Wear Resistance, Patterns of Wear and Plastic Properties of Cr,Mo-(Cr,Mo,)N-(Cr,Mo,Al)N Composite Coating with a Nanolayer Structure

Abstract

:1. Introduction

2. Materials and Methods

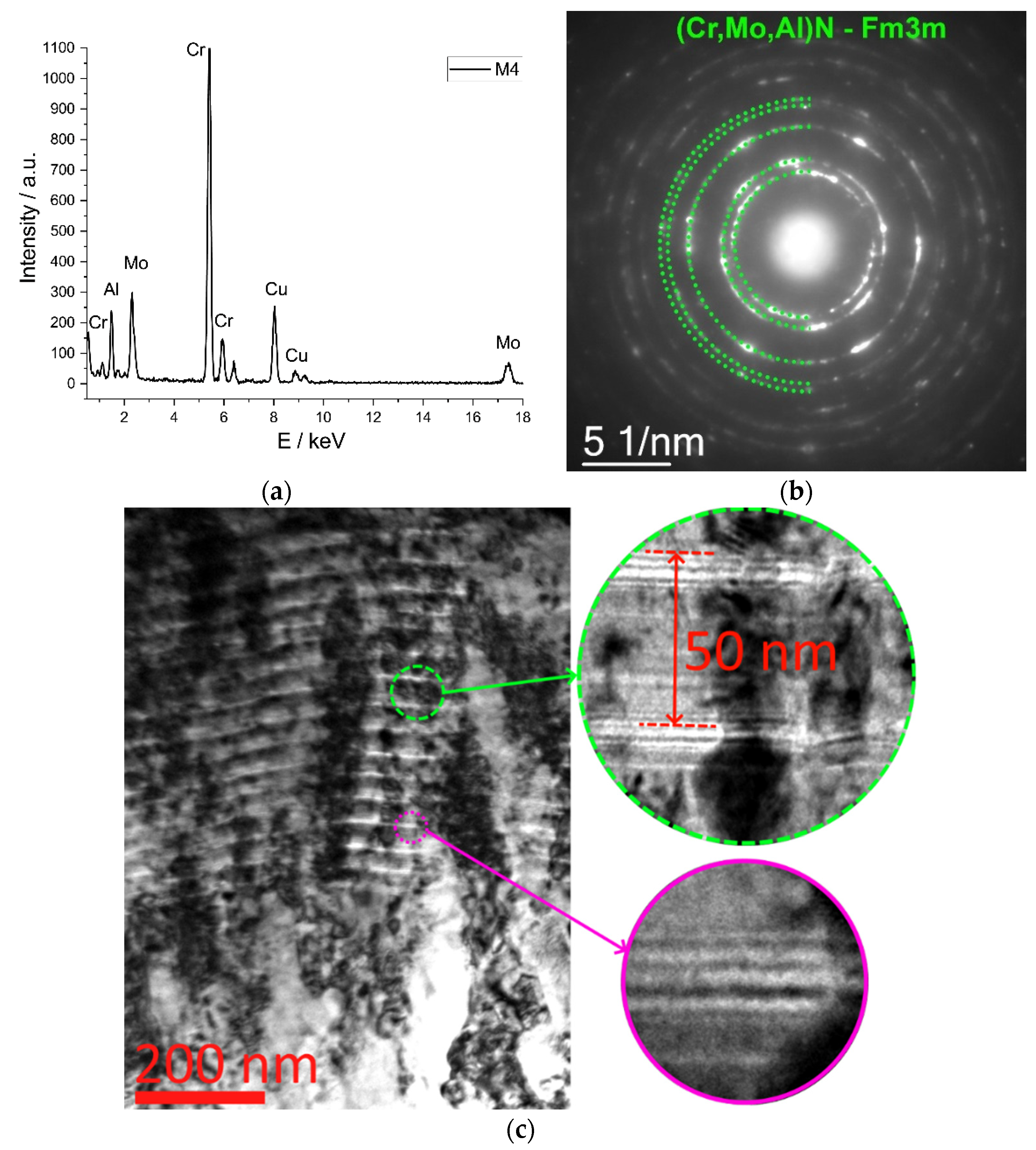

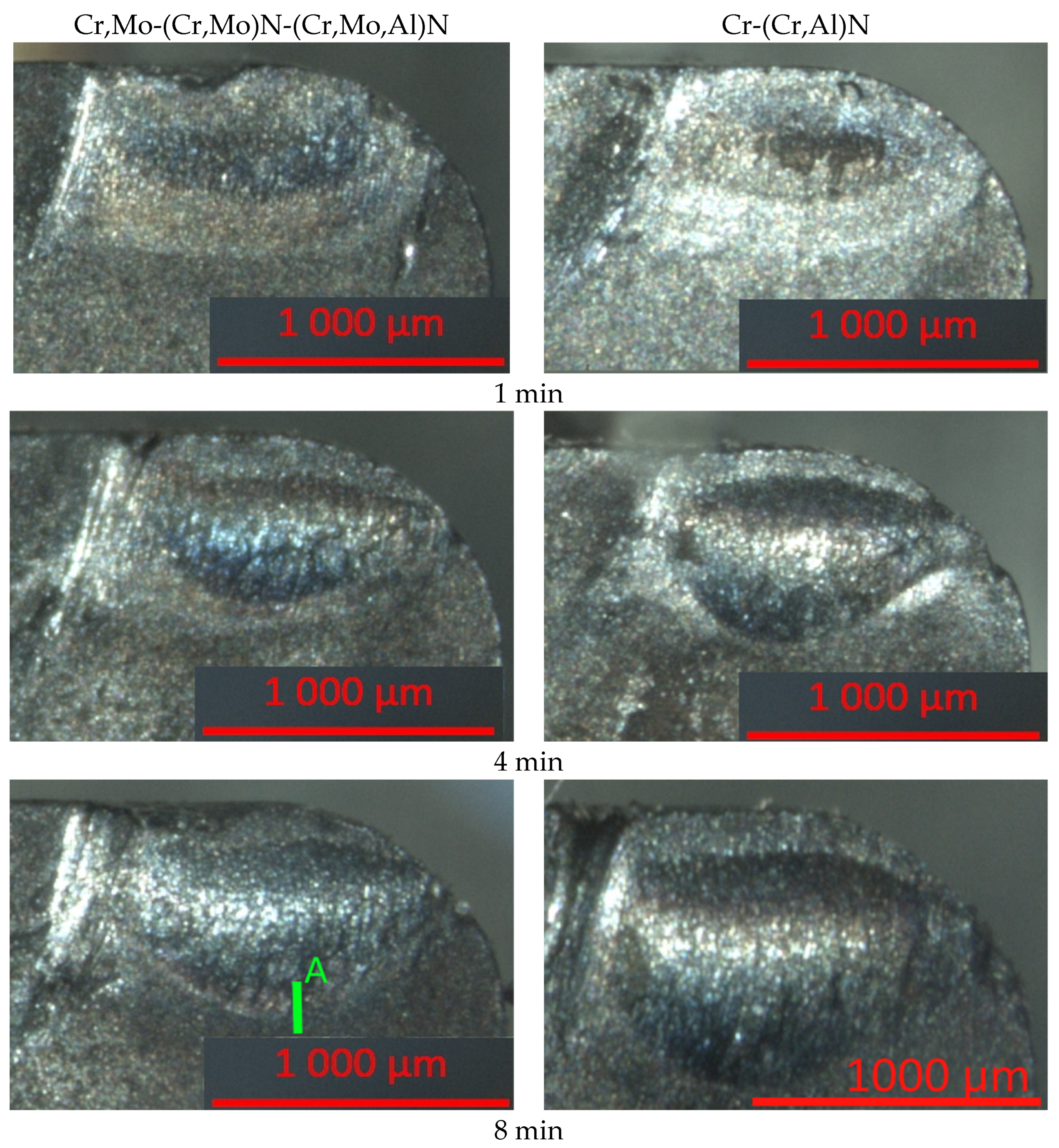

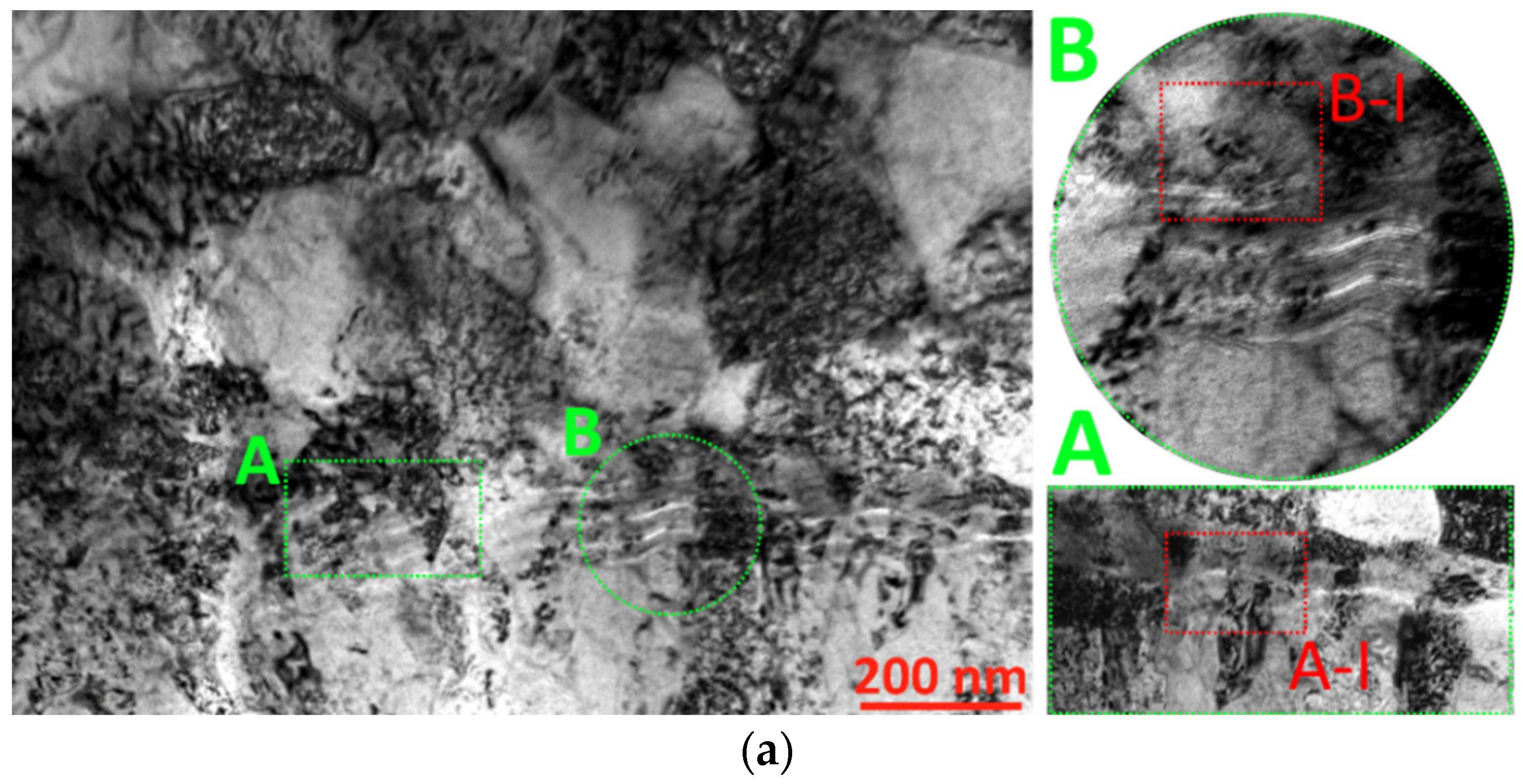

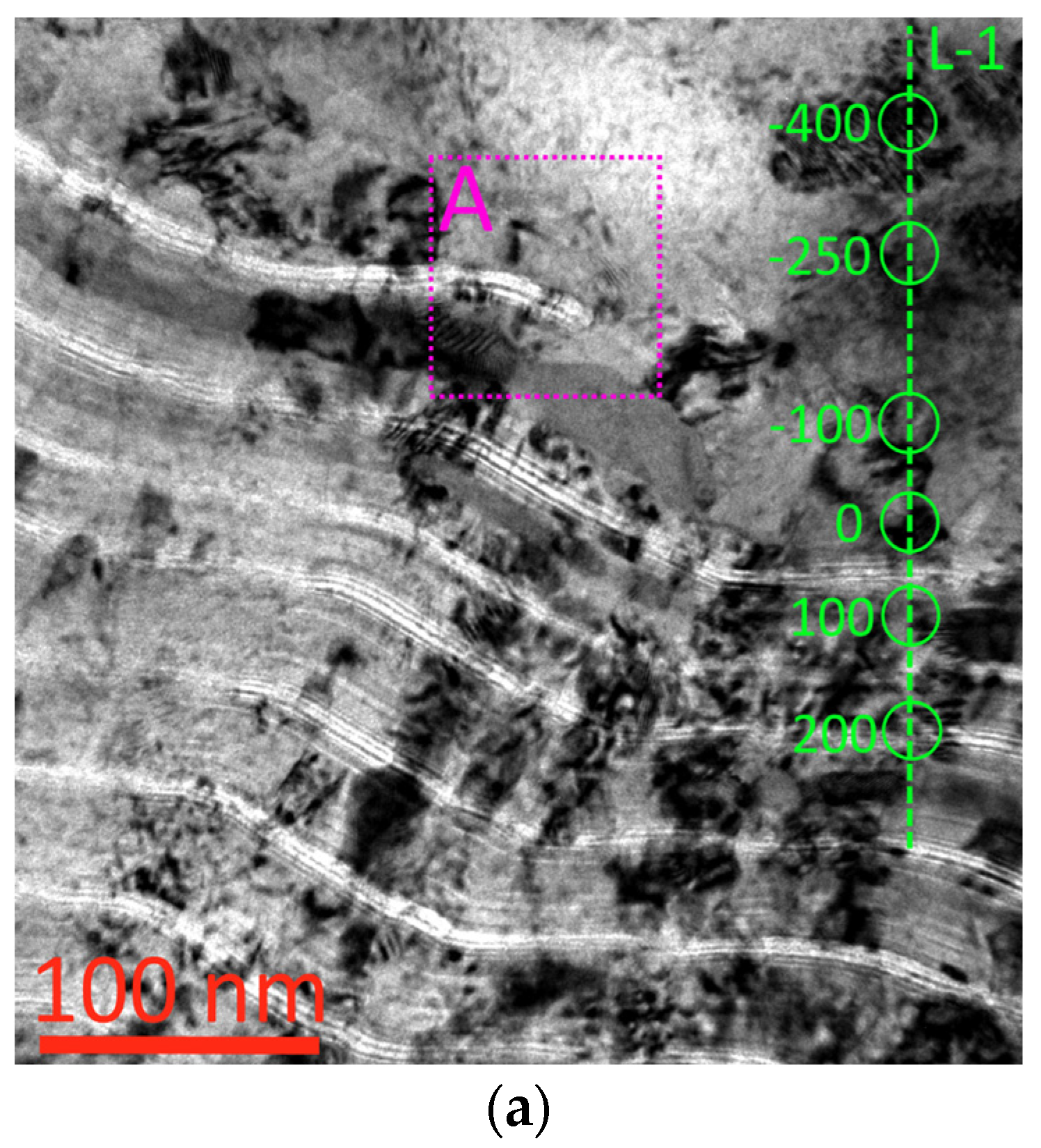

3. Results

4. Conclusions

- Introduction of 20 at.% Mo into the composition of the (Cr,Al)N coating increases the wear resistance of metal-cutting tools.

- For the coating based on the (Cr,Al)N system, more active growth of wear crater on the rake face is typical compared to the coating based on the (Cr,Mo,Al)N system.

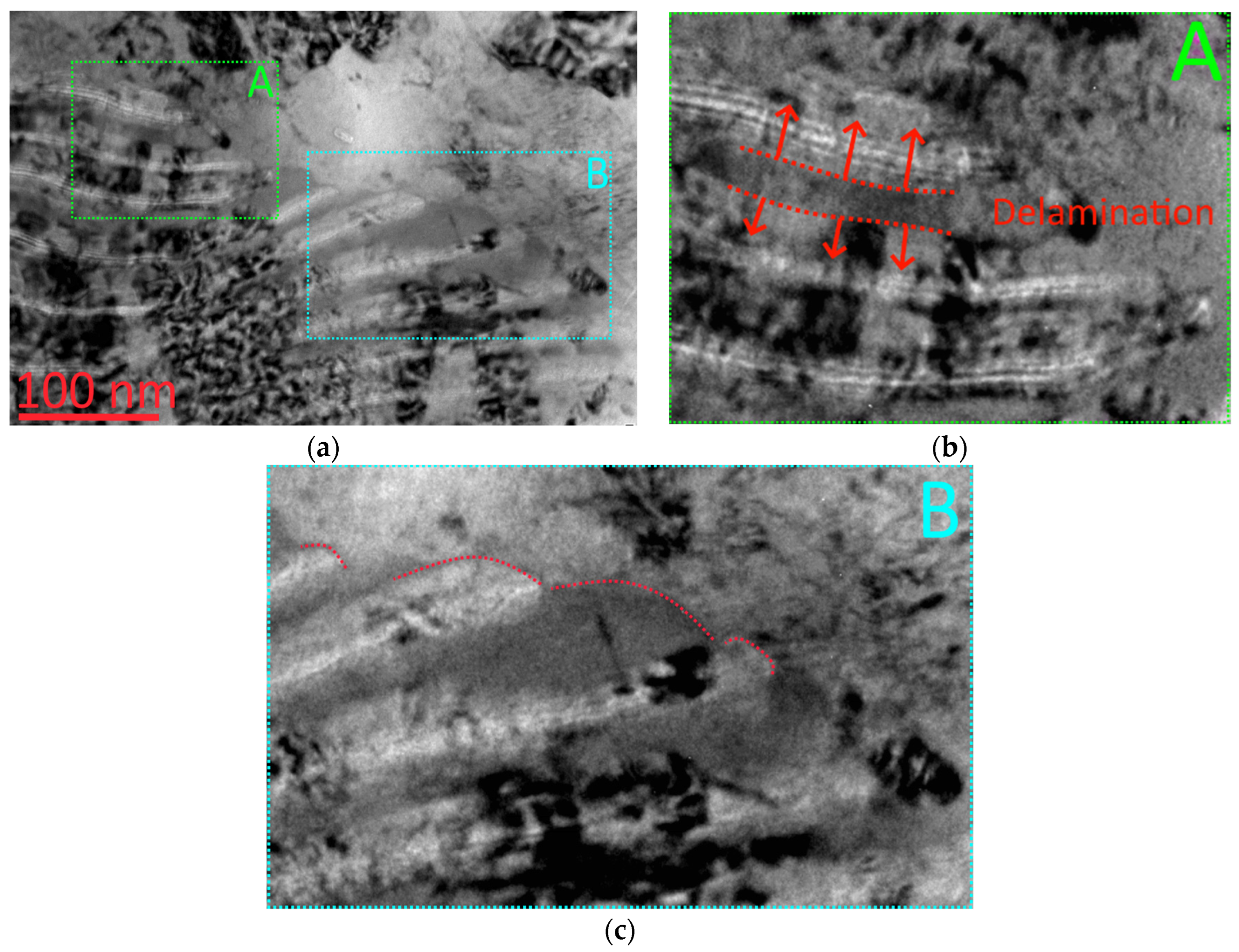

- The analysis of the pattern of wear on the coating with nanolayer structure in contact with the cut material flow reveals the following fracture mechanisms:

- Penetration of particles of the machined steel between nanolayers of the coating, resulting in interlayer delamination;

- Plastic deformation (bending) of nanolayers of the coating under the influence of the moving flow of the machined steel;

- Fracture of fragments from nanolayers of the coating with their further separation and removal by the cut material flow;

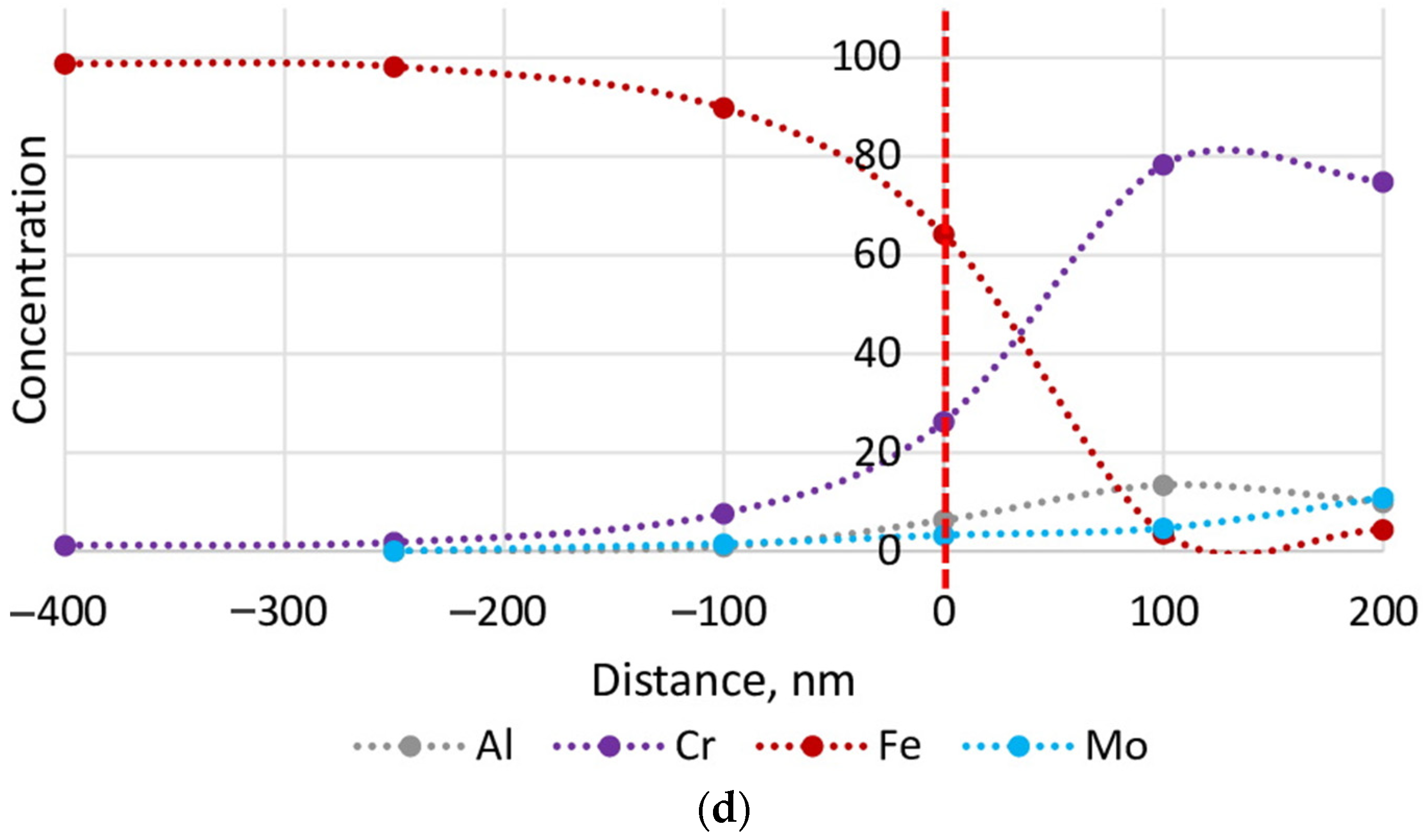

- During the cutting, the diffusion of iron into the coating (to the depth not exceeding 200 nm) and the diffusion of coating elements (Cr and Mo) into the machined steel to the depth not exceeding 250 nm occur;

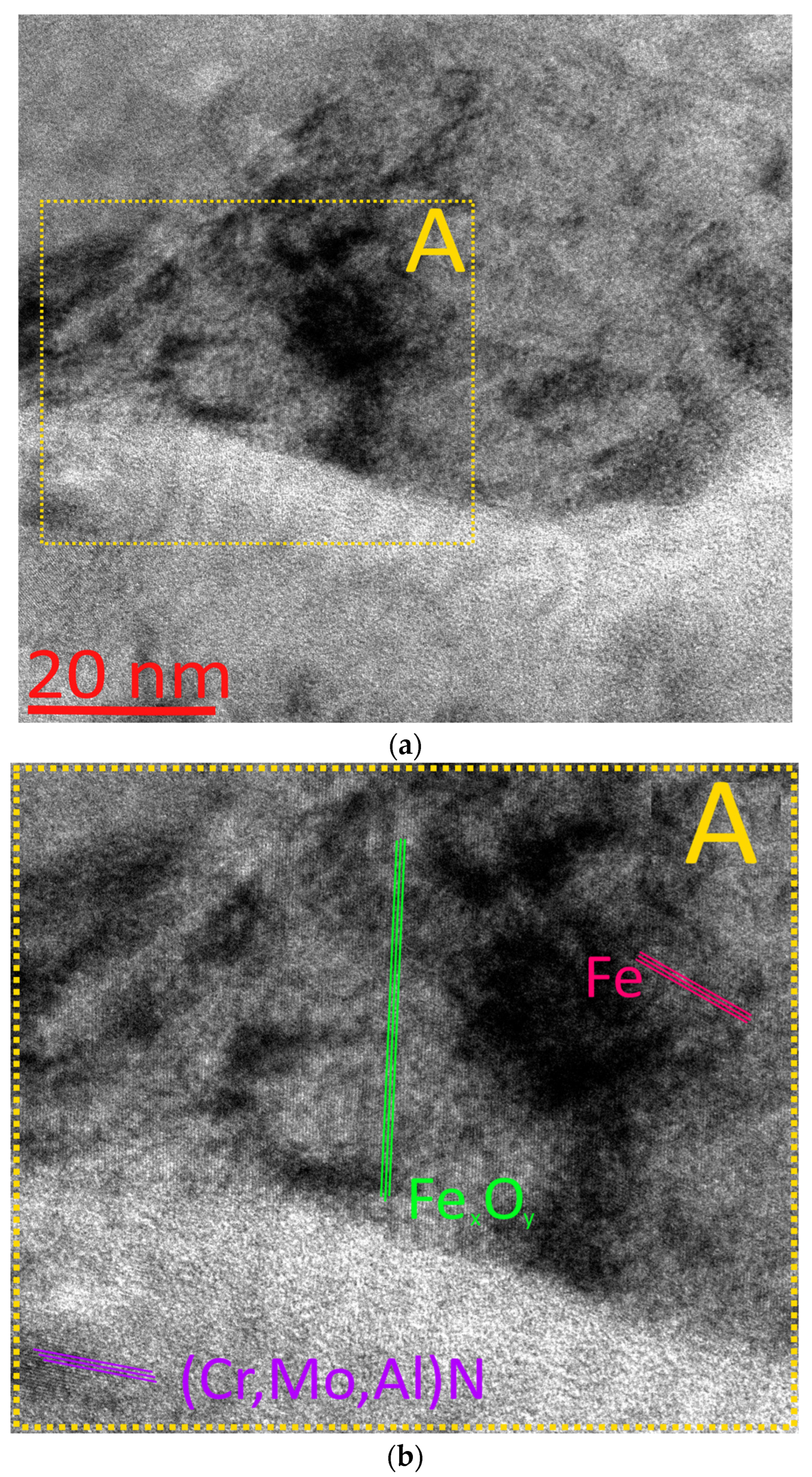

- Along with the particles of iron on the “coating- machined steel” interface, the particles of iron oxides are detected with significantly higher hardness compared to iron, which can thereby more actively affect the wear of the coating.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti, Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Bobzin, K. High-performance coatings for cutting tools CIRP. J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Ariharan, N.; Sriram, C.G.; Radhika, N.; Aswin, S.; Haridas, S. A comprehensive review of vapour deposited coatings for cutting tools: Properties and recent advances. Trans. Inst. Met. Finish. 2022, in press. [Google Scholar] [CrossRef]

- Klaus, M.; Genzel, C. Multilayer systems for cutting tools: On the relationship between coating design, surface processing, and residual stress. Adv. Eng. Mater. 2011, 13, 845–850. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, W.; Li, B.; Wang, C.; Kuang, T.; Li, Y. Physical vapor deposition technology for coated cutting tools: A review. Ceram. Int. 2020, 46, 18373–18390. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Grigoriev, S.N.; Volosova, M.A. The role of the thermal factor in the wear mechanism of ceramic tools: Part 1. Macrolevel. J. Frict. Wear 2014, 35, 505–510. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Gurin, V.D.; Volosova, M.A.; Cherkasova, N.Y. Development of residual cutting tool life prediction algorithm by processing on CNC machine tool. Mater. Werkst. 2013, 44, 790–796. [Google Scholar] [CrossRef]

- Grigoriev, S.; Fominski, V.; Gnedovets, A.; Romanov, R. Experimental and numerical study of the chemical composition of WSex thin films obtained by pulsed laser deposition in vacuum and in a buffer gas atmosphere. Appl. Surf. Sci. 2012, 258, 7000–7007. [Google Scholar] [CrossRef]

- Fominski, V.Y.; Grigoriev, S.N.; Celis, J.P.; Romanov, R.I.; Oshurko, V.B. Structure and mechanical properties of W-Se-C/diamond-like carbon and W-Se/diamond-like carbon bi-layer coatings prepared by pulsed laser deposition. Thin Solid Film. 2012, 520, 6476–6483. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Bublikov, J.; Kutina, N. Investigation of the properties of the Cr,Mo-(Cr,Mo,Zr,Nb)N-(Cr,Mo,Zr,Nb,Al)N multilayer composite multicomponent coating with nanostructured wear-resistant layer. Wear 2021, 468–469, 203597. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Tabakov, V.; Sitnikov, N.; Andreev, N.; Sviridova, T.; Bublikov, J. Investigation of multicomponent nanolayer coatings based on nitrides of Cr, Mo, Zr, Nb, and Al. Surf. Coat. Technol. 2020, 401, 126258. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Milovich, F.; Sitnikov, N.; Migranov, M.; Andreev, N.; Bublikov, J.; Sotova, C. Investigation of tribological and functional properties of Cr,Mo-(Cr,Mo)N-(Cr,Mo,Al)N multilayer composite coating. Tribol. Int. 2021, 155, 106804. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Andreev, N.; Bublikov, J.; Sitnikov, N.; Sotova, C.; Kutina, N. Investigation of wear mechanisms of multilayer nanostructured wear-resistant coatings during turning of steel. Part 2: Diffusion, oxidation processes and cracking in Ti-TiN-(Ti,Cr,Mo,Al)N coating. Wear 2021, 486–487, 204096. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Mitterer, C.; Hultman, L.; Clemens, H. Microstructural design of hard coatings. Prog. Mater. Sci. 2006, 51, 1032–1114. [Google Scholar] [CrossRef]

- Yamamoto, K.; Sato, T.; Takahara, K.; Hanaguri, K. Properties of (Ti,Cr,Al)N coatings with high Al content deposited by new plasma enhanced arc-cathode. Surf. Coat. Technol. 2003, 174–175, 620–626. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Sotova, C.; Kutina, N. Investigation of the influence of the thickness of nanolayers in wear-resistant layers of Ti-TiN-(Ti,Cr,Al)N coating on destruction in the cutting and wear of carbide cutting tools. Surf. Coat. Technol. 2020, 385, 125402. [Google Scholar] [CrossRef]

- Vereschaka, A.; Milovich, F.; Migranov, M.; Andreev, N.; Alexandrov, I.; Muranov, A.; Mikhailov, M.; Tatarkanov, A. Investigation of the tribological and operational properties of (Mex,Moy,Al1−(x+y))N (Me–Ti, Zr or Cr) coatings. Tribol. Int. 2022, 165, 107305. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Yamomoto, K.; Veldhuis, S.C.; Kovalev, A.I.; Dosbaeva, G.K. Tribological adaptability of TiAlCrN PVD coatings under high performance dry machining conditions. Surf. Coat. Technol. 2005, 200, 1804–1813. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Willmann, H.; Reiter, A.E. Structure and phase evolution of Cr-Al-N coatings during annealing. Surf. Coat. Technol. 2008, 202, 4935–4938. [Google Scholar] [CrossRef]

- Reiter, A.E.; Derflinger, V.H.; Hanselmann, B.; Bachmann, T.; Sartory, B. Investigation of the properties of Al1-xCrxN coatings prepared by cathodic arc evaporation. Surf. Coat. Technol. 2005, 200, 2114–2122. [Google Scholar] [CrossRef]

- Wistrela, E.; Schmied, I.; Schneider, M.; Gillinger, M.; Mayrhofer, P.M.; Bittner, A.; Schmid, U. Impact of sputter deposition parameters on the microstructural and piezoelectric properties of CrxAl1−xN thin films. Thin Solid Film. 2018, 648, 76–82. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Engels, M. Correlation of the Debye sheath thickness and (Cr,Al)N coating properties for HPPMS, dcMS, CAE and PCAE processes. Surf. Coat. Technol. 2017, 332, 233–241. [Google Scholar] [CrossRef]

- Hu, C.; Xu, Y.X.; Chen, L.; Pei, F.; Zhang, L.J.; Du, Y. Structural, mechanical and thermal properties of CrAlNbN coatings. Surf. Coat. Technol. 2018, 349, 894–900. [Google Scholar] [CrossRef]

- Hu, C.; Chen, L.; Moraes, V. Structure, mechanical properties, thermal stability and oxidation resistance of arc evaporated CrAlBN coatings. Surf. Coat. Technol. 2021, 417, 127191. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Z.; Yuan, T.; Mei, F.; Lin, X.; Gao, J.; Chen, W.; Xu, Y. The synergy of V and Si on the microstructure, tribological and oxidation properties of AlCrN based coatings. Surf. Coat. Technol. 2021, 412, 127082. [Google Scholar] [CrossRef]

- Wang, R.; Mei, H.; Li, R.; Zhang, T.; Wang, Q. Influence of V addition on the microstructure, mechanical, oxidation and tribological properties of AlCrSiN coatings. Surf. Coat. Technol. 2021, 407, 126767. [Google Scholar] [CrossRef]

- Hu, C.; Xu, Y.X.; Chen, L.; Pei, F.; Du, Y. Mechanical properties, thermal stability and oxidation resistance of Ta-doped CrAlN coatings. Surf. Coat. Technol. 2019, 368, 25–32. [Google Scholar] [CrossRef]

- Miyake, T.; Kishimoto, A.; Hasegawa, H. Tribological properties and oxidation resistance of (Cr,Al,Y)N and (Cr,Al,Si)N films synthesized by radio-frequency magnetron sputtering method. Surf. Coat. Technol. 2010, 205 (Suppl. 1), S290–S294. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, K.; Yao, C.; Li, Z. Effect of MoO3 on the microstructure and tribological properties of laser-clad Ni60/nanoCu/h-BN/MoO3 composite coatings over wide temperature range. Surf. Coat. Technol. 2020, 387, 125477. [Google Scholar] [CrossRef]

- Tao, H.; Tsai, M.T.; Chen, H.W.; Huang, J.C.; Duh, J.G. Improving high-temperature tribological characteristics on nanocomposite CrAlSiN coating by Mo doping. Surf. Coat. Technol. 2018, 349, 752–756. [Google Scholar] [CrossRef]

- Lu, Y.C.; Chen, H.W.; Chang, C.C.; Wu, C.Y.; Duh, J.G. Tribological properties of nanocomposite Cr-Mo-Si-N coatings at elevated temperature through silicon content modification. Surf. Coat. Technol. 2018, 338, 69–74. [Google Scholar] [CrossRef]

- Li, F.; Zhu, S.; Cheng, J.; Qiao, Z.; Yang, J. Tribological properties of Mo and CaF2 added SiC matrix composites at elevated temperatures. Tribol. Int. 2017, 111, 46–51. [Google Scholar] [CrossRef]

- Qi, D.; Chen, J.; Liu, J.; Lv, W.; Song, J.; Shen, L. Influence of Molybdenum Addition on Oxidation Resistance of CrN Coatings. Rare Metal Mater. Eng. 2021, 50, 1505–1512. [Google Scholar]

- Qi, D.; Lei, H.; Fan, D.; Pei, Z.; Gong, J.; Sun, C. Effect of Mo content on the microstructure and properties of CrMoN composite coatings. Acta Metall. Sin. 2015, 51, 371–377. [Google Scholar]

- Wang, Y.; Tang, Y.; Wan, W.; Zhang, X. High-Temperature Oxidation Resistance of CrMoN Films. J. Mater. Eng. Perform. 2020, 29, 6412–6416. [Google Scholar] [CrossRef]

- Amaya-Roncancio, S.; Arias-Mateus, D.F.; Gómez-Hermida, M.M.; Riaño-Rojas, J.C.; Restrepo-Parra, E. Molecular dynamics simulations of the temperature effect in the hardness on Cr and CrN films. Appl. Surf. Sci. 2012, 258, 4473–4477. [Google Scholar] [CrossRef]

- Cai, Z.; Zhang, P.; Di, Y. Microstructure, hardness and oxidation resistance of CrN and CrAlN coatings synthesized by multi-arc ion plating technology. Adv. Mater. Res. 2011, 168–170, 2430–2433. [Google Scholar] [CrossRef]

- Zeilinger, A.; Daniel, R.; Schöberl, T.; Stefenelli, M.; Sartory, B.; Keckes, J.; Mitterer, C. Resolving depth evolution of microstructure and hardness in sputtered CrN film. Thin Solid Film. 2015, 581, 75–79. [Google Scholar] [CrossRef]

- Ichimura, H.; Ando, I. Mechanical properties of arc-evaporated CrN coatings: Part I—Nanoindentation hardness and elastic modulus. Surf. Coat. Technol. 2001, 145, 88–93. [Google Scholar] [CrossRef]

- Tian, C.X.; Han, B.; Zou, C.W.; Xie, X.; Li, S.Q.; Liang, F.; Tang, X.S.; Wang, Z.S.; Pelenovich, V.O.; Zeng, X.M.; et al. Synthesis of monolayer MoNx and nanomultilayer CrN/Mo2N coatings using arc ion plating. Surf. Coat. Technol. 2019, 370, 125–129. [Google Scholar] [CrossRef]

- Shirazi, M.; Ghasemloo, M.; Etaati, G.R.; Hosseinnejad, M.T.; Toroghinejad, M.R. Plasma focus method for growth of molybdenum nitride thin films: Synthesis and thin film characterization. J. Alloys Compd. 2017, 727, 978–985. [Google Scholar] [CrossRef]

- Wang, J.; Munroe, P.; Zhou, Z.; Xie, Z. Nanostructured molybdenum nitride-based coatings: Effect of nitrogen concentration on microstructure and mechanical properties. Thin Solid Film. 2019, 682, 82–92. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, G.; Ren, S.; Jiang, B. Effect of nitrogen flow rate on structure and properties of MoNx coatings deposited by facing target sputtering. J. Alloys Compd. 2017, 701, 1–8. [Google Scholar] [CrossRef]

- Klimashin, F.; Koutná, N.; Euchner, H.; Holec, D.; Mayrhofer, P. The impact of nitrogen content and vacancies on structure and mechanical properties of Mo–N thin films. J. Appl. Phys. 2016, 120, 185301. [Google Scholar] [CrossRef] [Green Version]

- Vetter, J.; Eriksson, A.O.; Reiter, A.; Derflinger, V.; Kalss, W. Quo vadis: Alcr-based coatings in industrial applications. Coatings 2021, 11, 344. [Google Scholar] [CrossRef]

- Yoon, C.S.; Kim, K.H.; Kwon, S.H.; Park, I.W. Syntheses and properties of Cr-Al-Mo-N coatings fabricated by using a hybrid coating system. J. Korean Phys. Soc. 2009, 54, 1237–1241. [Google Scholar] [CrossRef]

- Klimashin, F.F.; Mayrhofer, P.H. Ab initio-guided development of super-hard Mo-Al-Cr-N coatings. Scr. Mater. 2017, 140, 27–30. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Stahl, K.; Lohner, T.; Yilmaz, M. Effects of (Cr,Al)N and (Cr,Al,Mo)N coatings on friction under minimum quantity lubrication. Surf. Coat. Technol. 2020, 402, 126154. [Google Scholar] [CrossRef]

- Wang, Y.; Lou, B. Microstructure and High-Temperature Friction and Wear Properties of CrAlMoN Film. Oxid. Met. 2021, 95, 239–250. [Google Scholar] [CrossRef]

- Iram, S.; Cai, F.; Wang, J.; Zhang, J.; Liang, J.; Ahmad, F.; Zhang, S. Effect of addition of Mo or V on the structure and cutting performance of AlCrN-based coatings. Coatings 2020, 10, 298. [Google Scholar] [CrossRef] [Green Version]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C. Arc PVD (Cr,Al,Mo)N and (Cr,Al,Cu)N coatings for mobility applications. Surf. Coat. Technol. 2020, 384, 125046. [Google Scholar] [CrossRef]

- Iram, S.; Wang, J.; Cai, F.; Zhang, J.; Ahmad, F.; Liang, J.; Zhang, S. Effect of bilayer number on mechanical and wear behaviours of the AlCrN/AlCrMoN coatings by AIP method. Surf. Eng. 2021, 37, 536–544. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Bublikov, J.; Sotova, C.; Oganian, G.; Sadov, I. Investigation of the properties of Ti-TiN-(Ti,Cr,Mo,Al)N multilayered composite coating with wear-resistant layer of nanolayer structure. Coatings 2020, 10, 1236. [Google Scholar] [CrossRef]

- Vereshchaka, A.A.; Vereshchaka, A.S.; Mgaloblishvili, O.; Morgan, M.N.; Batako, A.D. Nano-scale multilayered-composite coatings for the cutting tools. Int. J. Adv. Manuf. Technol. 2014, 72, 303–317. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Aksenenko, A.; Sitnikov, N.; Oganyan, G.; Seleznev, A.; Shevchenko, S. Effect of adhesion and the wear-resistant layer thickness ratio on mechanical and performance properties of ZrN-(Zr,Al,Si)N coatings. Surf. Coat. Technol. 2019, 357, 218–234. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Bolbukov, V.P. Characteristics of a fast neutral atom source with electrons injected into the source through its emissive grid from the vacuum chamber. Instrum. Exp. Tech. 2012, 55, 288–293. [Google Scholar] [CrossRef]

- Metel, A.; Grigoriev, S.; Melnik, Y.; Panin, V.; Prudnikov, V. Cutting Tools Nitriding in Plasma Produced by a Fast Neutral Molecule Beam. Jpn. J. Appl. Phys. 2011, 50, 08JG04. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Bolbukov, V.P. Broad beam sources of fast molecules with segmented cold cathodes and emissive grids. Instrum. Exp. Tech. 2012, 55, 122–130. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Metel, A.S.; Fedorov, S.V. Modification of the structure and properties of high-speed steel by combined vacuum-plasma treatment. Met. Sci. Heat Treat. 2012, 54, 8–12. [Google Scholar] [CrossRef]

- Fominski, V.Y.; Grigoriev, S.N.; Gnedovets, A.G.; Romanov, R.I. Pulsed laser deposition of composite Mo–Se–Ni–C coatings using standard and shadow mask configuration. Surf. Coat. Technol. 2012, 206, 5046–5054. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.S.; Panin, V.V.; Prudnikov, V.V. A compact vapor source of conductive target material sputtered by 3-keV ions at 0.05-Pa pressure. Instrum. Exp. Tech. 2009, 52, 731–737. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Mustafaev, E. Specific features of the structure and properties of arc-PVD coatings depending on the spatial arrangement of the sample in the chamber. Vacuum 2022, 200, 111047. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M.J. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- ASTM C1624-05(2015); Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing. ASTM International: West Conshohocken, PA, USA, 2010. [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Sotova, C. Investigation of the influence of the features of the deposition process on the structural features of microparticles in PVD coatings. Vacuum 2022, 202, 111144. [Google Scholar] [CrossRef]

- Mohamed, Y.S.; El-Gamal, H.; Zaghloul, M.M.Y. Micro-hardness behavior of fiber reinforced thermosetting composites embedded with cellulose nanocrystals. Alex. Eng. J. 2018, 57, 4113–4119. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.Y.M.; Zaghloul, M.M.Y. Experimental and modeling analysis of mechanical-electrical behaviors of polypropylene composites filled with graphite and MWCNT fillers. Polym. Test. 2017, 63, 467–474. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Steel, K.; Veidt, M.; Heitzmann, M.T. Wear behaviour of polymeric materials reinforced with man-made fibres: A comprehensive review about fibre volume fraction influence on wear performance. J. Reinf. Plast. Compos. 2022, 41, 215–241. [Google Scholar] [CrossRef]

- Mahmoud Zaghloul, M.Y.; Yousry Zaghloul, M.M.; Yousry Zaghloul, M.M. Developments in polyester composite materials—An in-depth review on natural fibres and nano fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.M. Mechanical properties of linear low-density polyethylene fire-retarded with melamine polyphosphate. J. Appl. Polym. Sci. 2018, 135, 46770. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Influence of flame retardant magnesium hydroxide on the mechanical properties of high density polyethylene composites. J. Reinf. Plast. Compos. 2017, 36, 1802–1816. [Google Scholar] [CrossRef]

- Varga, G.; Ferencsik, V. Analysis of Cylindricity Error of High and Low Temperature Storage Tested Alternator Stators. Int. J. Automot. Technol. 2020, 21, 1519–1526. [Google Scholar] [CrossRef]

- Kundrák, J.; Pálmai, Z.; Varga, G. Analysis of Tool Life Functions in Hard Turning. Teh. Vjesn. 2020, 27, 166–173. [Google Scholar]

- Karpuschewski, B.; Kundrák, J.; Felhő, C.; Varga, G.; Borysenko, D. Effects of the tool edge design on the roughness of face milled surfaces. Iop Conf. Ser. Mater. Sci. Eng. 2018, 448, 012056. [Google Scholar] [CrossRef]

- Astakhov, V.P. Tribology of Cutting Tools, Chapter 1. In Tribology in Manufacturing Technology; Springer: Dordrecht, The Netherlands, 2013; pp. 1–66. [Google Scholar]

- Gates, J.D. Two-body and three-body abrasion: A critical discussion. Wear 1998, 214, 139–146. [Google Scholar] [CrossRef]

- Moore, M.A. Abrasive wear. Mater. Eng. Appl. 1978, 1, 97–111. [Google Scholar] [CrossRef]

- Torrance, A.A. An explanation of the hardness differential needed for abrasion. Wear 1981, 68, 263–266. [Google Scholar] [CrossRef]

- Coronado, J.J.; Rodríguez, S.A.; Sinatora, A. Effect of particle hardness on mild-severe wear transition of hard second phase materials. Wear 2013, 301, 82–88. [Google Scholar] [CrossRef]

| Gas Pressure pN (Pa) | Voltage on Substrate U (V) | Cathode Arc Current (A) | |||

|---|---|---|---|---|---|

| Al | Cr-Mo | Cr | |||

| Heating and subsequent cleaning of samples with gas plasma | 2.0 | 100 DC | 75 | 110 | 75 |

| Coating deposition | 0.42 | −150 DC | 160 | 110 | 75 |

| Product cooling | 0.06 | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vereschaka, A.; Seleznev, A.; Gaponov, V. Wear Resistance, Patterns of Wear and Plastic Properties of Cr,Mo-(Cr,Mo,)N-(Cr,Mo,Al)N Composite Coating with a Nanolayer Structure. Coatings 2022, 12, 758. https://doi.org/10.3390/coatings12060758

Vereschaka A, Seleznev A, Gaponov V. Wear Resistance, Patterns of Wear and Plastic Properties of Cr,Mo-(Cr,Mo,)N-(Cr,Mo,Al)N Composite Coating with a Nanolayer Structure. Coatings. 2022; 12(6):758. https://doi.org/10.3390/coatings12060758

Chicago/Turabian StyleVereschaka, Alexey, Anton Seleznev, and Vladislav Gaponov. 2022. "Wear Resistance, Patterns of Wear and Plastic Properties of Cr,Mo-(Cr,Mo,)N-(Cr,Mo,Al)N Composite Coating with a Nanolayer Structure" Coatings 12, no. 6: 758. https://doi.org/10.3390/coatings12060758

APA StyleVereschaka, A., Seleznev, A., & Gaponov, V. (2022). Wear Resistance, Patterns of Wear and Plastic Properties of Cr,Mo-(Cr,Mo,)N-(Cr,Mo,Al)N Composite Coating with a Nanolayer Structure. Coatings, 12(6), 758. https://doi.org/10.3390/coatings12060758