Failure Mechanism of EB-PVD Thermal Barrier Coatings under the Synergistic Effect of Thermal Shock and CMAS Corrosion

Abstract

:1. Introduction

2. Experimental Procedure

2.1. TBC Preparation

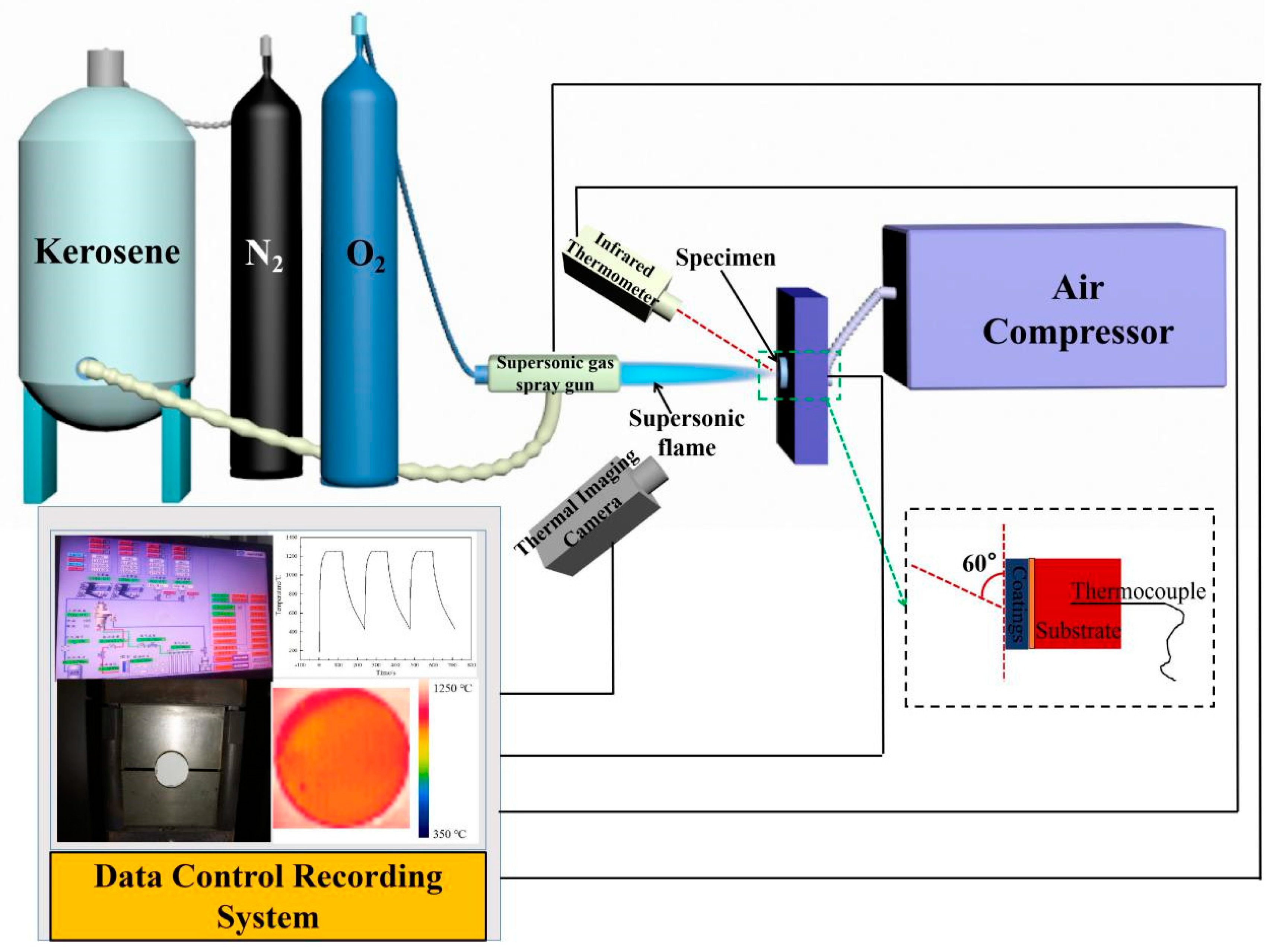

2.2. Environmental Simulator of TBCs and Determination of Infrared Emissivity

2.3. High-Temperature Experiment of TBCs under the Synergistic Effect of Thermal Shock and CMAS Corrosion

2.4. Failure Characterization

3. Results and Discussion

3.1. Phase Structure of 8YSZ Ceramic Coating

3.2. Macro-Morphology and Infrared Thermography Characteristics of TBCs

3.3. Microstructure Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vackel, A.; Dwivedi, G.; Sampath, S. Structurally integrated, damage-tolerant, thermal spray coatings. JOM 2015, 67, 1540–1553. [Google Scholar] [CrossRef]

- Mauget, F.; Hamon, F.; Morisset, M.; Cormier, J.; Riallant, F.; Mendez, J. Damage mechanisms in an EB-PVD thermal barrier coating system during TMF and TGMF testing conditions under combustion environment. Int. J. Fatigue 2017, 99, 225–234. [Google Scholar] [CrossRef]

- Guo, H.B.; Gong, S.K.; XU, H.B. Progress in thermal barrier coatings for advanced aeroengines. Mater. China 2009, 28, 18–26. [Google Scholar]

- Miller, R.A. Thermal barrier coatings for aircraft engines: History and directions. J. Therm. Spray Technol. 1997, 6, 35–42. [Google Scholar] [CrossRef]

- Padture, P.N. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Zhang, D.; Gong, S.; Xu, H.; Wu, Z. Effect of bond coat surface roughness on the thermal cyclic behavior of thermal barrier coatings. Surf. Coatings Technol. 2006, 201, 649–653. [Google Scholar] [CrossRef]

- Shen, Z.; He, L.; Xu, Z.; Mu, R.; Huang, G. LZC/YSZ DCL TBCs by EB-PVD: Microstructure, low thermal conductivity and high thermal cycling life. J. Eur. Ceram. Soc. 2019, 39, 1443–1450. [Google Scholar] [CrossRef]

- Shen, Z.Y.; Liu, Z.; Mu, R.D.; He, L.M.; Liu, G.X. LaGdZrO/8YSZ thermal barrier coatings by EB-PVD: Microstructure, thermal properties and failure mechanism. Chem. Eng. J. Adv. 2021, 5, 100073. [Google Scholar] [CrossRef]

- Levi, C.G.; Hutchinson, J.W.; Vidal-Sétif, M.-H.; Johnson, C.A. Environmental degradation of thermal-barrier coatings by molten deposits. MRS Bull. 2012, 37, 932–941. [Google Scholar] [CrossRef]

- Perepezko, J.H. The hotter the engine, the better. Science 2009, 326, 1068–1069. [Google Scholar] [CrossRef]

- Nieto, A.; Agrawal, R.; Bravo, L.; Hofmeister-Mock, C.; Pepi, M.; Ghoshal, A. Calcia–magnesia–alumina–silicate (CMAS) attack mechanisms and roadmap towards Sandphobic thermal and environmental barrier coatings. Int. Mater. Rev. 2021, 66, 451–492. [Google Scholar] [CrossRef]

- Li, L.; Hitchman, N.; Knapp, J. Failure of Thermal Barrier Coatings Subjected to CMAS Attack. J. Therm. Spray Technol. 2009, 19, 148–155. [Google Scholar] [CrossRef]

- Sohn, Y.H.; Kim, J.H.; Jordan, E.H.; Gell, M. Thermal cycling of EB-PVD/MCrAlY thermal barrier coatings: I. Microstructural development and spallation mechanisms. Surf. Coat. Technol. 2001, 146, 70–78. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Z.; Huang, G.; Mu, R.; He, L. Morphology, bond strength and thermal cycling behavior of (Ni, Pt)Al/YSZ EB-PVD thermal barrier coatings. J. Alloys Compd. 2015, 651, 445–453. [Google Scholar] [CrossRef]

- Cai, C.; Chang, S.; Zhou, Y.; Yang, L.; Zhou, G.; Wang, Y. Microstructure characteristics of EB-PVD YSZ thermal barrier coatings corroded by molten volcanic ash. Surf. Coat. Technol. 2016, 286, 49–56. [Google Scholar] [CrossRef]

- Krause, A.R.; Garces, H.F.; Dwivedi, G.; Ortiz, A.L.; Sampath, S.; Padture, N.P. Calcia-magnesia-alumino-silicate (CMAS)-induced degradation and failure of air plasma sprayed yttria-stabilized zirconia thermal barrier coatings. Acta Mater. 2016, 105, 355–366. [Google Scholar] [CrossRef]

- Yang, W.; Ye, F. The mechanical and thermal properties, CMAS corrosion resistance, and the wettability of novel thermal barrier material GdTaO4. Ceram. Int. 2021, 47, 28685–28697. [Google Scholar] [CrossRef]

- Mechnich, P.; Braue, W. Solid-State CMAS Corrosion of an EB-PVD YSZ Coated Turbine Blade: Zr4+ Partitioning and Phase Evolution. J. Am. Ceram. Soc. 2014, 98, 296–302. [Google Scholar] [CrossRef]

- Mechnich, P.; Braue, W.; Schulz, U. High-Temperature Corrosion of EB-PVD Yttria Partially Stabilized Zirconia Thermal Barrier Coatings with an Artificial Volcanic Ash Overlay. J. Am. Ceram. Soc. 2010, 94, 925–931. [Google Scholar] [CrossRef]

- Drexler, J.M.; Aygun, A.; Li, D.; Vaßen, R.; Steinke, T.; Padture, N. Thermal-gradient testing of thermal barrier coatings under simultaneous attack by molten glassy deposits and its mitigation. Surf. Coat. Technol. 2010, 204, 2683–2688. [Google Scholar] [CrossRef]

- Zhu, W.; Li, Z.Y.; Yang, L.; Zhou, Y.C.; Wei, J.F. Real-time Detection of CMAS Corrosion Failure in APS Thermal Barrier Coatings Under Thermal Shock. Exp. Mech. 2020, 60, 775–785. [Google Scholar] [CrossRef]

- Cao, Y.P.; Ning, X.J.; Wang, Q.S. Thermal shock behavior of Ba(Mg1/3Ta2/3)O3-8YSZ double-ceramic-layer thermal barrier coatings prepared by atmospheric plasma spraying. Surf. Coat. Technol. 2021, 409, 126842. [Google Scholar] [CrossRef]

- Gok, M.G.; Goller, G. Microstructural characterization of GZ/C8YSZ thermal barrier coatings after thermal shock and CMAS+hot corrosion test. J. Eur. Ceram. Soc. 2017, 37, 2501–2508. [Google Scholar] [CrossRef]

- Kirbiyik, F.; Gok, M.G.; Goller, G. Application of thermal gradient and thermal cycling tests to Al2O3/CYSZ functionally graded TBC in the presence of simultaneous hot corrosion and CMAS effects. Surf. Coat. Technol. 2022, 444, 128688. [Google Scholar] [CrossRef]

- Jackson, R.W.; Zaleski, E.M.; Poerschke, D.; Hazel, B.T.; Begley, M.R.; Levi, C.G. Interaction of molten silicates with thermal barrier coatings under temperature gradients. Acta Mater. 2015, 89, 396–407. [Google Scholar] [CrossRef]

- Mack, D.E.; Wobst, T.; Jarligo, M.O.D.; Sebold, D.; Vaßen, R. Lifetime and failure modes of plasma sprayed thermal barrier coatings in thermal gradient rig tests with simultaneous CMAS injection. Surf. Coat. Technol. 2017, 324, 36–47. [Google Scholar] [CrossRef]

- Li, S.; Xu, M.; Zhang, C.; Niu, Y.; Bao, Z.; Zhu, S.; Wang, F. Co-doping effect of Hf and Y on improving cyclic oxidation behavior of (Ni,Pt)Al coating at 1150 °C. Corros. Sci. 2020, 178, 109093. [Google Scholar] [CrossRef]

- Zhu, W.; Zhang, C.; Yang, L.; Zhou, Y.; Liu, Z. Real-time detection of damage evolution and fracture of EB-PVD thermal barrier coatings under thermal shock: An acoustic emission combined with digital image correlation method. Surf. Coat. Technol. 2020, 399, 126151. [Google Scholar] [CrossRef]

- Höser, D.; Wallimann, R.; Von Rohr, P.R. Uncertainty Analysis for Emissivity Measurement at Elevated Temperatures with an Infrared Camera. Int. J. Thermophys. 2016, 37, 14. [Google Scholar] [CrossRef]

- Craig, M.; Ndamka, N.; Wellman, R.; Nicholls, J. CMAS degradation of EB-PVD TBCs: The effect of basicity. Surf. Coat. Technol. 2015, 270, 145–153. [Google Scholar] [CrossRef]

- Mercer, C.; Faulhaber, S.; Evans, A.; Darolia, R. A delamination mechanism for thermal barrier coatings subject to calcium–magnesium–alumino-silicate (CMAS) infiltration. Acta Mater. 2005, 53, 1029–1039. [Google Scholar] [CrossRef]

- Kakuda, T.R.; Levi, C.G.; Bennett, T.D. The thermal behavior of CMAS-infiltrated thermal barrier coatings. Surf. Coat. Technol. 2015, 272, 350–356. [Google Scholar] [CrossRef]

- Evans, A.; Hutchinson, J. The mechanics of coating delamination in thermal gradients. Surf. Coat. Technol. 2007, 201, 7905–7916. [Google Scholar] [CrossRef]

- Zhang, G.; Fan, X.; Xu, R.; Su, L.; Wang, T. Transient thermal stress due to the penetration of calcium-magnesium-alumino-silicate in EB-PVD thermal barrier coating system. Ceram. Int. 2018, 44, 12655–12663. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, L.; Zhou, Q.; Zhou, Y.; Yan, G. Modeling stress evolution in porous ceramics subjected to molten silicate infiltration and corrosion. Corros. Sci. 2021, 191, 109698. [Google Scholar] [CrossRef]

| Co | Ta | Cr | W | Mo | Re | Al | Ni |

|---|---|---|---|---|---|---|---|

| 7.5 | 6.5 | 7 | 5 | 1.5 | 3 | 6.2 | Bal. |

| Composition | Pt(NH3)2(NO2)2 | Na(NO2) | Na3C6H5O7·2H2O | CH3COONa·3H2O | pH |

|---|---|---|---|---|---|

| Value | 10 g/L | 10 g/L | 12 g/L | 6 g/L | 9 |

| Layers | Current of Electron Beam (A) | Rotation Speed (rpm) | Voltage (KV) | Heating Temperature (°C) | Pressure in the Vacuum Chamber (Pa) |

|---|---|---|---|---|---|

| Ceramic coating | 0.1~1.0 | 20 | 10 | 900 ± 50 | 133.32 × 10−5 |

| Temperature | 1000 °C | 1100 °C | 1200 °C | 1250 °C | |

|---|---|---|---|---|---|

| Distance | |||||

| 70 cm | 0.981 | 0.978 | 0.976 | 0.975 | |

| 60 cm | 0.982 | 0.976 | 0.975 | 0.973 | |

| 53 cm | 0.978 | 0.971 | 0.968 | 0.963 | |

| Oxygen Inlet Pressure | Oxygen Inlet Flow | Kerosene Outlet Pressure | Kerosene Flow | Air Pressure | Cooling Gas Inlet Flow |

|---|---|---|---|---|---|

| 1.5 MPa | 180 L/min | 0.6 MPa | 5 L/h | 0.7~0.79 MPa | 40 L/min |

| Location | Composition (at.%) | |||

|---|---|---|---|---|

| Ca | Mg | Al | Si | |

| A | 41.60 | 6.88 | 17.36 | 34.16 |

| B | 37.71 | 7.80 | 19.80 | 34.69 |

| C | 24.53 | 4.25 | 13.82 | 57.40 |

| D | 42.56 | 7.53 | 12.87 | 37.04 |

| E | 41.48 | 6.12 | 13.48 | 38.92 |

| F | 31.18 | 4.52 | 10.79 | 53.51 |

| G | 45.89 | 6.94 | 8.54 | 38.63 |

| H | 42.32 | 5.61 | 10.05 | 42.02 |

| I | 29.23 | 5.02 | 9.67 | 56.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Liu, G.; Liu, Q.; Zhu, W.; Liu, S.; Ma, Z. Failure Mechanism of EB-PVD Thermal Barrier Coatings under the Synergistic Effect of Thermal Shock and CMAS Corrosion. Coatings 2022, 12, 1290. https://doi.org/10.3390/coatings12091290

Hu X, Liu G, Liu Q, Zhu W, Liu S, Ma Z. Failure Mechanism of EB-PVD Thermal Barrier Coatings under the Synergistic Effect of Thermal Shock and CMAS Corrosion. Coatings. 2022; 12(9):1290. https://doi.org/10.3390/coatings12091290

Chicago/Turabian StyleHu, Xiaopeng, Guolin Liu, Qing Liu, Wang Zhu, Sai Liu, and Zengsheng Ma. 2022. "Failure Mechanism of EB-PVD Thermal Barrier Coatings under the Synergistic Effect of Thermal Shock and CMAS Corrosion" Coatings 12, no. 9: 1290. https://doi.org/10.3390/coatings12091290

APA StyleHu, X., Liu, G., Liu, Q., Zhu, W., Liu, S., & Ma, Z. (2022). Failure Mechanism of EB-PVD Thermal Barrier Coatings under the Synergistic Effect of Thermal Shock and CMAS Corrosion. Coatings, 12(9), 1290. https://doi.org/10.3390/coatings12091290