Review: Modeling and Simulation of Membrane Electrode Material Structure for Proton Exchange Membrane Fuel Cells

Abstract

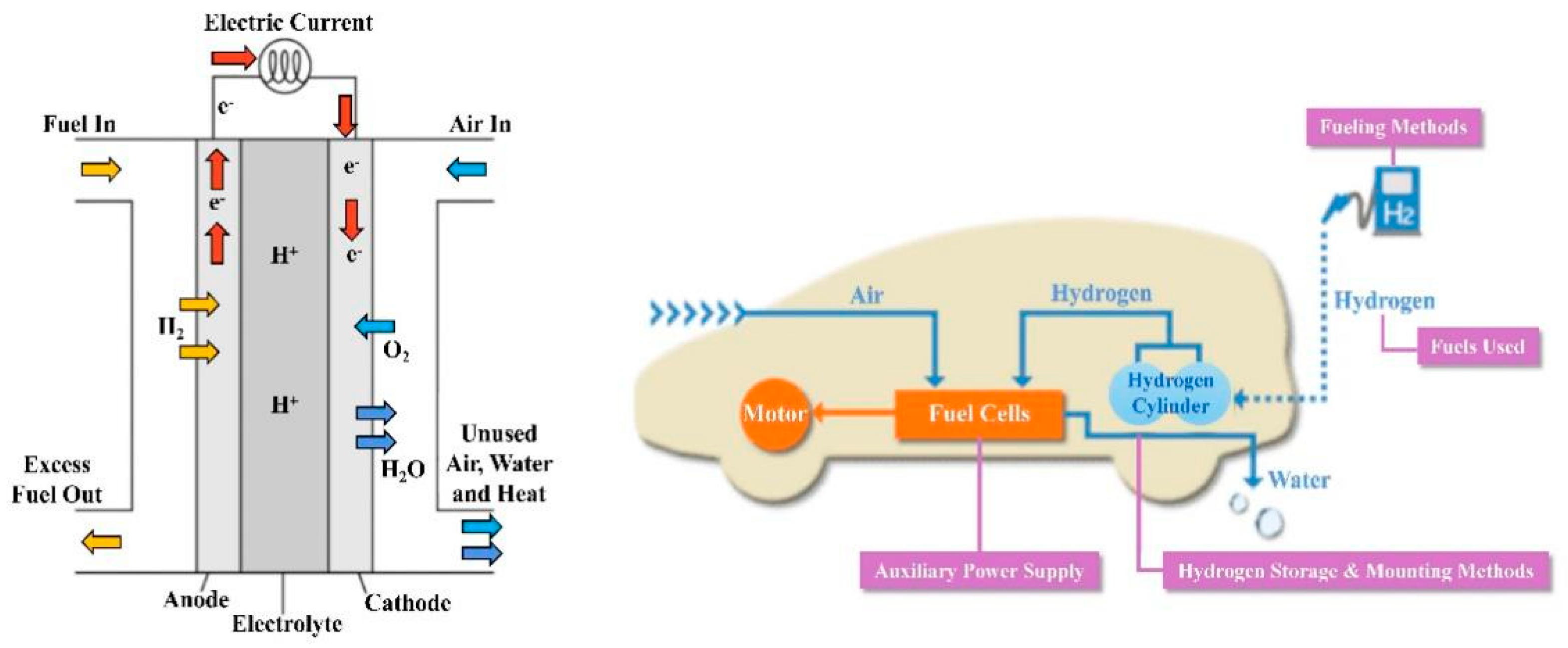

:1. Introduction

2. GDL Simulation Models

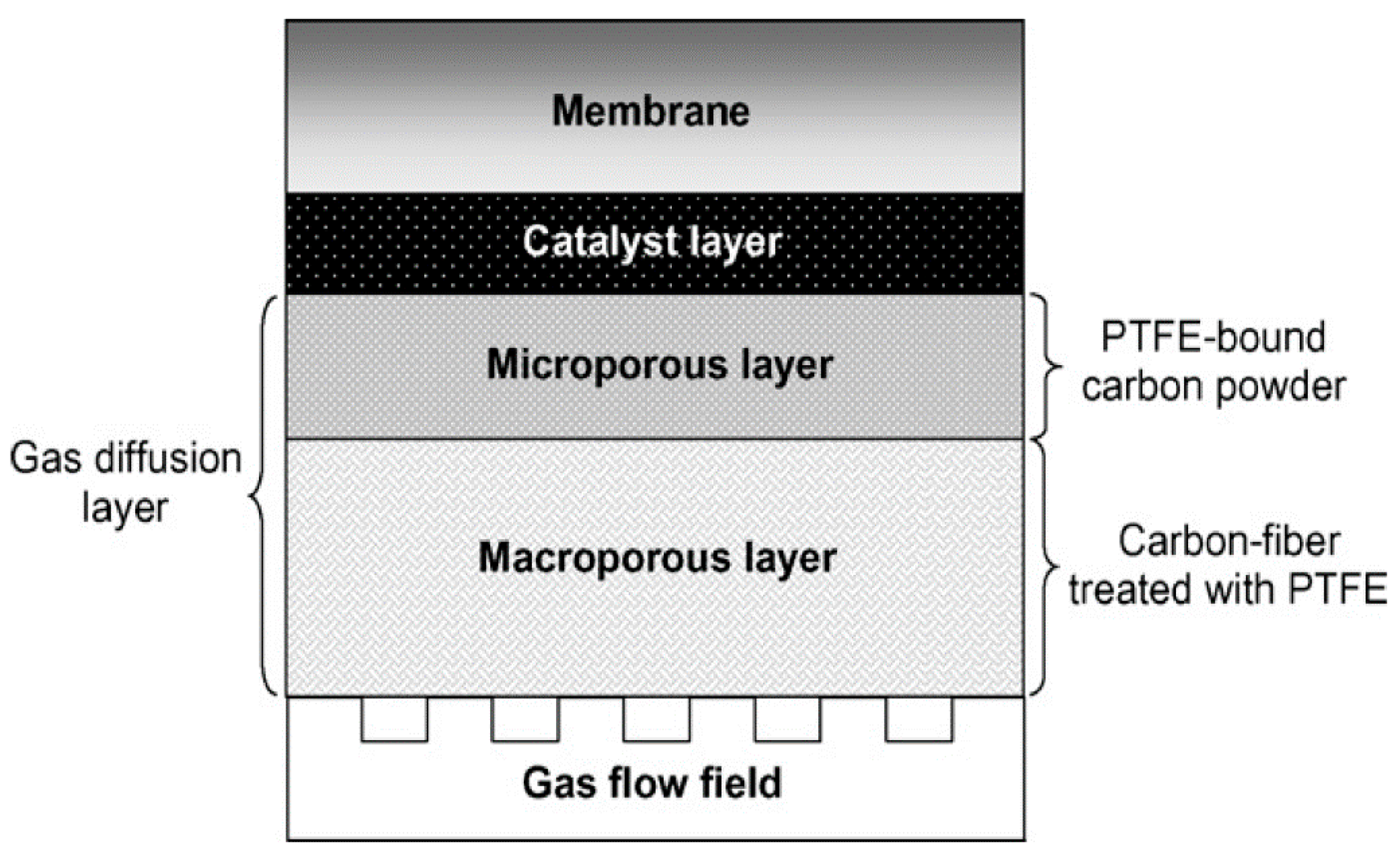

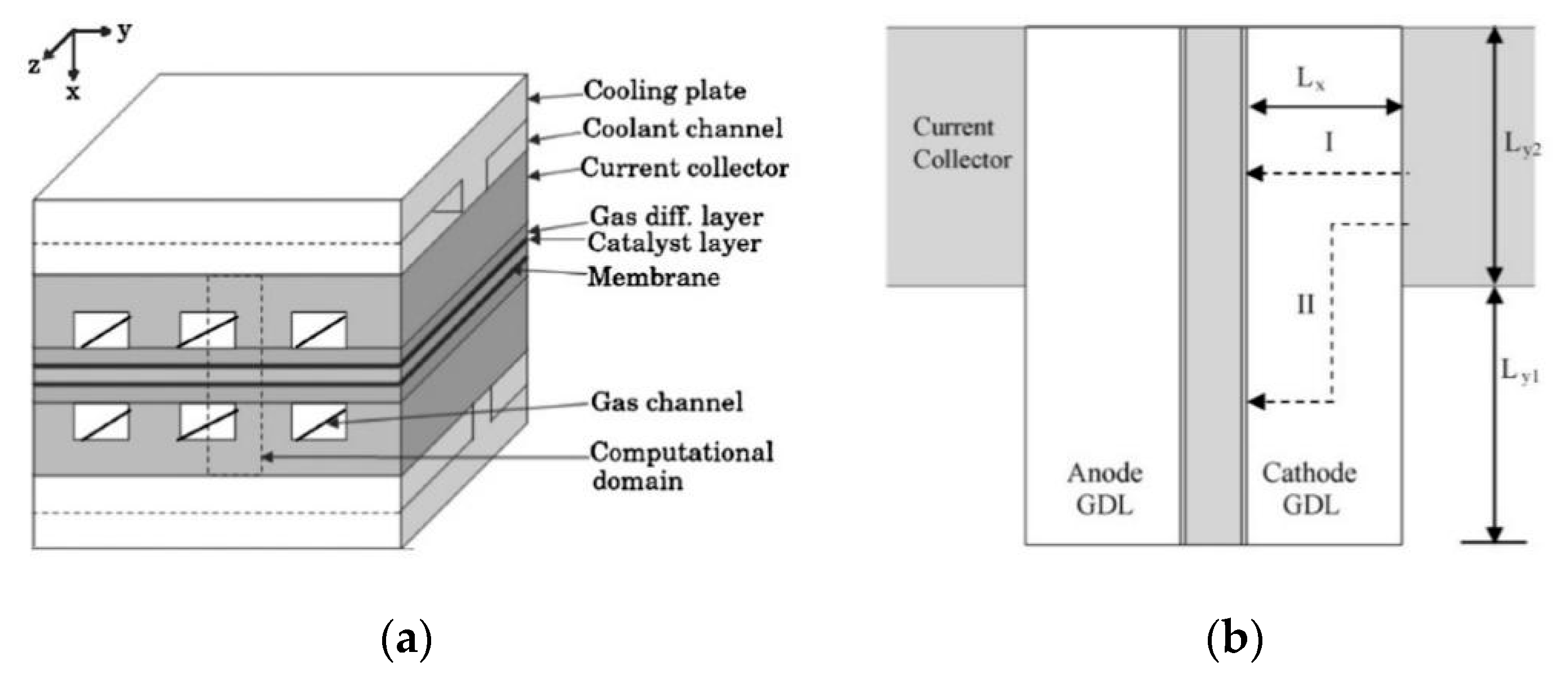

2.1. Brief Introduction

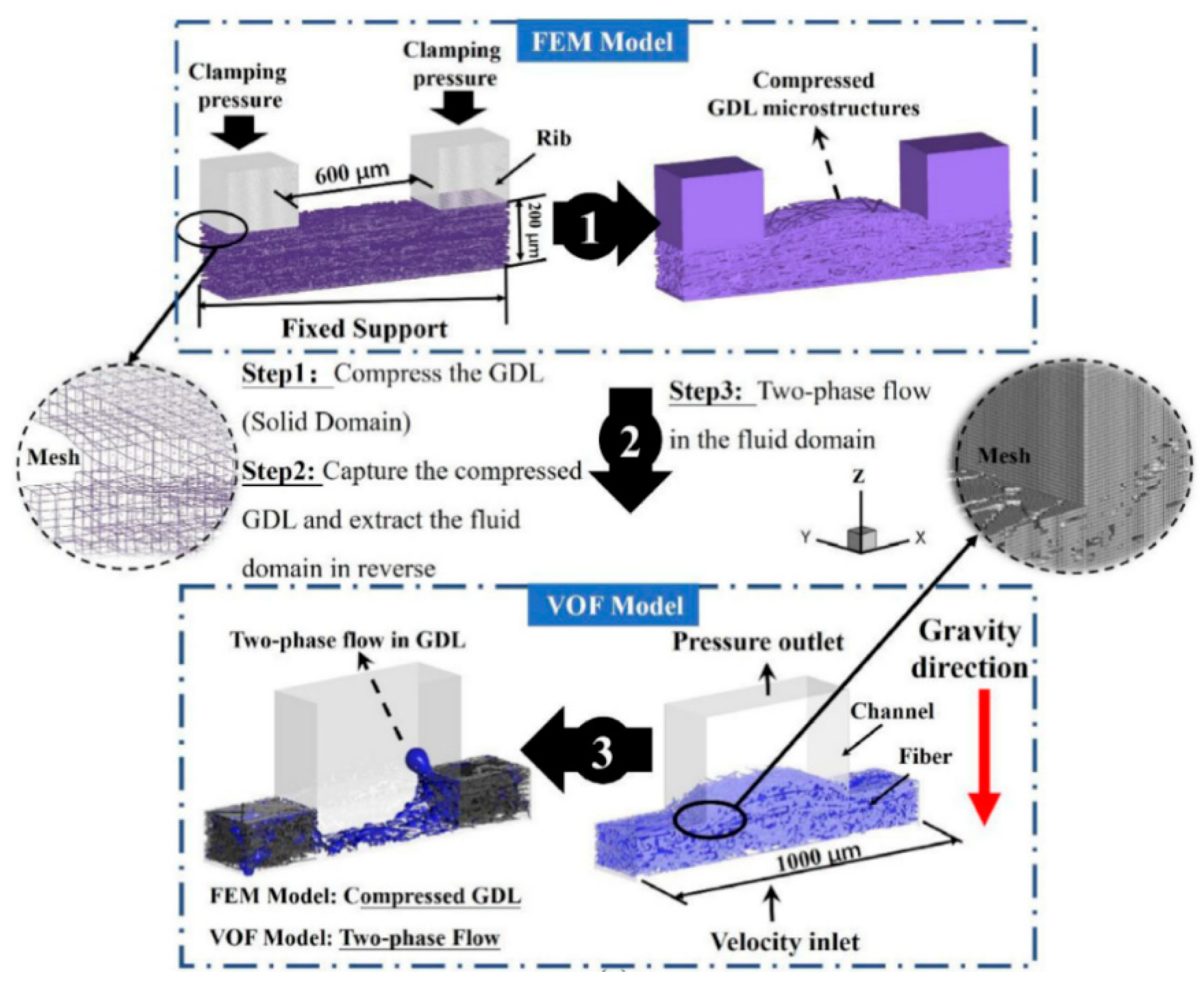

2.2. Two-Phase Calculation Models

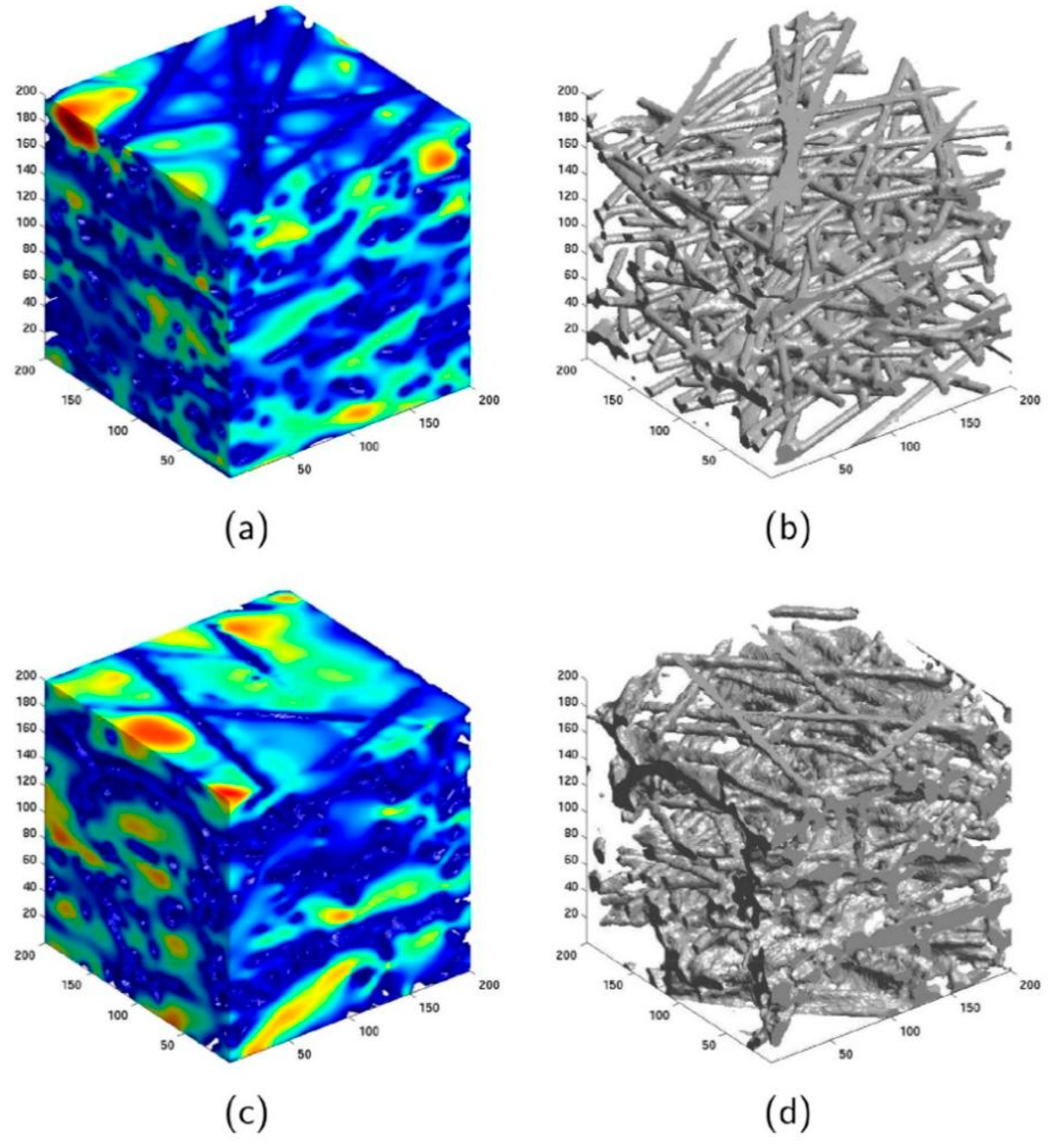

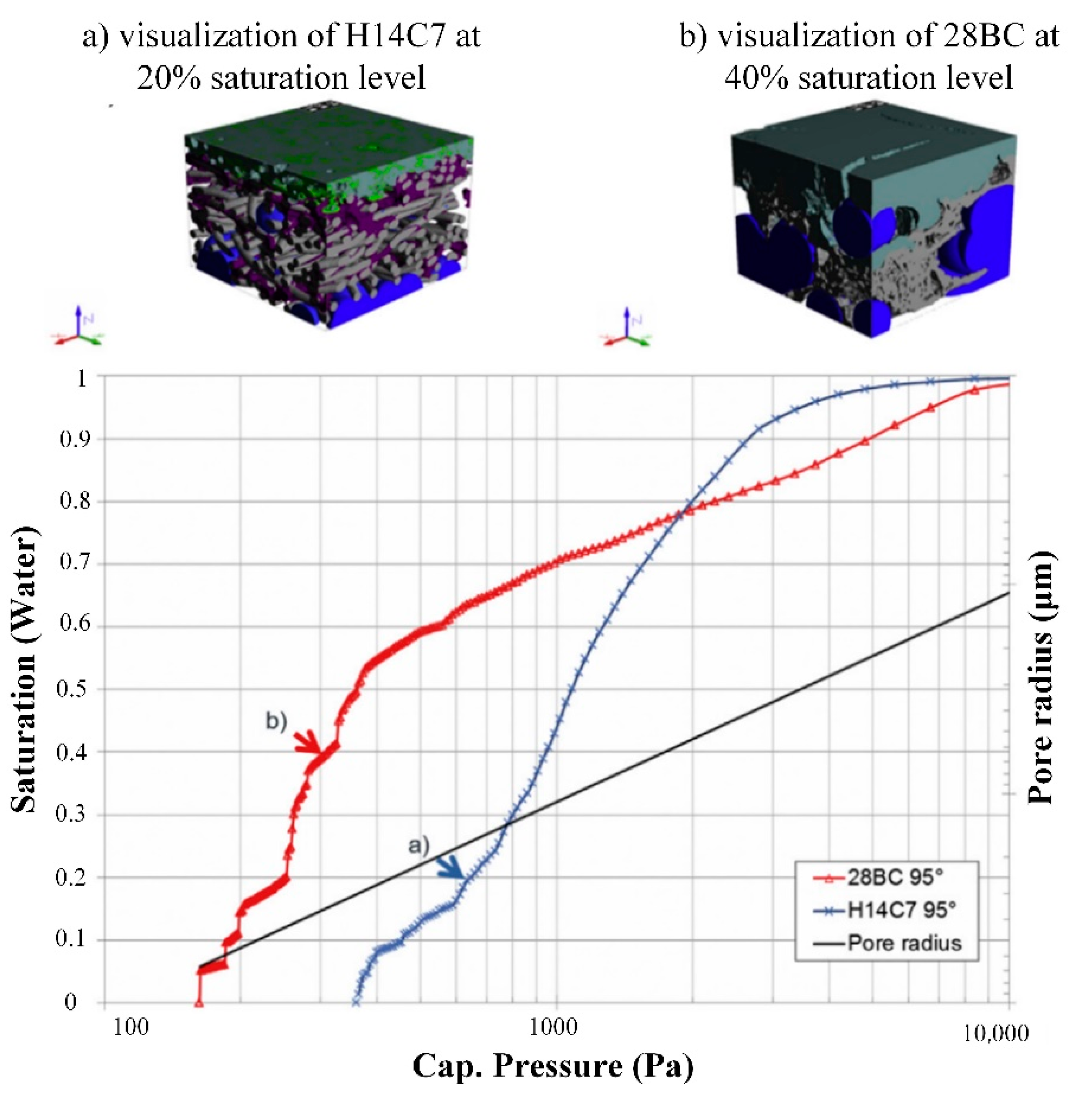

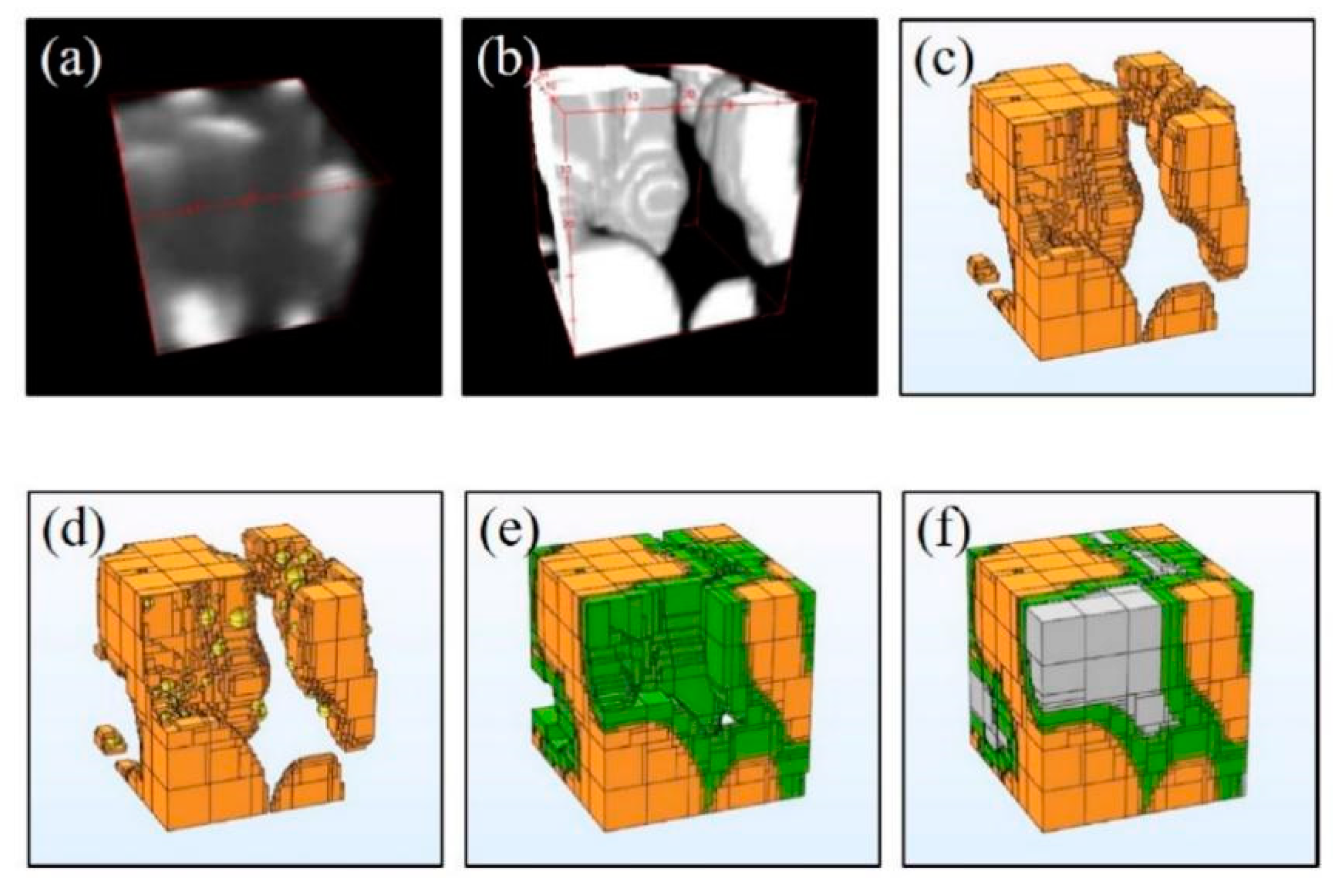

2.3. Microscopic Simulation Models

2.4. Summary

3. Simulation Models of CL

3.1. Brief Introduction

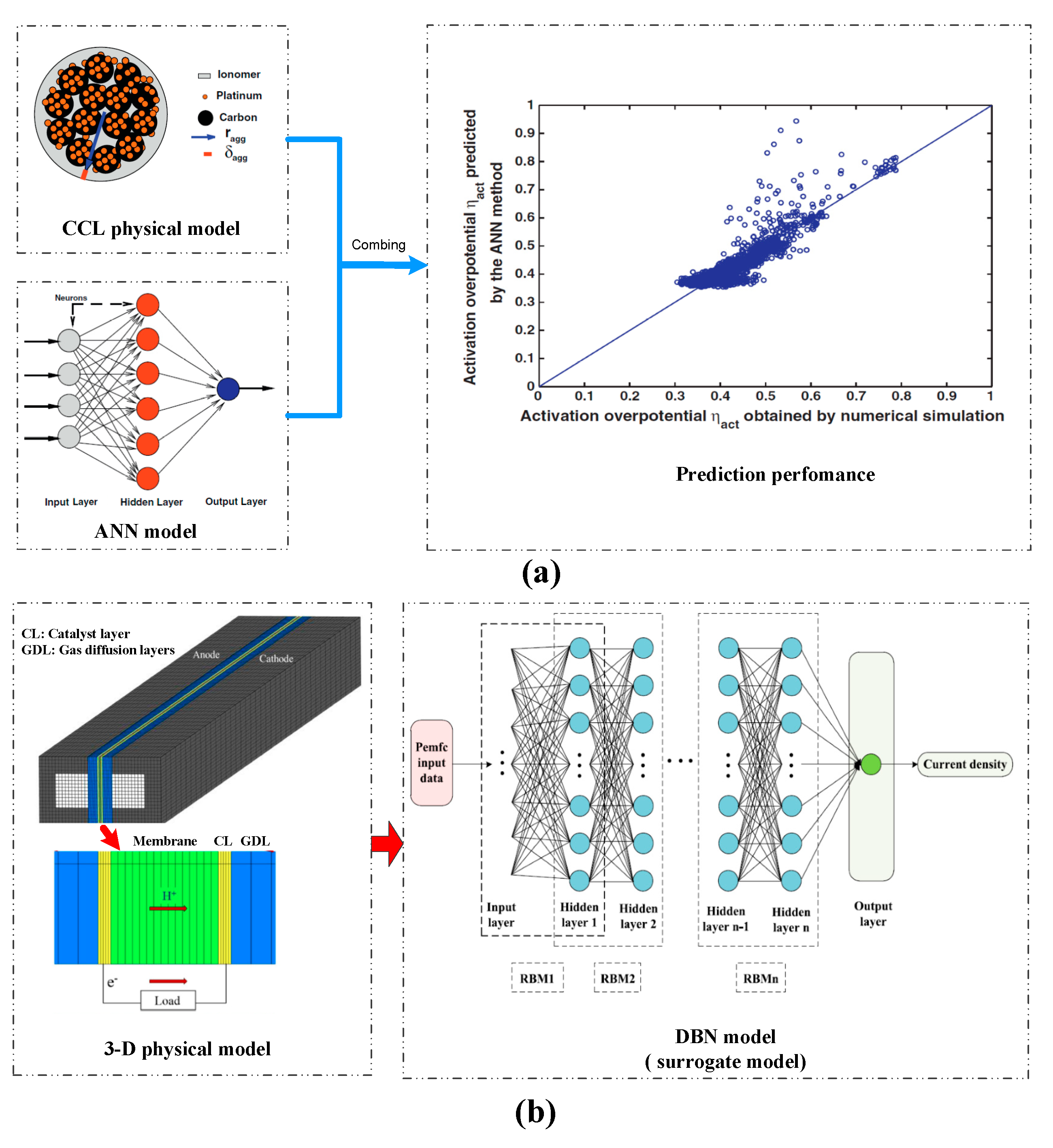

3.2. Models and Simulation Results

3.3. Summary

4. PEM Simulation Models

4.1. Brief Introduction

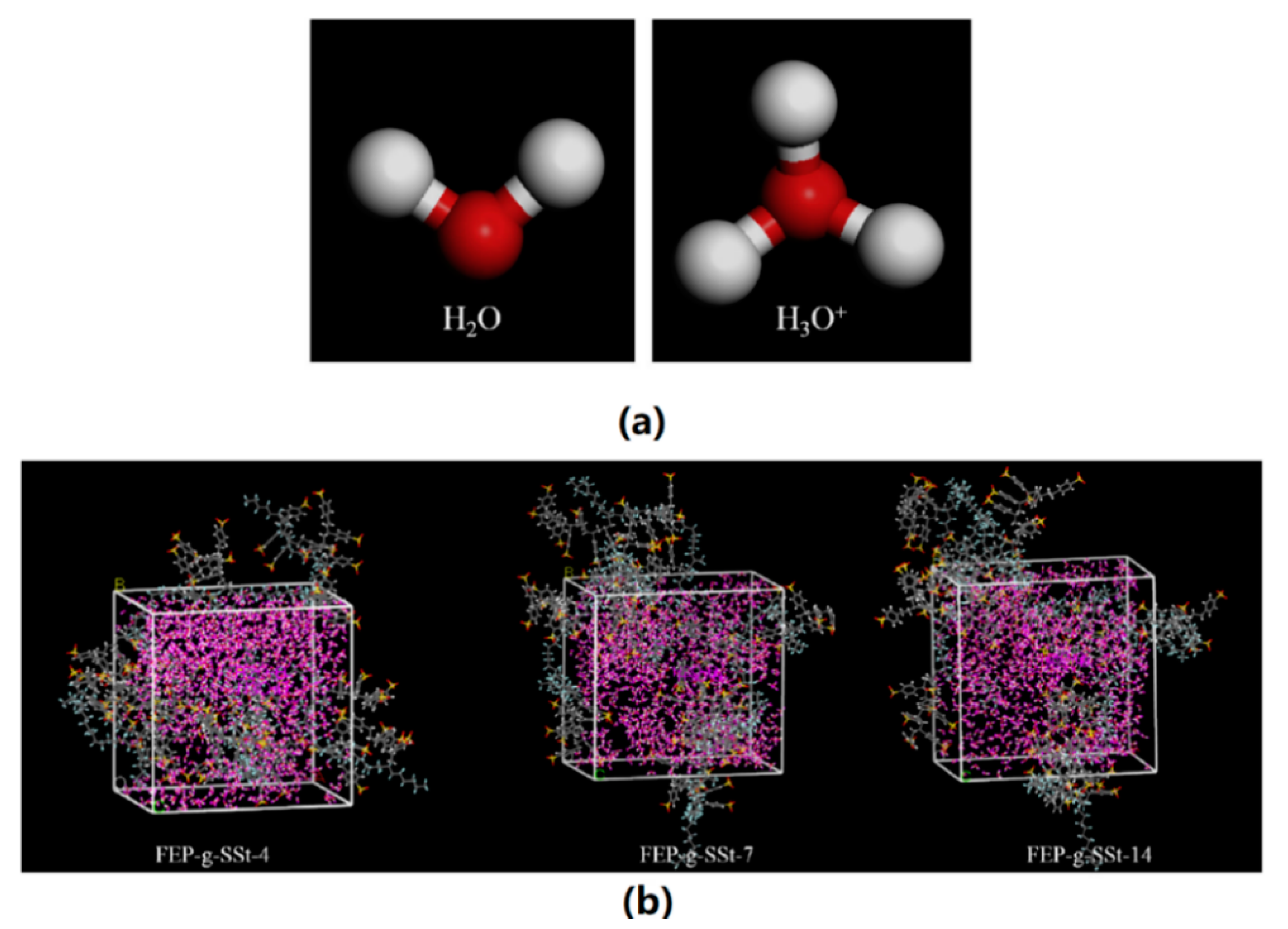

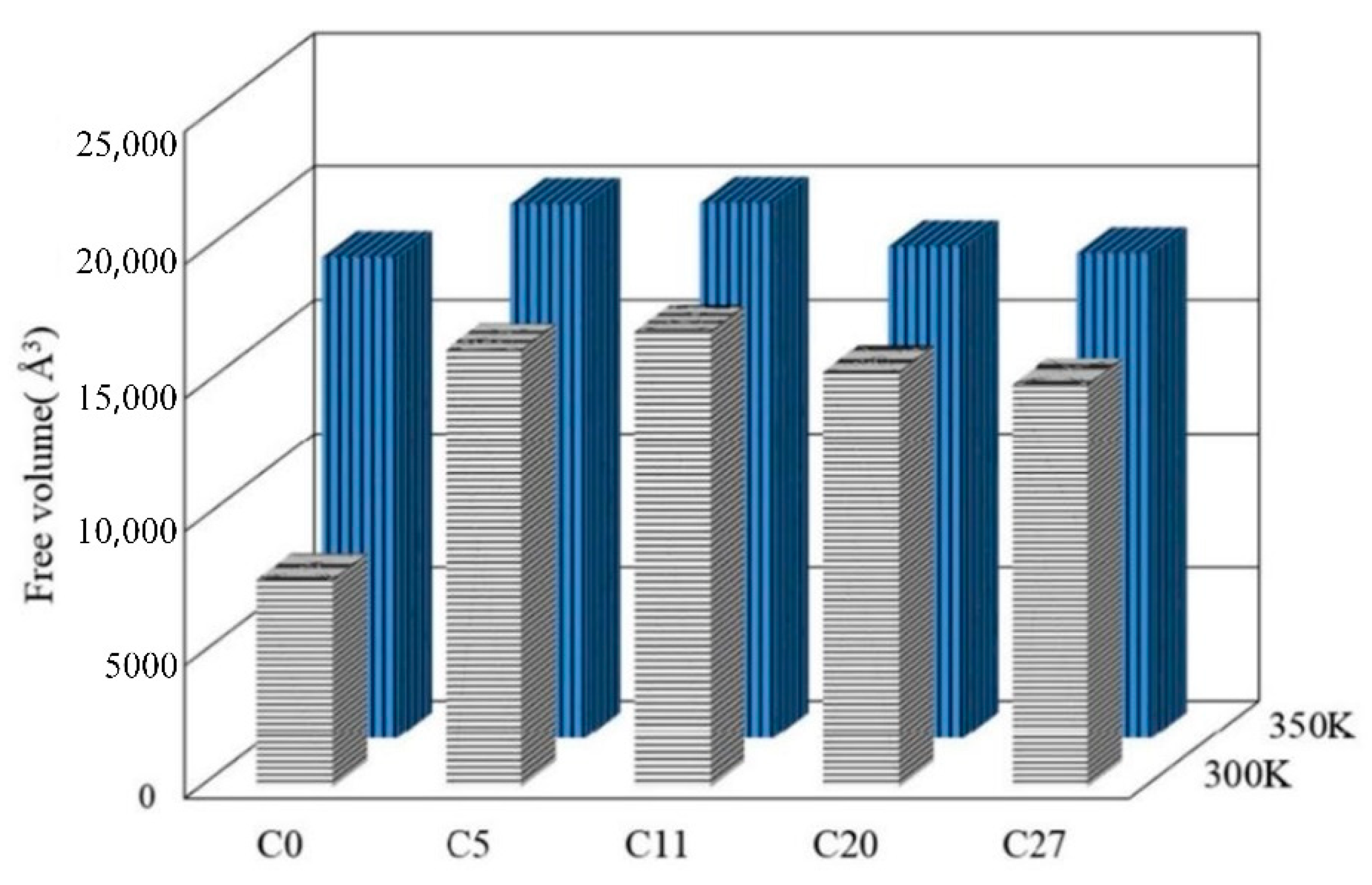

4.2. Molecular Dynamics Models and Results

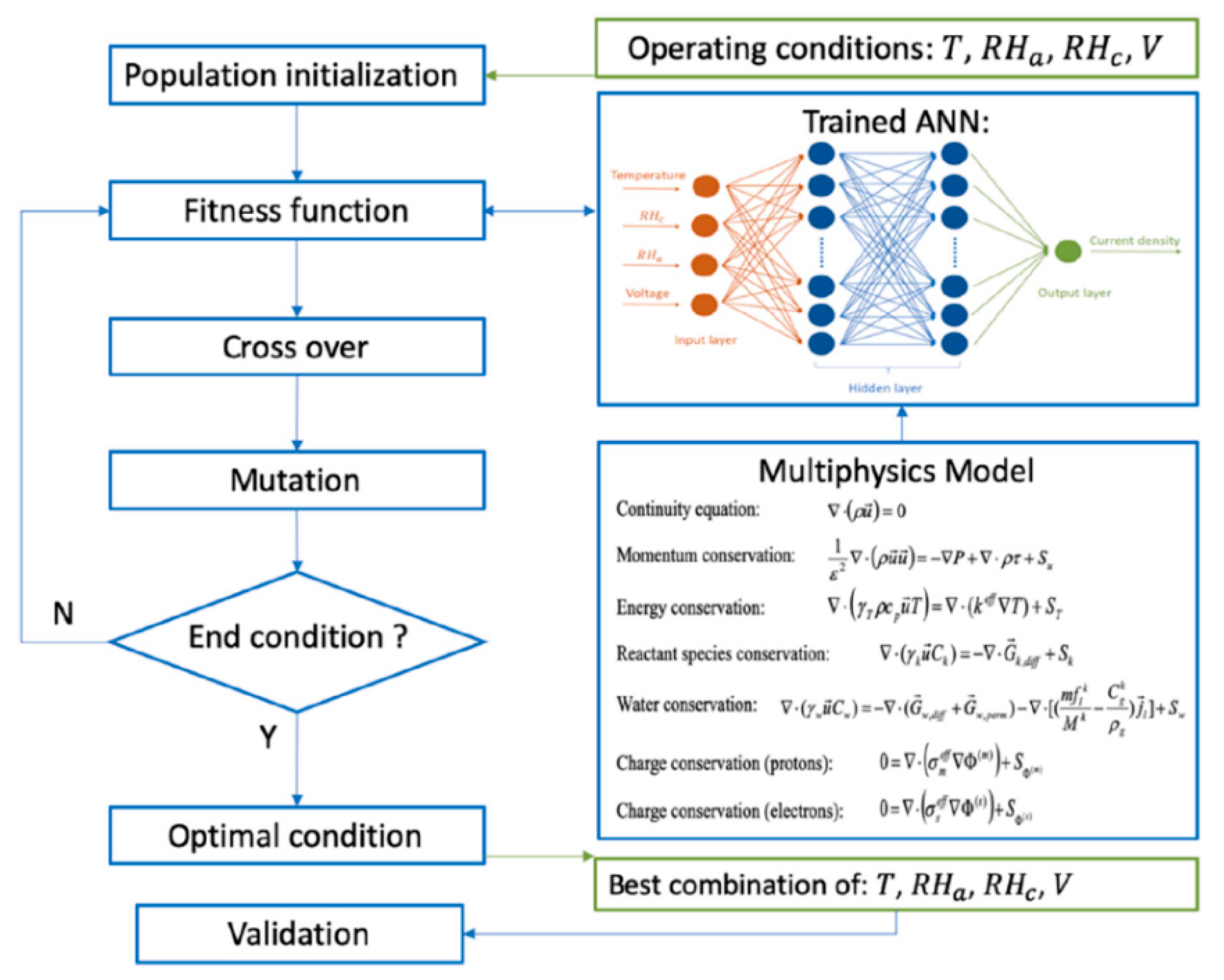

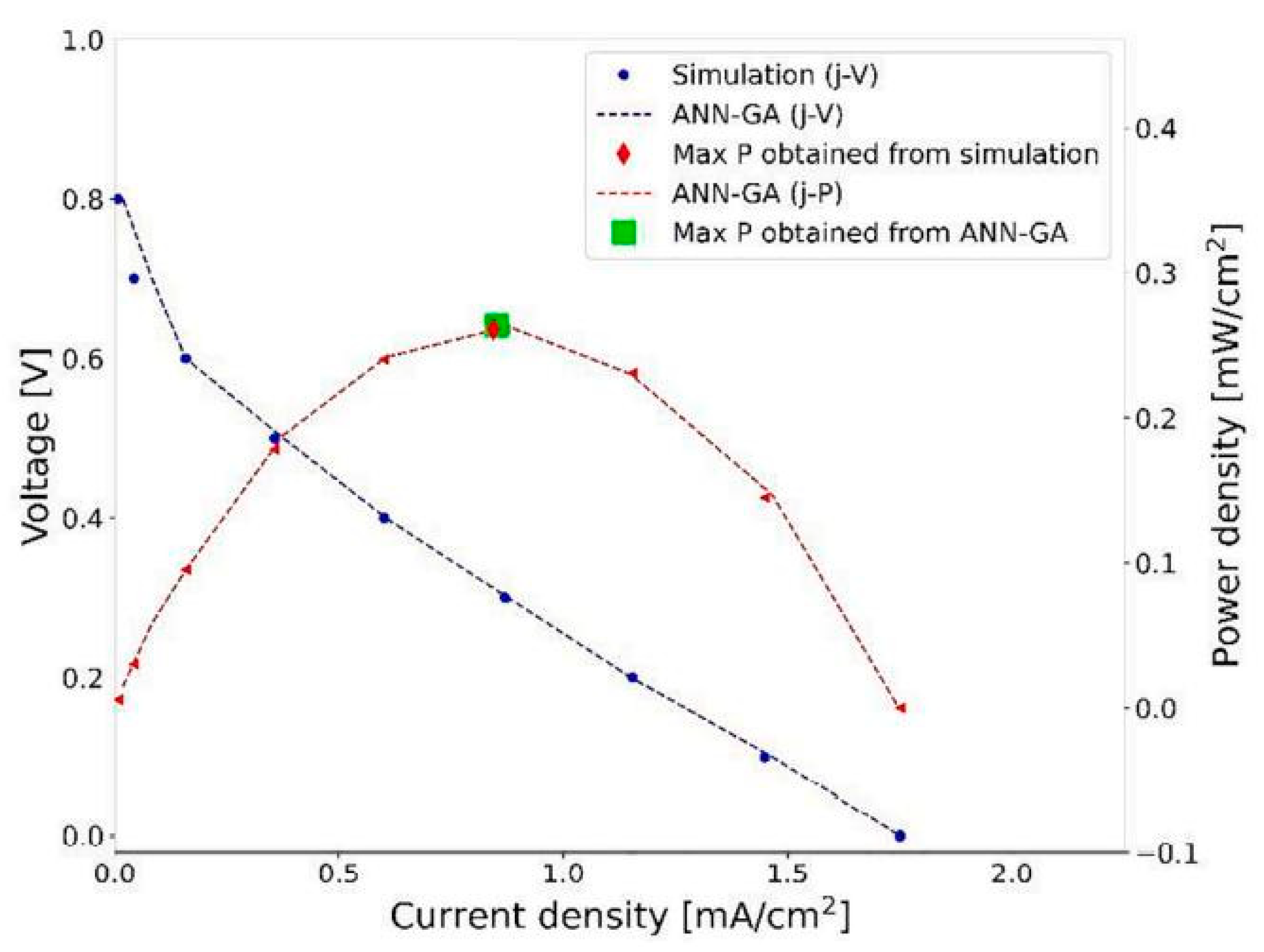

4.3. Multiphysics Simulation and ML Methods

4.4. Summary

5. Discussion

5.1. Similarity

5.2. Individuality

5.3. Complementarity

6. Outlook

- (1)

- For the modeling of membrane electrode material structure optimization, existing models are mainly constructed for GDL, CL or PEM single components. In the future, a hybrid model could be built; this would integrate the simulation model of the three components mentioned above to realize the overall modeling of MEAs. In addition, most of the existing simulation models involve single-scale modeling [30,53,93], either macro scale or micro material structure models. If a cross-scale hybrid model is established, it may be more beneficial for solving the existing difficulties.

- (2)

- To obtain a low-cost and long-life PEMFC, it is necessary to find a suitable and cheaper preparation method for the MEA microstructure. In addition to traditional preparation methods, non-traditional machining methods, such as laser machining [122,123], electrical discharge machining [124,125] and electrochemical machining [126,127], also made good progress in the preparation of microstructures. This means that a future 3D digital simulation MEA model must also consider the influence of the preparation process on the microstructure, so as to establish a more accurate model. In addition, reliability design, which can prolong the in-service time of equipment, is widely used in the engineering field [128,129]. When dealing with MEA material structure optimization modeling in the future, reliability design should be integrated into the simulation process to improve the life of PEMFCs.

- (3)

- With the rapid development of computer technology, ML technology is widely used in the fields of industrial inspection and measurement [130,131,132], medical diagnosis [133,134], life sciences [135,136] and so on. For example, AlphaFold2 constructed a protein structure prediction model through ML; it was able to predict the properties of proteins from gene sequences, obtaining 98.5% of the human protein structure [135]. Therefore, the combination of the ML method and an MEA simulation model to realize autonomous prediction (with preliminary artificial intelligence) may be the focus of research in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, G.; Zou, L.; Huang, Q.; Zou, Z.; Yang, H. Multidimensional nanostructured membrane electrode assemblies for proton exchange membrane fuel cell applications. J. Mater. Chem. A 2019, 7, 9447–9477. [Google Scholar] [CrossRef]

- Dai, G.; Wang, Q.; Xue, S.; Wang, G.; Zou, Z.; Yu, N.; Wu, Y. A sensor of liquid methanol for direct methanol fuel cells. Anal. Chim. Acta 2021, 1177, 338785. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.; Chun, Y.; Peck, D.; Shin, D. A novel process to fabricate membrane electrode assemblies for proton exchange membrane fuel cells. Int. J. Hydrogen Energy 1998, 23, 1045–1048. [Google Scholar] [CrossRef]

- New Era of Word View—A Big Test: Carbon Peak and Carbon Neutralization. 2022. Available online: http://cn.chinadaily.com.cn/a/202206/06/WS629ddedfa3101c3ee7ad9222.html (accessed on 5 June 2022).

- We Will Strive to Reach the Peak Value of Carbon Emissions by 2030 and Strive to Achieve Carbon Neutrality by 2060. 2020. Available online: https://www.scimall.org.cn/article/detail?id=4479161 (accessed on 5 June 2022).

- Address at the General Debate of the 75th United Nations General Assembly. Available online: http://www.thjj.org/sf_D68E6120FC25401F8C141EB8A3033DCF_227_bjmmgj.html (accessed on 8 June 2022).

- Wang, Y.; Seo, B.; Wang, B.; Zamel, N.; Jiao, K.; Adroher, X.C. Fundamentals, materials, and machine learning of polymer electrolyte membrane fuel cell technology. Energy AI 2020, 1, 100014. [Google Scholar] [CrossRef]

- Debe, M.K. Electrocatalyst approaches and challenges for automotive fuel cells. Nature 2012, 486, 43–51. [Google Scholar] [CrossRef]

- Duan, C.; Tong, J.; Shang, M.; Nikodemski, S.; Sanders, M.; Ricote, S.; Almansoori, O.R. Readily processed protonic ceramic fuel cells with high performance at low temperatures. Science 2015, 349, 1321–1326. [Google Scholar] [CrossRef]

- Bloom Energy 2020. Available online: https://www.bloomenergy.com (accessed on 12 June 2022).

- AFC Energy 2020. Available online: www.afcenergy.com (accessed on 12 June 2022).

- Doosan Fuel Cell 2020. Available online: www.doosanfuelcellamerica.com (accessed on 12 June 2022).

- FuelCell Energy 2020. Available online: www.fuelcellenergy.com (accessed on 13 June 2022).

- Song, Z.; Wang, B.; Cheng, N.; Yang, L.; Banham, D.; Li, R.; Ye, S.; Sun, X. Atomic layer deposited tantalum oxide to anchor Pt/C for a highly stable catalyst in PEMFCs. J. Mater. Chem. A 2017, 5, 9760–9767. [Google Scholar] [CrossRef]

- Mohiuddin, A.K.M.; Basran, N.; Khan, A.A. Modelling and validation of Proton exchange membrane fuel cell (PEMFC). Mater. Sci. Eng. 2018, 290, 012026. [Google Scholar] [CrossRef] [Green Version]

- Yang, B.; Han, Q.; Xiang, Z. Progress of membrane electrode structure and its design for proton exchange membrane fuel cell. Chem. Ind. Eng. Prog. 2021, 40, 4882–4893. (In Chinese) [Google Scholar]

- Fu, X.; Gao, R.; Jiang, G.; Li, M.; Bai, Z. Evolution of Atomic-scale Dispersion of FeNx in Hierarchically Porous 3D Air Electrode to Boost the Interfacial Electrocatalysis of Oxygen Reduction in PEMFC. Nano Energy 2021, 83, 105734. [Google Scholar] [CrossRef]

- Park, S.; Lee, J.W.; Popov, B.N. Effect of carbon loading in microporous layer on PEM fuel cell performance. J. Power Sources 2006, 163, 357–363. [Google Scholar] [CrossRef]

- Qi, Z.; Kaufman, A. Improvement of water management by a microporous sublayer for PEM fuel cells. J. Power Sources 2002, 109, 38–46. [Google Scholar] [CrossRef]

- Soler, J.; Hontanon, E.; Daza, L. Electrode permeability and flow-field configuration: Influence on the performance of a PEMFC. J. Power Sources 2003, 118, 172–178. [Google Scholar] [CrossRef]

- Bapat, C.J.; Thynell, S.T. Effect of anisotropic electrical resistivity of gas diffusion layers (GDLs) on current density and temperature distribution in a Polymer Electrolyte Membrane (PEM) fuel cell. J. Power Sources 2008, 185, 428–432. [Google Scholar] [CrossRef]

- Hakenjos, A.; Muenter, H.; Wittstadt, U.; Hebling, C. A PEM fuel cell for combined measurement of current and temperature distribution, and flow field flooding. J. Power Sources 2004, 131, 213–216. [Google Scholar] [CrossRef]

- Wang, M.; Guo, H.; Ma, C. Temperature distribution on the MEA surface of a PEMFC with serpentine channel flow bed. J. Power Sources 2006, 157, 181–187. [Google Scholar] [CrossRef]

- Vie, P.J.S.; Kjelstrup, S. Thermal conductivities from temperature profiles in the polymer electrolyte fuel cell. Electrochim. Acta 2004, 49, 1069–1077. [Google Scholar] [CrossRef]

- He, S.; Mench, M.M.; Tadigadapa, S. Thin film temperature sensor for real-time measurement of electrolyte temperature in a polymer electrolyte fuel cell. Sensor. Actuat. A Phys. 2006, 125, 170–177. [Google Scholar] [CrossRef]

- Mench, M.M.; Burford, D.J.; Davis, T.W. In situ temperature distribution measurement in an operating polymer electrolyte fuel cell. ASME Int. Mech. Eng. Congr. Expo. 2003, 37181, 415–428. [Google Scholar]

- Authayanun, S.; Saebea, D.; Patcharavorachot, Y.; Arpornwichanop, A. Effect of different fuel options on performance of high-temperature PEMFC (proton exchange membrane fuel cell) systems. Energy 2014, 68, 989–997. [Google Scholar] [CrossRef]

- Meng, H.; Wang, C.Y. Model of two-phase flow and flooding dynamics in polymer electrolyte fuel cells. J. Electrochem. Soc. 2005, 152, A1733. [Google Scholar] [CrossRef]

- Koido, T.; Furusawa, T.; Moriyama, K. An approach to modeling two-phase transport in the gas diffusion layer of a proton exchange membrane fuel cell. J. Power Sources 2008, 175, 127–136. [Google Scholar] [CrossRef]

- Zhou, X.; Wu, L.; Niu, Z.; Bao, Z.; Du, Q. Effects of surface wettability on two-phase flow in the compressed gas diffusion layer microstructures. Int. J. Heat Mass Transf. 2020, 151, 119370. [Google Scholar] [CrossRef]

- Shi, X.; Jiao, D.; Bao, Z.; Jiao, K.; Chen, W.; Liu, Z. Liquid transport in gas diffusion layer of proton exchange membrane fuel cells: Effects of micro-porous layer cracks. Int. J. Hydrogen Energy 2022, 47, 6247–6258. [Google Scholar] [CrossRef]

- Yiotis, A.G.; Kainourgiakis, M.E.; Charalambopoulou, G.C.; Stubos, A.K. Microscale characterisation of stochastically reconstructed carbon fiber-based Gas Diffusion Layers; effects of anisotropy and resin content. J. Power Sources 2016, 320, 153–167. [Google Scholar] [CrossRef]

- Goebel, M.; Godehardt, M.; Schladitz, K. Multi-scale structural analysis of gas diffusion layers. J. Power Sources 2017, 355, 8–17. [Google Scholar] [CrossRef]

- Zhou, Y.; Jiao, K.; Du, Q.; Yin, Y.; Li, X. Gas diffusion layer deformation and its effect on the transport characteristics and performance of proton exchange membrane fuel cell. Int. J. Hydrogen Energy 2013, 38, 12891–12903. [Google Scholar] [CrossRef]

- Zhou, X.; Niu, Z.; Bao, Z.; Wang, J.; Jiao, K. Two-phase flow in compressed gas diffusion layer: Finite element and volume of fluid modeling. J. Power Sources 2019, 437, 226933. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, K.S. Advanced control of liquid water region in diffusion media of polymer electrolyte fuel cells through a dimensionless number. J. Power Sources 2016, 315, 224–235. [Google Scholar] [CrossRef] [Green Version]

- Santamaria, A.D.; Mortazavi, M.; Chauhan, V.; Benner, J.; Philbrick, O.; Clemente, R.; Jia, H.; Ling, C. Machine Learning Applications of Two-Phase Flow Data in Polymer Electrolyte Fuel Cell Reactant Channels. J. Electrochem. Soc. 2021, 168, 054505. [Google Scholar] [CrossRef]

- Chauhan, V.; Mortazavi, M.; Benner, J.Z.; Santamaria, A.D. Two-phase flow characterization in PEM fuel cells using machine learning—ScienceDirect. Energy Rep. 2020, 6, 2713–2719. [Google Scholar] [CrossRef]

- Morey, C.; Baredar, P. Fuel Cell Technology-Polymer Electrolyte Membrane Fuel Cell; CRC Press: Boca Raton, FL, USA, 2020; pp. 107–122. [Google Scholar] [CrossRef]

- Springer, T.E.; Zawodzinski, T.A.; Gottesfeld, S. Polymer Electrolyte Fuel Cell Model. J. Electrochem. Soc. 1991, 138, 2334–2342. [Google Scholar] [CrossRef]

- Bernardi, D.M.; Verbrugge, M.W. A mathematical model of the solid-polymer-electrolyte fuel cell. J. Electrochem. Soc. 1992, 139, 2477–2491. [Google Scholar] [CrossRef]

- Nguyen, T.V.; White, R.E. A Water and Heat Management Model for Proton-Exchange-Membrane Fuel Cells. J. Electrochem. Soc. 1993, 140, 2178–2186. [Google Scholar] [CrossRef]

- Pasaogullari, U.; Wang, C.-Y.; Chen, K.S. Two-Phase Transport in Polymer Electrolyte Fuel Cells with Bilayer Cathode Gas Diffusion Media. J. Electrochem. Soc. 2005, 152, A1574–A1582. [Google Scholar] [CrossRef]

- Atyabi, S.A.; Afshari, E.; Wongwises, S.; Yan, W.-M.; Hadjadj, A.; Shadloo, M.S. Effects of assembly pressure on PEM fuel cell performance by taking into accounts electrical and thermal contact resistances. Energy 2019, 179, 490–501. [Google Scholar] [CrossRef]

- Berning, T.; Odgaard, M.; Kær, S.K. A Computational Analysis of Multiphase Flow through PEMFC Cathode Porous Media Using the Multifluid Approach. J. Electrochem. Soc. 2009, 156, B1301–B1311. [Google Scholar] [CrossRef]

- Ye, Q.; Nguyen, T.V. Three-Dimensional Simulation of Liquid Water Distribution in a PEMFC with Experimentally Measured Capillary Functions. J. Electrochem. Soc. 2007, 154, B1242–B1251. [Google Scholar] [CrossRef]

- Antolini, E. Review in applied electrochemistry. Number 54 recent developments in polymer electrolyte fuel cell electrodes. J. Appl. Electrochem. 2004, 34, 563–576. [Google Scholar] [CrossRef]

- Zhao, X.; Li, W.; Fu, Y.; Manthiram, A. Influence of ionomer content on the proton conduction and oxygen transport in the carbon-supported catalyst layers in DMFC. Int. J. Hydrogen Energy 2012, 37, 9845–9852. [Google Scholar] [CrossRef]

- Kulikovsky, A.A. Polarization curve of partially degraded catalyst layer. Electrochem. Commun. 2010, 12, 1780–1783. [Google Scholar] [CrossRef]

- Kandlikar, S.G. Microscale and Macroscale Aspects of Water Management Challenges in PEM Fuel Cells. Heat. Transfer Eng. 2008, 29, 575–587. [Google Scholar] [CrossRef]

- Marr, C.; Li, X. Composition and performance modelling of catalyst layer in a proton exchange membrane fuel cell. J. Power Sources 1999, 77, 17–27. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, K.S.; Mishler, J.; Cho, S.C.; Adroher, X.C. A review of polymer electrolyte membrane fuel cells: Technology, applications, and needs on fundamental research. Appl. Energy 2011, 88, 981–1007. [Google Scholar] [CrossRef] [Green Version]

- Ebrahimi, S.; Roshandel, R.; Vijayaraghavan, K. Power density optimization of PEMFC cathode with non-uniform catalyst layer by Simplex method and numerical simulation. Int. J. Hydrogen Energy 2016, 41, 22260–22273. [Google Scholar] [CrossRef]

- Sabharwal, M.; Pant, L.M.; Putz, A.; Susac, D.; Jankovic, J.; Secanell, M. Analysis of Catalyst Layer Microstructures: From Imaging to Performance. Fuel Cells 2016, 16, 734–753. [Google Scholar] [CrossRef]

- Salvado, M.B.; Schott, P.; Guetaz, L.; Gerard, M.; David, T.; Bultel, Y. Towards the understanding of transport limitations in a proton-exchange membrane fuel cell catalyst layer: Performing agglomerate scale direct numerical simulations on electron-microscopy-based geometries. J. Power Sources 2021, 482, 228893. [Google Scholar] [CrossRef]

- Khajeh-Hosseini-Dalasm, N.; Ahadian, S.; Fushinobu, K.; Okazaki, K.; Kawazoe, Y. Prediction and analysis of the cathode catalyst layer performance of proton exchange membrane fuel cells using artificial neural network and statistical methods. J. Power Sources 2011, 196, 3750–3756. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, G.; Wang, H.; Xuan, J.; Jiao, K. Multi-physics-resolved digital twin of proton exchange membrane fuel cells with a data-driven surrogate model. Energy AI 2020, 1, 100004. [Google Scholar] [CrossRef]

- Li, H.; Xu, B.; Du, C.; Yang, Y. Performance prediction and power density maximization of a proton exchange membrane fuel cell based on deep belief network. J. Power Sources 2020, 461, 228154. [Google Scholar] [CrossRef]

- Colombo, M.; Nova, I.; Tronconi, E. A simplified approach to modeling of dual-layer ammonia slip catalysts. Chem. Eng. Sci. 2012, 75, 75–83. [Google Scholar] [CrossRef]

- Tovazhnyanskii, L.L.; Tolchinsky, Y.A.; Ved, E.V.; Meshalkin, V.P. Three-level model of a surface catalytic reaction over a platinum catalyst. Theor. Found. Chem. Eng. 2011, 45, 589–594. [Google Scholar] [CrossRef]

- Selsil, A.; Movchan, N.V.; Movchan, A.B.; Kolaczkowski, S.T.; Awdry, S. Mathematical modelling of heat transfer in a catalytic reformer. IMA J. Appl. Math. 2005, 70, 201–220. [Google Scholar] [CrossRef]

- Melo, D.N.C.; Costa, C.B.B.; Vasco de Toledo, E.C.; Mariano, A.P.; Wolf Maciel, M.R.; Maciel Filho, R. Optimization of a three-phase catalytic slurry reactor using reduced statistical models. Int. J. Chem. React. Eng. 2010, 8, 1542–6580. [Google Scholar] [CrossRef]

- Melo, D.N.C.; Vasco de Toledo, E.C.; Mariano, A.P.; Santos, M.M.; Maciel Filho, R. An approach to optimization of a three phase catalyticslurry reactor by evolutionary optimization with geneticalgorithms. IFAC Proc. Vol. 2007, 40, 373–378. [Google Scholar] [CrossRef]

- Mariano, A.P.; Costa, C.B.B.; de Toledo, E.C.V.; Melo, D.N.C.; Maciel Filho, R. Analysis of the particle swarm algorithm in the optimization of a three-phase slurry catalytic reactor. Comput. Chem. Eng. 2011, 35, 2741–2749. [Google Scholar] [CrossRef]

- Hung, Y.; Tawfik, H.; Mahajan, D. Durability and characterization studies of polymer electrolyte membrane fuel cell’s coated aluminum bipolar plates and membrane electrode assembly. J. Power Sources 2009, 186, 123–127. [Google Scholar] [CrossRef]

- Thosar, A.U.; Agarwal, H.; Govarthan, S.; Lele, A.K. Comprehensive analytical model for polarization curve of a PEM fuel cell and experimental validation. Chem. Eng. Sci. 2019, 206, 96–117. [Google Scholar] [CrossRef]

- Dawes, J.E.; Hanspal, N.S.; Family, O.A.; Turan, A. Three dimensional CFD modelling of PEM fuel cells: An investigation into the effects of water flooding. Chem. Eng. Sci. 2009, 64, 2781–2794. [Google Scholar] [CrossRef] [Green Version]

- Han, C.; Chen, Z. Numerical simulations of two-phase flow in a proton-exchange membrane fuel cell based on the generalized design method. Energy Sources Part A 2019, 41, 1253–1271. [Google Scholar] [CrossRef]

- Mustata, R.; Valiño, L.; Barreras, F.; Gil, M.I.; Lozano, A. Study of the distribution of air flow in a proton exchange membrane fuel cell stack. J. Power Sources 2009, 192, 185–189. [Google Scholar] [CrossRef]

- Mazumder, S.; Cole, J.V. Rigorous 3-D Mathematical Modeling of PEM Fuel Cells. J. Electrochem. Soc. 2003, 150, A1503. [Google Scholar] [CrossRef]

- Ticianelli, E.A.; Derouin, C.R.; Srinivasan, S. Localization of platinum in low catalyst loading electrodes to to attain high power densities in SPE fuel cells. J. Electroanal. Chem 1988, 251, 275–295. [Google Scholar] [CrossRef]

- Wilson, M.S.; Gottesfeld, S. Thin-film catalyst layers for polymer electrolyte fuel cell electrodes. J. Appl. Electrochem. 1992, 22, 1–7. [Google Scholar] [CrossRef]

- Taylor, E.J.; Anderson, E.B.; Vilambi, N.R.K. Preparation of high-platinum-utilization gas diffusion electrodes for proton-exchange-membrane fuel cells. J. Electrochem. Soc. 1992, 139, L45. [Google Scholar] [CrossRef]

- Paganin, V.A.; Ticianelli, E.A.; Gonzalez, E.R. Development and electrochemical studies of gas diffusion electrodes for polymer electrolyte fuel cells. J. Appl. Electrochem. 1996, 26, 297–304. [Google Scholar] [CrossRef]

- Song, J.M.; Cha, S.Y.; Lee, W.M. Optimal composition of polymer electrolyte fuel cell electrodes determined by the AC impedance method. J. Power Sources 2001, 94, 78–84. [Google Scholar] [CrossRef]

- Antolini, E.; Giorgi, L.; Pozio, A.; Passalacqua, E. Influence of Nafion loading in the catalyst layer of gas-diffusion electrodes for PEFC. J. Power Sources 1999, 77, 136–142. [Google Scholar] [CrossRef]

- Lee, S.J.; Mukerjee, S.; McBreen, J.; Rho, Y.W.; Kho, Y.T.; Lee, T.H. Effects of Nafion impregnation on performances of PEMFC electrodes. Electrochim. Acta 1998, 43, 3693–3701. [Google Scholar] [CrossRef]

- Passalacqua, E.; Lufrano, F.; Squadrito, G.; Patti, A.; Giorgi, L. Nafion content in the catalyst layer of polymer electrolyte fuel cells: Effects on structure and performance. Electrochim. Acta 2001, 46, 799–805. [Google Scholar] [CrossRef]

- Sasikumar, G.; Ihm, J.W.; Ryu, H. Optimum Nafion content in PEM fuel cell electrodes. Electrochim. Acta 2004, 50, 601–605. [Google Scholar] [CrossRef]

- Uchida, M.; Aoyama, Y.; Eda, N.; Ohta, A. Investigation of the microstructure in the catalyst layer and effects of both perfluorosulfonate ionomer and PTFE-loaded carbon on the catalyst layer of polymer electrolyte fuel cells. J. Electrochem. Soc. 1995, 142, 4143. [Google Scholar] [CrossRef]

- Uchida, M.; Fukuoka, Y.; Sugawara, Y.; Ohara, H.; Ohta, A. Improved preparation process of very-low-platinum-loading electrodes for polymer electrolyte fuel cells. J. Electrochem. Soc. 1998, 145, 3708. [Google Scholar] [CrossRef]

- Deng, Y.; Chi, B.; Tian, X.; Cui, Z.; Liu, E.; Jia, Q.; Fan, W.; Wang, G.; Dang, D.; Li, M.; et al. g-C3N4 promoted MOF derived hollow carbon nanopolyhedra doped with high density/fraction of single Fe atoms as an ultra-high performance non-precious catalyst towards acidic ORR and PEM fuel cells. J. Mater. Chem. A 2019, 7, 5020–5030. [Google Scholar] [CrossRef]

- Hussain, A.; Ali, N.; Ali, S.S.; Hou, J.; Aslam, I.; Naeem, H.; Boota, M.; Ul-Hussan, M.; Yin, J.; Wang, X. Diverse morphological study for nonmetal-doped g-C3N4 composites with narrow bandgap for improved photocatalytic activity. Res. Chem. Intermed. 2022, 48, 2857–2870. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, L.; Jiang, J. Experimental study of assembly clamping pressure on performance of PEM fuel cells. Appl. Mech. Mater. 2011, 44, 2399–2403. [Google Scholar] [CrossRef]

- Manso, A.P.; Marzo, F.F.; Barranco, J.; Garikano, X.; Garmendia Mujika, M. Influence of geometric parameters of the flow fields on the performance of a PEM fuel cell. A review. Int. J. Hydrogen Energy 2012, 37, 15256–15287. [Google Scholar] [CrossRef]

- Chandan, A.; Hattenberger, M.; El-Kharouf, A.; Du, S.; Dhir, A.; Self, V.; Pollet, B.G.; Ingram, A.; Bujalski, W. High temperature (HT) polymer electrolyte membrane fuel cells (PEMFC) A review. J. Power Sources 2013, 231, 264–278. [Google Scholar] [CrossRef]

- Borup, R.L.; Kusoglu, A.; Neyerlin, K.C.; Mukundan, R.; Ahluwalia, R.K.; Cullen, D.A.; More, K.L.; Weber, A.Z.; Myers, D.J. Recent developments in catalyst -related PEM fuel cell durability. Curr. Opin. Electrochem. 2020, 21, 192–200. [Google Scholar] [CrossRef]

- Araya, S.S.; Zhou, F.; Liso, V.; Sahlin, S.L.; Vang, J.R.; Thomas, S.; Gao, X.; Jeppesen, C.; Kær, S.K. A comprehensive review of PBI-based high temperature PEM fuel cells. Int. J. Hydrogen Energy 2016, 41, 21310–21344. [Google Scholar] [CrossRef]

- Chen, Y.; Guo, X.; Zhang, G.; Cao, Y.; Shen, D.; Li, X.; Zhang, S.; Ming, W. Development of a hybrid intelligent process model for micro-electro discharge machining using the TTM-MDS and gaussian process regression. Micromachines 2022, 13, 845. [Google Scholar] [CrossRef] [PubMed]

- Ming, W.; Zhang, S.; Zhang, G.; Du, Z.; Ma, J.; He, W.; Cao, C.; Liu, K. Progress in modeling of electrical discharge machining process. Int. J. Heat Mass Transf. 2022, 187, 122563. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, G.; Huang, Y.; Ming, W.; Liu, M.; Huang, H. Investigation of the removing process of cathode material in Micro-EDM using an atomistic-continuum model. Appl. Surf. Sci. 2014, 315, 323–336. [Google Scholar] [CrossRef]

- Park, C.H.; Nam, S.Y.; Hong, Y.T. Molecular Dynamics (MD) study of proton exchange membranes for fuel cells. J. Membr. Sci. 2016, 26, 329–336. [Google Scholar] [CrossRef]

- Li, X.; Zhao, Y.; Li, W.; Wang, S.; Liu, X.; Xie, X.; Chen, J.; Li, Q.; Jensen, J.O. Molecular Dynamics simulation of radiation grafted FEP films as proton exchange membranes: Effects of the side chain length. Int. J. Hydrogen Energy 2017, 42, 29977–29987. [Google Scholar] [CrossRef]

- Rao, Z.; Zheng, C.; Geng, F. Proton conduction of fuel cell polymer membranes: Molecular Dynamics simulation. Comp. Mater. Sci. 2018, 142, 122–128. [Google Scholar] [CrossRef]

- Tai, C.C.; Chen, C.L.; Liu, C.W. Computer simulation to investigate proton transport and conductivity in perfluorosulfonate ionomeric membrane. Int. J. Hydrogen Energy 2017, 42, 3981–3986. [Google Scholar] [CrossRef]

- Zheng, C.; Geng, F.; Rao, Z. Proton mobility and thermal conductivities of fuel cell polymer membranes: Molecular Dynamics simulation. Comp. Mater. Sci. 2017, 132, 55–61. [Google Scholar] [CrossRef]

- Lyu, K.; Peng, Y.; Xiao, L.; Lu, J.; Zhuang, L. Communication water induced phase segregation in hydrocarbon proton exchange membranes. J. Energy Chem. 2018, 27, 1517–1520. [Google Scholar] [CrossRef] [Green Version]

- Park, C.H.; Kim, T.; Nam, S.Y.; Hong, Y.T. Water channel morphology of non-perfluorinated hydrocarbon proton exchange membrane under a low humidifying condition. Int. J. Hydrogen Energy 2019, 44, 2340–2348. [Google Scholar] [CrossRef]

- Jourdani, M.; Mounir, H.; Marjani, A.E.L. Numerical simulation of the performance of proton exchange membrane fuel cell with different membrane geometries. J. Mech. Eng. Sci. 2017, 11, 2941–2951. [Google Scholar] [CrossRef]

- Tsukamoto, T.; Aoki, T.; Kanesaka, H.; Taniguchi, T.; Yoneda, M. Three-dimensional numerical simulation of full-scale proton exchange membrane fuel cells at high current densities. J. Power Sources 2021, 488, 229412. [Google Scholar] [CrossRef]

- Haghayegh, M.; Eikani, M.H.; Rowshanzamir, S. Modeling and simulation of a proton exchange membrane fuel cell using computational fluid dynamics. Int. J. Hydrogen Energy 2017, 42, 21944–21954. [Google Scholar] [CrossRef]

- Sezgin, B.; Caglayan, D.G.; Devrim, Y.; Steenberg, T.; Eroglu, I. Modeling and sensitivity analysis of high temperature PEM fuel cells by using Comsol Multiphysics. Int. J. Hydrogen Energy 2016, 41, 10001–10009. [Google Scholar] [CrossRef]

- Jourdani, M.; Mounir, H.; El Marjani, A. Modeling a PEM fuel cell under different thicknesses of membrane. Adv. Appl. Fluid Mech. 2017, 20, 605–625. [Google Scholar] [CrossRef]

- Guo, S.J.; Zhang, S.; Sun, S.H. Tuning Nanoparticle Catalysis for the Oxygen Reduction Reaction. Angew. Chem. Int. Ed. 2013, 52, 8526–8544. [Google Scholar] [CrossRef]

- Wang, Y.J.; Wilkinson, D.P.; Zhang, J.J. Noncarbon Support Materials for Polymer Electrolyte Membrane Fuel Cell Electrocatalysts. Chem. Rev. 2011, 111, 7625–7651. [Google Scholar] [CrossRef]

- Trogadas, P.; Fuller, T.F.; Strasser, P. Carbon as catalyst and support for electrochemical energy conversion. Carbon 2014, 75, 5–42. [Google Scholar] [CrossRef]

- Cho, Y.H.; Park, H.S.; Cho, Y.H.; Jung, D.S.; Park, H.Y.; Sung, Y.E. Effect of platinum amount in carbon supported platinum catalyst on performance of polymer electrolyte membrane fuel cell. J. Power Sources 2007, 172, 89–93. [Google Scholar] [CrossRef]

- Guo, Y.; Pan, F.; Chen, W.; Ding, Z.; Yang, D.; Li, B.; Ming, P.; Zhang, C. The Controllable Design of Catalyst Inks to Enhance PEMFC Performance: A Review. Electrochem. Energy Rev. 2020, 4, 67–100. [Google Scholar] [CrossRef]

- Tian, P.; Liu, X.; Luo, K.; Li, H.; Wang, Y. Deep learning from three-dimensional multiphysics simulation in operational optimization and control of polymer electrolyte membrane fuel cell for maximum power. Appl. Energy 2021, 288, 116632. [Google Scholar] [CrossRef]

- Nguyen, D.D.; Pham, T.Q.D.; Tanveer, M.; Khan, H.; Park, J.W.; Park, C.W.; Kim, G.M. Deep learning–based optimization of a microfluidic membraneless fuel cell for maximum power density via data-driven three-dimensional multiphysics simulation. Bioresour. Technol. 2022, 348, 126794. [Google Scholar] [CrossRef]

- Yin, Z.; Razmjooy, N. PEMFC identification using deep learning developed by improved deer hunting optimization algorithm. Int. J. Power. Energy. Syst. 2020, 40, 189–203. [Google Scholar] [CrossRef]

- Zhou, D.; Wu, Y.; Gao, F.; Breaz, A.; Ravey, A. Miraoui Degradation prediction of PEM fuel cell stack based on multiphysical aging model with particle filter approach. IEEE Trans. Ind. Appl. 2017, 53, 4041–4052. [Google Scholar] [CrossRef]

- Shan, W.; Nackenhorst, U. An adaptive FE–MD model coupling approach. Comput. Mech. 2010, 46, 577–596. [Google Scholar] [CrossRef]

- Erban, R. From Molecular Dynamics to Brownian Dynamics. Proc. R. Soc. A Math. Phys. Eng. Sci. 2014, 470, 20140036. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Ding, R.; Cao, F.; Li, J.; Dong, H.; Shi, T.; Liu, J. Comparison of state-of-the-art machine learning algorithms and data-driven optimization methods for mitigating nitrogen crossover in PEM fuel cells. Chem. Eng. J. 2022, 442, 136064. [Google Scholar] [CrossRef]

- Yue, M.; Li, Z.; Roche, R.; Jemei, S.; Zerhouni, N. Degradation identification and prognostics of proton exchange membrane fuel cell under dynamic load. Eng. Pract. 2022, 118, 104959. [Google Scholar] [CrossRef]

- Mert, S.O.; Toprak, M.M. Exergetic Comparison of Various Flow Patterns in PEMFCs. Int. J. Thermodyn. 2019, 22, 159–166. [Google Scholar] [CrossRef]

- Dutta, S.; Shimpalee, S. Numerical Prediction of Temperature Distribution in PEM Fuel Cells. Numer. Heat Transf. Part A Appl. 2000, 38, 111–128. [Google Scholar] [CrossRef]

- Kvesic, M.; Reimer, U.; Froning, D.; Lüke, L.; Lehnert, W.; Stolten, D. 3D modeling of a 200 cm2 HT-PEFC short stack. Int. J. Hydrogen Energy 2012, 37, 2430–2439. [Google Scholar] [CrossRef]

- Wöhr, M.; Bolwin, K.; Schnurnberger, W.; Fischer, M.; Neubrand, W.; Eigenberger, G. Dynamic modelling and simulation of a polymer membrane fuel cell including mass transport limitation. Int. J. Hydrogen Energy 1998, 23, 213–218. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Z.; Liu, X.; Wu, W.-T. Modeling of PEM fuel cell with thin MEA under low humidity operating condition. Appl. Energy 2019, 242, 1513–1527. [Google Scholar] [CrossRef]

- Huang, H.; Xu, Y.; Luo, G.; Xie, Z.; Ming, W. Molecular Dynamics Study of Laser Interaction with Nanoparticles in Liquids and Its Potential Application. Nanomaterials 2022, 12, 1524. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Liu, D.; Zhang, Y.; Zhao, J.; Zhang, G. Bubble Behavior and Its Effect on Surface Integrity in Laser-Induced Plasma Micro Machining Silicon Wafer. J. Manuf. Sci. Eng. 2022, 144, 091008. [Google Scholar] [CrossRef]

- Shen, D.; Ming, W.; Ren, X.; Xie, Z.; Liu, X. Progress in Non-Traditional Processing for Fabricating Superhydrophobic Surfaces. Micromachines 2021, 12, 1003. [Google Scholar] [CrossRef] [PubMed]

- Ming, W.; Xie, Z.; Ma, J.; Du, J.; Zhang, G.; Cao, C.; Zhang, Y. Critical review on sustainable techniques in electrical discharge machining. J. Manuf. Process. 2021, 72, 375–399. [Google Scholar] [CrossRef]

- Li, J.; Yang, Y.; Zhu, G.; Sun, C.; Chen, Y.; Wang, K.; Shi, S. The Anisotropic Electrochemical Machinability of Laser Cladding Deposited Ti6Al4V Alloy in NaCl Solution. Materials 2022, 15, 3642. [Google Scholar] [CrossRef]

- Schupp, A.; Beyss, O.; Rommes, B.; Klink, A.; Zander, D. Insights on the Influence of Surface Chemistry and Rim Zone Microstructure of 42CrMo4 on the Efficiency of ECM. Materials 2021, 14, 2132. [Google Scholar] [CrossRef]

- Li, X.; Zhu, H.; Chen, Z.; Ming, W.; Cao, Y.; He, W.; Ma, J. Limit state Kriging modeling for reliability-based design optimization through classification uncertainty quantification. Reliab. Eng. Syst. Saf. 2022, 224, 108539. [Google Scholar] [CrossRef]

- Li, X.; Han, X.; Chen, Z.; Ming, W.; Cao, Y.; Ma, J. A multi-constraint failure-pursuing sampling method for reliability-based design optimization using adaptive Kriging. Eng. Comput. 2020, 38, 297–310. [Google Scholar] [CrossRef]

- Ming, W.; Zhang, S.; Liu, X.; Liu, K.; Yuan, J.; Xie, Z.; Sun, P.; Guo, X. Survey of Mura Defect Detection in Liquid Crystal Displays Based on Machine Vision. Crystals 2021, 11, 1444. [Google Scholar] [CrossRef]

- He, W.; Jiang, Z.; Ming, W.; Zhang, G.; Yuan, J.; Yin, L. A critical review for machining positioning based on computer vision. Measurement 2021, 184, 109973. [Google Scholar] [CrossRef]

- Ming, W.; Cao, C.; Zhang, G.; Zhang, H.; Zhang, F.; Jiang, Z.; Yuan, J. Application of Convolutional Neural Network in Defect Detection of 3C Products. IEEE Access 2021, 9, 135657–135674. [Google Scholar] [CrossRef]

- Kandubothula, V.; Uppada, R.; Nandan, D. A review on detection of breast cancer cells by using various techniques. Soft Comput. Theor. Appl. 2020, 1154, 813–823. [Google Scholar] [CrossRef]

- He, W.; Liu, T.; Han, Y.; Ming, W.; Du, J.; Liu, Y.; Yang, Y.; Wang, L.; Jiang, Z.; Wang, Y.; et al. A review: The detection of cancer cells in histopathology based on machine vision. Comput. Biol. Med. 2022, 146, 105636. [Google Scholar] [CrossRef]

- Jumper, J.; Evans, R.; Pritzel, A.; Green, T.; Figurnov, M.; Ronneberger, O.; Tunyasuvunakool, K.; Bates, R.; Žídek, A.; Potapenko, A.; et al. Highly accurate protein structure prediction with AlphaFold. Nature 2021, 596, 583–589. [Google Scholar] [CrossRef]

- Sherman, M.A.; Yaari, A.U.; Priebe, O.; Dietlein, F.; Loh, P.R.; Berger, B. Genome-wide mapping of somatic mutation rates uncovers drivers of cancer. Nat. Biotechnol. 2022, 1–10. [Google Scholar] [CrossRef]

| Model Dimension | Area of Study | Data Used for Model Validation | Reference |

|---|---|---|---|

| One- dimensional | Fuel cell performance | Experimental data | Springer et al. [40] |

| Species migration mechanism and factors affecting fuel cell performance | Experimental data | Bernardi et al. [41] | |

| Two- dimensional | Humidification effects | None | Nguyen et al. [42] |

| Transport of two phases within the PEM fuel cell | None | Pasaogullari et al. [43] | |

| Microstructure of two-phase flow in GDL and the influence of surface wettability distribution | None | Zhou et al. [30] | |

| Microstructure of MPL-containing carbon fiber-based GDL materials | None | Göbel et al. [33] | |

| Three-dimensional | Effect of cell assembly pressure on contact resistance between bipolar plate and GDL | None | Atyabi et al. [44] |

| Liquid water flow from GDLs to the gas channels of the PEM fuel cell | Experimental data | Berning et al. [45] | |

| Formation of liquid water with GDLs and CLs of the PEM fuel cell | None | Ye et al. [46] |

| Model Dimension | Area of Study | Data Used for Model Validation | Reference |

|---|---|---|---|

| One- dimensional | Coarsening and performance monitoring of Pt particles | None | Hung et al. [65] |

| Two-dimensional | Calculation method of diffusion coefficient of in situ oxygen under different conditions | None | Thosar et al. [66] |

| Predicting the current density of PEMFCs by combining a 3D physical model with DBN model | None | Li et al. [58] | |

| A multi-physical model to realize its discretization and morphology design of microstructure | None | Barreiros et al. [55] | |

| Three-dimensional | Influence of water flooding on performance of PEM fuel cell | None | Dawes et al. [67] |

| Effects of the air velocity and wettability | Experimental data | Han et al. [68] | |

| Air flow distribution in the PEM fuel stack for two different configurations | None | Mustata et al. [69] | |

| Transport and formation of liquid water | Experimental data | Mazumder et al. [70] |

| Model Dimension | Area of Study | Data Used for Model Validation | Reference |

|---|---|---|---|

| Two- dimensional | Effects of heat generation on PEM fuel cell performance | None | Dutta et al. [118] |

| Microstructure of MPL-containing carbon fiber-based GDL materials | None | Zhou et al. [112] | |

| Three- dimensional | Performance of multi-cell PEM stack (five single cells) | Experimental data | Kvesić et al. [119] |

| Thermal and water management of single PEM fuel cell and multi-cell stacks | None | Wöhr et al. [120] | |

| Effects of oxygen transfer resistance and catalyst reduction on performance of Automotive PEM fuel cells at high current density | None | Li et al. [121] | |

| Deep learning-based method for optimizing a membraneless microfluidic fuel cell performance by combining the artificial neural network and genetic algorithm | None | Nguyen et al. [110] | |

| Method combining ANN, genetic algorithm and a 3D multiphysics model to predict the performance of PEM fuel cells | Experimental data | Tian et al. [109] | |

| A 3D numerical model was developed to study the influence of different membrane geometries on PEMFC performance | None | Jourdani et al. [99] |

| Propose | Models | Based On Microstructure Simulation | Integration with ML | Advantages | Shortcomings |

|---|---|---|---|---|---|

| GDL | Two-dimensional two-phase model [21]; Two-phase flow model [28] | No | No | Simple modeling and less calculation | Lack of GDL material microstructure characterization |

| Two-phase flow model [30] | Yes | No | Convenient to study the influence of material structure on its performance | Complex modeling | |

| A process-based algorithm [32]; a stochastic model [35] | Yes | No | Could investigate the microscopic properties of materials | Multiple integrating models required to complete | |

| CL | A two-dimensional model [37] | No | No | Easy to determine the optimal catalyst loading distribution | Microstructure of CL material is not considered. |

| A multi-physical model [39] | Yes | No | Could be used to design the structural heterogeneity | High modeling complexity | |

| A physical model with ANN [49] | Yes | Yes | Can be predicted the CCL performance | Multidisciplinary knowledge involved | |

| PEM | Molecular dynamics models [93,94] | Yes | No | To study details of its morphology, structure, etc. | Complex modeling and long calculation time |

| Multiphysics simulation [99] | No | No | To obtain different membrane geometries on the performance of PEMFCs | Lack of research on material microstructure | |

| Multiphysics simulation with ML [104] | Yes | Yes | Suitable for predicting fuel cell performance | Interdisciplinary knowledge required |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Liu, Y.; Xu, Y.; Guo, X.; Cao, Y.; Ming, W. Review: Modeling and Simulation of Membrane Electrode Material Structure for Proton Exchange Membrane Fuel Cells. Coatings 2022, 12, 1145. https://doi.org/10.3390/coatings12081145

Chen Y, Liu Y, Xu Y, Guo X, Cao Y, Ming W. Review: Modeling and Simulation of Membrane Electrode Material Structure for Proton Exchange Membrane Fuel Cells. Coatings. 2022; 12(8):1145. https://doi.org/10.3390/coatings12081145

Chicago/Turabian StyleChen, Yanyan, Yuekun Liu, Yingjie Xu, Xudong Guo, Yang Cao, and Wuyi Ming. 2022. "Review: Modeling and Simulation of Membrane Electrode Material Structure for Proton Exchange Membrane Fuel Cells" Coatings 12, no. 8: 1145. https://doi.org/10.3390/coatings12081145

APA StyleChen, Y., Liu, Y., Xu, Y., Guo, X., Cao, Y., & Ming, W. (2022). Review: Modeling and Simulation of Membrane Electrode Material Structure for Proton Exchange Membrane Fuel Cells. Coatings, 12(8), 1145. https://doi.org/10.3390/coatings12081145