Author Contributions

Conceptualization, A.D., S.B. and A.H.; methodology A.D., S.B., A.H. and N.A.; experimentation, A.D., S.B. and A.H.; validation of data, A.D., S.B., A.H., S.M.A.S. and S.A.A.; formal analysis, A.D., S.B., A.H., S.M.A.S. and A.Y.A.; investigation, A.D., S.B., A.H., S.M.A.S., S.A.A. and N.A.; resources, A.D., S.B., A.H. and N.A.; writing—original draft preparation, A.D. and S.M.A.S.; writing—review and editing, A.D., S.B., A.H., N.A., A.Y.A., S.M.A.S., S.A.A. and A.U.R.; supervision, S.B., A.H., N.A., A.Y.A. and A.U.R.; project administration, A.D., S.B., A.H. and N.A.; All authors have read and agreed to the published version of the manuscript.

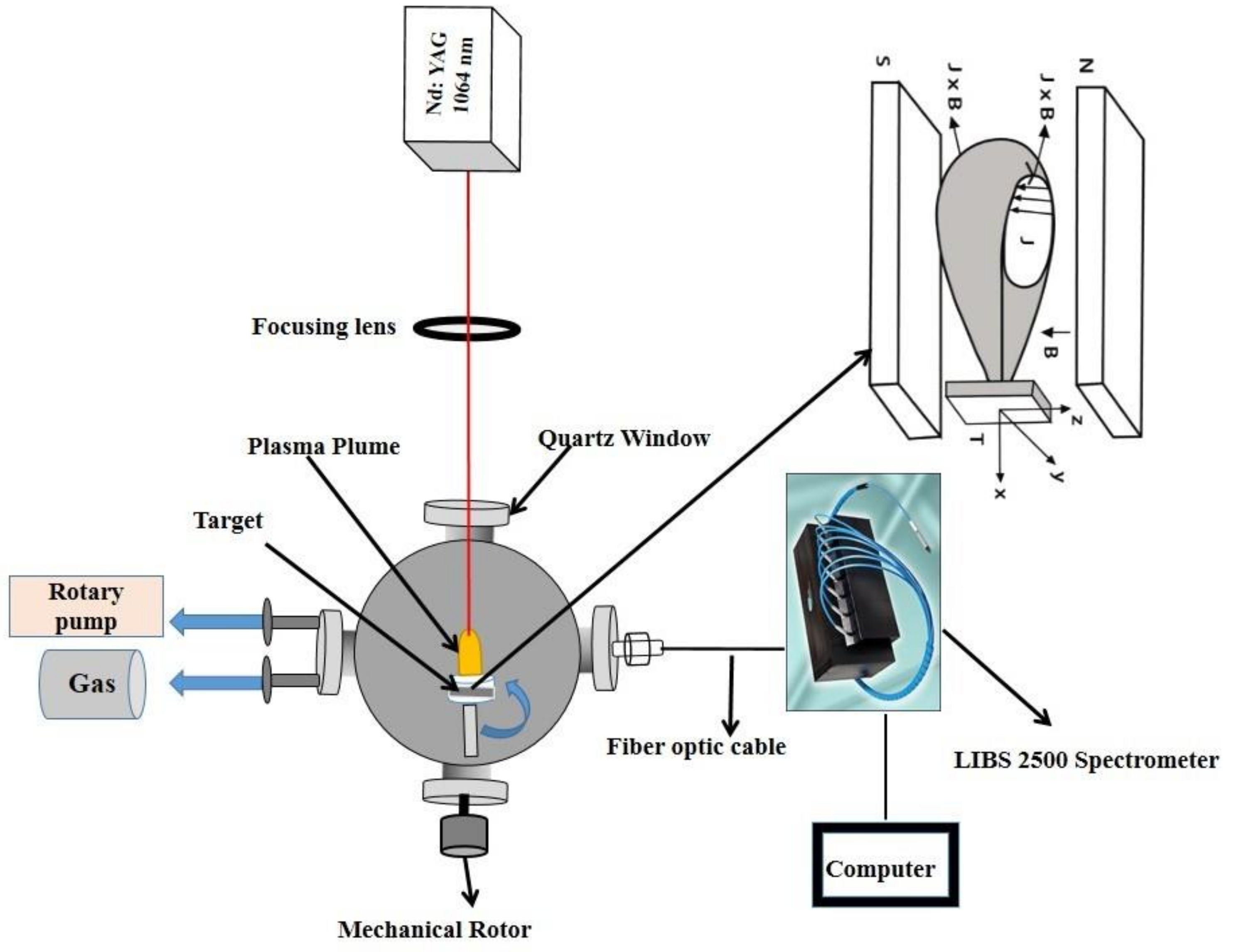

Figure 1.

Schematic of the experimental setup for investigating the impact of magnetic fields on the laser-induced breakdown spectroscopy of Mg alloy plasma produced with an Nd: YAG laser.

Figure 1.

Schematic of the experimental setup for investigating the impact of magnetic fields on the laser-induced breakdown spectroscopy of Mg alloy plasma produced with an Nd: YAG laser.

Figure 2.

The emission spectra of selected Mg lines under 5 Torr pressure of Ar gas at 2 GW/cm2 irradiance with and without TMF in the spectral range from 370 nm to 520 nm.

Figure 2.

The emission spectra of selected Mg lines under 5 Torr pressure of Ar gas at 2 GW/cm2 irradiance with and without TMF in the spectral range from 370 nm to 520 nm.

Figure 3.

The spectral intensity variation of laser-induced Mg alloy plasma under several pressure levels of the inert gases Ar (a,b), Ne (c,d), and He (e,f) at 2 GW/cm2 irradiance.

Figure 3.

The spectral intensity variation of laser-induced Mg alloy plasma under several pressure levels of the inert gases Ar (a,b), Ne (c,d), and He (e,f) at 2 GW/cm2 irradiance.

Figure 4.

The variation in excitation temperature of laser-induced Mg alloy plasma at various pressures of Ar, Ne, and He environments at ns laser irradiance of 2 GW/cm2 in the absence (a) and presence (b) of TMF.

Figure 4.

The variation in excitation temperature of laser-induced Mg alloy plasma at various pressures of Ar, Ne, and He environments at ns laser irradiance of 2 GW/cm2 in the absence (a) and presence (b) of TMF.

Figure 5.

The variation in ne of laser-induced Mg alloy plasma at various pressures under Ar, Ne, and He environments at an irradiance of 2.0 GW/cm2 in the absence (a) and presence (b) of TMF.

Figure 5.

The variation in ne of laser-induced Mg alloy plasma at various pressures under Ar, Ne, and He environments at an irradiance of 2.0 GW/cm2 in the absence (a) and presence (b) of TMF.

Figure 6.

The variation in thermal beta of laser-induced Mg alloy plasma at various pressures under Ar, Ne, and He environments at ns laser irradiance of 2 GW/cm2.

Figure 6.

The variation in thermal beta of laser-induced Mg alloy plasma at various pressures under Ar, Ne, and He environments at ns laser irradiance of 2 GW/cm2.

Figure 7.

The variation of Texc of LPP of Mg at different time delays in (a) the absence and (b) the presence of a magnetic field under Ar, Ne, and He.

Figure 7.

The variation of Texc of LPP of Mg at different time delays in (a) the absence and (b) the presence of a magnetic field under Ar, Ne, and He.

Figure 8.

The variation in electron number density of LPP of Mg alloy at different time delays in (a) the absence and (b) the presence of a magnetic field.

Figure 8.

The variation in electron number density of LPP of Mg alloy at different time delays in (a) the absence and (b) the presence of a magnetic field.

Figure 9.

The variation in thermal beta at different time delays.

Figure 9.

The variation in thermal beta at different time delays.

Figure 10.

SEM micrographs exhibiting the variation in surface morphology under an ambient environment of Ar at a constant pressure of 5 Torr and a laser irradiance of 2.0 GW/cm2 in the field-free case, where (a) laser-ablated crater on the Mg surface, (b) non-uniform melting of material and cavities at the boundary of the laser-ablated crater, (c) non-uniform micro-sized spikes and droplets at the laser-ablated crater, (d–h) various irregularly sized cones and cavities.

Figure 10.

SEM micrographs exhibiting the variation in surface morphology under an ambient environment of Ar at a constant pressure of 5 Torr and a laser irradiance of 2.0 GW/cm2 in the field-free case, where (a) laser-ablated crater on the Mg surface, (b) non-uniform melting of material and cavities at the boundary of the laser-ablated crater, (c) non-uniform micro-sized spikes and droplets at the laser-ablated crater, (d–h) various irregularly sized cones and cavities.

Figure 11.

SEM images illustrating the surface morphology of the laser-ablated areas of Mg under an ambient environment of Ar at a constant pressure of 5 Torr and a laser irradiance of 2.0 GW/cm2 in magnetic field where (a) laser ablated areas of Mg at the boundaries and central areas, (b) 1st sample of micro-sized cones are formed at the periphery area of the laser-ablated crater, (c) 2nd sample of micro-sized cones are formed at the periphery area of the laser-ablated crater, (d) Droplets at laser-ablated crater due to maximum deposition of laser energy at the center, (e) left-hand side outer boundaries at laser ablated crater (f) right-hand side outer boundaries at laser ablated crater (g) cavities and particulate formation at laser-ablated crater, (h) micro-sized cones, and (i) micro-sized spikes.

Figure 11.

SEM images illustrating the surface morphology of the laser-ablated areas of Mg under an ambient environment of Ar at a constant pressure of 5 Torr and a laser irradiance of 2.0 GW/cm2 in magnetic field where (a) laser ablated areas of Mg at the boundaries and central areas, (b) 1st sample of micro-sized cones are formed at the periphery area of the laser-ablated crater, (c) 2nd sample of micro-sized cones are formed at the periphery area of the laser-ablated crater, (d) Droplets at laser-ablated crater due to maximum deposition of laser energy at the center, (e) left-hand side outer boundaries at laser ablated crater (f) right-hand side outer boundaries at laser ablated crater (g) cavities and particulate formation at laser-ablated crater, (h) micro-sized cones, and (i) micro-sized spikes.

Figure 12.

SEM micrographs of the laser-ablated areas of Mg showing the variation in surface morphology under an ambient environment of Ne and a constant pressure of 5 Torr for a laser irradiance of 2.0 GW/cm2 in the field-free case, where (a) the surface structure at the boundaries of the laser-ablated crater of the Mg alloy, (b) the cones and irregularly sized cavities at the left side, (c) the cones and irregularly sized cavities at the upper side, (d) the cones and irregularly sized cavities at the right side of laser-ablated crater, (e) small circular crater near the large laser-ablated crater, (f) Micro-sized ridges and cavities can be observed at the lower outer boundary of the crater.

Figure 12.

SEM micrographs of the laser-ablated areas of Mg showing the variation in surface morphology under an ambient environment of Ne and a constant pressure of 5 Torr for a laser irradiance of 2.0 GW/cm2 in the field-free case, where (a) the surface structure at the boundaries of the laser-ablated crater of the Mg alloy, (b) the cones and irregularly sized cavities at the left side, (c) the cones and irregularly sized cavities at the upper side, (d) the cones and irregularly sized cavities at the right side of laser-ablated crater, (e) small circular crater near the large laser-ablated crater, (f) Micro-sized ridges and cavities can be observed at the lower outer boundary of the crater.

Figure 13.

SEM images revealing the surface morphology of laser-irradiated Mg at constant pressure of 5 Torr of Ne gas and laser irradiance of 2.0 GW/cm2 in the presence of a magnetic field, where (a) the surface structure at the boundaries of the laser ablated-crater of the Mg alloy, (b–d) sample micro-sized conical spikes and cavities in the periphery areas, (e) A top view of conical spikes, (f) flakes at the lower boundary of the ablated crater, and (g) non-uniform melting and resulting dendritic structures.

Figure 13.

SEM images revealing the surface morphology of laser-irradiated Mg at constant pressure of 5 Torr of Ne gas and laser irradiance of 2.0 GW/cm2 in the presence of a magnetic field, where (a) the surface structure at the boundaries of the laser ablated-crater of the Mg alloy, (b–d) sample micro-sized conical spikes and cavities in the periphery areas, (e) A top view of conical spikes, (f) flakes at the lower boundary of the ablated crater, and (g) non-uniform melting and resulting dendritic structures.

Figure 14.

SEM images of the laser-irradiated areas of Mg showing the different surface features under He ambient environment at a constant pressure of 5 Torr and laser irradiance of 2.0 GW/cm2 in the magnetic field-free case, where (a) laser-ablated crater of the Mg, (b) small crater near the main laser-ablated area, (c) non-uniform cones with cavities on the cones, (d) forward-peaked cones with wide bases and spherical caps on top, and (e) cavities and cones due to turbulent melt flow of molten material towards the outer boundary.

Figure 14.

SEM images of the laser-irradiated areas of Mg showing the different surface features under He ambient environment at a constant pressure of 5 Torr and laser irradiance of 2.0 GW/cm2 in the magnetic field-free case, where (a) laser-ablated crater of the Mg, (b) small crater near the main laser-ablated area, (c) non-uniform cones with cavities on the cones, (d) forward-peaked cones with wide bases and spherical caps on top, and (e) cavities and cones due to turbulent melt flow of molten material towards the outer boundary.

Figure 15.

SEM micrographs of the laser irradiated areas of Mg exhibiting the surface morphology under ambient environment of He at a constant pressure of 5 Torr and laser irradiance of 2.0 GW/cm2 in the presence of a magnetic field, where (a) laser-ablated crater of the Mg alloy, (b) dendritic structures, cavities, and conical protrusions at left-hand outer boundary (c) dendritic structures, cavities, and conical protrusions at right-hand outer boundary of the laser ablated, (d) dendritic structures, turbulent melt flow towards the outer boundary, and cavities at the upper outer boundary of the laser ablated crater, (e) dendritic structures, turbulent melt flow towards the outer boundary, and cavities at lower outer boundary of the laser ablated crater, and (f) micro-sized crater and forward peaked cones.

Figure 15.

SEM micrographs of the laser irradiated areas of Mg exhibiting the surface morphology under ambient environment of He at a constant pressure of 5 Torr and laser irradiance of 2.0 GW/cm2 in the presence of a magnetic field, where (a) laser-ablated crater of the Mg alloy, (b) dendritic structures, cavities, and conical protrusions at left-hand outer boundary (c) dendritic structures, cavities, and conical protrusions at right-hand outer boundary of the laser ablated, (d) dendritic structures, turbulent melt flow towards the outer boundary, and cavities at the upper outer boundary of the laser ablated crater, (e) dendritic structures, turbulent melt flow towards the outer boundary, and cavities at lower outer boundary of the laser ablated crater, and (f) micro-sized crater and forward peaked cones.

Table 1.

Spectroscopic parameters of Mg I lines obtained from the NIST Database and the existing literature [

28].

Table 1.

Spectroscopic parameters of Mg I lines obtained from the NIST Database and the existing literature [

28].

| Wavelength (nm) | Transitions | Terms | Energy of Upper Level Em (cm−1) | Statistical Weight gm | Transition Probabilities (108 s−1) |

|---|

| 382.93 | | 3po–3D | 47,957.06 | 3 | 0.9 |

| 389.12 | 3p2–3p.3d | 3P–3Do | 83,511.25 | 3 | 1.31 |

| 470.30 | | 1po–1D | 56,308 | 5 | 0.255 |

| 517.27 | | 3po–3S | 41,197 | 3 | 0.346 |

Table 2.

Evaluated Texc, ne, and βt values for laser-irradiated Mg plasma at various Ar pressures in the presence and absence of TMF.

Table 2.

Evaluated Texc, ne, and βt values for laser-irradiated Mg plasma at various Ar pressures in the presence and absence of TMF.

| Argon |

|---|

| Pressure (Torr) | Excitation Temp (Field Free Case) (Kelvin) | Excitation Temp (Magnetic Field) (Kelvin) | ne (1017) (Field Free Case) (cm−3) | ne (1017) (Magnetic Field) (cm−3) | Thermal Beta |

|---|

| 1 | 12,098 | 12,311 | 7.2 | 8.6 | 0.30 |

| 2 | 12,371 | 12,548 | 8.0 | 9.1 | 0.33 |

| 3 | 12,711 | 13,762 | 9.4 | 9.4 | 0.37 |

| 4 | 12,805 | 14,576 | 9.7 | 10.0 | 0.42 |

| 5 | 13,730 | 15,808 | 10.4 | 10.6 | 0.44 |

| 10 | 12,964 | 14,886 | 9.7 | 10.3 | 0.40 |

| 20 | 12,328 | 14,009 | 9.3 | 10.1 | 0.38 |

| 30 | 11,464 | 13,558 | 8.8 | 9.9 | 0.34 |

| 40 | 11,378 | 13,187 | 7.3 | 9.6 | 0.32 |

| 50 | 11,010 | 12,638 | 6.3 | 9.3 | 0.30 |

| 60 | 10,792 | 12,199 | 5.9 | 8.9 | 0.28 |

| 70 | 10,702 | 11,800 | 5.4 | 8.8 | 0.26 |

| 80 | 10,454 | 11,301 | 4.9 | 8.5 | 0.25 |

| 90 | 9765 | 11,010 | 4.4 | 8.3 | 0.24 |

| 100 | 9669 | 10,814 | 3.3 | 7.9 | 0.22 |

Table 3.

Evaluated Texc, ne, and βt values for laser-irradiated Mg plasma at various Ne pressures in the presence and absence of TMF.

Table 3.

Evaluated Texc, ne, and βt values for laser-irradiated Mg plasma at various Ne pressures in the presence and absence of TMF.

| Neon |

|---|

| Pressure (Torr) | Excitation Temp (Field Free Case) (Kelvin) | Excitation Temp (Magnetic Field) (Kelvin) | ne (1017) (Field Free Case) (cm−3) | ne (1017) (Magnetic Field) (cm−3) | Thermal Beta |

|---|

| 1 | 11,559 | 12,011 | 6.5 | 7.6 | 0.26 |

| 2 | 11,888 | 12,405 | 6.8 | 8.3 | 0.29 |

| 3 | 12,004 | 13,152 | 7.2 | 8.9 | 0.33 |

| 4 | 12,737 | 14,072 | 8.4 | 9.5 | 0.38 |

| 5 | 13,377 | 15,370 | 9.8 | 10.3 | 0.42 |

| 10 | 12,367 | 14,000 | 8.3 | 9.6 | 0.36 |

| 20 | 12,185 | 13,414 | 7.6 | 8.8 | 0.32 |

| 30 | 11,262 | 13,000 | 7.4 | 8.3 | 0.28 |

| 40 | 10,908 | 12,600 | 7.0 | 7.7 | 0.25 |

| 50 | 10,618 | 12,200 | 6.2 | 7.0 | 0.21 |

| 60 | 10,524 | 11,000 | 5.5 | 6.6 | 0.19 |

| 70 | 9939 | 10,671 | 4.8 | 5.9 | 0.17 |

| 80 | 9593 | 10,521 | 3.8 | 5.6 | 0.15 |

| 90 | 9476 | 10,210 | 3.2 | 4.9 | 0.12 |

| 100 | 9327 | 10,240 | 3.2 | 4.1 | 0.10 |

Table 4.

Evaluated Texc, ne, and βt values for laser-irradiated Mg plasma at various He pressures in the presence and absence of TMF.

Table 4.

Evaluated Texc, ne, and βt values for laser-irradiated Mg plasma at various He pressures in the presence and absence of TMF.

| Helium |

|---|

| Pressure (Torr) | Excitation Temp (Field Free Case) (Kelvin) | Excitation Temp (Magnetic Field) (Kelvin) | ne (1017) (Field Free Case) (cm−3) | ne (1017) (Magnetic Field) (cm−3) | Thermal Beta |

|---|

| 1 | 11,428 | 11,893 | 5.7 | 6.0 | 0.20 |

| 2 | 11,728 | 12,319 | 6.1 | 6.8 | 0.24 |

| 3 | 11,859 | 12,831 | 6.7 | 7.4 | 0.27 |

| 4 | 12,169 | 13,826 | 7.6 | 9.2 | 0.36 |

| 5 | 12,774 | 15,130 | 9.4 | 9.8 | 0.39 |

| 10 | 11,779 | 13,051 | 7.8 | 8.2 | 0.30 |

| 20 | 11,581 | 12,498 | 7.5 | 7.5 | 0.27 |

| 30 | 11,211 | 11,628 | 7.2 | 7.2 | 0.24 |

| 40 | 10,814 | 11,160 | 5.1 | 6.5 | 0.21 |

| 50 | 10,222 | 10,700 | 3.5 | 5.8 | 0.17 |

| 60 | 9739 | 10,202 | 2.5 | 5.1 | 0.14 |

| 70 | 9487 | 9825 | 1.5 | 4.8 | 0.13 |

| 80 | 9186 | 9497 | 1.1 | 4.3 | 0.11 |

| 90 | 9034 | 9185 | 1.0 | 4.0 | 0.10 |

| 100 | 8793 | 8876 | 1.0 | 3.6 | 0.09 |

Table 5.

Evaluated values of excitation temperature, electron number density, and thermal beta for LPP of Mg under Ar environment at different time delays with and without TMF.

Table 5.

Evaluated values of excitation temperature, electron number density, and thermal beta for LPP of Mg under Ar environment at different time delays with and without TMF.

| Argon |

|---|

| Time Delay (µs) | Excitation Temp (Field Free Case) (Kelvin) | Excitation Temp (Magnetic Field) (Kelvin) | ne (1017) (Field Free Case) (cm−3) | ne (1017) (Magnetic Field) (cm−3) | Thermal Beta |

|---|

| 0.42 | 14,870 | 16,858 | 10.8 | 11.21 | 0.54 |

| 0.83 | 14,005 | 16,420 | 10.5 | 11.01 | 0.48 |

| 1.25 | 13,730 | 15,808 | 10.4 | 10.6 | 0.44 |

| 1.67 | 13,380 | 15,408 | 10.1 | 10.5 | 0.4 |

| 2.08 | 13,030 | 15,008 | 9.75 | 10.38 | 0.38 |

| 2.50 | 12,680 | 14,608 | 9.65 | 10.19 | 0.35 |

| 2.92 | 12,330 | 14,208 | 9.45 | 10.01 | 0.31 |

| 3.33 | 12,030 | 13,893 | 9.12 | 9.84 | 0.28 |

| 3.75 | 11,730 | 13,578 | 8.75 | 9.6 | 0.27 |

| 4.58 | 11,430 | 13,263 | 8.44 | 9.35 | 0.25 |

| 5.42 | 11,130 | 12,948 | 8.21 | 9.21 | 0.24 |

| 6.25 | 10,830 | 12,648 | 8.01 | 9.01 | 0.21 |

| 7.08 | 10,616 | 12,348 | 7.85 | 8.85 | 0.2 |

| 7.92 | 10,402 | 12,048 | 7.64 | 8.65 | 0.19 |

| 8.75 | 10,188 | 11,798 | 7.49 | 8.54 | 0.18 |

| 9.58 | 9854 | 11,548 | 7.05 | 8.41 | 0.17 |

Table 6.

Evaluated values of excitation temperature, electron number density, and thermal beta for LPP of Mg under Ne environment at different time delays with and without TMF.

Table 6.

Evaluated values of excitation temperature, electron number density, and thermal beta for LPP of Mg under Ne environment at different time delays with and without TMF.

| Neon |

|---|

| Time Delay (µs) | Excitation Temp (Field Free Case) (Kelvin) | Excitation Temp (Magnetic Field) (Kelvin) | ne (1017) (Field Free Case) (cm−3) | ne (1017) (Magnetic Field) (cm−3) | Thermal Beta |

|---|

| 0.42 | 14,255 | 16,059 | 10.11 | 10.49 | 0.47 |

| 0.83 | 13,955 | 15,459 | 10.08 | 10.41 | 0.44 |

| 1.25 | 13,377 | 15,370 | 9.8 | 10.30 | 0.42 |

| 1.67 | 13,062 | 15,020 | 9.7 | 10.00 | 0.38 |

| 2.08 | 12,747 | 14,670 | 9.55 | 9.85 | 0.34 |

| 2.50 | 12,432 | 14,320 | 9.29 | 9.54 | 0.30 |

| 2.92 | 12,117 | 13,920 | 8.94 | 9.16 | 0.25 |

| 3.33 | 11,802 | 13,520 | 8.54 | 9.00 | 0.22 |

| 3.75 | 11,552 | 13,120 | 8.24 | 8.91 | 0.21 |

| 4.58 | 11,302 | 12,720 | 8.01 | 8.78 | 0.18 |

| 5.42 | 11,052 | 12,320 | 7.91 | 8.57 | 0.15 |

| 6.25 | 10,752 | 11,920 | 7.75 | 8.34 | 0.14 |

| 7.08 | 10,452 | 11,732 | 7.45 | 8.11 | 0.12 |

| 7.92 | 10,152 | 11,417 | 7.15 | 8.01 | 0.10 |

| 8.75 | 9852 | 11,102 | 7.01 | 7.94 | 0.08 |

| 9.58 | 9552 | 10,787 | 6.75 | 7.5 | 0.06 |

Table 7.

Evaluated values of excitation temperature, electron number density, and thermal beta for LPP of Mg under He environment at different time delays with and without TMF.

Table 7.

Evaluated values of excitation temperature, electron number density, and thermal beta for LPP of Mg under He environment at different time delays with and without TMF.

| Helium |

|---|

| Time Delay (µs) | Excitation Temp (Field Free Case) (Kelvin) | Excitation Temp (Magnetic Field) (Kelvin) | ne (1017) (Field Free Case) (cm−3) | ne (1017) (Magnetic Field) (cm−3) | Thermal Beta |

|---|

| 0.42 | 13,475 | 16,012 | 9.7 | 10.0 | 0.42 |

| 0.83 | 13,001 | 15,782 | 9.6 | 9.95 | 0.41 |

| 1.25 | 12,774 | 15,130 | 9.4 | 9.80 | 0.39 |

| 1.67 | 12,470 | 14,680 | 9.25 | 9.61 | 0.35 |

| 2.08 | 12,184 | 14,278 | 9.15 | 9.34 | 0.31 |

| 2.50 | 11,894 | 13,876 | 8.75 | 9.19 | 0.28 |

| 2.92 | 11,554 | 13,406 | 8.45 | 8.72 | 0.22 |

| 3.33 | 11,214 | 12,919 | 8.15 | 8.53 | 0.19 |

| 3.75 | 10,974 | 12,449 | 7.72 | 8.35 | 0.17 |

| 4.58 | 10,644 | 12,031 | 7.45 | 8.2 | 0.14 |

| 5.42 | 10,456 | 11,577 | 7.14 | 8.0 | 0.11 |

| 6.25 | 10,238 | 11,165 | 7.00 | 7.81 | 0.09 |

| 7.08 | 10,020 | 10,780 | 6.87 | 7.56 | 0.08 |

| 7.92 | 9766 | 10,390 | 6.73 | 7.38 | 0.05 |

| 8.75 | 9512 | 10,036 | 6.54 | 7.25 | 0.049 |

| 9.58 | 9258 | 9616 | 6.45 | 7.00 | 0.03 |