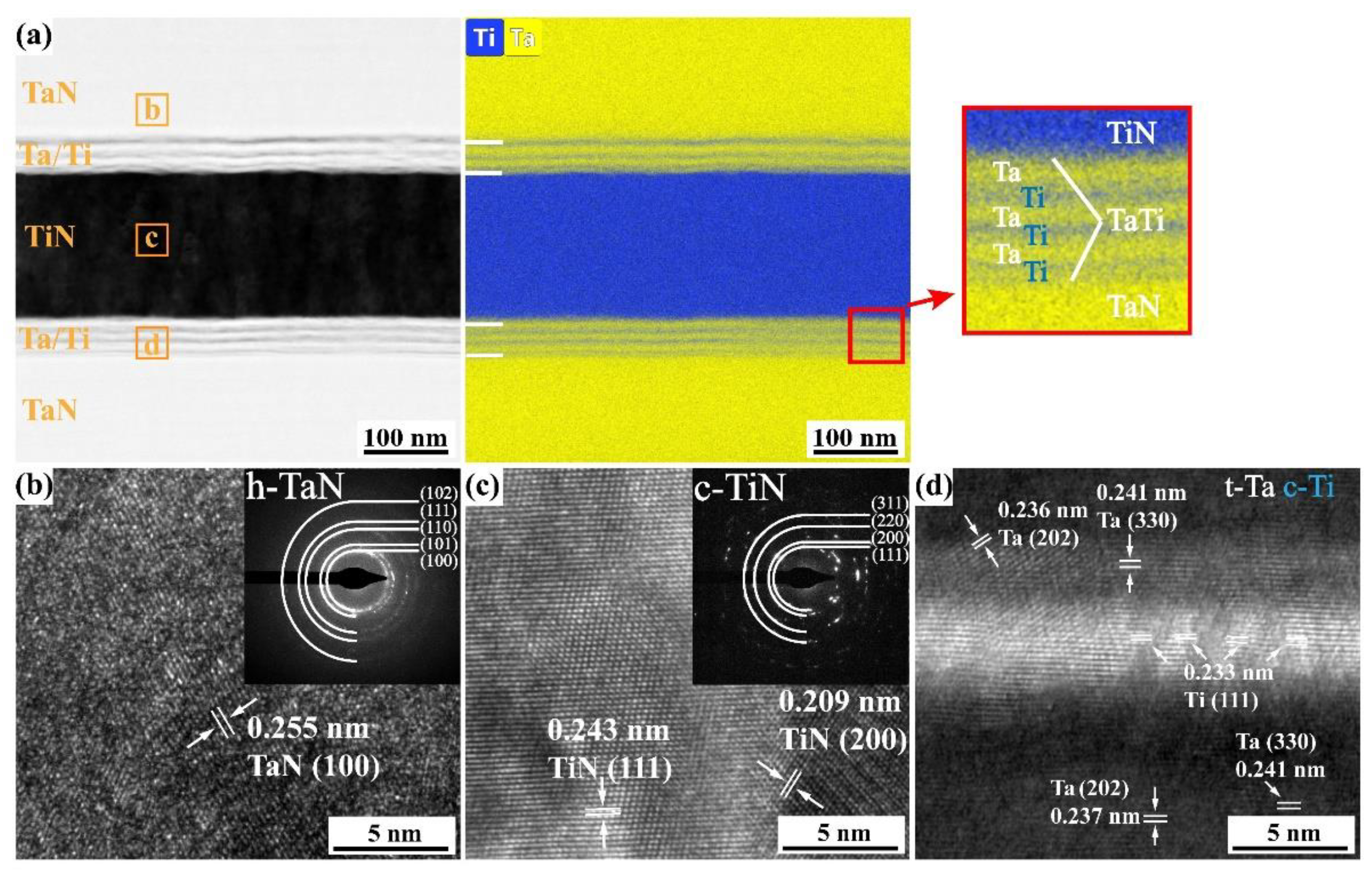

3.1. Phase Composition and Microstructure

3.2. Mechanical Properties

3.3. Tribological and Adhesive Properties

3.4. Corrosion Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Soe, W.H.; Yamamoto, R. Mechanical Properties of Ceramic Multilayers: TiN/CrN, TiN/ZrN, and TiN/TaN. Mater. Phys. 1997, 50, 176–181. [Google Scholar] [CrossRef]

- Zhang, R.F.; Sheng, S.H.; Veprek, S. Stability of Ti–B–N solid solutions and the formation of nc-TiN/a-BN nanocomposites studied by combined ab initio and thermodynamic calculations. Acta Mater. 2008, 56, 4440–4449. [Google Scholar] [CrossRef]

- Xu, X.; Su, F.H.; Li, Z.J. Tribological properties of nanostructured TiAlN/W2N multilayer coating produced by PVD. Wear 2019, 430–431, 67–75. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Arghavani, M.; Mayer, J.; Weirich, T.E. Plastic Deformation Behavior of Nanostructured CrN/AlN Multilayer Coatings Deposited by Hybrid dcMS/HPPMS. Surf. Coat. Technol. 2017, 332, 253–261. [Google Scholar] [CrossRef]

- Azizpour, A.; Rainer, H.; Klimashin, F.F.; Wojcik, T.; Poursaeidi, E.; Mayrhofer, P.H. Deformation and Cracking Mechanism in CrN/TiN Multilayer Coatings. Coatings 2019, 9, 363. [Google Scholar] [CrossRef] [Green Version]

- Bressan, J.D.; Daros, D.P.; Sokolowski, A.; Mesquita, R.A.; Barbosa, C.A. Influence of Hardness on the wear resistance of 17-4 PH stainless steel evaluated by the pin-on-disc testing. J. Mater. Process. Technol. 2008, 205, 353–359. [Google Scholar] [CrossRef]

- Ren, P.; Mao, W.; Zhang, K.; Du, S.X.; Zhang, Y.D.; Chen, J.H.; Zheng, W.T. Self-Assembly of TaC@Ta Core-Shell-Like Nanocomposite Film via Solid-State Dewetting: Toward Superior Wear and Corrosion Resistance. Acta Mater. 2018, 160, 72–84. [Google Scholar] [CrossRef]

- Helmersson, U.; Todorova, S.; Barnett, S.A. Growth of single-crystal TiN/VN strained-layer superlattices with extremelyhigh mechanical hardness. Appl. Phys. 1987, 62, 481–484. [Google Scholar] [CrossRef]

- Koehler, J.S. The production of large tensile stresses by dislocations. Phys. Rev. B 1970, 2, 547–551. [Google Scholar] [CrossRef]

- Shinn, M.; Hultman, L.; Barnett, S.A. Growth structure and microhardness of epitaxial TiN/NbN superlattices. J. Mater. Res. 1992, 7, 901–911. [Google Scholar] [CrossRef]

- Madan, A.; Chu, X.; Barnett, S.A. Reactive unbalanced magnetron sputter deposition of polycrystalline TiN/NbN superlattice coatings. Surf. Coat. Technol. 1993, 57, 13–18. [Google Scholar] [CrossRef]

- Veprek, S.; Nesladek, P.; Niederhofer, A.; Mannling, H.; Jilek, M. Superhard nanocrystalline composites: Present status of the research and possible industrial applications. J. Vac. Sci. Technol. A 1999, 17, 2401–2420. [Google Scholar]

- Li, Y.; Ye, Q.W.; Zhu, Y.J.; Zhang, L.; He, Y.Y.; Zhang, S.Z.; Xiu, J.J. Microstructure, adhesion and tribological properties of CrN/CrTiAlSiN/WCrTiAlN multilayer coatings deposited on nitrocarburized AISI 4140 steel. Surf. Coat. Technol. 2019, 362, 27–34. [Google Scholar] [CrossRef]

- Illana, A.; Almandoz, E.; Fuentes, G.G.; Perez, F.J.; Mato, S. Comparative study of CrAlSiN monolayer and CrN/AlSiN superlattice multilayer coatings: Behavior at high temperature in steam atmosphere. J. Alloys Compd. 2019, 778, 652–661. [Google Scholar] [CrossRef]

- Vega, J.; Scheerer, H.; Andersohn, G.; Oechsner, M. Experimental studies of the effect of Ti interlayers on the corrosion resistance of TiN PVD coatings by using electrochemical methods. Corros. Sci. 2018, 133, 240–250. [Google Scholar] [CrossRef]

- Bi, F.F.; Hou, K.; Yi, P.Y.; Peng, L.F.; Lai, X.M. Mechanisms of growth, properties and degradation of amorphous carbon films by closed field unbalanced magnetron sputtering on stainless steel bipolar plates for PEMFCs. Appl. Surf. Sci. 2017, 422, 921–931. [Google Scholar] [CrossRef]

- Sopok, S.; Rickard, C.; Dunn, S. Thermal-chemical-mechanical gun bore erosion of an advanced artillery system part one: Theories and mechanisms. Wear 2005, 258, 671–683. [Google Scholar] [CrossRef]

- Mulligan, C.P.; Smith, S.B.; Vigilante, G.N. Characterization and Comparison of Magnetron Sputtered and Electroplated Gun Bore Coatings. J. Press. Vessel. Technol. 2006, 128, 240–245. [Google Scholar] [CrossRef]

- Lee, S.L.; Windover, D.; Audino, M.; Matson, D.W.; McClanahan, E.D. High-rate sputter deposited tantalum coating on steel for wear and erosion mitigation. Surf. Coat. Technol. 2002, 149, 62–69. [Google Scholar] [CrossRef]

- Myers, S.; Lin, J.L.; Souza, R.M.; Sproul, W.D.; Moore, J.J. The β to α phase transition of tantalum coatings deposited by modulated pulsed power magnetron sputtering. Surf. Coat. Technol. 2013, 214, 38–45. [Google Scholar] [CrossRef]

- Wang, B.Z.; Li, D.X.; Yang, Z.H. Microstructural evolution and mechanical properties of in situ nano Ta4HfC5 reinforced SiBCN composite ceramics. J. Adv. Ceram. 2020, 9, 739–748. [Google Scholar] [CrossRef]

- Yu, Z.J.; Yang, Y.J.; Mao, K.W. Single-source-precursor synthesis and phase evolution of SiC-TaC-C ceramic nanocomposites containing core-shell structured TaC@C nanoparticles. J. Adv. Ceram. 2020, 9, 320–328. [Google Scholar] [CrossRef]

- Ren, X.R.; Lv, J.S.; Li, W. Influence of MoSi2 on oxidation protective ability of TaB2-SiC coating in oxygen-containing environments within a broad temperature range. J. Adv. Ceram. 2020, 9, 703–715. [Google Scholar] [CrossRef]

- Chang, C.L.; Shih, S.G.; Chen, P.H. Effect of duty cycles on the deposition and characteristics of high power impulse magnetron sputtering deposited TiN thin films. Surf. Coat. Technol. 2014, 259, 232–237. [Google Scholar] [CrossRef]

- Nordin, M.; Larsson, M.; Hogmark, S. Mechanical and tribological properties of multilayered PVD TiN/CrN, TiN/MoN, TiN/NbN and TiN/TaN coatings on cemented carbide. Surf. Coat. Technol. 1998, 106, 234–241. [Google Scholar] [CrossRef]

- Patel, N.; Wang, S.L.; Inspektor, A.; Salvador, P.A. Secondary hardness enhancement in large period TiN/TaN superlattices. Surf. Coat. Technol. 2014, 254, 21–27. [Google Scholar] [CrossRef]

- Chang, C.L.; Chiou, T.H.; Chen, P.H. Characteristics of TiN/W2N multilayers prepared using magnetron sputter deposition with dc and pulsed dc powers. Surf. Coat. Technol. 2016, 303, 25–31. [Google Scholar] [CrossRef]

- Čekada, M.; Panjan, P.; Drnovšek, A.; Drobnič, M. Increase of coating thickness on sharp edges, deposited by cathodic arc evaporation. Surf. Coat. Technol. 2021, 405, 126691. [Google Scholar] [CrossRef]

- Ma, Y.H.; Yang, J.G.; Tian, X.B.; Gong, C.G.; Zheng, W.J.; He, Y.M.; Li, H.X.; Gao, Z.L.; Zhang, K.X.; Wei, L.F. Enhanced discharge and surface properties of TiSiCN coatings deposited by pulse-enhanced vacuum arc evaporation. Surf. Coat. Technol. 2020, 403, 126413. [Google Scholar] [CrossRef]

- Cai, X.J.; Gao, Y.; Cai, F.; Zhang, L.; Zhang, S.H. Effects of multi-layer structure on microstructure, wear and erosion performance of the Cr/CrN films on Ti alloy substrate. Appl. Surf. Sci. 2019, 483, 661–669. [Google Scholar] [CrossRef]

- Cai, F.; Zhang, J.M.; Wang, J.M.; Zheng, J.; Wang, Q.M.; Zhang, S.H. Improved adhesion and erosion wear performance of CrSiN/Cr multi-layer coatings on Ti alloy by inserting ductile Cr layers. Tribol. Int. 2021, 153, 106657. [Google Scholar] [CrossRef]

- Liang, F.K.; Shen, Y.F.; Pei, C.R.; Qiu, B.; Lei, J.; Sun, D. Microstructure evolution and corrosion resistance of multi interfaces Al-TiAlN nanocomposite films on AZ91D magnesium alloy. Surf. Coat. Technol. 2019, 357, 83–92. [Google Scholar] [CrossRef]

- Lutisan, J.; Cvengros, J. Mean free path of molecules on molecular distillation. Chem. Eng. J. Biochem. Eng. J. 1995, 56, 39–50. [Google Scholar] [CrossRef]

- Lee, J.W.; Tien, S.K.; Kuo, Y.C. The effects of pulse frequency and substrate bias to the mechanical properties of CrN coatings deposited by pulsed DC magnetron sputtering. Thin Solid Film. 2006, 494, 161–167. [Google Scholar] [CrossRef]

- Elo, R.; Jacobson, S.; Kubart, T. Tailoring residual stresses in CrNx films on alumina and silicon deposited by high-power impulse magnetron sputtering. Surf. Coat. Technol. 2020, 397, 125990. [Google Scholar] [CrossRef]

- Elbert, C.R.; Joan, C.O.; Roberto, T.S.; Abel, H.M.; Maryory, G.B. Microstructure, mechanical and tribological performance of nanostructured TiAlTaN-(TiAlN/TaN)n coatings: Understanding the effect of quaternary/multilayer volume fraction. Surf. Coat. Technol. 2019, 377, 124875. [Google Scholar] [CrossRef]

- Cao, H.T.; Wen, F.; Kumar, S.; Rudolf, P.; Hosson, J.T.M.D.; Pei, Y.T. On the S/W stoichiometry and triboperformance of WSxC(H) coatings deposited by magnetron sputtering. Surf. Coat. Technol. 2019, 365, 41–51. [Google Scholar] [CrossRef] [Green Version]

- Du, H.; Zanáka, M.; Brenning, N.; Helmersson, U. Bipolar HiPIMS: The role of capacitive coupling in achieving ion bombardment during growth of dielectric thin films. Surf. Coat. Technol. 2021, 416, 127152. [Google Scholar] [CrossRef]

- Shtanskii, D.V.; Kulinich, S.A.; Levashov, E.A.; Moore, J.J. Structure and physical-mechanical properties of nanostructured thin films. Phys. Solid State 2003, 45, 1177–1184. [Google Scholar] [CrossRef]

- Glechner, T.; Hahn, R.; Wojcik, T.; Holec, D. Assessment of ductile character in superhard Ta-C-N thin films. Acta Mater. 2019, 179, 17–25. [Google Scholar] [CrossRef]

- Koller, C.M.; Marihart, H.; Bolvardi, H.; Kolozsvári, S.; Mayrhofer, P.H. Structure, phase evolution, and mechanical properties of DC, pulsed DC, and high power impulse magnetron sputtered Ta-N films. Surf. Coat. Technol. 2018, 347, 304–312. [Google Scholar] [CrossRef]

- Elizabeth, A.E.; Markus, C.; Han, S.C.; Shefford, P.B. Effect of sputter pressure on microstructure and properties of β-Ta thin films. Acta Mater. 2020, 183, 504–513. [Google Scholar] [CrossRef]

- Li, J.L.; Wang, J.; Kumar, A.; Li, H.; Xiong, D.S. High temperatures tribological properties of Ta-Ag films deposited at various working pressures and sputtering powers. Surf. Coat. Technol. 2018, 349, 186–197. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.L.; Li, H.; Zhang, X.F.; Huang, J.W.; Xiong, D.S. Friction and wear properties of amorphous and nanocrystalline Ta-Ag films at elevated temperatures as function of working pressure. Surf. Coat. Technol. 2018, 353, 135–147. [Google Scholar] [CrossRef]

- Asempah, I.; Xu, J.H.; Yu, L.H.; Wang, L. Effect of boron concentration on the mechanical, tribological and corrosion properties of Ta–B–N films by reactive magnetron sputtering. Ceram. Int. 2019, 45, 19395–19403. [Google Scholar] [CrossRef]

- Koller, C.M.; Hollerweger, R.; Rachbauer, R.; Kolozsvári, S.; Paulitsch, J.; Mayrhofer, P.H. Annealing studies and oxidation tests of a hybrid multilayer arrangement of cathodic arc evaporated Ti-Al-N and reactively sputtered Ta–Al–N coatings. Surf. Coat. Technol. 2015, 283, 89–95. [Google Scholar] [CrossRef]

- Hernández-Navarro, C.; Rivera, L.P.; Flores-Martínez, M.; Camps, E.; Muhl, S.; García, E. Tribological study of a mono and multilayer coating of TaZrN/TaZr produced by magnetron sputtering on AISI-316L stainless steel. Tribol. Int. 2019, 131, 288–298. [Google Scholar] [CrossRef]

- Yang, L.; Wen, L.; Dai, X.; Cheng, G.; Zhang, K. Ultrafine Ceramic Grains Embedded in Metallic Glass Matrix: Achieving Superior Wear Resistance via Increase in Both Hardness and Toughness. ACS Appl. Mater. Interfaces 2018, 10, 16124–16132. [Google Scholar] [CrossRef]

- Hao, K.; Zhang, Y.D.; Ren, P.; Zhang, K.; Chen, J.H.; Du, S.X.; Wang, M.J. Spinodal decomposition in the Ta-Mo-Al-N films activated by Mo incorporation: Toward enhanced hardness and toughness. Ceram. Int. 2018, 44, 21358–21364. [Google Scholar] [CrossRef]

- Duan, H.; Du, K.; Yan, C.; Wang, F. Electrochemical corrosion behavior of composite coatings of sealed MAO film on magnesium alloy AZ91D. Electrochim. Acta 2006, 51, 2898–2908. [Google Scholar] [CrossRef]

| Layer | Time (min) | Pressure (Pa) | Bias Voltage (V) | Cathode Current (A) | Flow Rate (Sccm) | ||

|---|---|---|---|---|---|---|---|

| Ta | Ti | Ar | N2 | ||||

| TaN | 5 | 2.0 | −100 | 200 | / | 65 | 300 |

| (Ta/Ti) | 1 | 0.4 | −100 | 200 | 130 | 65 | / |

| TiN | 5 | 2.0 | −100 | / | 130 | 65 | 300 |

| Ti | 2 | 0.4 | −100 | / | 130 | 65 | / |

| Ion etching | 20 | 0.4 | −160 | / | / | / | / |

| Ar etching | 20 | 2.0 | −1000 | / | / | / | / |

| Heating and pumping | 60 | 8 × 10−3 | / | / | / | / | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, R.; Yang, M.; Yuan, Y.; Min, R.; Li, Q.; Yang, M.; Ji, B.; Zhang, S. Sandwich Structure to Enhance the Mechanical and Electrochemical Performance of TaN/(Ta/Ti)/TiN Multilayer Films Prepared by Multi-Arc Ion Plating. Coatings 2022, 12, 694. https://doi.org/10.3390/coatings12050694

Tu R, Yang M, Yuan Y, Min R, Li Q, Yang M, Ji B, Zhang S. Sandwich Structure to Enhance the Mechanical and Electrochemical Performance of TaN/(Ta/Ti)/TiN Multilayer Films Prepared by Multi-Arc Ion Plating. Coatings. 2022; 12(5):694. https://doi.org/10.3390/coatings12050694

Chicago/Turabian StyleTu, Rong, Mai Yang, Yang Yuan, Rui Min, Qizhong Li, Meijun Yang, Baifeng Ji, and Song Zhang. 2022. "Sandwich Structure to Enhance the Mechanical and Electrochemical Performance of TaN/(Ta/Ti)/TiN Multilayer Films Prepared by Multi-Arc Ion Plating" Coatings 12, no. 5: 694. https://doi.org/10.3390/coatings12050694

APA StyleTu, R., Yang, M., Yuan, Y., Min, R., Li, Q., Yang, M., Ji, B., & Zhang, S. (2022). Sandwich Structure to Enhance the Mechanical and Electrochemical Performance of TaN/(Ta/Ti)/TiN Multilayer Films Prepared by Multi-Arc Ion Plating. Coatings, 12(5), 694. https://doi.org/10.3390/coatings12050694