The Effect of Process-Induced Porosity on Fatigue Properties of Ti6Al4V Alloy via High-Power Direct Energy Deposition

Abstract

:1. Introduction:

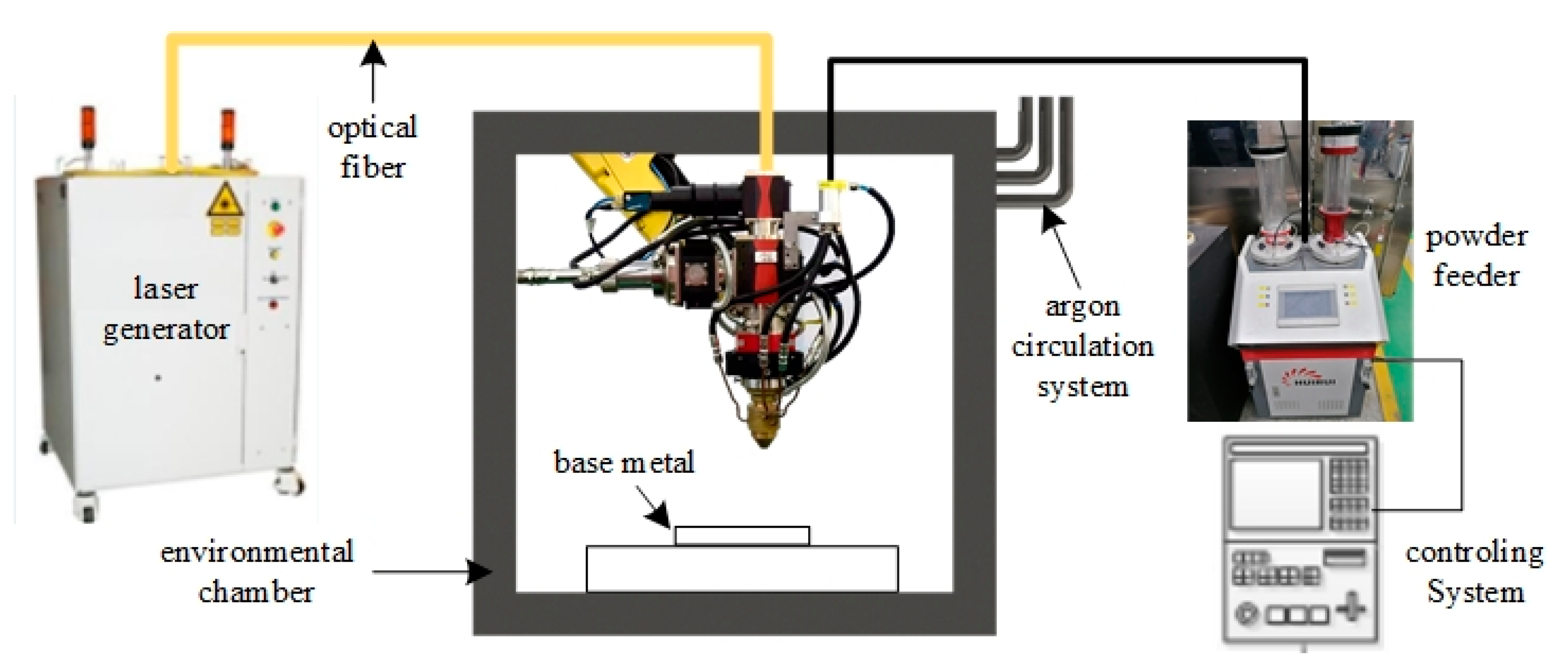

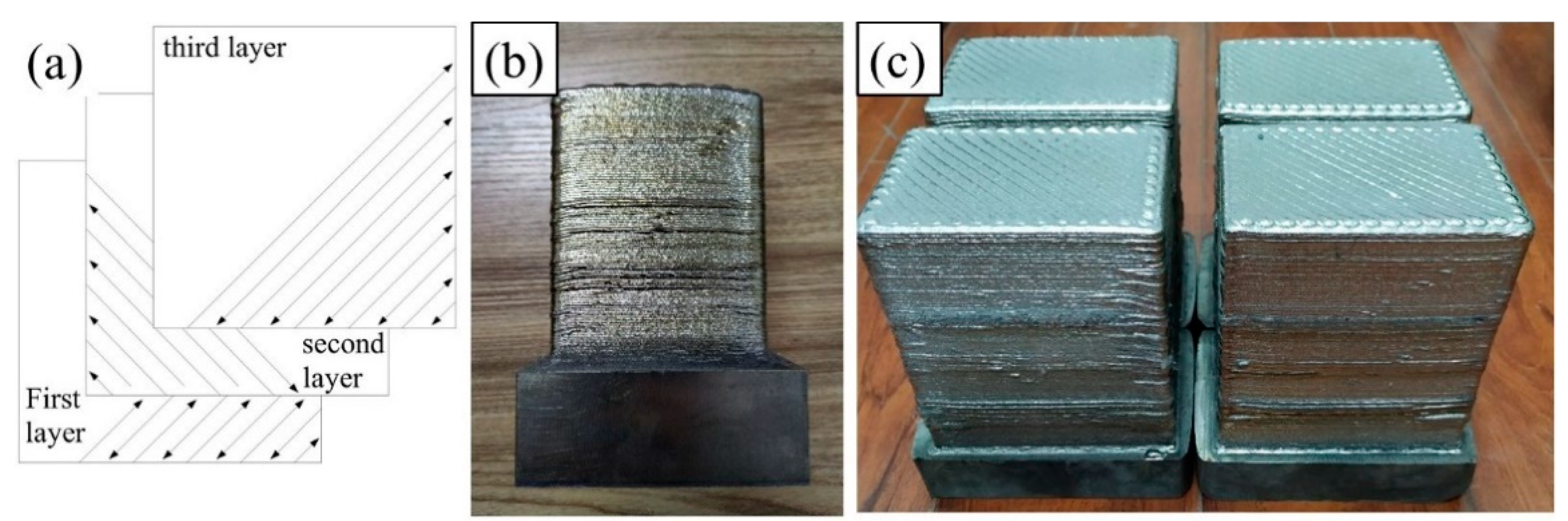

2. Experimental Material and Methods

2.1. Manufacturing Procedures

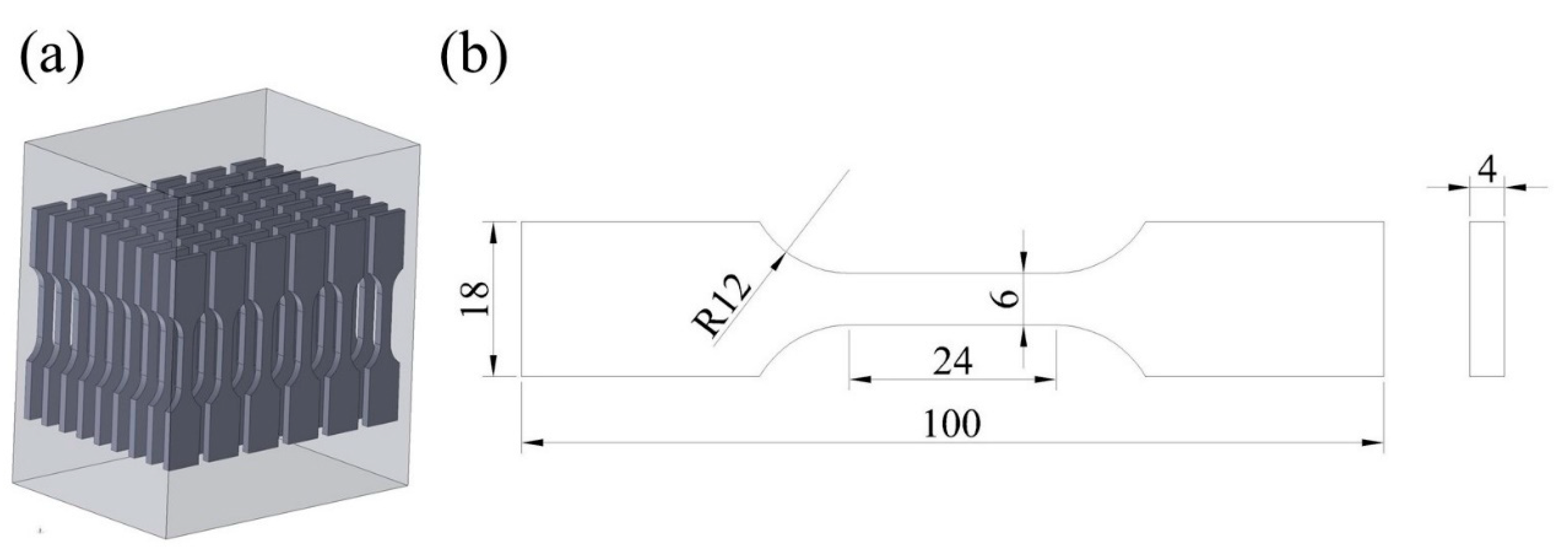

2.2. Microstructure Characterization, Tensile Testing and Fatigue Testing

3. Results and Discussion

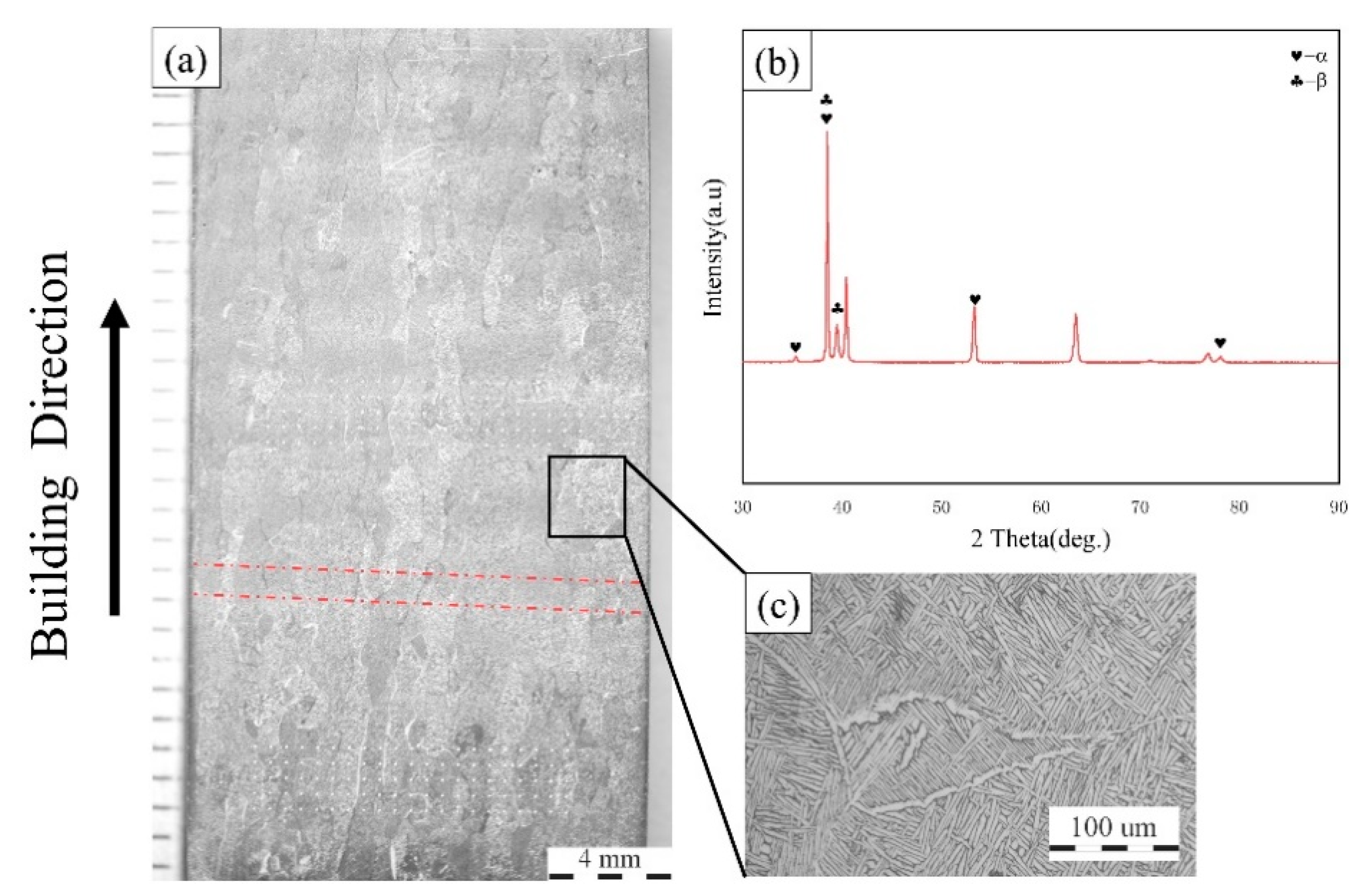

3.1. Microstructure Characterization and Tensile Testing

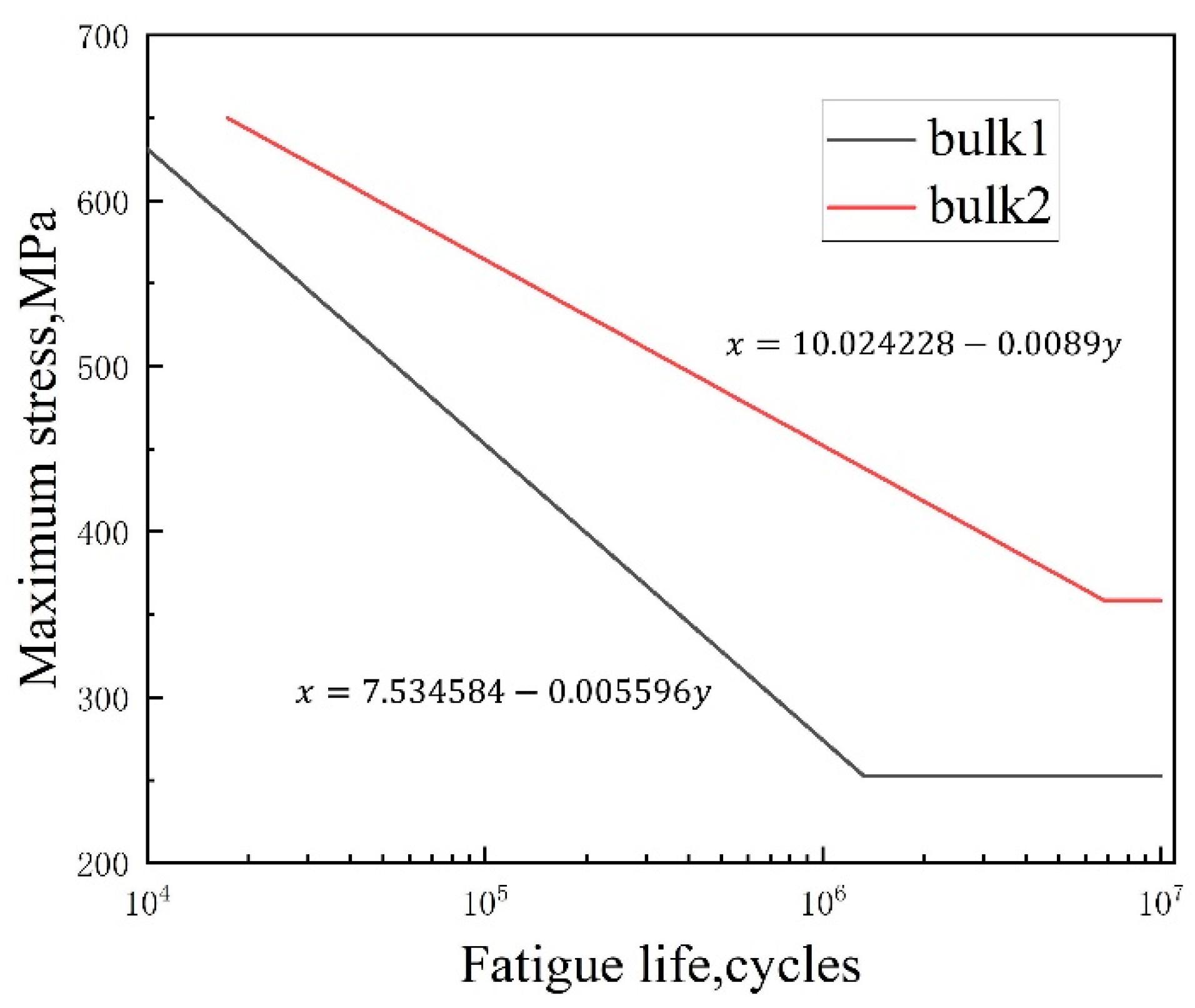

3.2. High Cycle Fatigue Testing

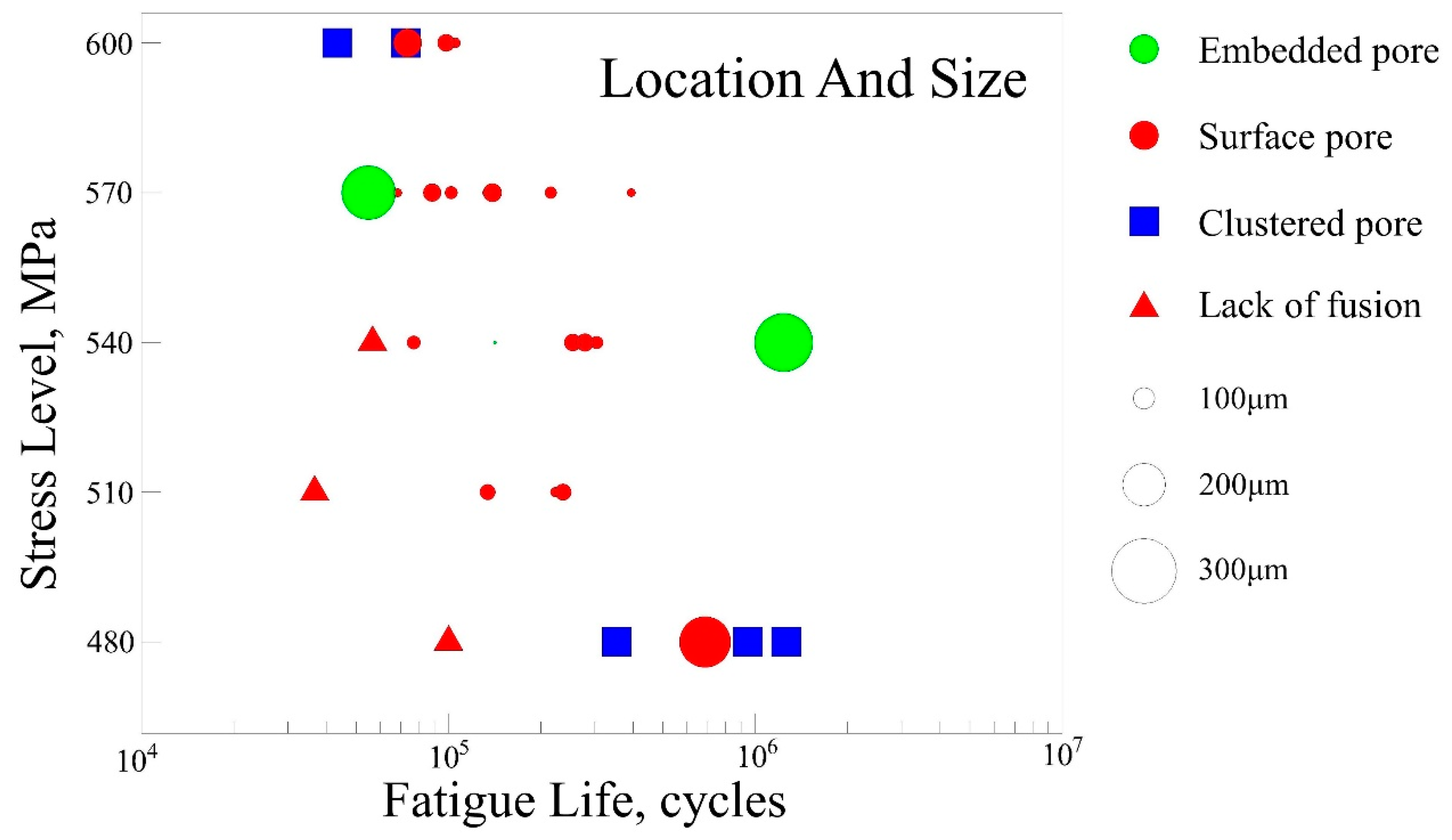

3.2.1. The Effect of Porosity Population

3.2.2. The Effect of Lack of Fusion

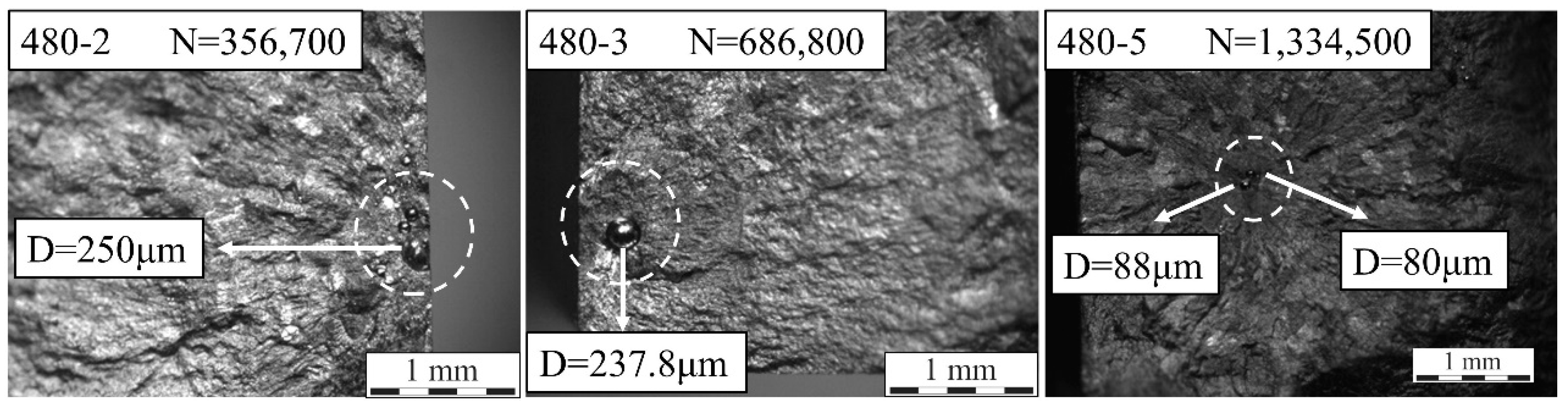

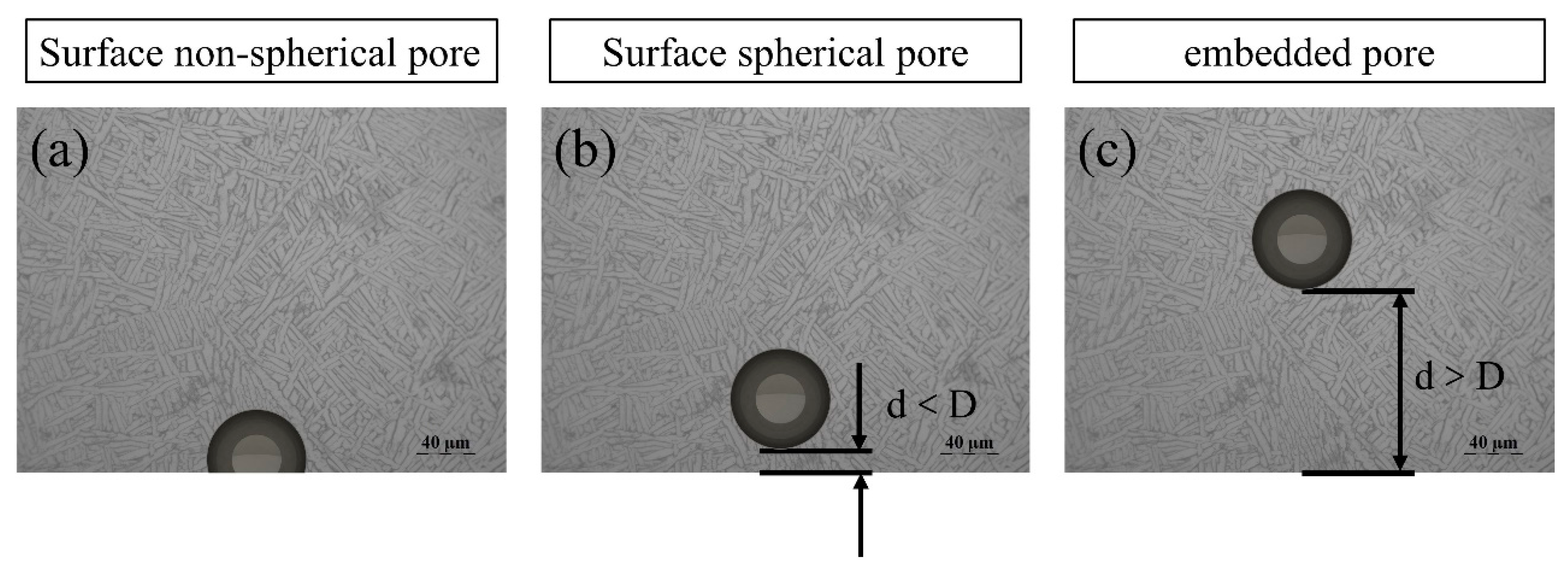

3.2.3. The Effect of Spherical Pores

3.2.4. Discussion

4. Conclusions

- (1)

- The microstructure feature of HP-DED fabricated Ti6Al4V is similar to the other AM technologies, which mainly consist of basket-weave microstructure and an colony within elongated prior β columnar grains.

- (2)

- The porosity of the as-build part using contaminated powder is extremely large, which consequently leads to an inferior HCF performance compared with parts fabricated with original powder. The HCF performance of both bulks is far from its wrought counterpart.

- (3)

- The fatigue strength of the Ti6Al4V part fabricated with original powder is approximately 358.57 MPa. Lack of fusion, spherical pores and un-melted particles are the main porosity defects in the HP-DED fabricated Ti6Al4V part.

- (4)

- The high-power laser will increase the instability of the molten pool and key-hole, which further leads to a higher porosity in the as-build part. Future research will concentrate on the processing monitoring and closed-loop controlling of the HP-DED process. In addition, feasible measures should be proposed to reduce the porosity in the as-build part of the HP-DED process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, R.D.; Yu, H.C. Effects of Building Orientation on Fatigue Behavior of Ti-6Al-4V Alloy Produced by Selective Laser Melting. Key Eng. Mater. 2019, 795, 208–214. [Google Scholar] [CrossRef]

- Azarniya, A.; Colera, X.G.; Mirzaali, M.J.; Sovizi, S.; Bartolomeu, F.; Weglowski, M.K.S.; Wits, W.W.; Yap, C.Y.; Ahn, J.; Miranda, G.; et al. Additive manufacturing of Ti–6Al–4V parts through laser metal deposition (LMD): Process, microstructure, and mechanical properties. J. Alloy. Comp. 2019, 804, 163–191. [Google Scholar] [CrossRef]

- Ren, Y.; Lin, X.; Jian, Z.; Peng, H.; Huang, W. Long fatigue crack growth behavior of Ti–6Al–4V produced via high-power laser directed energy deposition. Mater. Sci. Eng. A 2021, 819, 141392. [Google Scholar] [CrossRef]

- Ren, Y.M.; Lin, X.; Guo, P.F.; Yang, H.O.; Tan, H.; Chen, J.; Li, J.; Zhang, Y.Y.; Huang, W.D. Low cycle fatigue properties of Ti-6Al-4V alloy fabricated by high-power laser directed energy deposition: Experimental and prediction. Int. J. Fatigue 2019, 127, 58–73. [Google Scholar] [CrossRef]

- Ren, Y.M.; Lin, X.; Yang, H.O.; Tan, H.; Chen, J.; Jian, Z.Y.; Li, J.Q.; Huang, W.D. Microstructural features of Ti-6Al-4V manufactured via high power laser directed energy deposition under low-cycle fatigue. J. Mater. Sci. Technol. 2021, 83, 18–33. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, R.; Cheng, X.; Zhu, Y.; Zhang, J.; Wang, H. Effects of microstructure on fatigue crack propagation behavior in a bi-modal TC11 titanium alloy fabricated via laser additive manufacturing. J. Mater. Sci. Technol. 2019, 35, 403–408. [Google Scholar] [CrossRef]

- Brandl, E.; Schoberth, A.; Leyens, C. Morphology, microstructure, and hardness of titanium (Ti-6Al-4V) blocks deposited by wire-feed additive layer manufacturing (ALM). Mater. Sci. Eng. A 2012, 532, 295–307. [Google Scholar] [CrossRef]

- Brandl, E.; Palm, F.; Michailov, V.; Viehweger, B.; Leyens, C. Mechanical properties of additive manufactured titanium (Ti–6Al–4V) blocks deposited by a solid-state laser and wire. Mater. Des. 2011, 32, 4665–4675. [Google Scholar] [CrossRef]

- Tshephe, T.S.; Akinwamide, S.O.; Olevsky, E.; Olubambi, P.A. Additive manufacturing of titanium-based alloys-A review of methods, properties, challenges, and prospects. Heliyon 2022, 8, e09041. [Google Scholar] [CrossRef]

- Li, E.; Zhou, Z.; Wang, L.; Shen, H.; Zou, R.; Yu, A. Particle scale modelling of melt pool dynamics and pore formation in selective laser melting additive manufacturing. Powder Technol. 2022, 397, 117012. [Google Scholar] [CrossRef]

- Akgun, E.; Zhang, X.; Biswal, R.; Zhang, Y.; Doré, M. Fatigue of wire+arc additive manufactured Ti-6Al-4V in presence of process-induced porosity defects. Int. J. Fatigue 2021, 150, 106315. [Google Scholar] [CrossRef]

- Biswal, R.; Zhang, X.; Syed, A.K.; Awd, M.; Ding, J.; Walther, F.; Williams, S. Criticality of porosity defects on the fatigue performance of wire + arc additive manufactured titanium alloy. Int. J. Fatigue 2019, 122, 208–217. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.N.; Wu, S.C.; Wu, Z.K.; Zhong, X.L.; Ahmed, S.; Karabal, S.; Xiao, X.H.; Zhang, H.O.; Withers, P.J. A new approach to correlate the defect population with the fatigue life of selective laser melted Ti-6Al-4V alloy. Int. J. Fatigue 2020, 136, 105584. [Google Scholar] [CrossRef]

- Li, W.B.; Pang, J.C.; Zhang, H.; Li, S.X.; Zhang, Z.F. The high-cycle fatigue properties of selective laser melted Inconel 718at room and elevated temperatures. Mater. Sci. Eng. A 2022, 836, 142716. [Google Scholar] [CrossRef]

- Liu, F.; He, C.; Chen, Y.; Zhang, H.; Wang, Q.; Liu, Y. Effects of defects on tensile and fatigue behaviors of selective laser melted titanium alloy in very high cycle regime. Int. J. Fatigue 2020, 140, 105795. [Google Scholar] [CrossRef]

- Deng, K.; Wei, H.; Liu, W.; Zhang, M.; Zhao, P.; Zhang, Y. Probabilistic-based random maximum defect estimation and defect-related fatigue life prediction for laser direct deposited 316L parts. J. Mater. Process. Technol. 2022, 299, 117389. [Google Scholar] [CrossRef]

- Tang, D.; He, X.; Wu, B.; Wang, X.; Wang, T.; Li, Y. The effect of porosity defects on the mid-cycle fatigue behavior of directed energy deposited Ti-6Al-4V. Theor. Appl. Fract. Mech. 2022, 119, 103322. [Google Scholar] [CrossRef]

- Biswal, R.; Syed, A.K.; Zhang, X. Assessment of the effect of isolated porosity defects on the fatigue performance of additive manufactured titanium alloy. Addit. Manuf. 2018, 23, 433–442. [Google Scholar] [CrossRef]

- Luo, Y.W.; Zhang, B.; Feng, X.; Song, Z.M.; Qi, X.B.; Li, C.P.; Chen, G.F.; Zhang, G.P. Pore-affected fatigue life scattering and prediction of additively manufactured Inconel 718: An investigation based on miniature specimen testing and machine learning approach. Mater. Sci. Eng. A 2021, 802, 140693. [Google Scholar] [CrossRef]

- Zhan, Z.; Hu, W.; Meng, Q. Data-driven fatigue life prediction in additive manufactured titanium alloy: A damage mechanics based machine learning framework. Eng. Fract. Mech. 2021, 252, 107850. [Google Scholar] [CrossRef]

- Gerhard, W.; Boyer, R.R.; Collings, E.W. Materials Properties Handbook: Titanium Alloys; ASM International: Almere, The Netherlands, 1994. [Google Scholar]

- Wang, X.; Meng, Q.; Hu, W. Continuum damage mechanics-based model for the fatigue analysis of welded joints considering the effects of size and position of inner pores. Int. J. Fatigue 2020, 139, 105749. [Google Scholar] [CrossRef]

- Wu, Z.; Kou, H.; Chen, N.; Zhang, Z.; Qiang, F.; Fan, J.; Tang, B.; Li, J. Microstructural influences on the high cycle fatigue life dispersion and damage mechanism in a metastable β titanium alloy. J. Mater. Sci. Technol. 2021, 70, 12–23. [Google Scholar] [CrossRef]

- Zhan, Z.; Ao, N.; Hu, Y.; Liu, C. Defect-induced fatigue scattering and assessment of additively manufactured 300M-AerMet100 steel: An investigation based on experiments and machine learning. Eng. Fract. Mech. 2022, 264, 108352. [Google Scholar] [CrossRef]

- Rans, C.; Michielssen, J.; Walker, M.; Wang, W.; Hoen-Velterop, L.T. Beyond the orthogonal: On the influence of build orientation on fatigue crack growth in SLM Ti-6Al-4V. Int. J. Fatigue 2018, 116, 344–354. [Google Scholar] [CrossRef]

- Ferro, P.; Fabrizi, A.; Berto, F.; Savio, G.; Meneghello, R.; Rosso, S. Defects as a root cause of fatigue weakening of additively manufactured AlSi10Mg components. Theor. Appl. Fract. Mech. 2020, 108, 102611. [Google Scholar] [CrossRef]

- Pineau, A.; Antolovich, S.D. Probabilistic approaches to fatigue with special emphasis on initiation from inclusions. Int. J. Fatigue 2016, 93, 422–434. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, M.; Wang, B.; Tan, X.; Wu, W.J.; Liu, Y.; Bi, G.J.; Tor, S.B.; Liu, E. Influence of surface porosity on fatigue life of additively manufactured ASTM A131 EH36 steel. Int. J. Fatigue 2021, 142, 105894. [Google Scholar] [CrossRef]

| Element | C | O | N | H | Al | V | Fe | Ti |

|---|---|---|---|---|---|---|---|---|

| Content | 0.005 | 0.062 | 0.006 | 0.0028 | 6.11 | 3.97 | 0.194 | Bal. |

| Laser Power (W) | Scanning Speed (mm/min) | Powder Feeding Rate (g/min) | Layer Thickness (mm) | Overlapping Ratio |

|---|---|---|---|---|

| 4000 | 1200 (inner hatching) 800 (Contour scanning) | 31 | 0.9 | 50% |

| Element | Contaminated Powder | Original Powder |

|---|---|---|

| Oxygen | 0.10464% | 0.02421% |

| Nitrogen | 0.00785% | 0.00188% |

| State | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Bulk1 | 1033.33 | 951.67 | 6.74 |

| Bulk2 | 933.76 | 825.67 | 9.99 |

| Mean Value of Fatigue Strength | Standard Deviation | |

|---|---|---|

| Bulk1 | 252.5 MPa | 64.2573 MPa |

| Bulk2 | 358.57 MPa | 8.87 MPa |

| Specimen No. | Maximum Defect Length (mm) | Stress Level (MPa) | Fatigue Life (N) |

|---|---|---|---|

| LOF1 | 1.83 mm | 380 | 3800 |

| LOF2 | 0.6 mm | 510 | 37,100 |

| LOF3 | 0.4 mm | 480 | 100,200 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, H.; Zhang, Z.; Li, J.; Liu, Y.; Chen, H.; He, H.; Cheng, J.; Chen, Y. The Effect of Process-Induced Porosity on Fatigue Properties of Ti6Al4V Alloy via High-Power Direct Energy Deposition. Coatings 2022, 12, 822. https://doi.org/10.3390/coatings12060822

Lv H, Zhang Z, Li J, Liu Y, Chen H, He H, Cheng J, Chen Y. The Effect of Process-Induced Porosity on Fatigue Properties of Ti6Al4V Alloy via High-Power Direct Energy Deposition. Coatings. 2022; 12(6):822. https://doi.org/10.3390/coatings12060822

Chicago/Turabian StyleLv, Hang, Zhenlin Zhang, Junjie Li, Yan Liu, Hui Chen, Huabing He, Jing Cheng, and Yong Chen. 2022. "The Effect of Process-Induced Porosity on Fatigue Properties of Ti6Al4V Alloy via High-Power Direct Energy Deposition" Coatings 12, no. 6: 822. https://doi.org/10.3390/coatings12060822

APA StyleLv, H., Zhang, Z., Li, J., Liu, Y., Chen, H., He, H., Cheng, J., & Chen, Y. (2022). The Effect of Process-Induced Porosity on Fatigue Properties of Ti6Al4V Alloy via High-Power Direct Energy Deposition. Coatings, 12(6), 822. https://doi.org/10.3390/coatings12060822