Influence of Moisture, Temperature and Bleaching on the Mechanical Properties of Coated Fiber-Based Substrates

Abstract

:1. Introduction

1.1. Mathematical Representation of Moisture Content

1.2. Industrial Coating of Fiber-Based Substrates

2. Materials and Methods

2.1. Moisture Content/Sorption Isothermes

2.2. Hygroexpansion

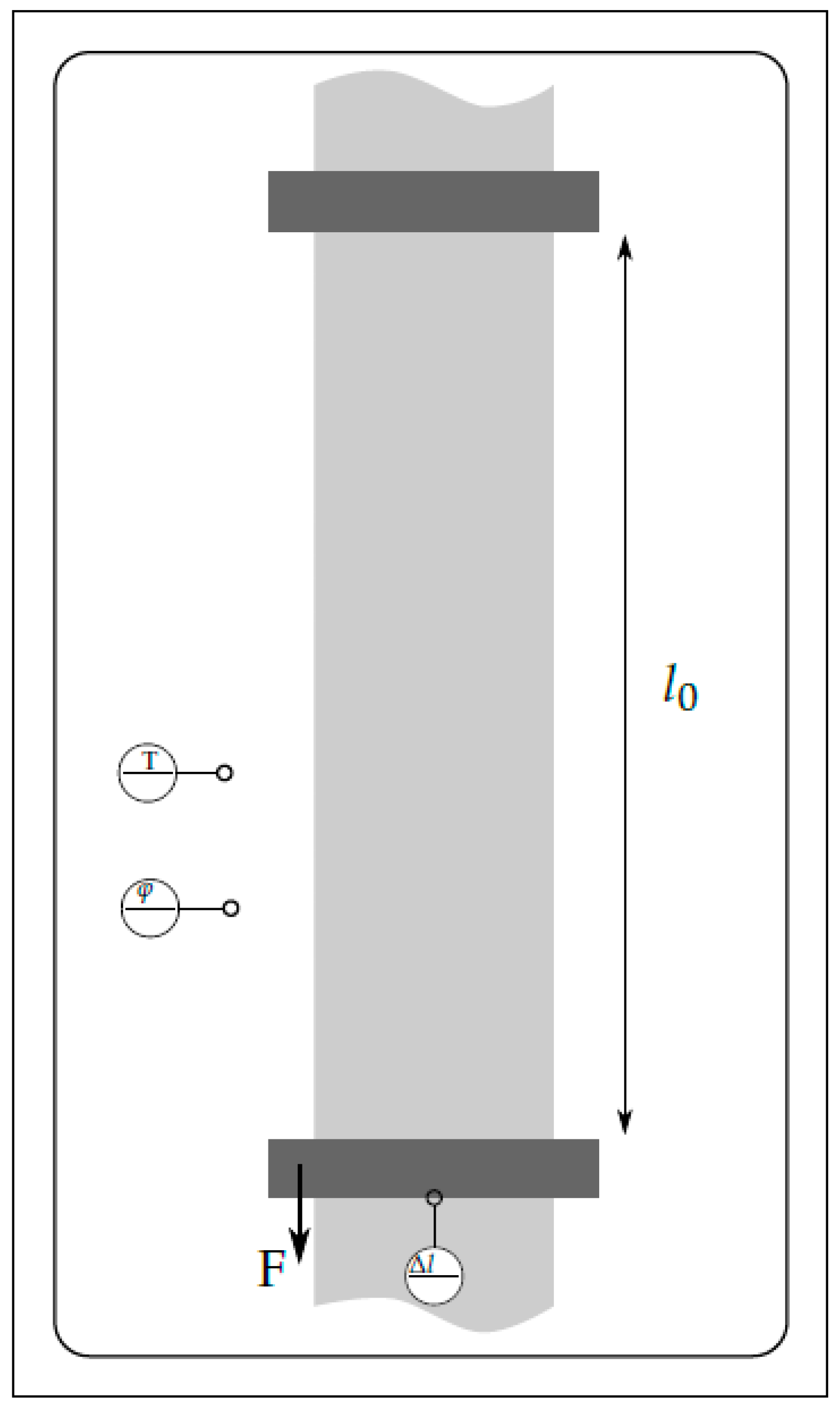

2.3. Tensile Test

2.4. Materials

3. Results and Discussion

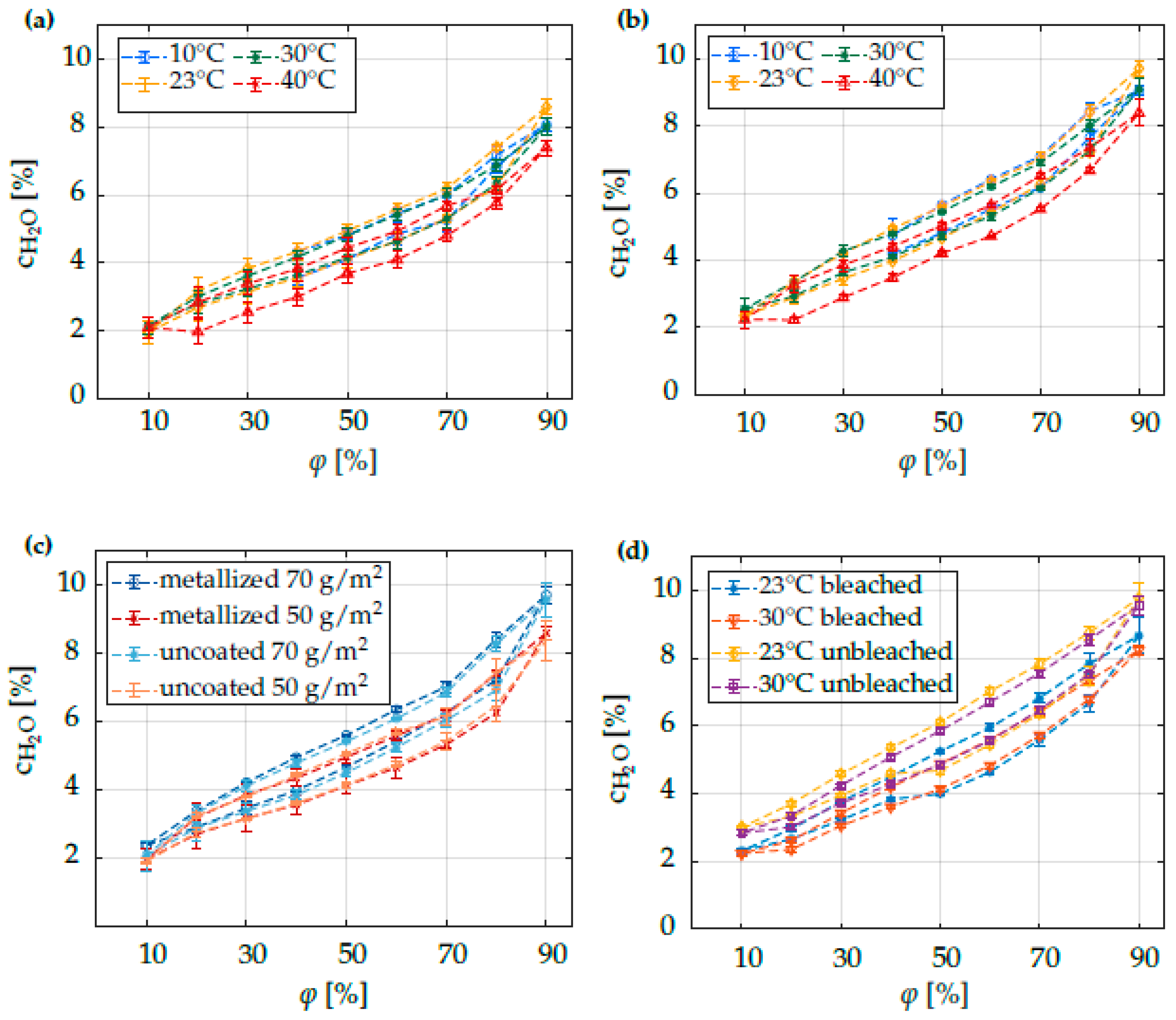

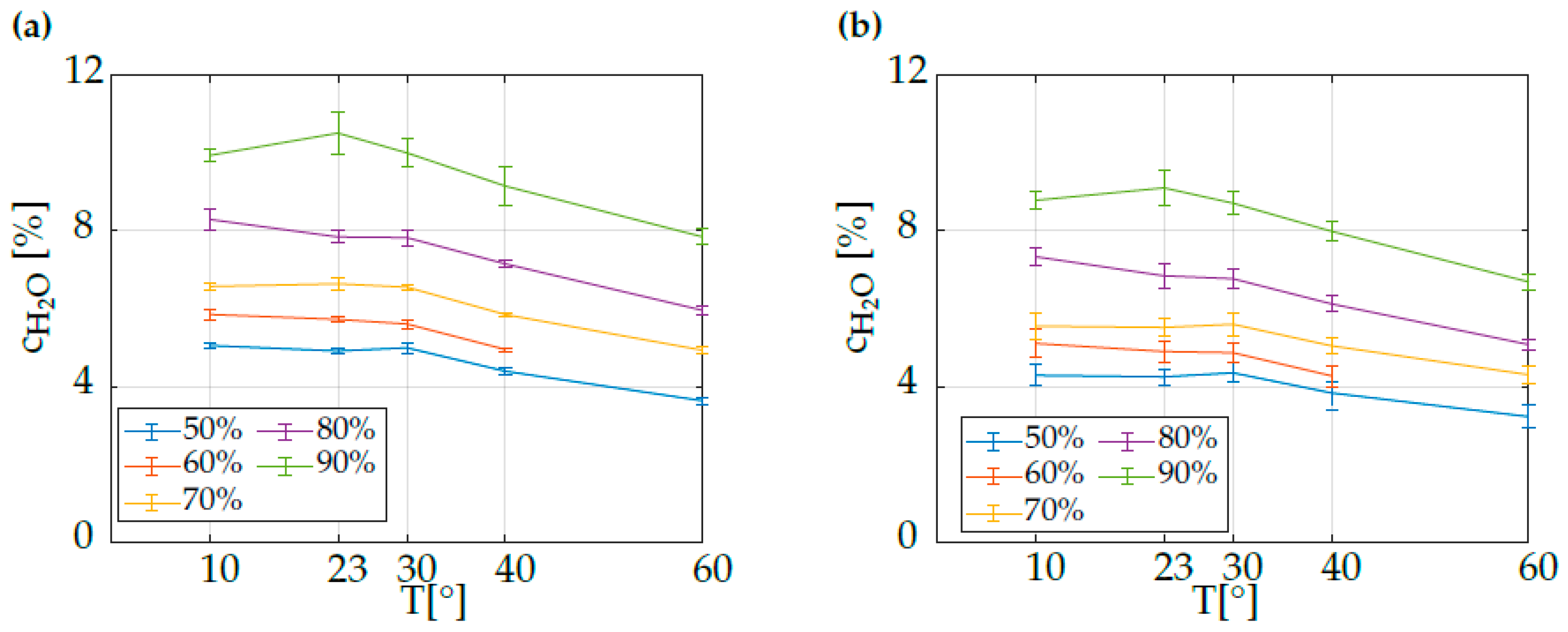

3.1. Moisture content

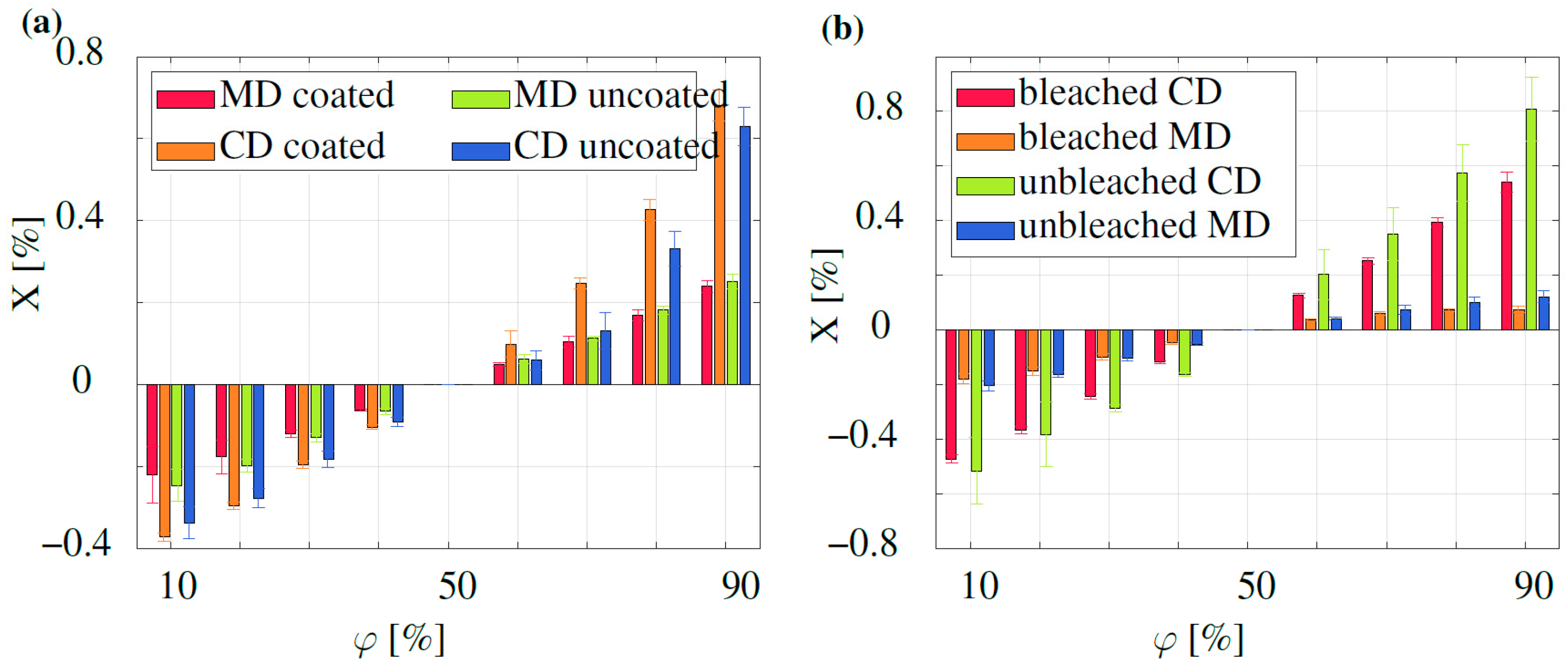

3.2. Hygroexpansion

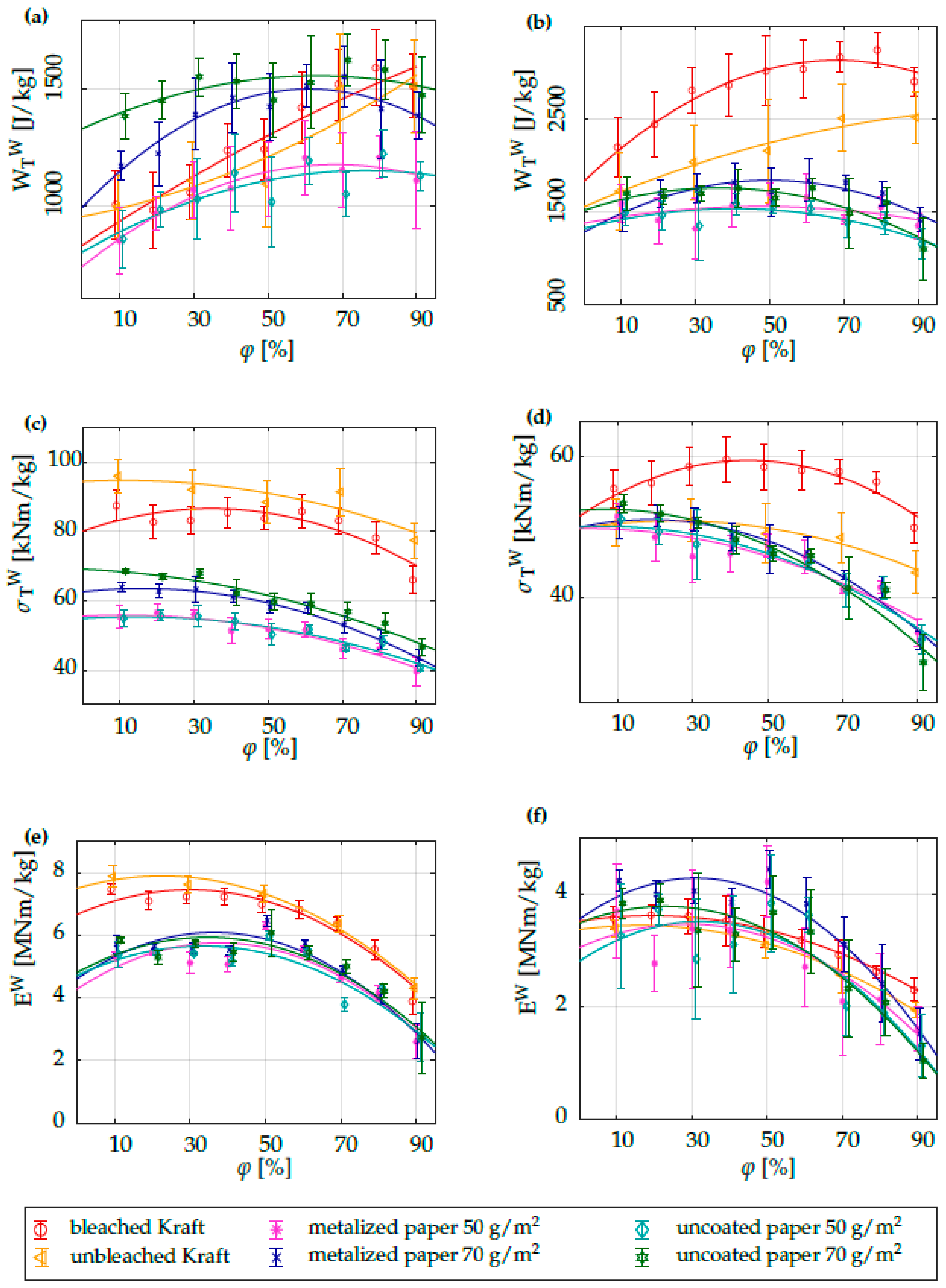

3.3. Tensile Stiffness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| width [mm] | |

| moisture content [%] | |

| monolayer moisture content [%] | |

| constant related to the net heat of sorption | |

| tensile stiffness [kN/m] | |

| tensile stiffness index [MNm/kg] | |

| increase in tensile force [N] | |

| mean breaking Force [N] | |

| length at equilibrium for given relative humidity [mm] | |

| length at 50% relative humidity [mm] | |

| constant | |

| mass [g] | |

| mass after drying [g] | |

| molecular weight [g/mol] | |

| vapor pressure [Pa] | |

| maximum vapor pressure [Pa] | |

| relative vapor pressure [-] | |

| radius [m] | |

| gas constant [J/(mol K] | |

| maximum slope of tensile force over elongation [N/mm] | |

| temperature [K] | |

| mean breaking energy [mJ] | |

| grammage, mass per unit area [g/m2] | |

| tensile energy absorption [J/m2] | |

| tensile energy absorption index [J/kg] | |

| hygroexpansion [%] | |

| surface tension [N/m] | |

| increase in elongation [mm] | |

| contact angle [°] | |

| density [kg/m3] | |

| breaking force index [kNm/kg] | |

| relative humidity [%] | |

| BET | Brunauer–Emmett–Teller equation |

| CD | cross direction |

| GAB | Guggenheim–Andersen–de Boer equation |

| LDPE | low density polyethylene |

| MD | machine direction |

References

- Alava, M.; Kajanto, I.; Ketoja, J.; Kettle, J.; Niskanen, K.; Pakarinen, P.; Pauler, N.; Sirviö, J. Paper Physics, 2nd ed.; Finnish PaperEngineers’ Association/Paperi ja Puu Oy: Helsinki, Finland, 2008. [Google Scholar]

- Dano, M.L.; Bourque, J.P. Deformation behaviour of paper and board subjected to moisture diffusion. Int. J. Solids Struct. 2009, 46, 1305–1316. [Google Scholar] [CrossRef]

- Kroenert GmbH & Co., KG. Imagebrochure KROENERT Reco. 2022. Available online: https://www.kroenert.de/fileadmin/user_upload/Ueber_uns/Downloads/RECO_dtdl_01.0.pdf (accessed on 5 August 2022).

- Amiri, R.; Hamel, J.; McDonald, J.D. Moisture Distribution in paper rolls: The effect of wrapping materials. J. Pulp Pap. Sci. 2002, 28, 143–150. [Google Scholar]

- Nienke, T.; Eggerath, D. Influence of moisture and temperature on the mechanical properties of coated fiber-based substrates and its application to industrial coating processes. In Proceedings of the 14th European Coating Symposium, Brussels, Belgium, 6–9 September 2021; Buchlin, J.M., Mendez, M., Scheid, B., Eds.; Université Libre de Bruxelles: Brussels, Belgium, 2021. Number 14. pp. 142–145. [Google Scholar]

- Blechschmidt, J. Taschenbuch der Papiertechnik, 2nd ed.; Fachbuchverlag Leipzig im Carl Hanser Verlag: München, Germany, 2013; p. 654. [Google Scholar]

- Ek, M.; Gellerstedt, G.; Henriksson, G. Paper Products Physics and Technology; De Gruyter: Berlin, Germany, 2009; Volume 4. [Google Scholar] [CrossRef]

- DIN EN ISO 638:2009; Paper, Board and Pulps—Determination of Dry Matter Content—Oven-Drying Method. Deutsches Institut für Normung e.V.: Berlin, Germany, 2009.

- Lindner, M. Factors affecting the hygroexpansion of paper. J. Mater. Sci. 2018, 53, 1–26. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Guggenheim, E. Applications of Statistical Mechanics; Elsevier Science: Amsterdam, The Netherlands, 1966. [Google Scholar]

- Anderson, R.B. Modifications of the Brunauer, Emmett and Teller Equation. J. Am. Chem. Soc. 1946, 68, 686–691. [Google Scholar] [CrossRef]

- Venkateswaran, A. Sorption of aqueous and nonaqueous media by wood and cellulose. Chem. Rev. 1970, 70, 619–637. [Google Scholar] [CrossRef]

- Erhard, K.; Kretzschmar, J. PTS-Forschungsbericht IW 081042: Reduzierung der Feucht- und Nassdehnung von Druck- und Spezialpapieren zur Verbesserung des Dimensionsverhaltens und der Planlage bei der Verarbeitung; Technical Report; Papiertechnische Stiftung PTS: Heidenau, Germany, 2010. [Google Scholar]

- Gupta, H.; Chatterjee, S.G. Parallel Diffusion of Moisture in Paper Part 1: Steady-State Conditions. Ind. Eng. Chem. Res. 2003, 42, 6582–6592. [Google Scholar] [CrossRef]

- Ramarao, B.; Massoquete, A.; Lavrykov, S.A.; Ramaswamy, S. Moisture transport in paper materials in the hygroscopic range and characteristics of diffusion parameters. A review. Dry. Technol. 2003, 21, 2007–2056. [Google Scholar] [CrossRef]

- Motamedian, H.R.; Kulachenko, A. Simulating the hygroexpansion of paper using a 3D beam network model and concurrentmultiscale approach. Int. J. Solids Struct. 2019, 161, 23–41. [Google Scholar] [CrossRef]

- Alexandersson, M.; Askfelt, H.; Ristinmaa, M. Triphasic Model of Heat and Moisture Transport with Internal Mass Exchange inPaperboard. Transp. Porous Media 2016, 112, 381–408. [Google Scholar] [CrossRef]

- Parker, M.E.; Bronlund, J.E.; Mawson, A.J. Moisture sorption isotherms for paper and paperboard in food chain conditions. Packag. Technol. Sci. 2006, 19, 193–209. [Google Scholar] [CrossRef]

- Szewczyk, W.; Głowacki, K. Impact of humidity on energy absorption during paper tensile test. Fibres Text. East. Eur. 2018, 26, 116–121. [Google Scholar] [CrossRef]

- Rhim, J.W. Effect of moisture content on tensile properties of paper-based food packaging materials. Food Sci. Biotechnol. 2010, 19, 243–247. [Google Scholar] [CrossRef]

- Chirife, J.; Iglesias, H.A. Equations for fitting water sorption isotherms of foods: II. Evaluation of various two-parameter models. Int. J. Food Sci. Technol. 1978, 13, 319–327. [Google Scholar] [CrossRef]

- Sørensen, G.; Hoffmann, J. Moisture Sorption in Moulded Fibre Trays and Effect on Static Compression Strength. Packag. Sci. 2003, 16, 159–169. [Google Scholar] [CrossRef]

- El-Sherif, H.M.; Nasser, A.M.; Hussin, A.I.; Abd El-Wahab, H.; Ghazy, M.B.; Elsayed, A.E. Tailoring of mechanical properties andprintability of coated recycled papers. Polym. Bull. 2019, 76, 2965–2990. [Google Scholar] [CrossRef]

- Kettle, J.; Lamminmäki, T.; Gane, P. A review of modified surfaces for high speed inkjet coating. Surf. Coat. Technol. 2010, 204, 2103–2109. [Google Scholar] [CrossRef]

- Bordenave, N.; Grelier, S.; Pichavant, F.; Coma, V. Water and moisture susceptibility of chitosan and paper-based materials: Structure-property relationships. J. Agric. Food Chem. 2007, 55, 9479–9488. [Google Scholar] [CrossRef]

- Schoelkopf, J.; Gane, P.A.; Ridgway, C.J.; Matthews, G.P. Influence of inertia on liquid absorption into paper coating structures. Nord. Pulp Pap. Res. J. 2000, 15, 422–430. [Google Scholar] [CrossRef]

- Van Der Wel, G.K.; Adan, O.C. Moisture in organic coatings—A review. Prog. Org. Coat. 1999, 37, 1–14. [Google Scholar] [CrossRef]

- De Assis, T.; Reisinger, L.W.; Pal, L.; Pawlak, J.; Jameel, H.; Gonzalez, R.W. Understanding the Effect of Machine Technology and Cellulosic Fibers on Tissue Properties—A Review. BioResources 2018, 13, 4593–4629. [Google Scholar] [CrossRef]

- Lätti, H.; Heikkinen, A.; Kettunen, H. Drying Induced Tension Variation in Paper Web. In The Science of Papermaking, Proceedings of the 12th Fundamental Research Symposium, Oxford, UK, 17–21 September 2001; The Pulp and Paper Fundamental Research Society: Bury, UK, 2001; Volume 1, pp. 737–758. [Google Scholar]

- ISO 8226 (1998); Paper and Board—Measurement of Hygroexpansivity. Deutsches Institut für Normung e.V.: Berlin, Germany, 1998.

- DIN ISO 1924-3(2007); Paper and Board—Determination of Tensile Properties—Part 3: Constant Rate of Elongation Method (100 mm/min). Deutsches Institut für Normung e.V.: Berlin, Germany, 2007.

- Wahba, M.; Nashed, S. Moisture Relations of Cellulose. Sorption Hysteresis and the effect of temperature. J. Text. Inst. 1957, 48, 127–138. [Google Scholar] [CrossRef]

- Lavrykov, S.A.; Ramarao, B.V.; Lyne, O.L. The planar transient hygroexpansion of copy paper: Experiments and analysis. Nord. Pulp Pap. Res. J. 2004, 19, 183–190. [Google Scholar] [CrossRef]

- Larsson, P. Hygro- and Hydroexpansion of Paper—Influence of Fibre-Joint Formation and Fibre Sorptivity. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2010. [Google Scholar]

- Lindner, M.; Heider, J.; Reinelt, M.; Langowski, H.C. Hygroexpansion and surface roughness cause defects and increase theelectrical resistivity of physical vapor deposited aluminum coatings on paper. Coatings 2019, 9, 33. [Google Scholar] [CrossRef] [Green Version]

- Falter, K.A. Klima, Papier und Druck; Technical Report; FOGRA: München, Germany, 1998. [Google Scholar]

| Material | Type Of Paper | Grammage [g/m2] | Coating | Coating Weight [g/m2] |

|---|---|---|---|---|

| 1 | unbleached, woodfree, sized, CaCO3-coating | 50 | dispersion base coating, 20 nm metallization, dispersion top coating | 3.2 |

| 2 | unbleached, woodfree, sized, CaCO3-coating | 50 | none | - |

| 3 | unbleached, woodfree, sized, CaCO3-coating | 70 | dispersion base coating, 20 nm metallization, dispersion top coating | 3.2 |

| 4 | unbleached, woodfree, sized, CaCO3-coating | 70 | none | - |

| 5 | bleached Kraft paper | 70 | LDPE | 20 |

| 6 | unbleached Kraft paper | 70 | LDPE | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nienke, T.; Kwade, A.; Eggerath, D. Influence of Moisture, Temperature and Bleaching on the Mechanical Properties of Coated Fiber-Based Substrates. Coatings 2022, 12, 1287. https://doi.org/10.3390/coatings12091287

Nienke T, Kwade A, Eggerath D. Influence of Moisture, Temperature and Bleaching on the Mechanical Properties of Coated Fiber-Based Substrates. Coatings. 2022; 12(9):1287. https://doi.org/10.3390/coatings12091287

Chicago/Turabian StyleNienke, Tobias, Arno Kwade, and Daniel Eggerath. 2022. "Influence of Moisture, Temperature and Bleaching on the Mechanical Properties of Coated Fiber-Based Substrates" Coatings 12, no. 9: 1287. https://doi.org/10.3390/coatings12091287

APA StyleNienke, T., Kwade, A., & Eggerath, D. (2022). Influence of Moisture, Temperature and Bleaching on the Mechanical Properties of Coated Fiber-Based Substrates. Coatings, 12(9), 1287. https://doi.org/10.3390/coatings12091287