Comparative Investigation on Wear Properties of Composite Coatings with Varying CeO2 Contents

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Laser Cladding

2.2. Hardness and Wear Resistance Testing

3. Results and Discussion

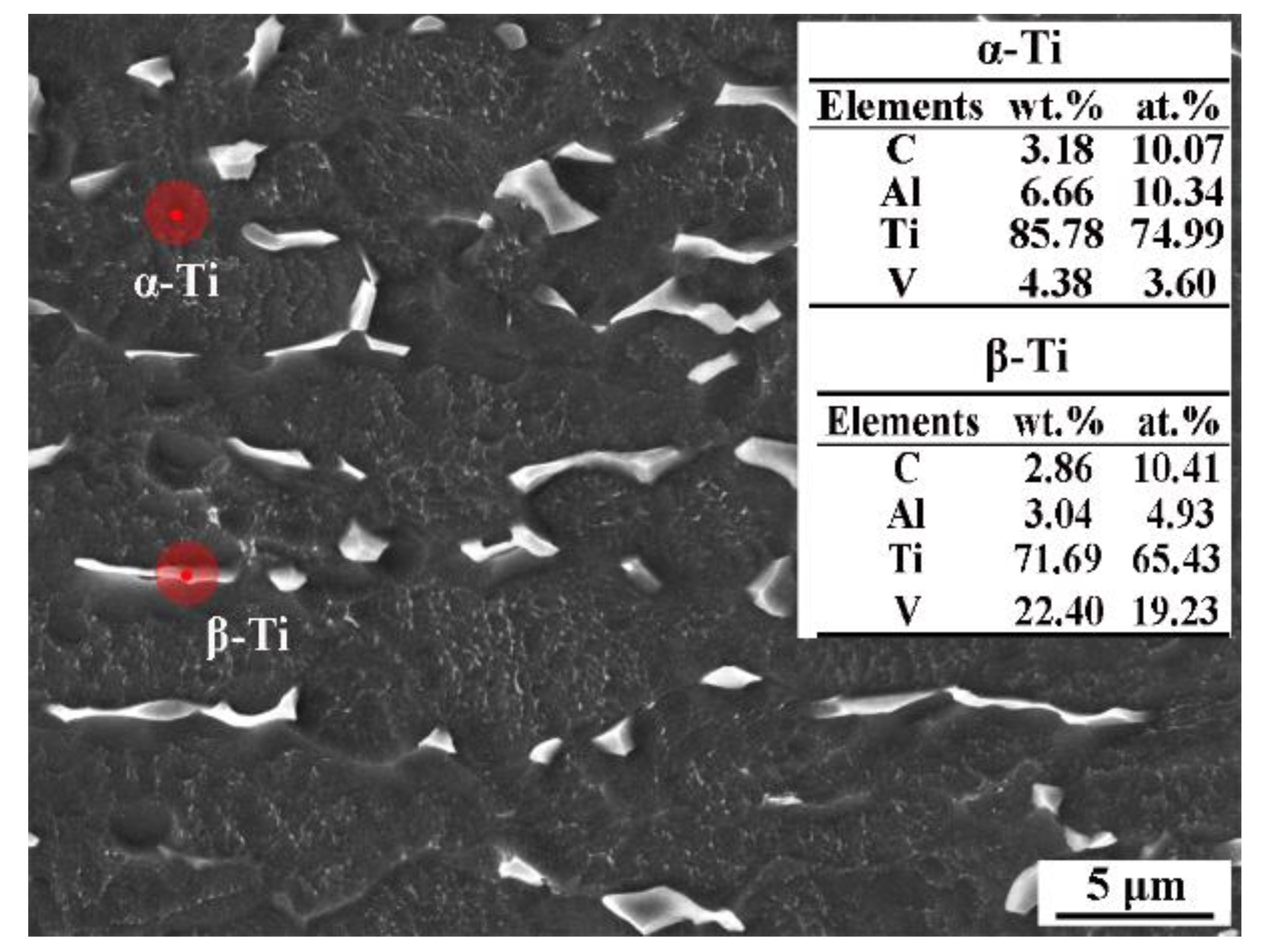

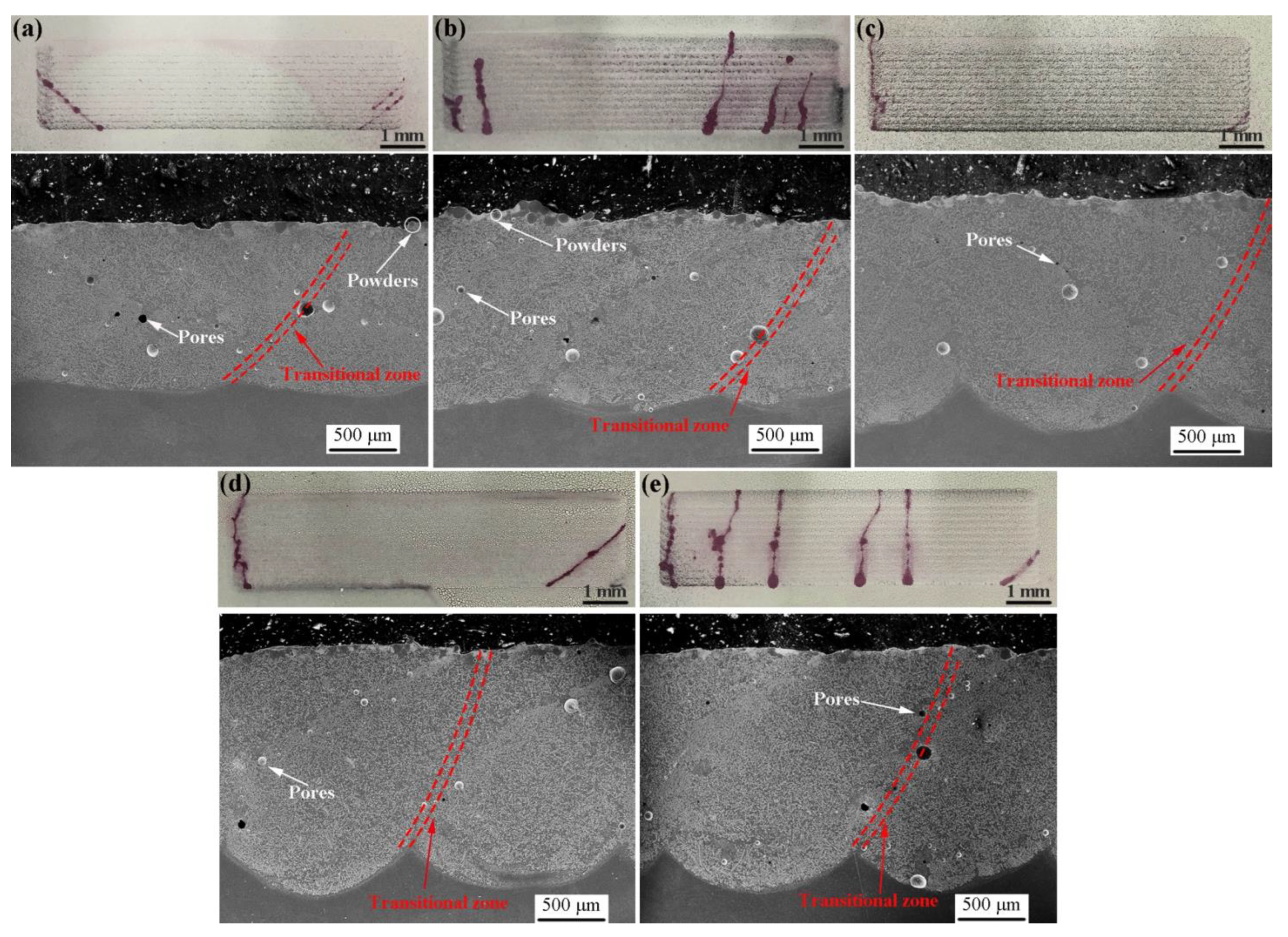

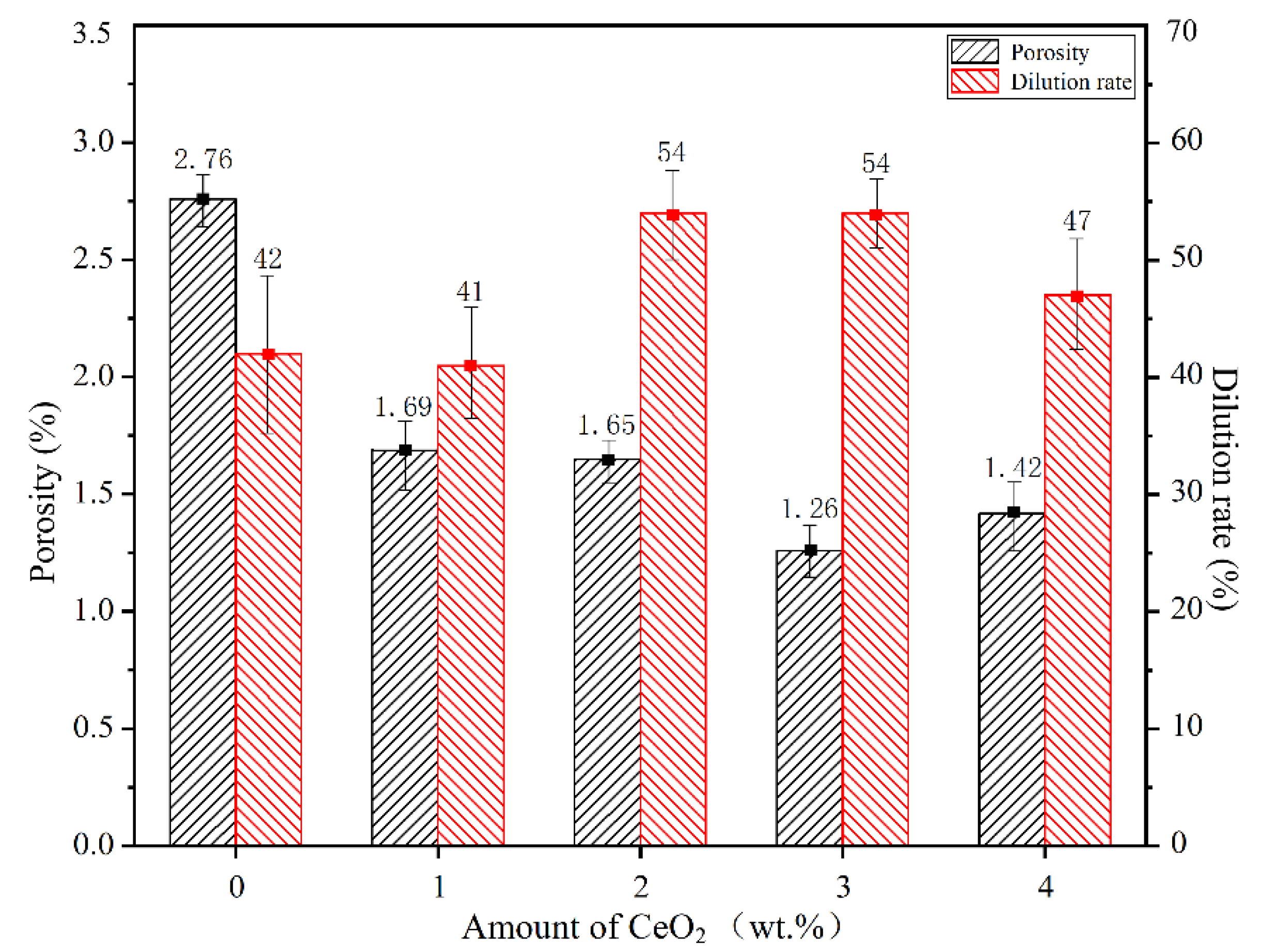

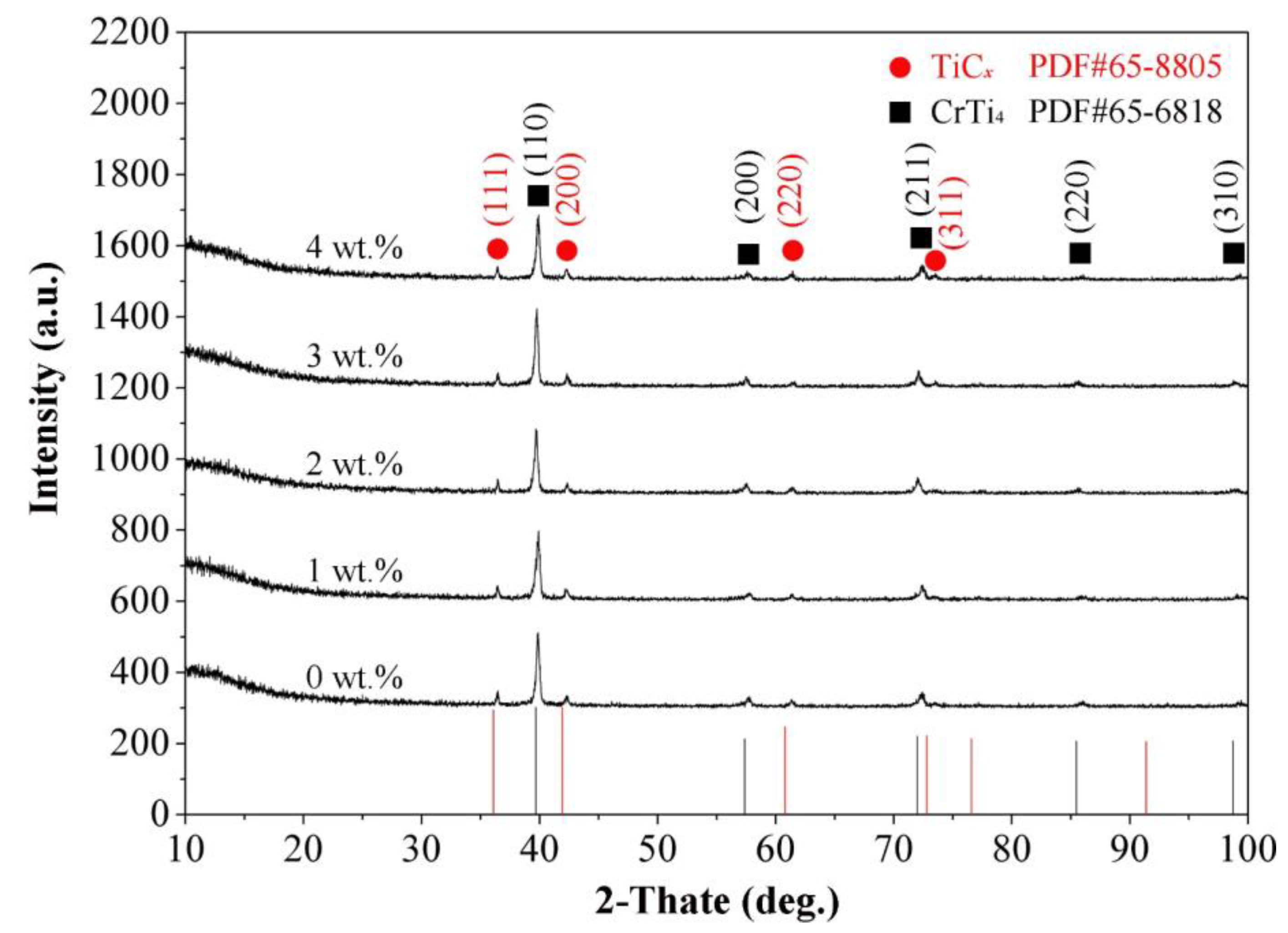

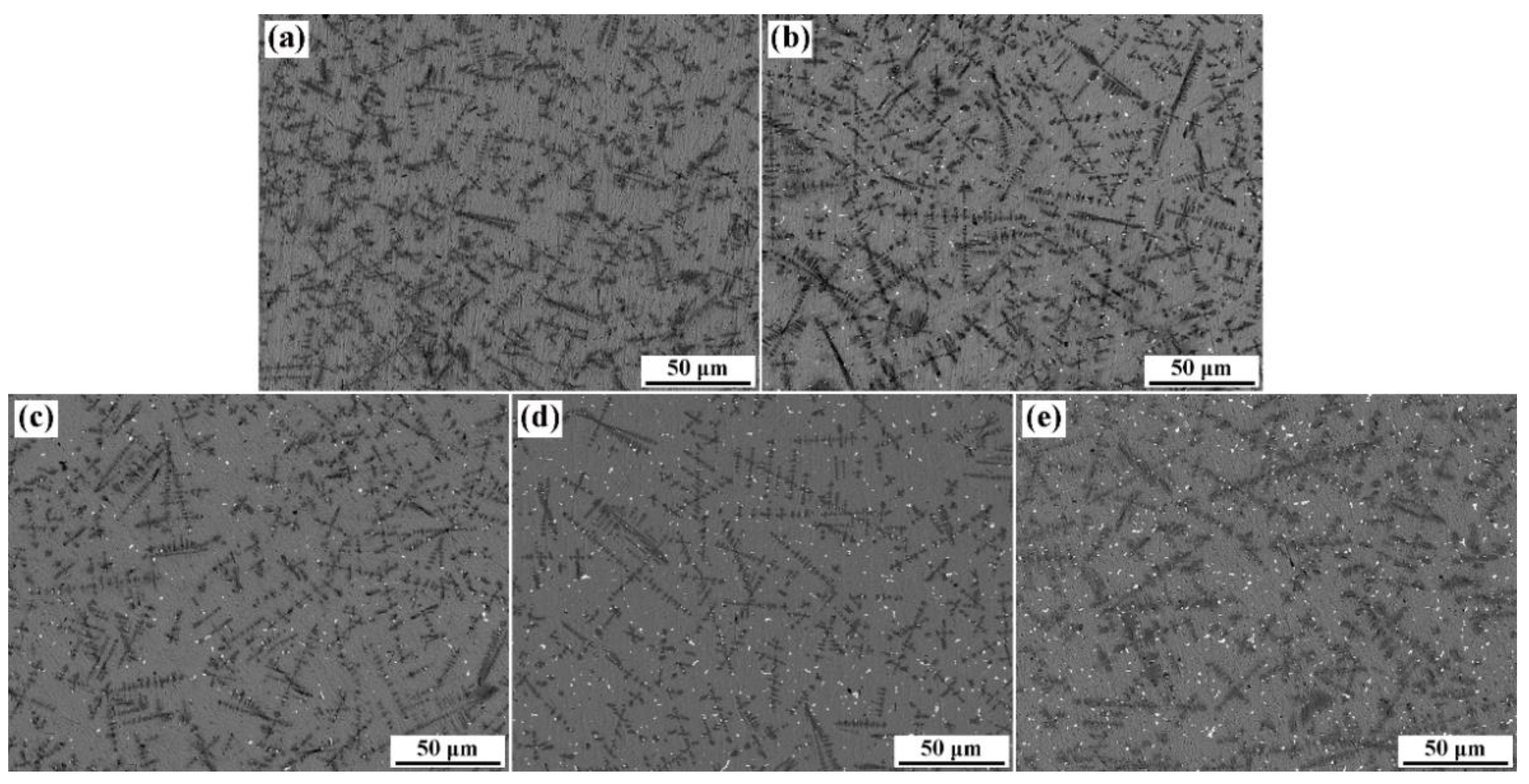

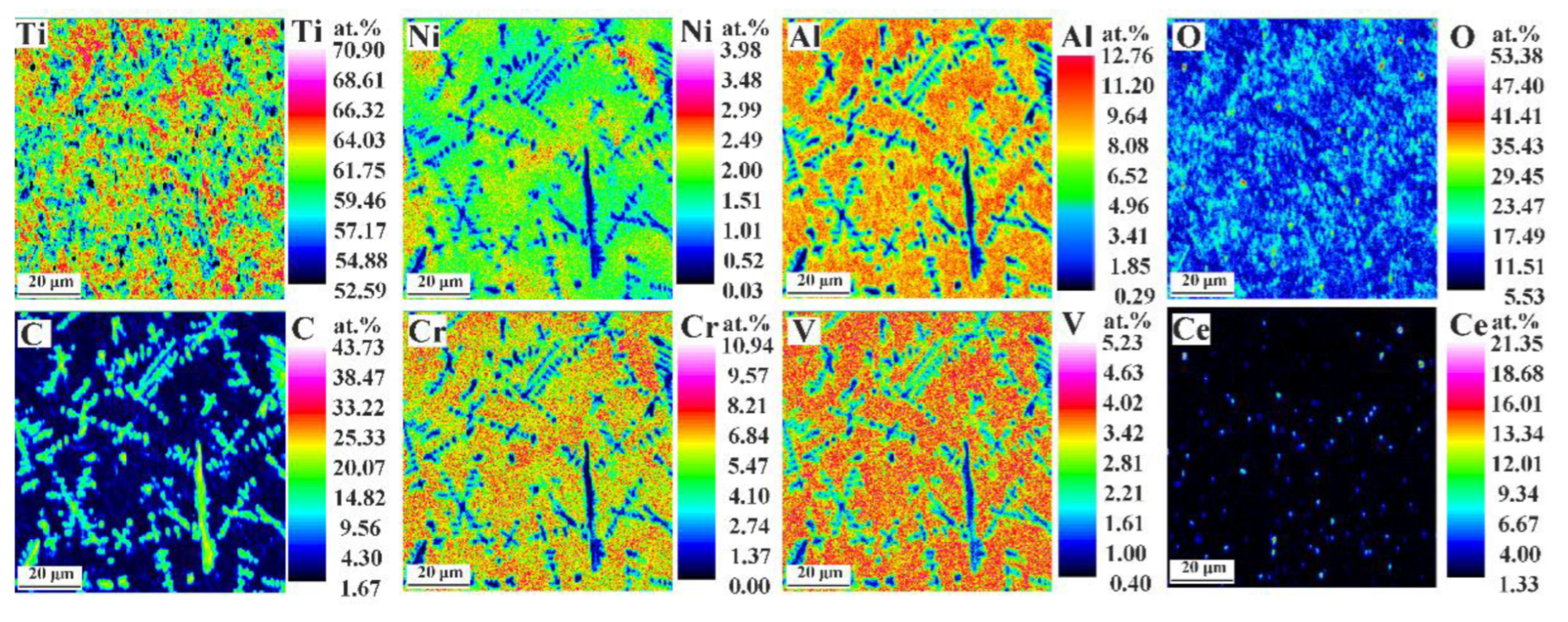

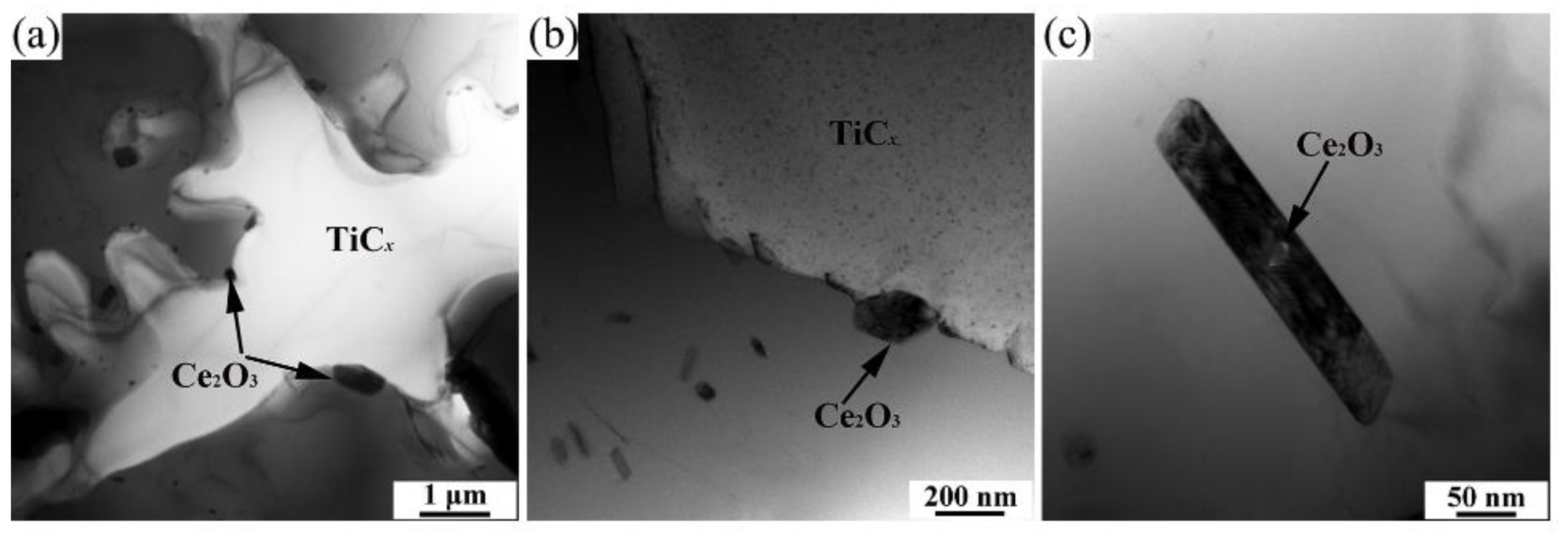

3.1. Microstructure

3.2. Hardness and Tribological Performance

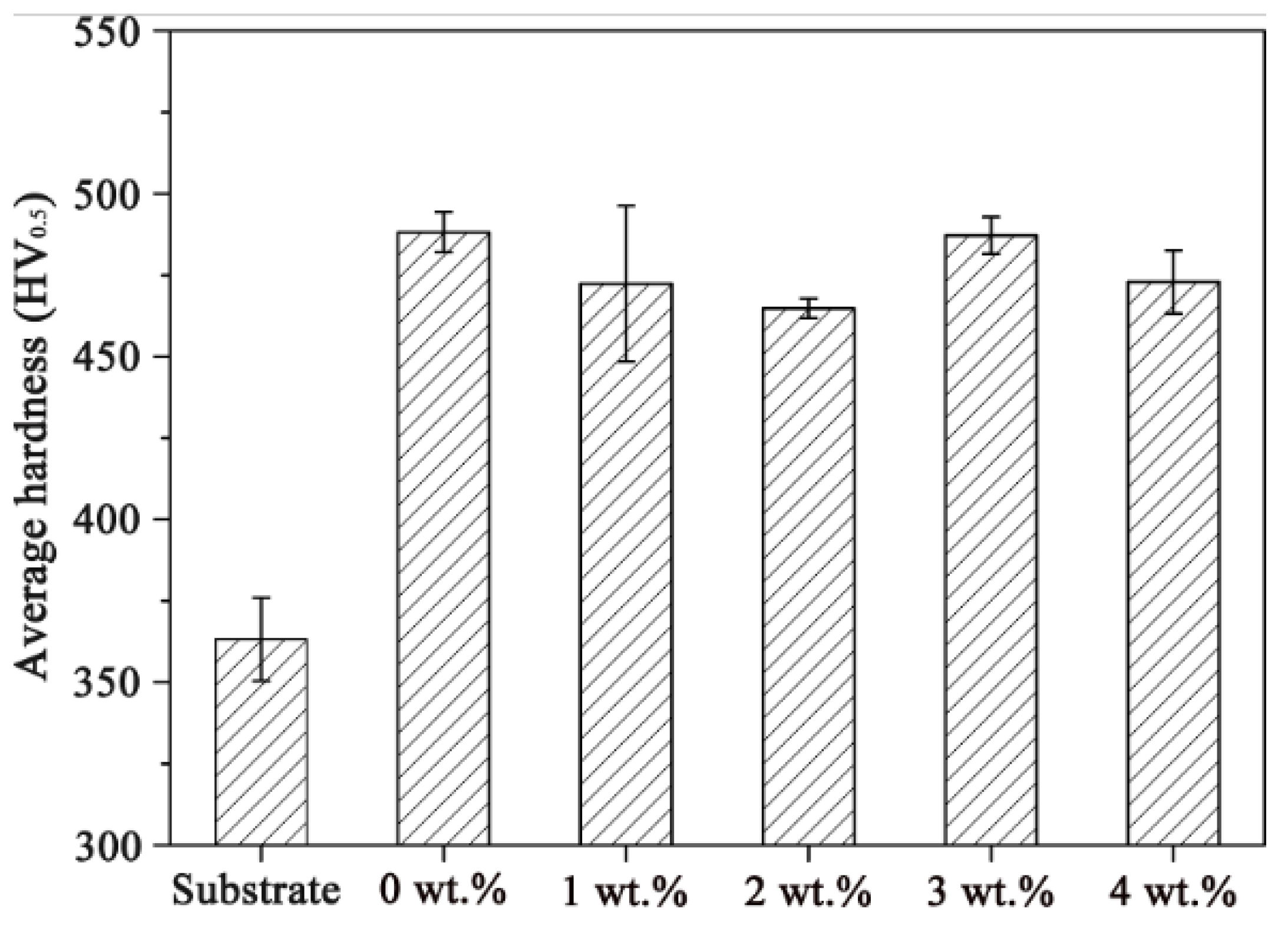

3.2.1. Microhardness

3.2.2. Friction Coefficient

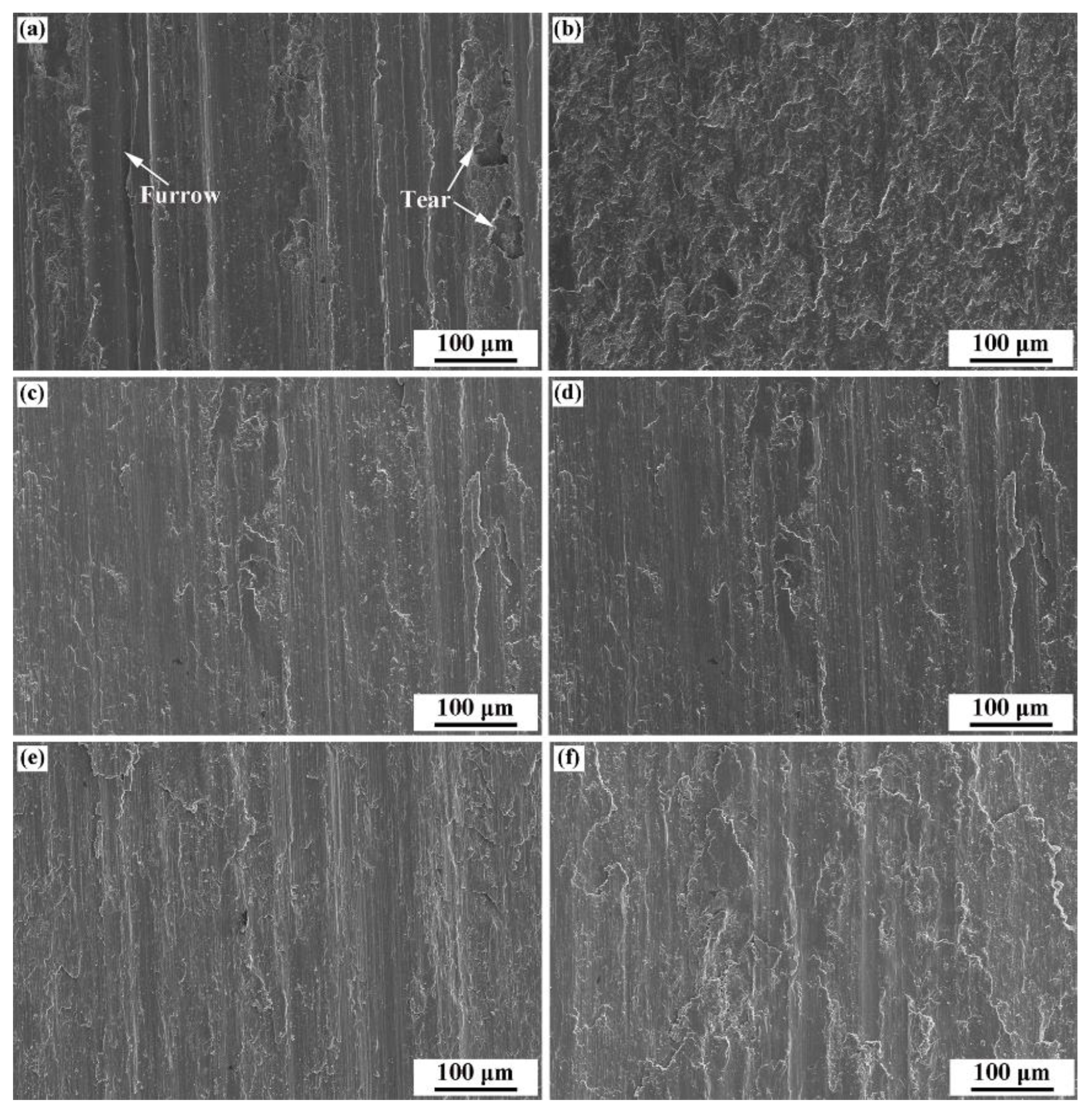

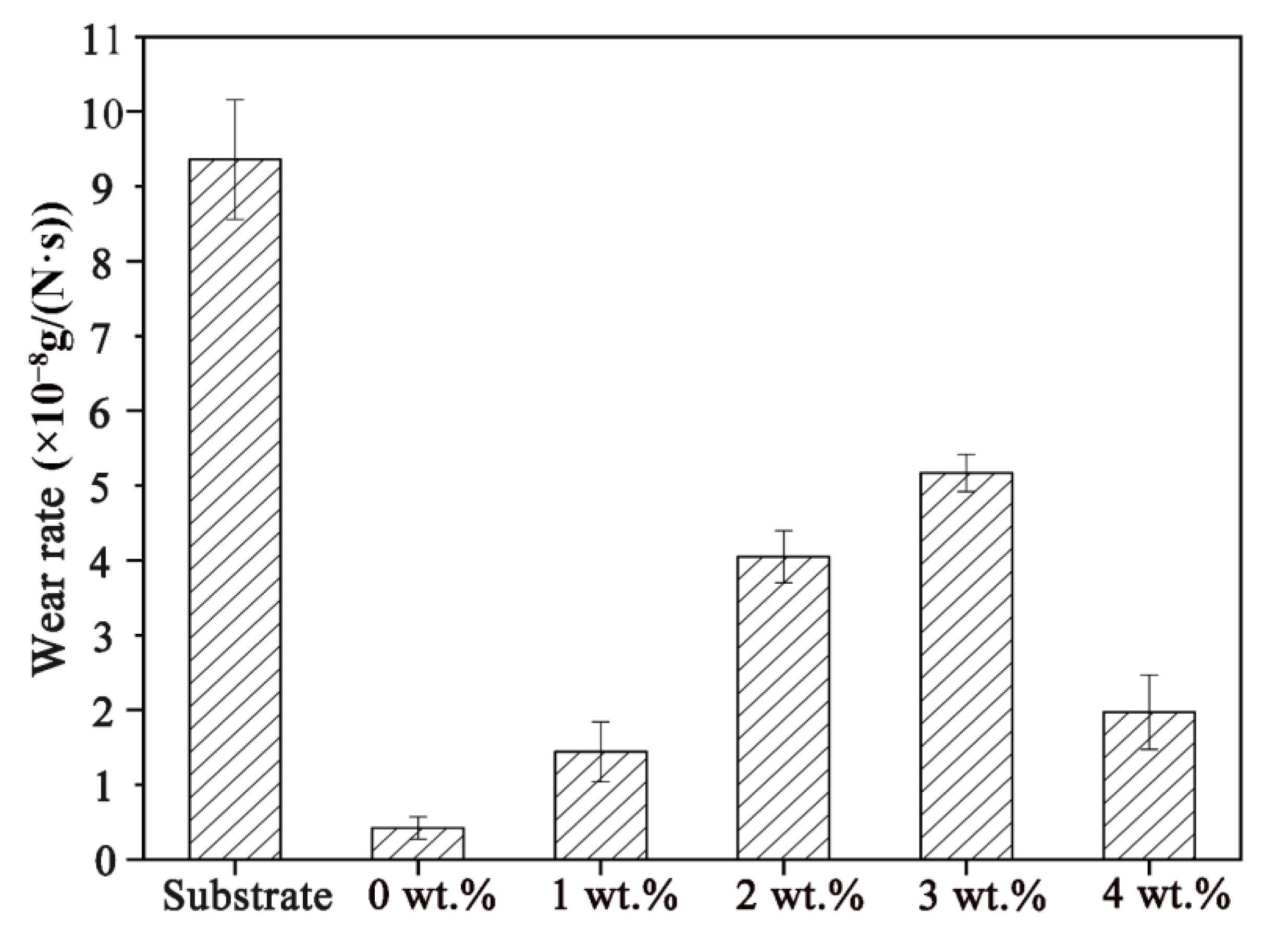

3.2.3. Wear Morphology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, H.; Shi, X.; Lu, G.; Chen, Y.; Yang, Z.; Wu, C.; Xue, Y.; Ahmed, M. Friction and wear behaviors of TC4 alloy with surface microporous channels filled by Sn-Ag-Cu and Al2O3 nanoparticles. Surf. Coat. Technol. 2020, 387, 125552. [Google Scholar] [CrossRef]

- Nuno, C.; Gil, J.; Punset, M.; Manero, J.M.; JTondela, P.; Verdeguer, P.; Aparicio, C.; Rúperez, E. Relevant aspects of piranha passivation in Ti6Al4V alloy dental meshes. Coatings 2022, 12, 154. [Google Scholar]

- Qin, Y.K.; Xiong, D.S.; Li, J.L.; Tyagi, R. Compositions and tribological properties of PEO coatings on Ti6Al4V alloy. Surf. Eng. 2017, 33, 895–902. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, X.B.; Liu, Y.F.; Wang, G.; Meng, Y.; Liang, J. Development and characterization of Co-Cu/Ti3SiC2 self-lubricating wear resistant composite coatings on Ti6Al4V alloy by laser cladding. Surf. Coat. Technol. 2021, 424, 127664. [Google Scholar] [CrossRef]

- Ochonogor, O.; Meacock, C.; Abdulwahab, M.; Pityana, S.; Popoola, A. Effects of Ti and TiC ceramic powder on laser-cladded Ti-6Al-4V in situ intermetallic composite. Appl. Surf. Sci. 2012, 263, 591–596. [Google Scholar] [CrossRef]

- Qi, C.; Zhan, X.; Gao, Q.; Liu, L.; Song, Y.; Li, Y. The influence of the pre-placed powder layers on the morphology, microscopic characteristics and microhardness of Ti-6Al-4V/WC MMC coatings during laser cladding. Opt. Laser Technol. 2019, 119, 105572. [Google Scholar] [CrossRef]

- Anand, A.; Das, M.; Kundu, B.; Krishna Balla, V.; Bodhak, S.; Gangadharan, S. Plasma-sprayed Ti6Al4V alloy composite coatings reinforced with in situ formed TiB-TiN. J Therm. Spray Technol. 2017, 26, 2013–2019. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, J.; He, G.; Yang, G. Fatigue and mechanical behavior of Ti-6Al-4V alloy with CrN and TiN coating deposited by magnetic filtered cathodic vacuum arc process. Coatings 2019, 9, 689. [Google Scholar] [CrossRef] [Green Version]

- Fei, W.; Yu, H.; Chen, C.; Liu, J.; Dai, J. Effect of process parameters on the microstructure evolution and wear property of the laser cladding coatings on Ti-6Al-4V alloy. J. Alloys Compd. 2016, 692, 989–996. [Google Scholar]

- Wang, J.; Li, C.; Zeng, M.; Guo, Y.; Wang, Y. Microstructural evolution and wear behaviors of NbC-reinforced Ti-based composite coating. Int. J. Adv. Manuf. Technol. 2020, 107, 2397–2407. [Google Scholar] [CrossRef]

- Qu, C.; Li, J.; Bai, L.; Shao, J.; Song, R.; Chen, J. Effects of the thickness of the pre-placed layer on microstructural evolution and mechanical properties of the laser-clad coatings. J. Alloys Compd. 2015, 644, 450–463. [Google Scholar] [CrossRef]

- Yang, M.; Liu, X.; Fan, J.; He, X.; Shi, S.; Fu, G.; Wang, M.; Chen, S. Microstructure and wear behaviors of laser clad NiCr/Cr3C2–WS2 high temperature self-lubricating wear-resistant composite coating. Appl. Surf. Sci. 2012, 258, 3757–3762. [Google Scholar] [CrossRef]

- Mohseni, E.; Zalnezhad, E.; Bushroa, A. Comparative investigation on the adhesion of hydroxyapatite coating on Ti–6Al–4V implant: A review paper. Int. J. Adhes. Adhes. 2014, 48, 238–257. [Google Scholar] [CrossRef]

- Fan, H.; Liu, H.; Ren, J.; Meng, X.; Liu, X. Microstructural characteristics and wear properties of NiCr/Cr3C2-WS2 self-lubricant wear-resistant composite coating on Ti6Al4V by laser cladding. Appl. Mech. Mater. 2013, 395–396, 814–817. [Google Scholar] [CrossRef]

- Aghili, S.; Shamanian, M.; Najafabadi, R.; Keshavarzkermani, A.; Esmaeilizadeh, R.; Ali, U.; Marzbanrad, E.; Toyserkani, E. Microstructure and oxidation behavior of NiCr-chromium carbides coating prepared by powder-fed laser cladding on titanium aluminide substrate. Ceram. Int. 2020, 46, 1668–1679. [Google Scholar] [CrossRef]

- Quazi, M.; Fazal, M.; Haseeb, A.; Yusof, F.; Masjuki, H.; Arslan, A. Effect of rare earth elements and their oxides on tribo-mechanical performance of laser claddings: A review. J. Rare Earth 2016, 34, 549–564. [Google Scholar] [CrossRef]

- Zhang, T.; Xiao, H.; Zhang, Z.; Yao, B.; Yang, F. Effect of Y2O3 addition on microstructural characteristics and microhardness of laser-cladded Ti6Al4V alloy coating. J. Mater. Eng. Perform. 2020, 29, 8221–8235. [Google Scholar] [CrossRef]

- Sharma, S.; Dwivedi, D.; Jain, P. Effect of La2O3 addition on the microstructure, hardness and abrasive wear behavior of flame sprayed Ni based coatings. Wear 2009, 267, 853–859. [Google Scholar] [CrossRef]

- Zhang, S.; Li, M.; Cho, T.; Yoon, J.; Lee, C.; He, Y. Laser clad Ni-base alloy added nano- and micron-size CeO2 composites. Opt. Laser Technol. 2008, 40, 716–722. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, F.; Zhang, H.; Zhang, T.; Wang, H.; Xu, Y.; Ma, Q. Influence of CeO2 addition on forming quality and microstructure of TiCx-reinforced CrTi4-based laser cladding composite coating. Mater. Charact. 2020, 171, 110732. [Google Scholar] [CrossRef]

- Xie, Z.; Deng, Y.; Yang, Y.; Su, H.; Zhou, D.; Liu, C.; Yang, W. Preparation of nano-sized titanium carbide particles via a vacuum carbothermal reduction approach coupled with purification under hydrogen/argon mixed gas. RSC Adv. 2017, 7, 9037–9044. [Google Scholar] [CrossRef] [Green Version]

- Vasanthakumar, K.; Karthiselva, N.; Chawake, N.; Bakshi, S. Formation of TiCx during reactive spark plasma sintering of mechanically milled Ti/carbon nanotube mixtures. J. Alloys Compd. 2017, 709, 829–841. [Google Scholar] [CrossRef]

- Sun, S.; Fu, H.; Ping, X.; Guo, X.; Lin, J.; Lei, Y.; Wu, W.; Zhou, J. Effect of CeO2 addition on microstructure and mechanical properties of in-situ (Ti, Nb)C/Ni coating. Surf. Coat. Technol. 2019, 359, 300–313. [Google Scholar] [CrossRef]

- Sumitomo, T.; Aizawa, T.; Yamamoto, S. In-situ formation of self-lubricating tribo-films for dry machinability. Surf. Coat. Technol. 2005, 200, 1797–1803. [Google Scholar] [CrossRef]

- Gurappa, I. Protection of titanium alloy components against high temperature corrosion. Mater. Sci. Eng. A 2003, 356, 372–380. [Google Scholar] [CrossRef]

- Deshmukh, V.; Kadam, R.; Joshi, S. Removal of alpha case on titanium alloy surfaces using chemical milling. Mach. Sci. Technol. 2017, 21, 257–278. [Google Scholar] [CrossRef]

- Voitovich, B. Mechanism of the High Temperature Oxidation of Titanium Carbide. High Temp. Mat. PR-ISR 1997, 16, 243–254. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, C.; Chen, L.; Huo, Q. Effect of RE oxides on the microstructure of the coatings fabricated on titanium alloys by laser alloying technique. Scripta Mater. 2006, 54, 847–852. [Google Scholar] [CrossRef]

- Ding, L.; Hu, S. Effect of nano-CeO2 on microstructure and wear resistance of Co-based coatings. Surf. Coat. Technol. 2015, 276, 565–572. [Google Scholar] [CrossRef]

- Stanković, M.; Marinković, A.; Grbović, A.; Mišković, Ž.; Rosić, B.; Mitrović, R. Determination of Archard’s wear coefficient and wear simulation of sliding bearings. Ind. Lubr. Tribol. 2019, 71, 119–125. [Google Scholar] [CrossRef]

| CeO2 Content | Ti/(at.%) | C/(at.%) | Al/(at.%) | V/(at.%) | Cr/(at.%) | Ni/(at.%) |

|---|---|---|---|---|---|---|

| 0 wt.% | 74.33 | 3.82 | 8.86 | 2.05 | 8.53 | 2.41 |

| 74.22 | 4.29 | 9.01 | 2.19 | 8.39 | 1.90 | |

| 1 wt.% | 73.20 | 3.89 | 8.80 | 2.13 | 9.55 | 2.43 |

| 73.13 | 4.22 | 9.32 | 2.14 | 9.22 | 1.97 | |

| 2 wt.% | 73.7 | 4.04 | 8.82 | 2.10 | 9.04 | 2.30 |

| 73.3 | 4.08 | 8.95 | 1.97 | 9.55 | 2.15 | |

| 3 wt.% | 73.16 | 5.66 | 8.98 | 2.09 | 8.22 | 1.89 |

| 72.90 | 6.25 | 8.83 | 2.02 | 7.90 | 2.10 | |

| 4 wt.% | 73.07 | 2.71 | 9.37 | 2.20 | 10.28 | 2.37 |

| 72.90 | 3.72 | 9.10 | 2.09 | 10.01 | 2.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Yang, Q.; Yang, F.; Zhang, H.; Zhang, T.; Wang, H.; Ma, Q. Comparative Investigation on Wear Properties of Composite Coatings with Varying CeO2 Contents. Coatings 2022, 12, 906. https://doi.org/10.3390/coatings12070906

Zhang Z, Yang Q, Yang F, Zhang H, Zhang T, Wang H, Ma Q. Comparative Investigation on Wear Properties of Composite Coatings with Varying CeO2 Contents. Coatings. 2022; 12(7):906. https://doi.org/10.3390/coatings12070906

Chicago/Turabian StyleZhang, Zhiqiang, Qian Yang, Fan Yang, Hongwei Zhang, Tiangang Zhang, Hao Wang, and Qiang Ma. 2022. "Comparative Investigation on Wear Properties of Composite Coatings with Varying CeO2 Contents" Coatings 12, no. 7: 906. https://doi.org/10.3390/coatings12070906