Cylinder Fatigue Design of Low-Speed, High-Torque Radial Piston Motor

Abstract

:1. Introduction

2. Materials and Methods

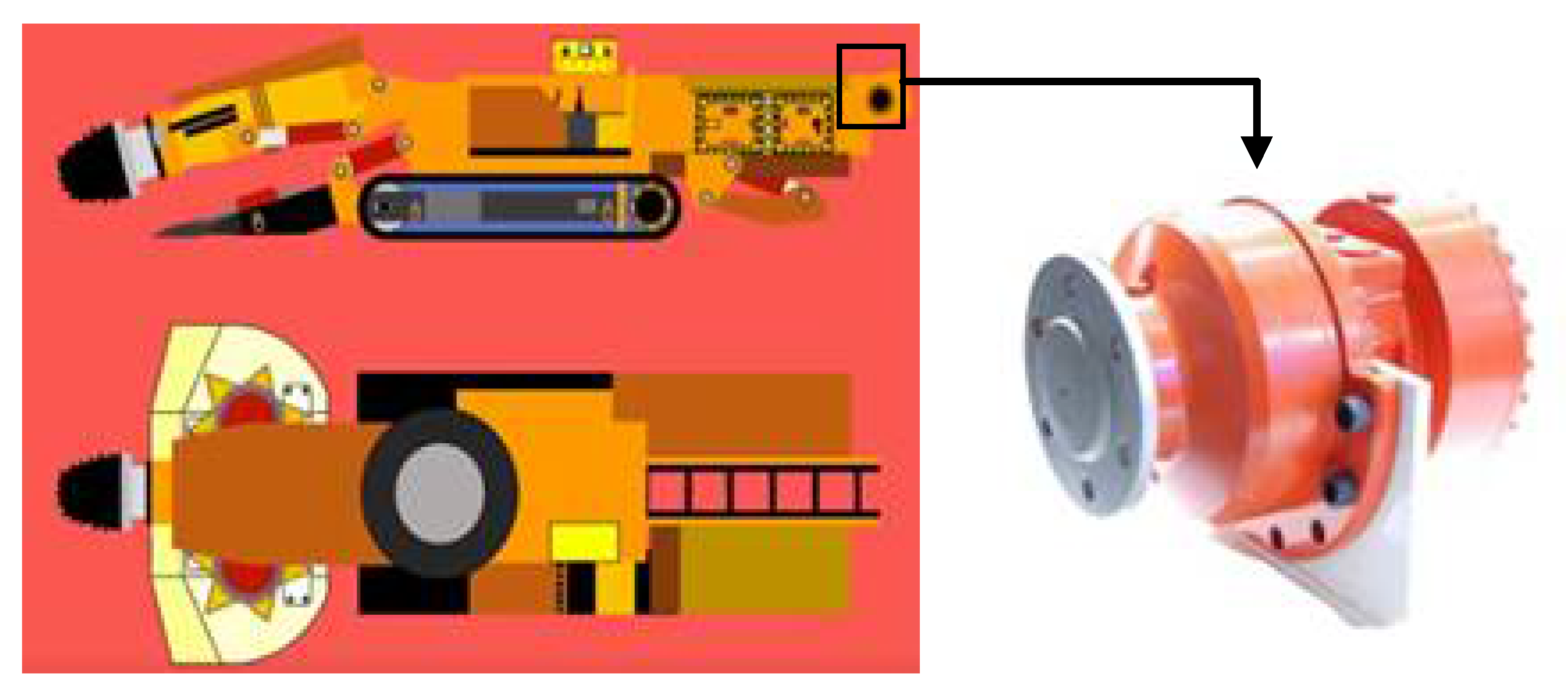

2.1. Motor Cylinder Parameters

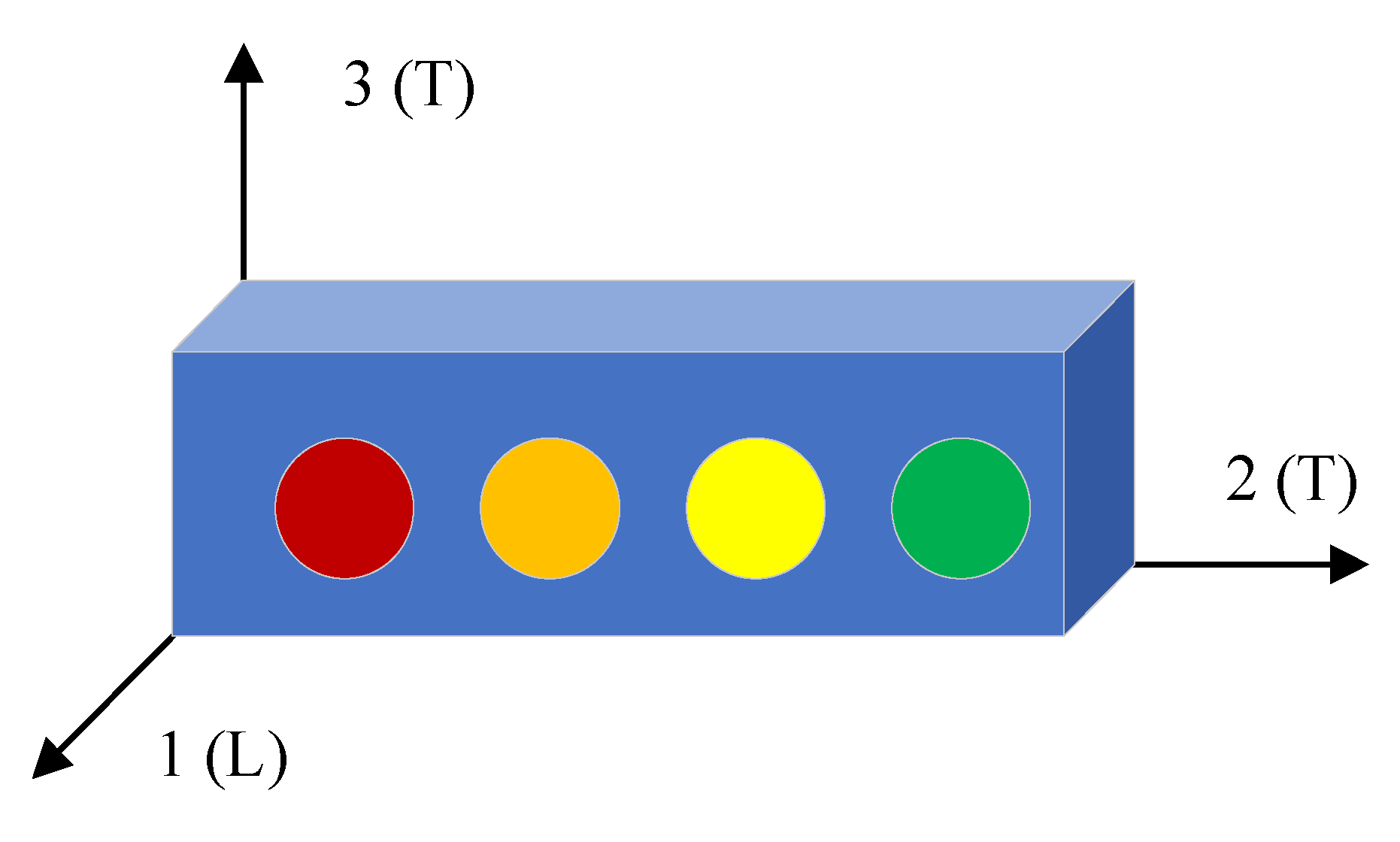

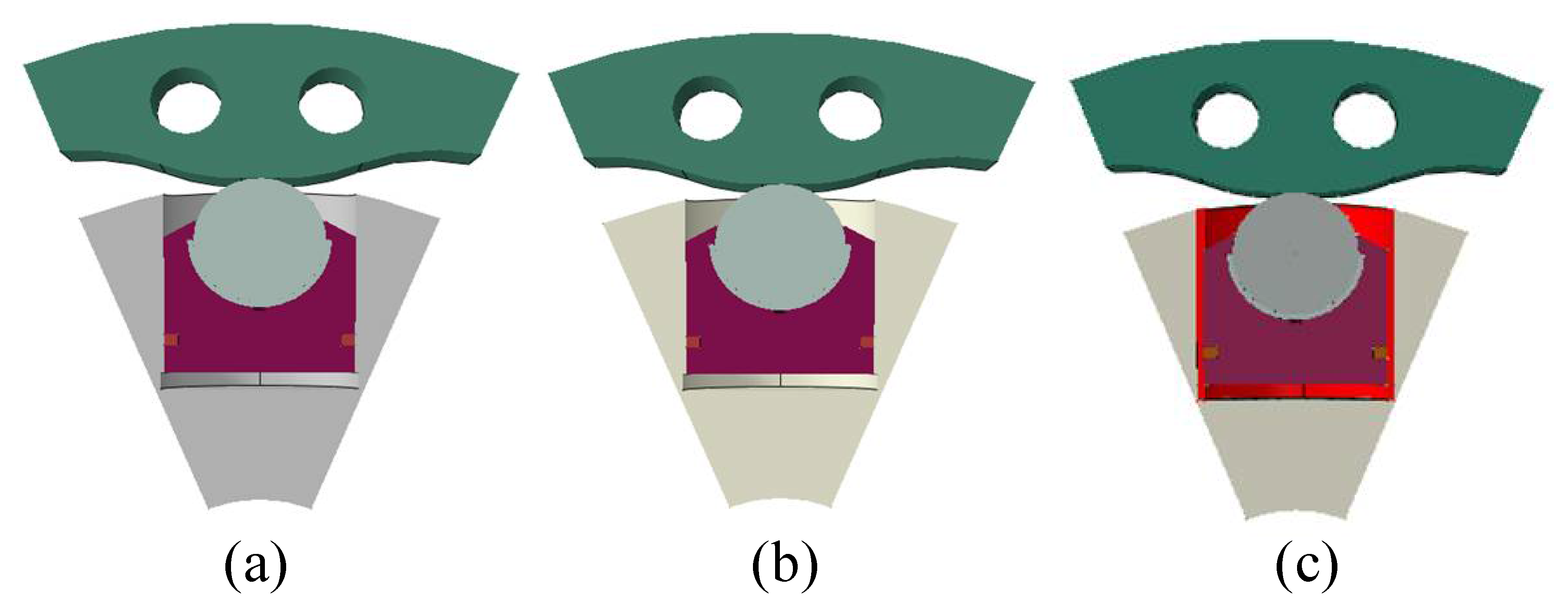

2.2. Three Theories of Cylinder Design

2.3. Fatigue Performance Verification Theory

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, P.; Cai, M. Challenges and new insights for exploitation of deep underground metal mineral resources. Trans. Nonferr. Met. Soc. China 2021, 31, 3478–3505. [Google Scholar] [CrossRef]

- Ağbulut, Ü. Forecasting of transportation-related energy demand and CO2 emissions in Turkey with different machine learning algorithms. Sustain. Prod. Consum. 2022, 29, 141–157. [Google Scholar] [CrossRef]

- Lin, T.; Lin, Y.; Ren, H.; Chen, H.; Chen, Q.; Li, Z. Development and key technologies of pure electric construction machinery. Renew. Sustain. Energy Rev. 2020, 132, 110080. [Google Scholar] [CrossRef]

- Trinh, H.A.; Truong, H.V.A.; Do, T.C.; Nguyen, M.H.; Phan, V.D.; Ahn, K.K. Optimization-based energy management strategies for hybrid construction machinery: A review. Energy Rep. 2022, 8, 6035–6057. [Google Scholar] [CrossRef]

- Almeida, R.S.M.; Chen, S.A.; Besser, B.; Tushtev, K.; Li, Y.; Rezwan, K. Fatigue behavior and damage analysis of PIP C/SiC composite. J. Eur. Ceram. Soc. 2022, 42, 5391–5398. [Google Scholar] [CrossRef]

- Gao, J.; Zhu, P.; Yuan, Y.; Wu, Z.; Xu, R. Strength and stiffness degradation modeling and fatigue life prediction of composite materials based on a unified fatigue damage model. Eng. Fail. Anal. 2022, 137, 106290. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, H.; Yang, F.; Tong, L.; Yan, D.; Yang, Y.; Wang, Y.; Wu, Y. Experimental investigation of pneumatic motor for transport application. Renew. Energy 2021, 179, 517–527. [Google Scholar] [CrossRef]

- Wang, X.; Lyu, X. Experimental study on vertical water entry of twin spheres side-by-side. Ocean. Eng. 2021, 221, 108508. [Google Scholar] [CrossRef]

- Xiong, X.; Ma, Q.; Yingying, Y.; Wu, Z.; Zhang, M. Current situation and key manufacturing considerations of green furniture in China: A review. J. Clean. Prod. 2020, 267, 121957. [Google Scholar] [CrossRef]

- Watkins, M.; Casamayor, J.L.; Ramirez, M.; Moreno, M.; Faludi, J.; Pigosso, D.C.A. Sustainable Product Design Education: Current Practice. She Ji J. Des. Econ. Innov. 2021, 7, 611–637. [Google Scholar] [CrossRef]

- Wang, N.; Wang, H.; Ren, J.; Gao, G.; Zhao, G.; Yang, Y.; Wang, J. High-efficient and environmental-friendly PTFE@SiO2 core-shell additive with excellent AW/EP properties in PAO6. Tribol. Int. 2021, 158, 106930. [Google Scholar] [CrossRef]

- Sharma, R.; Jha, B.K.; Pahuja, V.; Sharma, S. Role of environmental friendly machining on machinability. Mater. Today Proc. 2022, 50, 640–648. [Google Scholar] [CrossRef]

- Anselma, P.G. Electrified powertrain sizing for vehicle fleets of car makers considering total ownership costs and CO2 emission legislation scenarios. Appl. Energy 2022, 314, 118902. [Google Scholar] [CrossRef]

- Barkh, H.; Yu, A.; Friend, D.; Shani, P.; Tu, Q.; Swei, O. Vehicle fleet electrification and its effects on the global warming potential of highway pavements in the United States. Resour. Conserv. Recycl. 2022, 185, 106440. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, Z.; Rao, X.; Xu, Y.; Sheng, C.; Yuan, C. A comprehensive review on the material performance affected by gaseous alternative fuels in internal combustion engines. Eng. Fail. Anal. 2022, 139, 106507. [Google Scholar] [CrossRef]

- Woydt, M. The importance of tribology for reducing CO2 emissions and for sustainability. Wear 2021, 474, 203768. [Google Scholar] [CrossRef]

- Woydt, M. Material efficiency through wear protection—The contribution of tribology for reducing CO2 emissions. Wear 2022, 488, 204134. [Google Scholar] [CrossRef]

- Ganesarajan, D.; Simon, L.; Tamrakar, S.; Kiziltas, A.; Mielewski, D.; Behabtu, N.; Lenges, C. Hybrid composites with engineered polysaccharides for automotive lightweight. Compos. Part C Open Access 2022, 7, 100222. [Google Scholar] [CrossRef]

- Junk, S.; Rothe, N. Lightweight design of automotive components using generative design with fiber-reinforced additive manufacturing. Procedia CIRP 2022, 109, 119–124. [Google Scholar] [CrossRef]

- Mistry, P.J.; Johnson, M.S.; Li, S.; Bruni, S.; Bernasconi, A. Parametric sizing study for the design of a lightweight composite railway axle. Compos. Struct. 2021, 267, 113851. [Google Scholar] [CrossRef]

- Solazzi, L. Feasibility study of hydraulic cylinder subject to high pressure made of aluminum alloy and composite material. Compos. Struct. 2019, 209, 739–746. [Google Scholar] [CrossRef]

- Solazzi, L.; Assi, A.; Ceresoli, F. Excavator arms: Numerical, experimental and new concept design. Compos. Struct. 2019, 217, 60–74. [Google Scholar] [CrossRef]

- Collotta, M.; Solazzi, L. New design concept of a tank made of plastic material for firefighting vehicle. Int. J. Automot. Mech. Eng. 2017, 14, 4603–4615. [Google Scholar] [CrossRef]

- Solazzi, L.; Assi, A.; Ceresoli, F. New Design Concept for an Excavator Arms by Using Composite Material. Appl. Compos. Mater. 2018, 25, 601–617. [Google Scholar] [CrossRef]

- Solazzi, L. Experimental and analytical study on elevating working platform. Procedia Eng. 2017, 199, 2597–2602. [Google Scholar] [CrossRef]

- Solazzi, L. Design and experimental tests on hydraulic actuator made of composite material. Compos. Struct. 2020, 232, 111544. [Google Scholar] [CrossRef]

- Solazzi, L.; Buffoli, A. Telescopic Hydraulic Cylinder Made of Composite Material. Appl. Compos. Mater. 2019, 26, 1189–1206. [Google Scholar] [CrossRef]

- Solazzi, L.; Buffoli, A. Fatigue design of hydraulic cylinder made of composite material. Compos. Struct. 2021, 277, 114647. [Google Scholar] [CrossRef]

- Huang, W.; Zhong, H.; Lei, L.; Fang, G. Microstructure and mechanical properties of multi-pass forged and annealed 42CrMo steel. Mater. Sci. Eng. A 2022, 831, 142191. [Google Scholar] [CrossRef]

- Kali, N.; Chelimilla, N.; Korla, S. Influence of damages (hole/slits) on tensile behavior of Al 7075-T6/glass fibre-based hybrid laminates. Mater. Today Proc. 2022, 56, 631–636. [Google Scholar] [CrossRef]

- Puttaraju, D.G.; Hanumantharaju, H.G. Finite element analysis and validation of tensile properties of carbon fiber reinforced polymer matrix composites. Mater. Today Proc. 2022, 62, 2800–2807. [Google Scholar] [CrossRef]

- Abdollahzadeh, M.A.; Ali, H.Q.; Yildiz, M.; Kefal, A. Experimental and numerical investigation on large deformation reconstruction of thin laminated composite structures using inverse finite element method. Thin-Walled Struct. 2022, 178, 109485. [Google Scholar] [CrossRef]

- Yan, B.; Zhu, S.; Tong, M.; Pan, S. Experimental study on the mechanical properties of laminates made of thin carbon fiber plies. Compos. Struct. 2020, 245, 112336. [Google Scholar] [CrossRef]

- Solazzi, L. Stress variability in multilayer composite hydraulic cylinder. Compos. Struct. 2021, 259, 113249. [Google Scholar] [CrossRef]

- Buragohain, M.K. Composite Structures: Design, Mechanics, Analysis, Manufacturing, and Testing; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Gay, D.; Hoa, S.V. Composite Materials. Design and Applications, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2015; pp. 118–119. [Google Scholar]

- Bedi, D.; Sharma, S. Prediction of principal stresses and strains in laminated composites using MATLAB. Mater. Today Proc. 2021, 44, 4643–4650. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, A.; Szafraniec, M.; Barnat-Hunek, D.; Sadowska-Buraczewska, B. Static Analysis of Skew Functionally Graded Plate Using Novel Shear Deformation Theory. Materials 2022, 15, 4633. [Google Scholar] [CrossRef]

- Mognhod Bezzie, Y.; Paramasivam, V.; Tilahun, S.; Selvaraj, S.K. A review on failure mechanisms and analysis of multidirectional laminates. Mater. Today Proc. 2021, 46, 7380–7388. [Google Scholar] [CrossRef]

- Mishra, B.B.; Kumar, A.; Zaburko, J.; Sadowska-Buraczewska, B.; Barnat-Hunek, D. Dynamic Response of Angle Ply Laminates with Uncertainties Using MARS, ANN-PSO, GPR and ANFIS. Materials 2021, 14, 395. [Google Scholar] [CrossRef]

- Balasubramanian, M. Composite Materials and Processing; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Kar, K.K. Composite Materials: Processing, Applications, Characterizations; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Azeem, M.; Ya, H.H.; Alam, M.A.; Kumar, M.; Stabla, P.; Smolnicki, M.; Gemi, L.; Khan, R.; Ahmed, T.; Ma, Q.; et al. Application of Filament Winding Technology in Composite Pressure Vessels and Challenges: A Review. J. Energy Storage 2022, 49, 103468. [Google Scholar] [CrossRef]

- Tiwari, A.; Alenezi, M.R.; Jun, S.C. Advanced Composite Materials; Composite Materials for Application in Printed Electronics; Scrivener Publishing LLC.: Beverly, MA, USA, 2016. [Google Scholar]

- Vassilopoulos, A.P. Fatigue and Fracture of Adhesively-Bonded Composite Joints; Woodhead Publishing: Sawston, UK, 2015; pp. 443–491. [Google Scholar]

- Barbosa, J.F.; Correia, J.A.; Júnior, R.F.; Zhu, S.P.; Jesus, A.M.D. Probabilistic S-N fields based on statistical distributions applied to metallic and composite materials: State of the art. Adv. Mech. Eng. 2019, 11, 168781401987039. [Google Scholar] [CrossRef]

- Köbler, J.; Magino, N.; Andrä, H.; Welschinger, F.; Müller, R.; Schneider, M. A computational multi-scale model for the stiffness degradation of short-fiber reinforced plastics subjected to fatigue loading. Comput. Methods Appl. Mech. Eng. 2021, 373, 113522. [Google Scholar] [CrossRef]

- Murakami, Y.; Takagi, T.; Wada, K.; Matsunaga, H. Essential structure of S-N curve: Prediction of fatigue life and fatigue limit of defective materials and nature of scatter. Int. J. Fatigue 2021, 146, 106138. [Google Scholar] [CrossRef]

- Muc, A. Fuzzy approach in modeling static and fatigue strength of composite materials and structures. Neurocomputing 2020, 393, 156–164. [Google Scholar] [CrossRef]

- Vassilopoulos, A.P.; Maier, J.; Pinter, G.; Gaier, C. 18—Computational tools for the fatigue life modeling and prediction of composite materials and structures. In Fatigue Life Prediction of Composites and Composite Structures, 2nd ed.; Vassilopoulos, A.P., Ed.; Woodhead Publishing: Sawston, UK, 2020; pp. 635–680. [Google Scholar]

- Maljaars, J.; Leonetti, D.; Hashemi, B.; Snijder, H.H. Systematic derivation of safety factors for the fatigue design of steel bridges. Struct. Saf. 2022, 97, 102229. [Google Scholar] [CrossRef]

- Huang, Z.; Ma, W.; Jia, C.; Lei, X.; Zhang, Z.; Ma, Z. Gradient design of tubular of the fiber-reinforced composites pressure vessel for diminishing of the edge effect. Int. J. Press. Vessel. Pip. 2021, 192, 104398. [Google Scholar] [CrossRef]

- Kushwah, S.; Parekh, S.; Mistry, H.; Darji, J.; Gandhi, R. Analysis of cylindrical pressure vessels with dissimilar ends and material comparison. Mater. Today Proc. 2022, 51, 355–368. [Google Scholar] [CrossRef]

- Wu, E.; Zhao, Y.; Zhao, B.; Xu, W. Fatigue life prediction and verification of high-pressure hydrogen storage vessel. Int. J. Hydrogren Energy 2021, 46, 30412–30422. [Google Scholar] [CrossRef]

- Cardoso, A.S.M.; Pardal, J.M.; Chales, R.; Martins, C.H.; Silva, M.M.; Tavares, S.S.M.; Pedroza, B.C.; Barbosa, C. Fatigue resistance performance of universal cardan joint for automotive application. Eng. Fail. Anal. 2022, 135, 106128. [Google Scholar] [CrossRef]

- Balavignesh, V.N.; Balasubramaniam, B.; Kotkunde, N. Numerical investigations of fracture parameters for a cracked hydraulic cylinder barrel and its redesign. Mater. Today Proc. 2017, 4, 927–936. [Google Scholar] [CrossRef]

| Serial Number | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Part name | Stator | Cylinder | Piston | Roller | Tile | Piston ring |

| Motor Power P [kw] | Quality m [kg] | Displacement q [mL/r] | Preset Pressure P [MPa] | Rated Torque T [N·m] | Rated Speed n [r/min] |

|---|---|---|---|---|---|

| 25 | 55 | 468 | 30 | 1749 | 90 |

| Cylinder Diameter D [mm] | Cylinder Bore Diameter d [mm] | Number of Cylinders N |

|---|---|---|

| 163 | 33.3 | 8 |

| Material | Density ρ [kg/m3] | Young’s Modulus E [MPa] | Poisson’s Ratio ν | Yield Strength σs [MPa] | Tensile Strength σb [MPa] |

|---|---|---|---|---|---|

| 42CrMo | 7850 | 212,000 | 0.28 | 950 | 1100 |

| Al 7075-T6 | 2800 | 72,000 | 0.33 | 450 | 560 |

| Material | Density ρ [kg/m3] | Young’s Modulus E [MPa] | Shear Modulus G [MPa] | Poisson’s Ratio ν | Fiber Volume [%] |

|---|---|---|---|---|---|

| Epoxy resin | 1200 | 2800 | 1600 | 0.4 | 40 |

| Carbon fiber | 1750 | 230,000 | 50,000 | 0.3 | 60 |

| Material | Density ρ [kg/m3] | Young’s Modulus Ex [MPa] | Young’s Modulus Ey [MPa] | Shear Modulus Gxy [MPa] | Main Poisson’s Ratio νxy | Sub-Poisson’s Ratio νyx |

|---|---|---|---|---|---|---|

| Composite material | 1530 | 134,000 | 7000 | 4200 | 0.25 | 0.013 |

| Material | X1T [MPa] | X1C [Mpa] | Y2T [Mpa] | Y2C [Mpa] | S12 [Mpa] |

|---|---|---|---|---|---|

| Composite material | 1270 | −1130 | 42 | −141 | 63 |

| Material | σadm [MPa] |

|---|---|

| 42CrMo | 458 |

| Al 7075-T6 | 233 |

| Cycles | Alternating Stress [MPa] |

|---|---|

| 1 | 780 |

| 10 | 770 |

| 102 | 720 |

| 103 | 650 |

| 104 | 580 |

| 105 | 530 |

| 106 | 480 |

| 107 | 430 |

| Theory Used | Calculate Thickness [mm] |

|---|---|

| Macromechanics of orthotropic layers | 3.44 |

| Carpet plot | 1.17 |

| Winding angle | 0.95 |

| Material | S (mm) |

|---|---|

| 42CrMo | 1.2 |

| Al 7075-T6 | 2.5 |

| Composite material | 2.5 |

| N | σN |

|---|---|

| 103 | 650 |

| 106 | 480 |

| ησ | ηN |

|---|---|

| 1.32 | 550 |

| Material | Cylinder Weight [N] | ηstatic | ηfatigue |

|---|---|---|---|

| 42CrMo | 32 | 2.1 | 2.18 |

| Composite material | 7 | 2.9 | 1.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, L.; Chen, X.; Wei, G. Cylinder Fatigue Design of Low-Speed, High-Torque Radial Piston Motor. Coatings 2022, 12, 1192. https://doi.org/10.3390/coatings12081192

Cheng L, Chen X, Wei G. Cylinder Fatigue Design of Low-Speed, High-Torque Radial Piston Motor. Coatings. 2022; 12(8):1192. https://doi.org/10.3390/coatings12081192

Chicago/Turabian StyleCheng, Lifu, Xinyuan Chen, and Guoqian Wei. 2022. "Cylinder Fatigue Design of Low-Speed, High-Torque Radial Piston Motor" Coatings 12, no. 8: 1192. https://doi.org/10.3390/coatings12081192

APA StyleCheng, L., Chen, X., & Wei, G. (2022). Cylinder Fatigue Design of Low-Speed, High-Torque Radial Piston Motor. Coatings, 12(8), 1192. https://doi.org/10.3390/coatings12081192