Modeling and Characteristics of Airless Spray Film Formation

Abstract

:1. Introduction

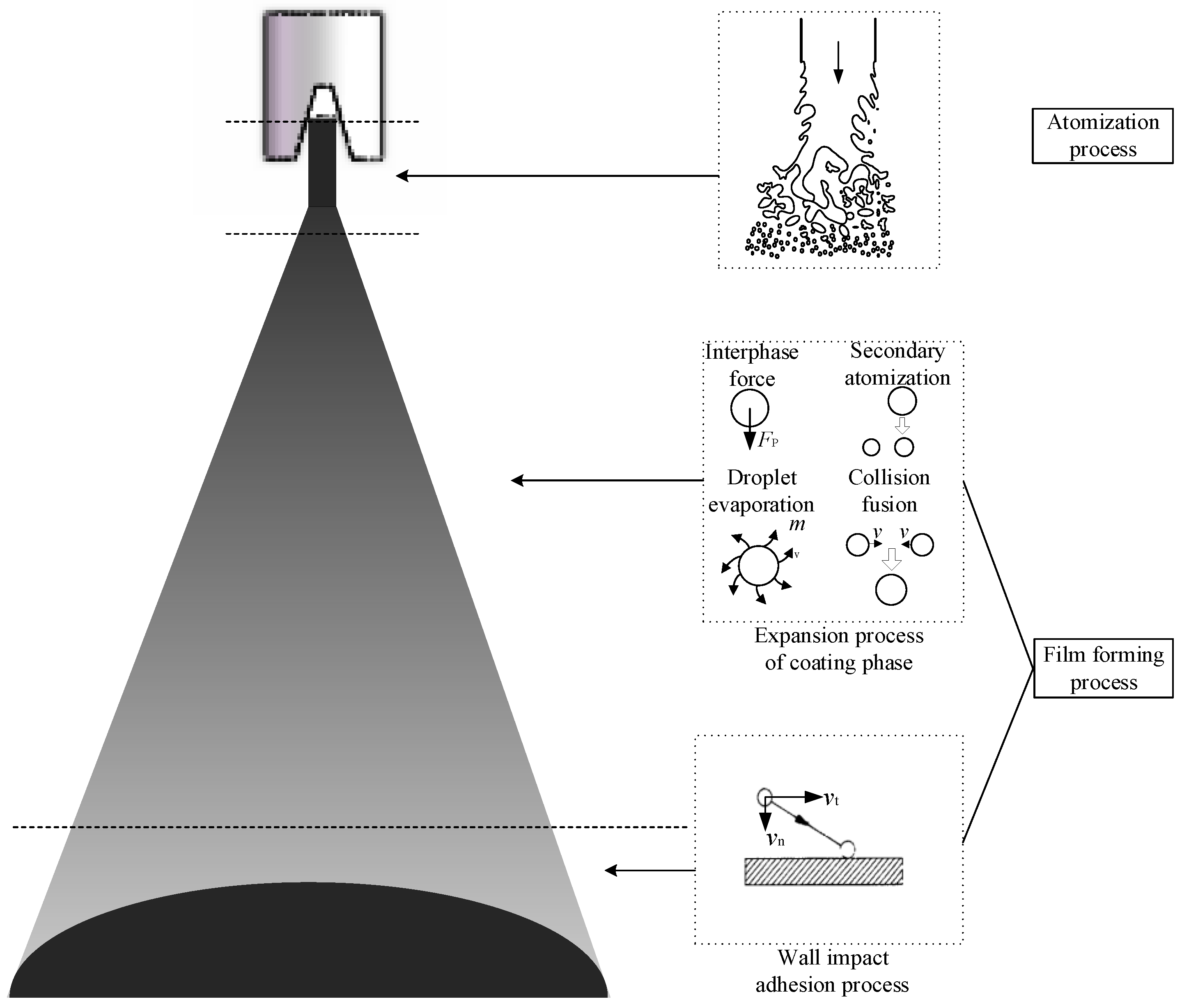

2. Film Formation Model

2.1. Airless Spraying Process

2.2. Paint Expansion Model

2.2.1. Two-Phase Flow Governing Equation

2.2.2. Turbulence Model

2.3. Wall Impact Model

2.3.1. Near-Wall Model

2.3.2. Liquid Film Model

3. Numerical Simulations

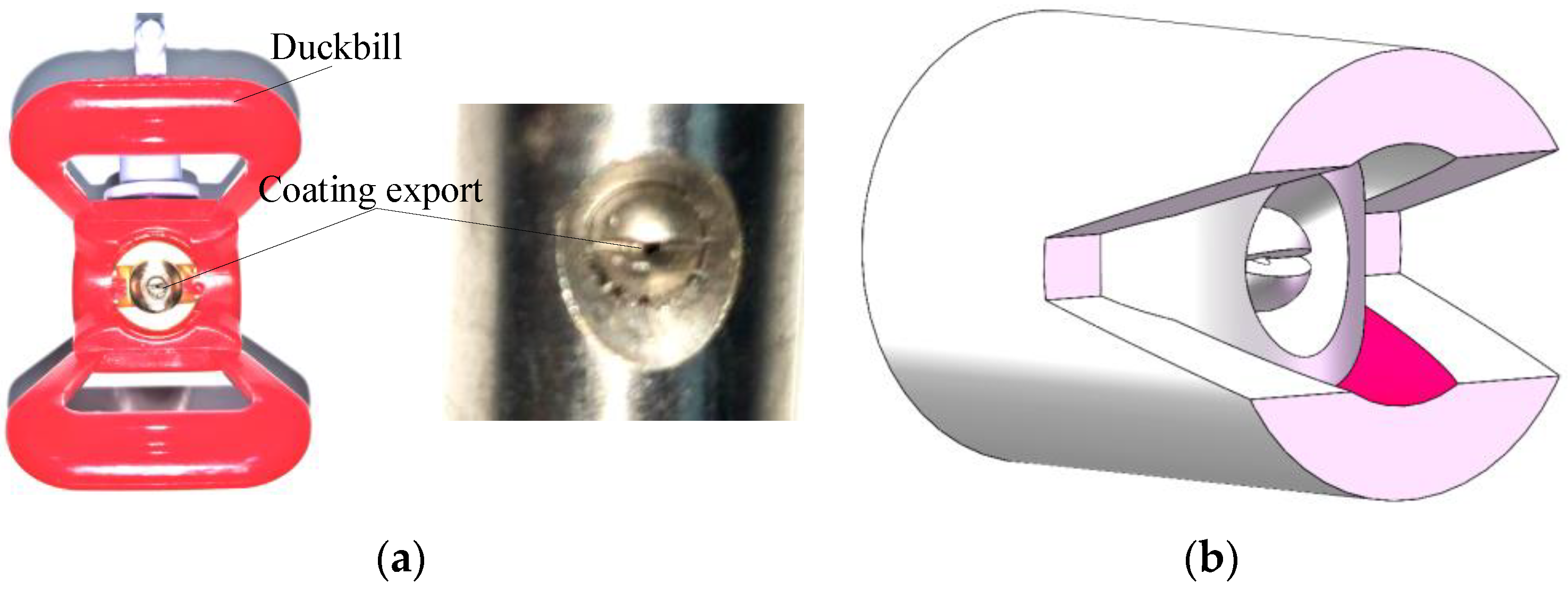

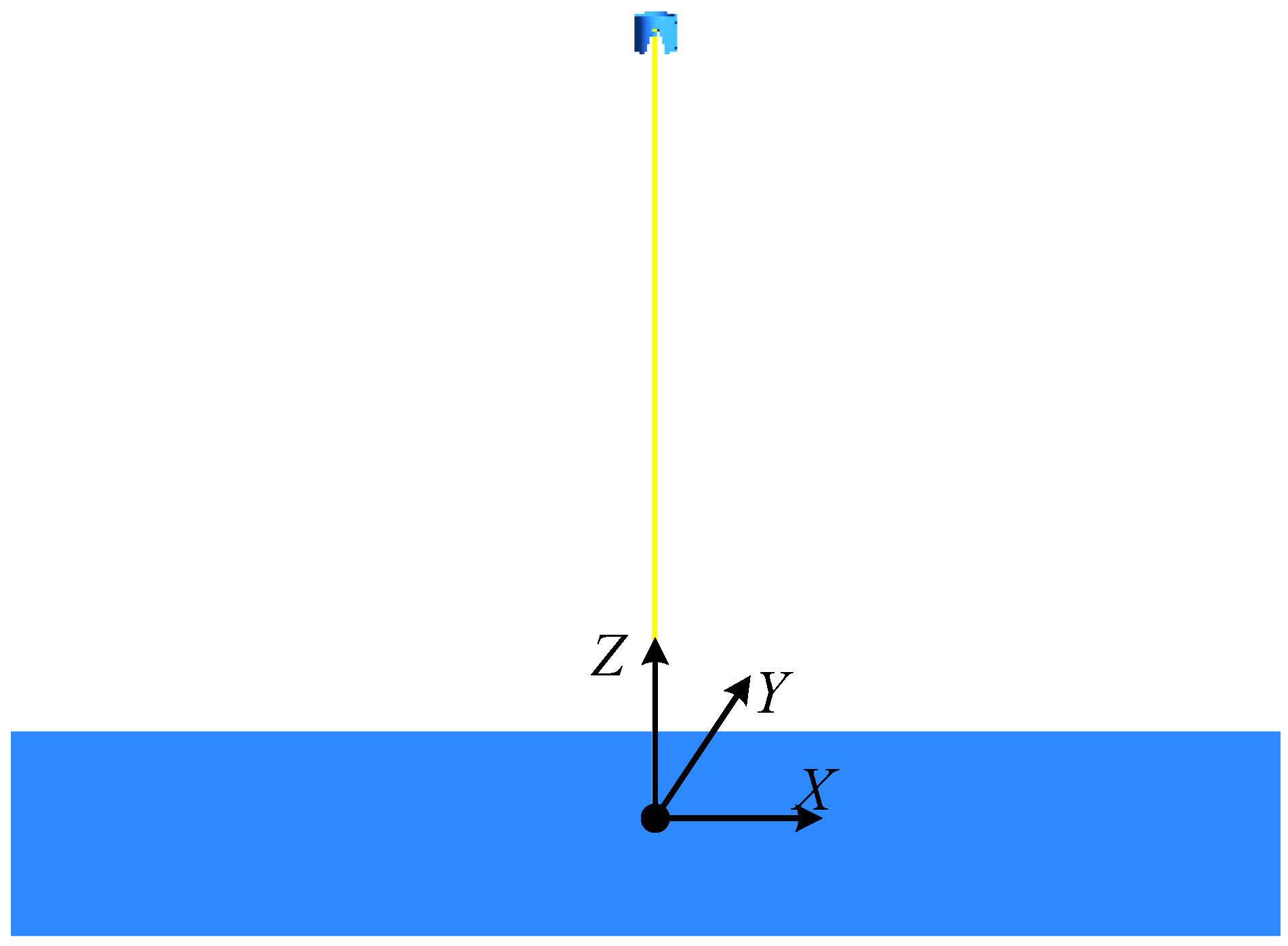

3.1. Nozzle Geometry Model

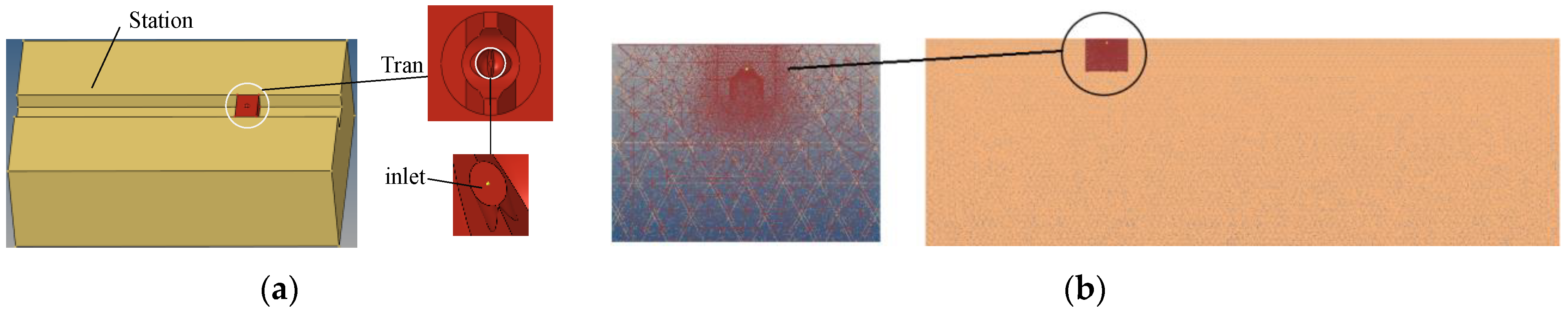

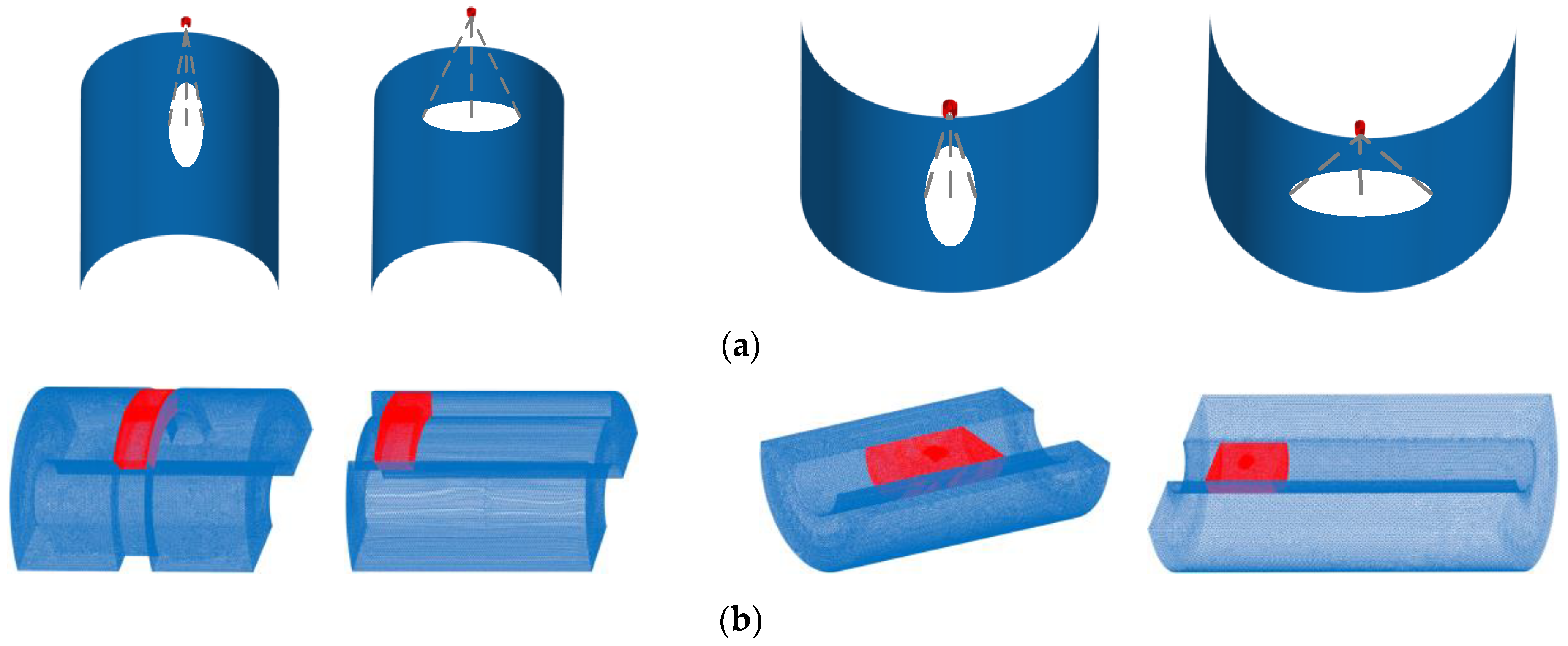

3.2. Computational Domain and Meshing

3.3. Parameter Setting

4. Characteristics of the Spray Flow Field

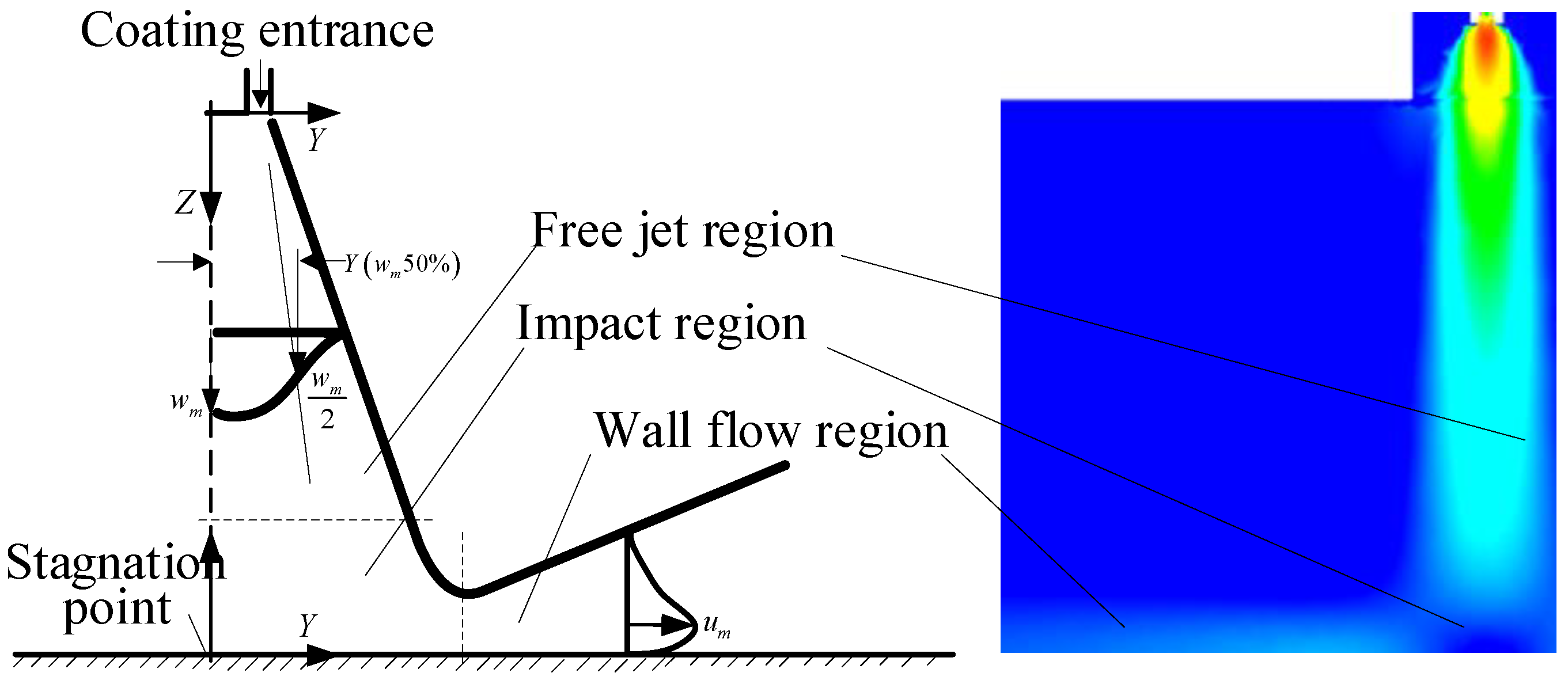

4.1. Division of the Spray Flow Field

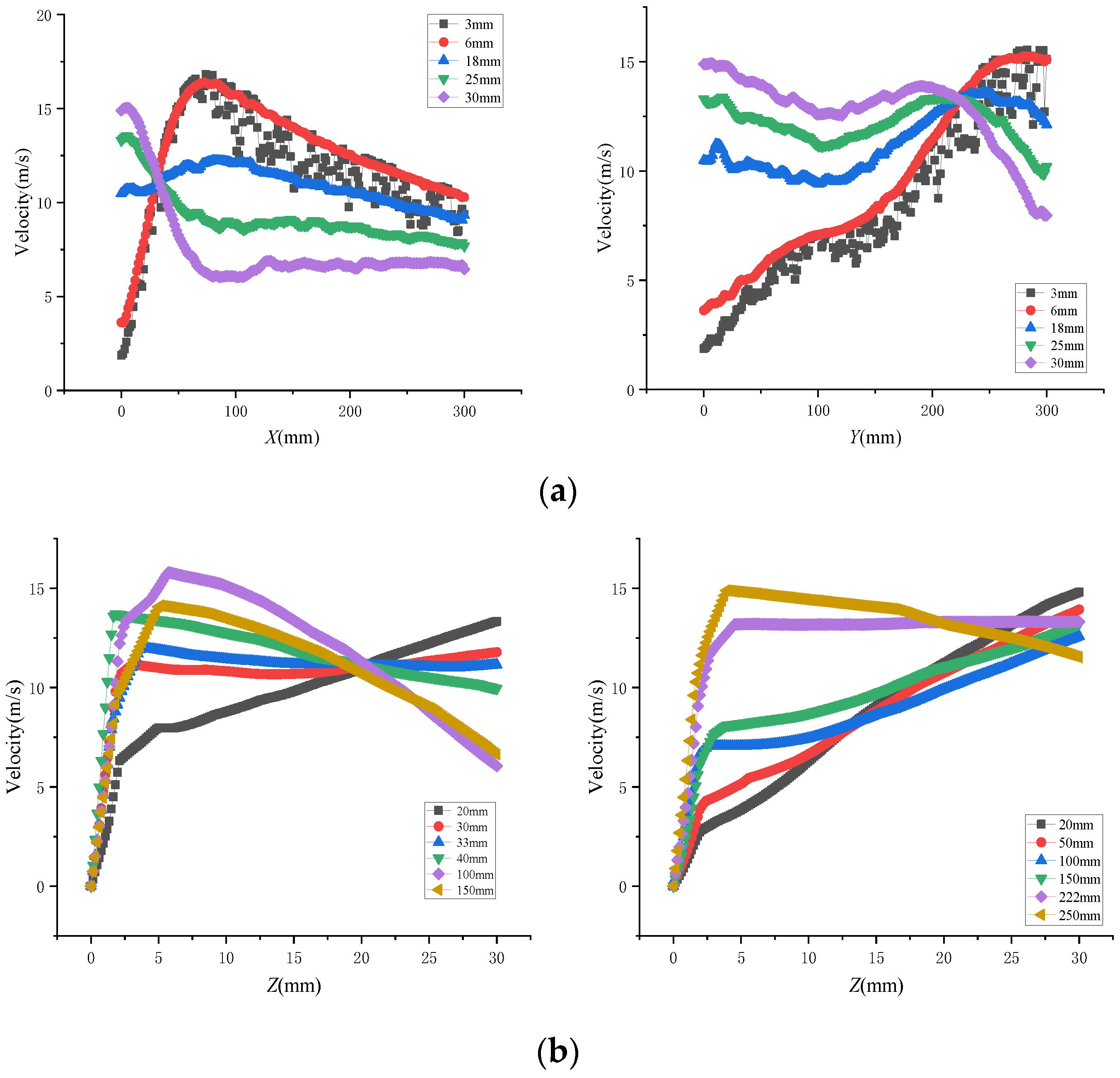

4.2. Velocity Distribution Characteristics

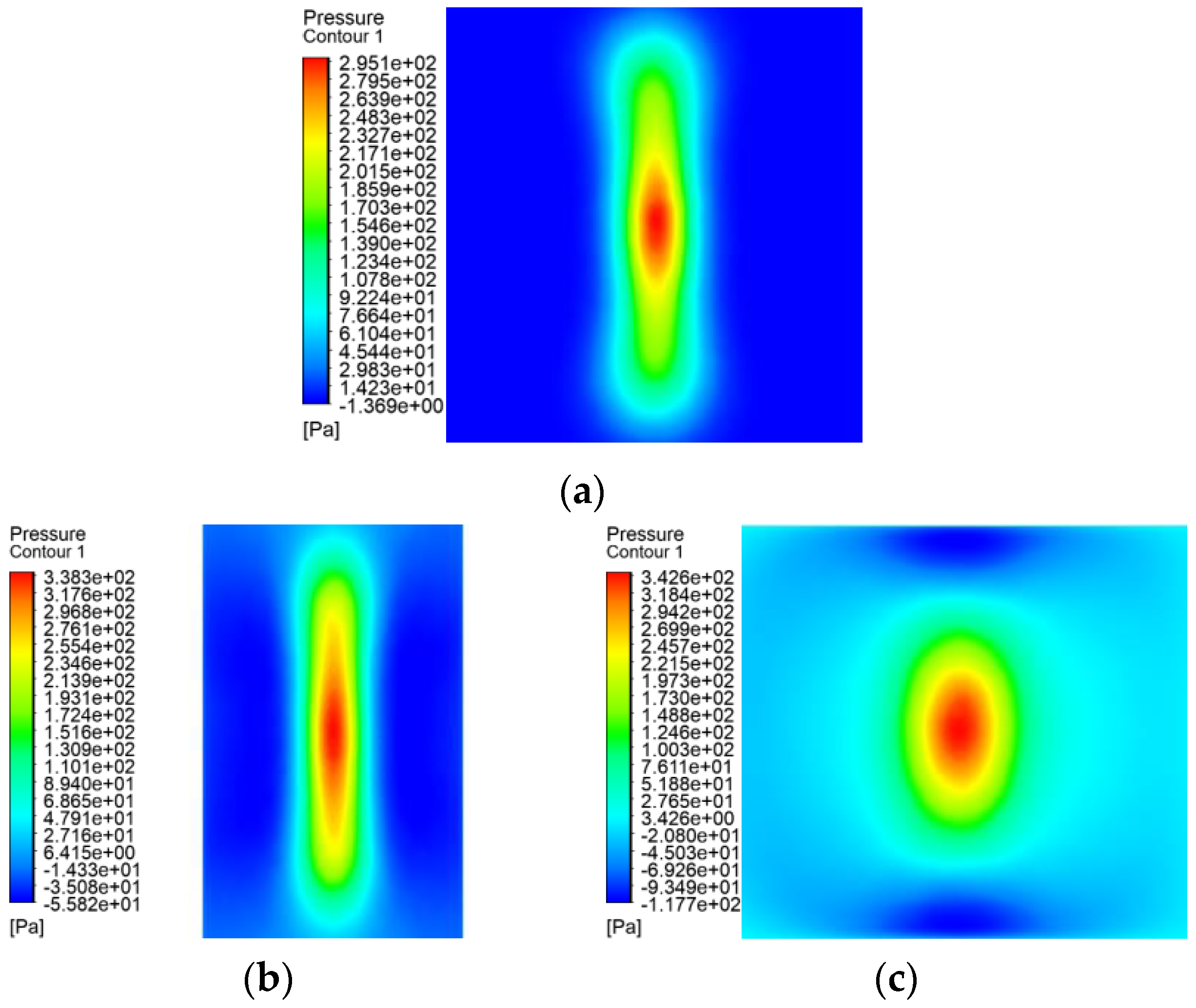

4.3. Pressure Distribution Characteristics

5. Coating Film Characteristics

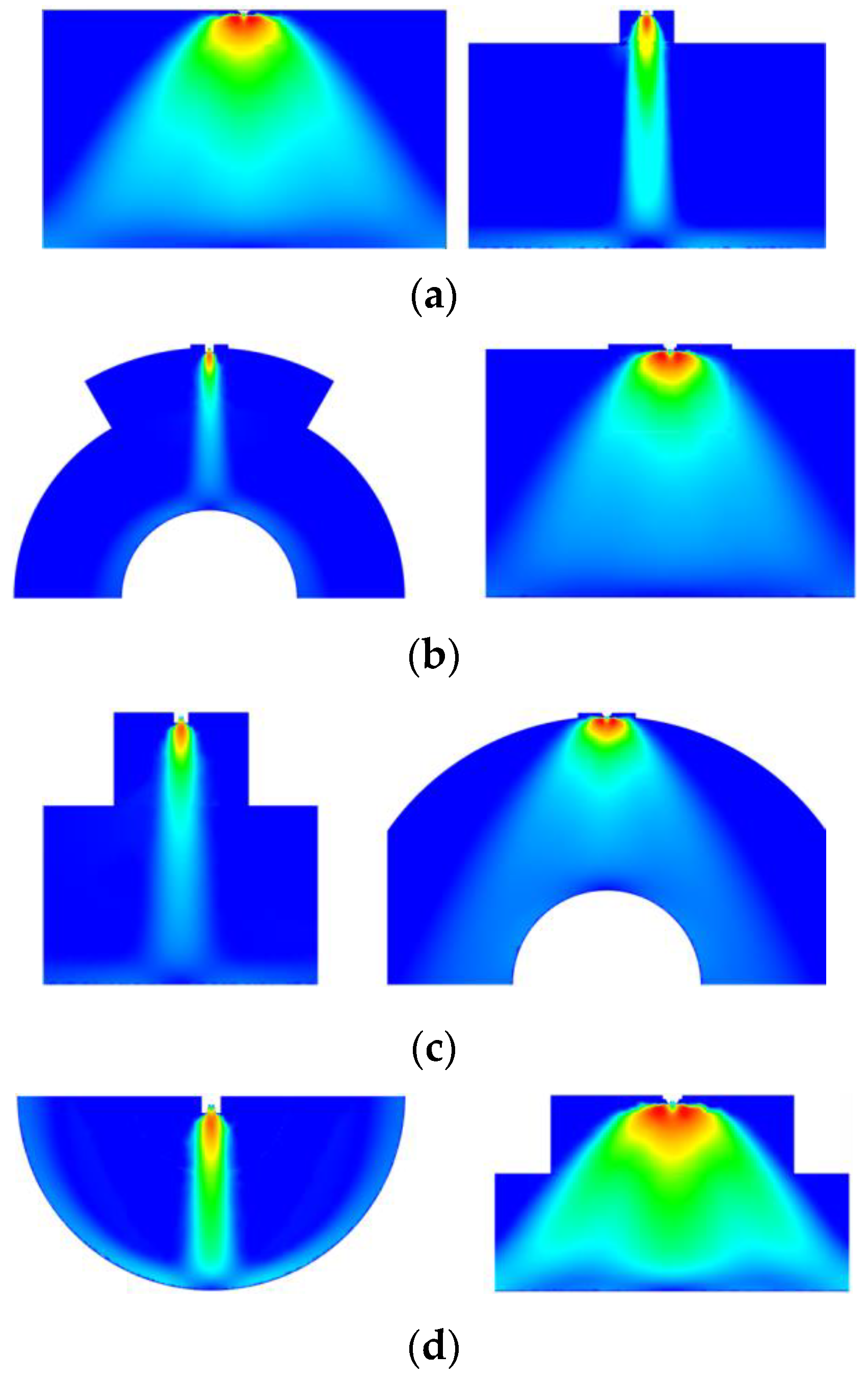

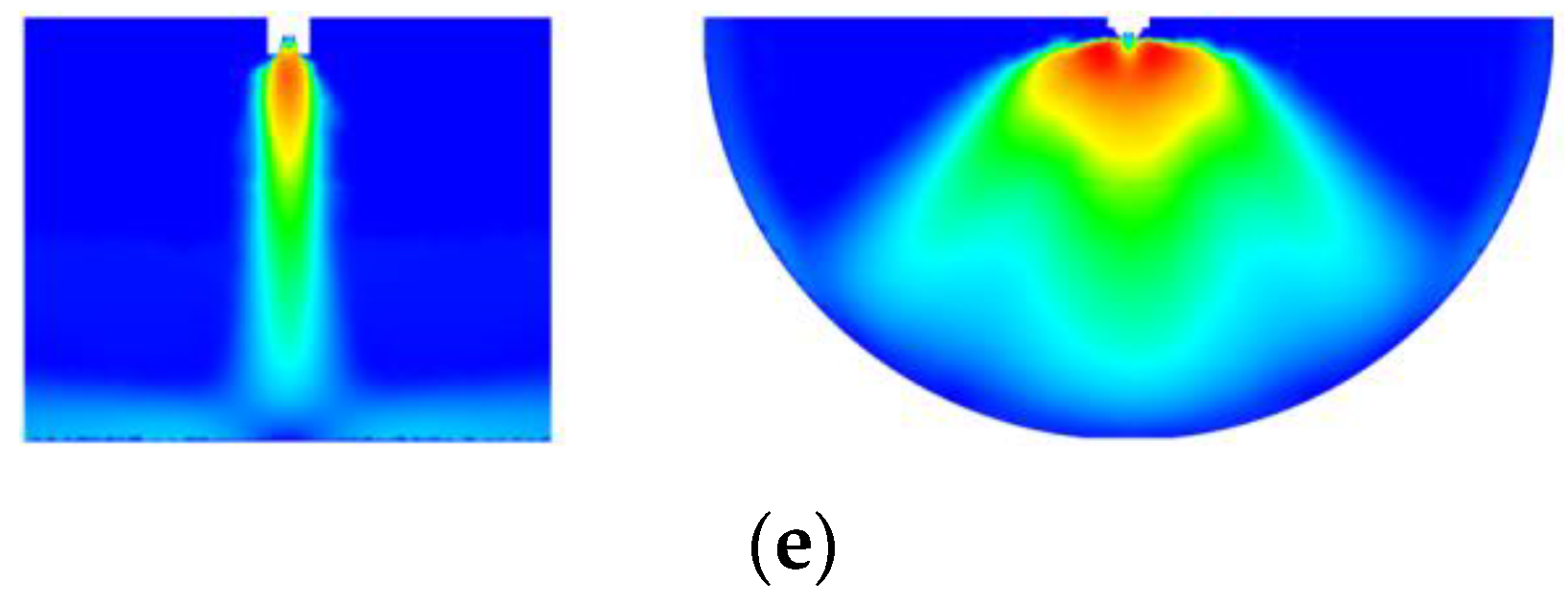

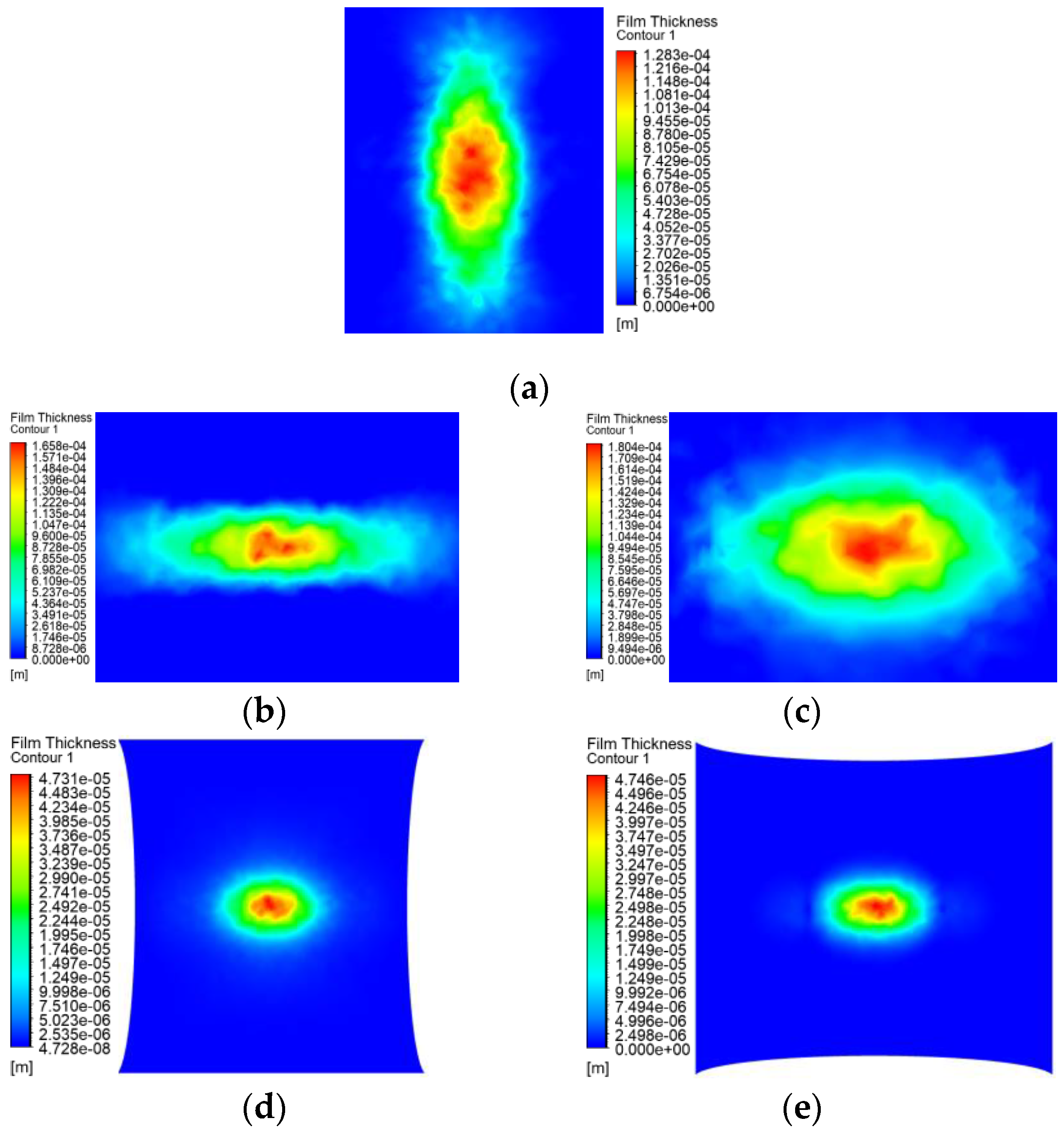

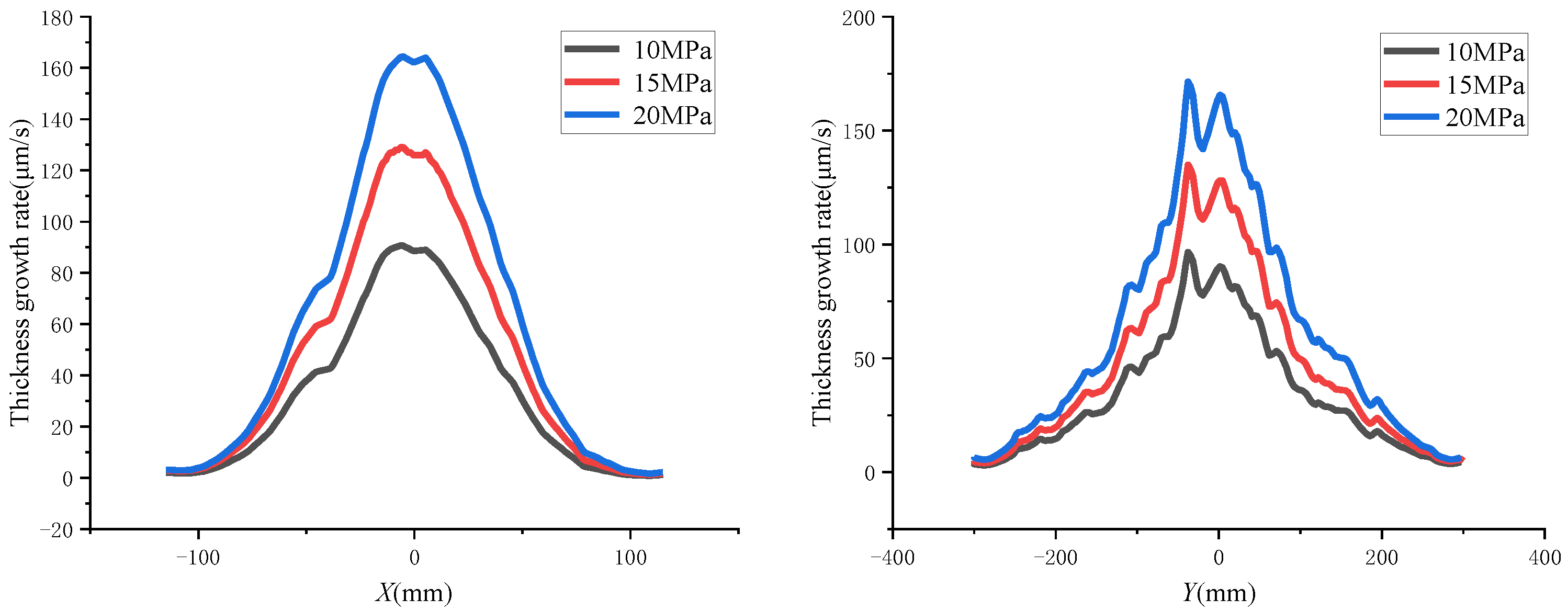

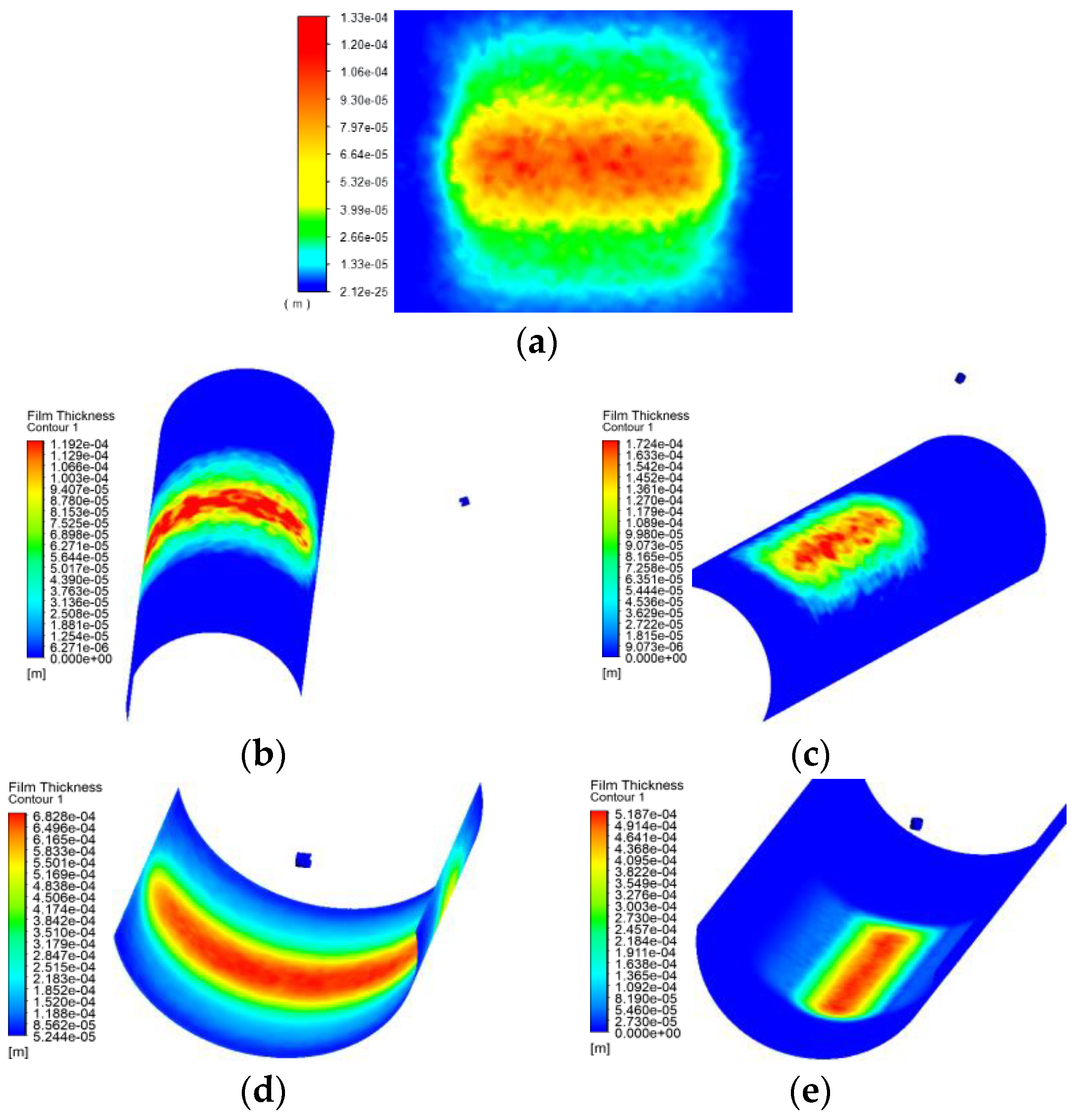

5.1. Characteristics of the Static Spraying Coating Film

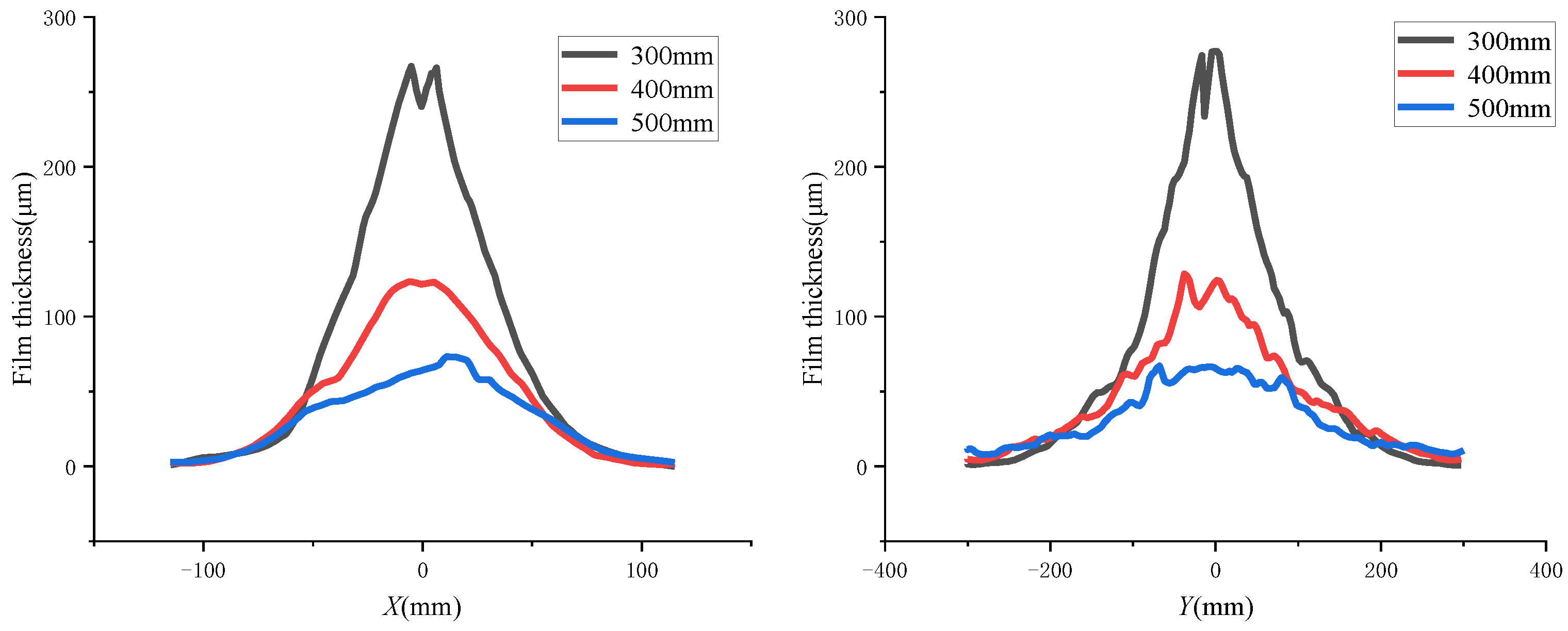

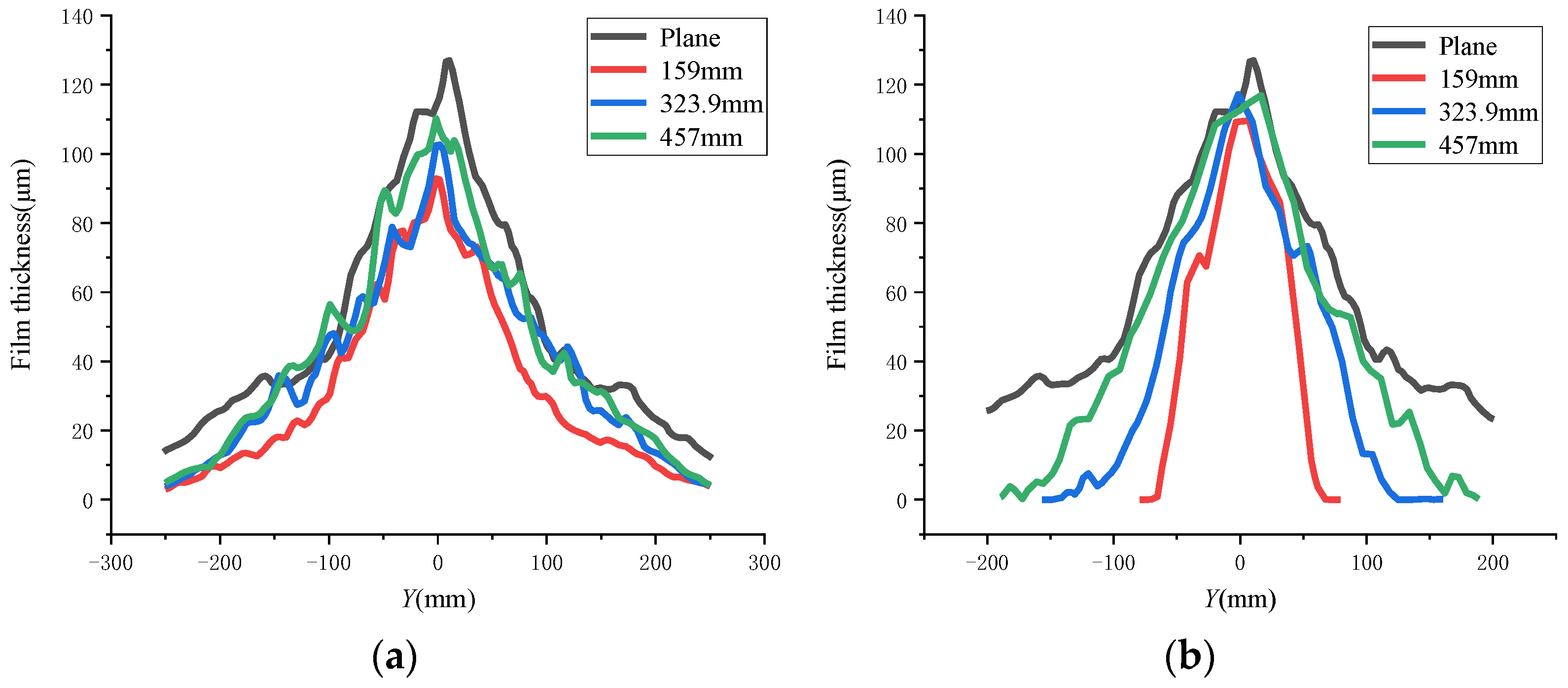

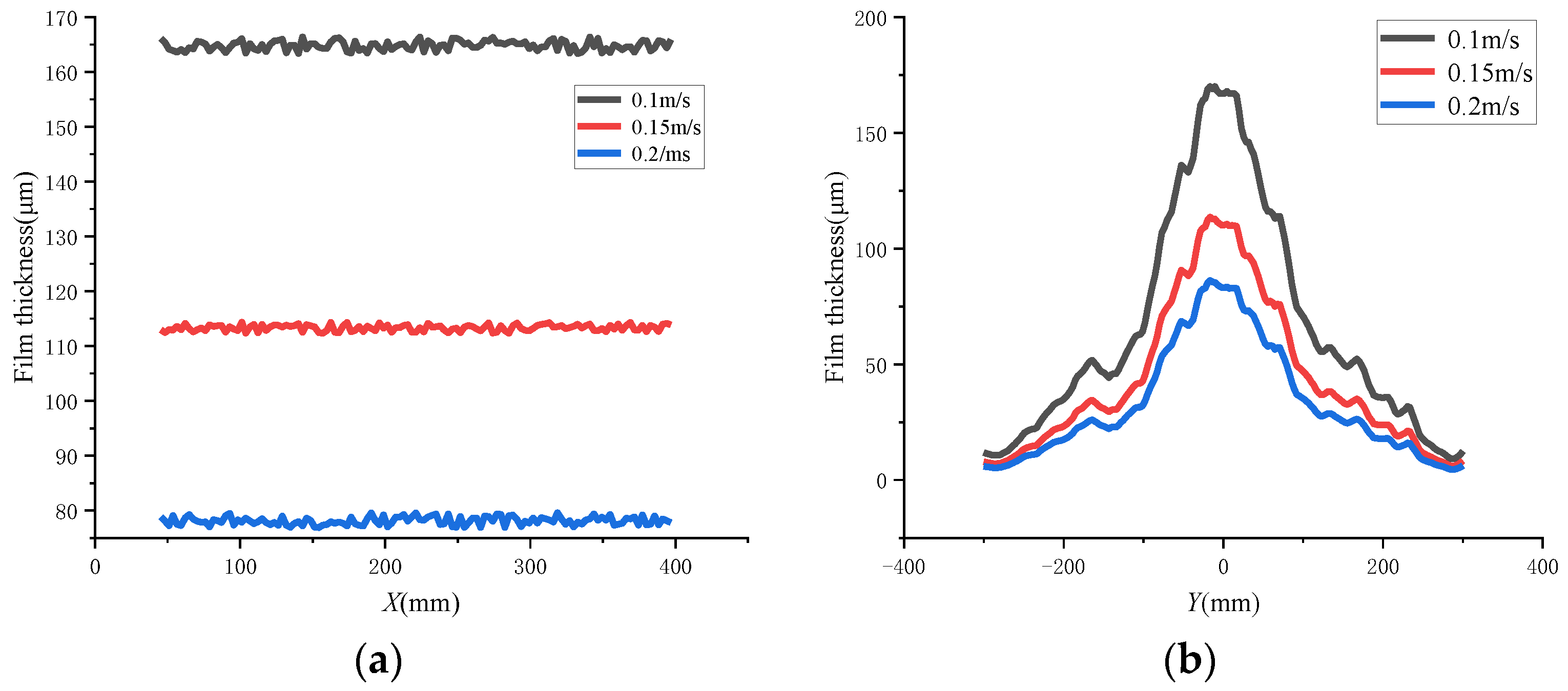

5.2. Dynamic Coating Characteristics

6. Experimental Validations

6.1. Coating Film Morphology Verification

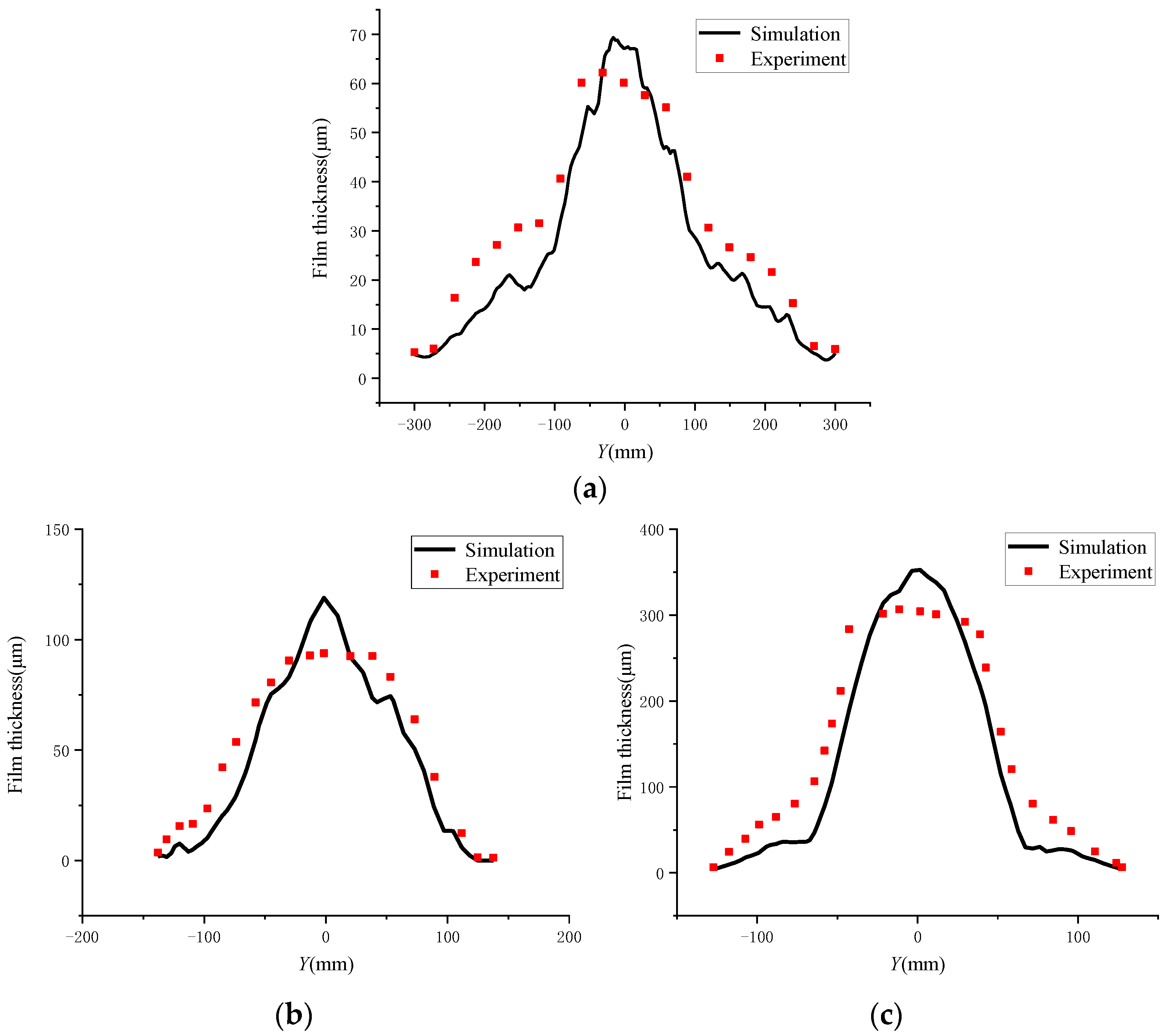

6.2. Verification of the Film Thickness

7. Conclusions

- (1)

- According to the physical process of airless spraying, a film formation model of airless spraying including the paint expansion model and the wall impact model was established. The experiments verified the correctness of the film formation model.

- (2)

- In the outer surface spraying, the short-axis direction of the busbar spraying and the long-axis direction of the circumferential spraying showed similar pressure distribution characteristics to those of the plane spraying. In the inner surface spraying, the variation trend of the busbar spraying in the direction of the short axis was similar to that of the circumferential spraying. The circumferential spraying appeared a secondary pressure center in the long-axis direction.

- (3)

- When spraying the outer surface, the width in the long axis direction of the busbar spraying was larger than that of the circumferential spraying but smaller than that of the circumferential spraying in the short-axis direction. The characteristics of the inner surface spraying were completely opposite compared to those of the outer surface spraying. During the static spraying, the film thickness growth rate and the coating area increased with the increase of the spraying pressure and the deceasing of the spraying distance. During the dynamic spraying, the larger the diameter of the arc surface, the larger the thickness of the outer surface film and the smaller the thickness of the inner surface film.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cowlard, T. Airless Spraying. Trans. IMF 2017, 34, 420–426. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, W.; Zhang, C.; Liao, H.; Zhang, Y.; Deng, S. A spherical surface coating thickness model for a robotized thermal spray system. Robot. Comput. Integr. Manuf. 2019, 59, 297–304. [Google Scholar] [CrossRef]

- Zhou, Y.; Ma, S.; Li, A.; Yang, L. Path planning for spray painting robot of horns surfaces in ship manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2019, 521, 012015. [Google Scholar] [CrossRef]

- Guan, L.; Chen, L. Trajectory planning method based on transitional segment optimization of spray painting robot on complex free surface. Ind. Robot. 2019, 46, 31–43. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Y.; Zhang, W.; He, S.; Li, B.; Jiang, J. Paint thickness simulation for robotic painting of curved surfaces based on Euler–Euler approach. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 199. [Google Scholar] [CrossRef]

- Ye, Q.; Domnick, J. Analysis of droplet impingement of different atomizers used in spray coating processes. J. Coat. Technol. Res. 2017, 14, 1–10. [Google Scholar] [CrossRef]

- Eric, R.; John, L.; Josh, C. How to select an airless sprayer: Power sources. J. Prot. Coat. Linings 2019, 36, 24–26. [Google Scholar]

- Chen, Y.; Chen, W.Z.; He, S.W.; Pan, H.W.; Li, B.; Zhang, W.M. Spray flow characteristics of painting cylindrical surface with a pneumatic atomizer. China Surf. Eng. 2017, 30, 122–131. [Google Scholar]

- Chen, Y.; Chen, S.M.; Chen, W.Z.; Hu, J.; Jiang, J. An atomization model of air spraying using the volume-of-fluid method and large eddy simulation. Coatings 2021, 11, 1400. [Google Scholar] [CrossRef]

- Chen, S.; Chen, W.; Chen, Y.; Jiang, J.; Wu, Z.; Zhou, S. Research on film-forming characteristics and mechanism of painting V-shaped surfaces. Coatings 2022, 12, 658. [Google Scholar] [CrossRef]

- Ye, Q.; Karlheinz, P. Numerical and experimental investigation on the spray coating process using a pneumatic atomizer: Influences of operating conditions and target geometries. Coatings 2017, 7, 13. [Google Scholar] [CrossRef] [Green Version]

- Yu, Y.; Li, Y.; Jiang, M.; Zhou, Q. Meso scale drag model designed for coarse grid Eulerian-Lagrangian simulation of gas solid flows. Chem. Eng. Sci. 2020, 223, 115747. [Google Scholar] [CrossRef]

- Mergheni, M.A.; Ticha, H.B.; Sautet, J.C.; Nasrallah, S.B. Interaction particle turbulence in dispersed two phase flows using the eulerian-lagrangian approach. Int. J. Fluid Mech. Res. 2008, 35, 273–286. [Google Scholar] [CrossRef]

- Gu, J.; Shao, Y.; Liu, X.; Zhong, W.; Yu, A. Modelling of particle flow in a dual circulation fluidized bed by a Eulerian-Lagrangian approach. Chem. Eng. Sci. 2018, 192, 619–633. [Google Scholar] [CrossRef]

- Josef, A.; Jk, B.; Ss, B.; Radl, S. Coarse graining Euler Lagrange simulations of cohesive particle fluidization Science Direct. Powder Technol. 2020, 364, 167–182. [Google Scholar]

- Yang, G.; Chen, Y.; Chen, S.M.; Zhang, F. Modeling of Film Formation in Airless Spray. In Proceedings of the 2021 2nd International Conference on Modeling, Big Data Analytics and Simulation (MBDAS2021), Shenzhen, China, 14–15 November 2021. [Google Scholar]

- Zhou, W.; Xu, X.; Yang, Q.; Zhao, R.; Jin, Y. Experimental and numerical investigations on the spray characteristics of liquid-gas pintle injector. Aerosp. Sci. Technol. 2022, 121, 107354. [Google Scholar] [CrossRef]

- Venkatachalam, P.; Sahu, S.; Anupindi, K. Numerical investigation on the role of a mixer on spray impingement and mixing in channel cross-stream airflow. Phys. Fluids 2022, 34, 033316. [Google Scholar] [CrossRef]

- Pandal, A.; García Oliver, J.M.; Novella, R.; Pastor, J.M. A computational analysis of local flow for reacting Diesel sprays by means of an Eulerian CFD model. Int. J. Multiph. Flow 2018, 99, 257–272. [Google Scholar] [CrossRef] [Green Version]

- Zhong, J.; Dai, Y.; Liang, C.; Zhu, X.; Xu, L. CFD investigation of air-oil two-phase flow in oil jet nozzle. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022. [Google Scholar] [CrossRef]

- Payri, R.; Gimeno, J.; Marti-Aldaravi, P.; Martinez, M. Transient nozzle flow analysis and near field characterization of gasoline direct fuel injector using Large Eddy Simulation. Int. J. Multiph. Flow 2022, 148, 103920. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, W.Z.; Li, B.; Zhang, G.; Zhang, W. Paint thickness simulation for painting robot trajectory planning: A review. Ind. Robot. -Int. J. Robot. Res. Appl. 2017, 44, 629–638. [Google Scholar] [CrossRef]

- Sazhin, S. Droplets and Sprays; Springer: London, UK, 2014. [Google Scholar]

- Spalding, B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 103, 269–289. [Google Scholar]

- Mirko, G.; Marco, V.; Giancarlo, B. CFD modeling of a spray deposition process of paint. Macromol. Symp. 2002, 187, 719–730. [Google Scholar]

- O’Rourke, P.J.; Amsden, A.A. A Particle Numerical Model for Wall Film Dynamics in Port-Injected Engines. Off. Sci. Tech. Inf. Tech. Rep. 1996, 1, 961961. [Google Scholar]

| Parameters | Values |

|---|---|

| Density | 1320 kg/m3 |

| Dynamic viscosity | 0.275 kg/(m·s) |

| Surface tension coefficient | 0.036 N/m |

| Spraying distance | 400 mm |

| Mass flow rate | 0.0787 g/s |

| 0.103 kg/s | |

| 0.125 kg/s | |

| Turbulence intensity | 5% |

| Hydraulic diameter | 0.6 mm |

| Maximum time step | 700 |

| Spraying speed | 0.15 m/s |

| Spraying Method | Maximum Error (μm) | Average Error (μm) |

|---|---|---|

| Plane spraying | 9.1 | 4.1 |

| Outer surface translation spraying | 21.8 | 9.7 |

| Inner surface translation spraying | 49.1 | 28.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, G.; Wu, Z.; Chen, Y.; Chen, S.; Jiang, J. Modeling and Characteristics of Airless Spray Film Formation. Coatings 2022, 12, 949. https://doi.org/10.3390/coatings12070949

Yang G, Wu Z, Chen Y, Chen S, Jiang J. Modeling and Characteristics of Airless Spray Film Formation. Coatings. 2022; 12(7):949. https://doi.org/10.3390/coatings12070949

Chicago/Turabian StyleYang, Guichun, Zhaojie Wu, Yan Chen, Shiming Chen, and Junze Jiang. 2022. "Modeling and Characteristics of Airless Spray Film Formation" Coatings 12, no. 7: 949. https://doi.org/10.3390/coatings12070949

APA StyleYang, G., Wu, Z., Chen, Y., Chen, S., & Jiang, J. (2022). Modeling and Characteristics of Airless Spray Film Formation. Coatings, 12(7), 949. https://doi.org/10.3390/coatings12070949