Effect of the Surface States of 1Cr18Ni9Ti Stainless Steel on Mn-Based Brazing Alloy Wetting

Abstract

:1. Introduction

2. Experimental Section

2.1. Wetting Experiment

2.2. Characterization

3. Result and Discussion

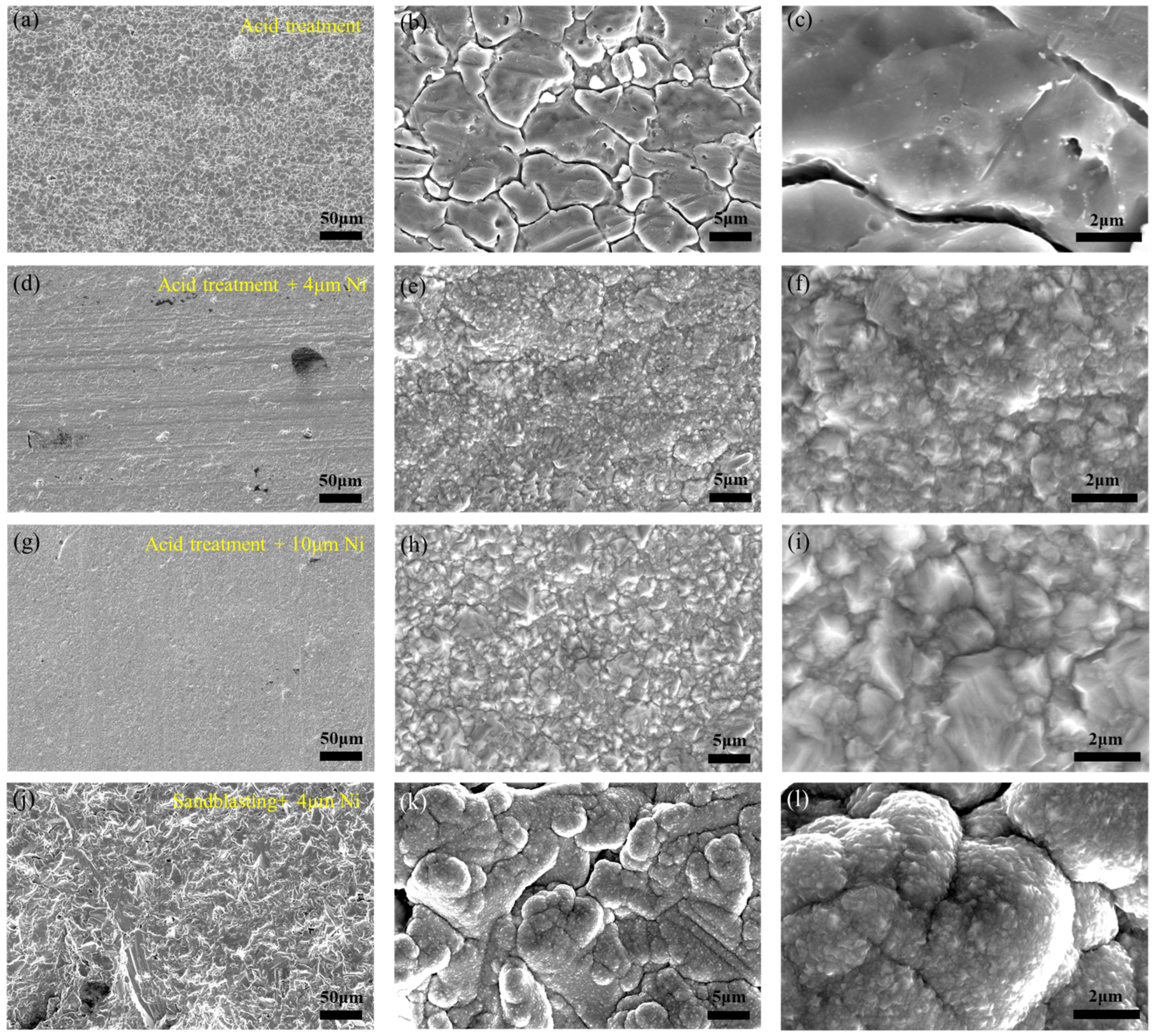

3.1. The Characterization of Substrates

3.2. In Situ Observation of the Brazing Alloy Contact Angle

3.3. The Wetting and Spreading Properties

3.4. The Interfacial Microstructure between Brazing Alloy and Substrates

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lodhi, M.; Deen, K.M.; Wacker, M.G.; Haider, W. Additively manufactured 316L stainless steel with improved corrosion resistance and biological response for biomedical applications. Addit. Manuf. 2019, 27, 8–19. [Google Scholar] [CrossRef]

- Dinu, M.; Parau, A.C.; Viadescu, A.; Kiss, A.E.; Pana, I.; Mouele, E.S.M.; Petrik, L.F.; Braic, V. Corrosion Improvement of 304L Stainless Steel by ZrSiN and ZrSi(N,O) Mono- and Double-Layers Prepared by Reactive Cathodic Arc Evaporation. Coatings 2021, 11, 1257. [Google Scholar] [CrossRef]

- Kong, D.; Dong, C.; Ni, X.; Zhang, L.; Yao, J.; Man, C.; Cheng, X.; Xiao, K.; Li, X. Mechanical properties and corrosion behavior of selective laser melted 316L stainless steel after different heat treatment processes. J. Mater. Sci. Technol. 2019, 35, 1499–1507. [Google Scholar] [CrossRef]

- Zhu, W.; Zhang, H.; Guo, C.; Liu, Y.; Ran, X. Wetting and brazing characteristic of high nitrogen austenitic stainless steel and 316L austenitic stainless steel by Ag–Cu filler. Vacuum 2019, 166, 97–106. [Google Scholar] [CrossRef]

- Khan, M.; Dewan, M.W.; Sarkar, M.Z. Effects of welding technique, filler metal and post-weld heat treatment on stainless steel and mild steel dissimilar welding joint. J. Manuf. Process. 2021, 64, 1307–1321. [Google Scholar] [CrossRef]

- Liu, G.W.; Li, W.; Qiao, G.J.; Wang, H.J.; Yang, J.F.; Lu, T.J. Microstructures and interfacial behavior of zirconia/stainless steel joint prepared by pressureless active brazing. J. Alloy. Compd. 2009, 470, 163–167. [Google Scholar] [CrossRef]

- Liu, D.; Long, W.; Wu, M.; Qi, K.; Pu, J. Microstructure Evolution and Lifetime Extension Mechanism of Sn-Added Fe-Based Pre-Alloy Brazing Coating in Diamond Tools. Coatings 2019, 9, 364. [Google Scholar] [CrossRef]

- Long, W.M.; Zhang, G.X.; Zhang, Q.K. In situ synthesis of high strength ag brazing filler metals during induction brazing process. Scr. Mater. 2015, 110, 41–43. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, G.; Lv, M.; Al-Nehari, M.; Xiao, C. Comparative study on the joining performance of TiH2 and ZrH2 modified AgCu28 brazing alloys with pulsed laser welding-brazing. J. Manuf. Process. 2019, 41, 56–65. [Google Scholar] [CrossRef]

- Lin, J.; Ba, J.; Cai, Y.; Ma, Q.; Luo, D.; Wang, Z.; Qi, J.; Cao, J.; Feng, J. Brazing SiO2f /SiO2 with TC4 alloy with the help of coating graphene. Vacuum 2017, 145, 241–244. [Google Scholar] [CrossRef]

- Lin, P.; Lin, T.; He, P.; Wang, M.; Yang, J. Microstructure evolution and mechanical properties of a vacuum-brazed Al2O3/Ti joint with Mo-coating on Al2O3 and Ti surfaces. Ceram. Int. 2019, 45, 11195–11203. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, L.; Tian, X.; Peng, H.; Feng, J. Interfacial microstructure and mechanical properties of joining electroless nickel plated quartz fibers reinforced silica composite to invar. Mater. Des. 2011, 32, 382–387. [Google Scholar] [CrossRef]

- Cheng, F.; Sun, J. Fabrication of a double-layered Co-Mn-O spinel coating on stainless steel via the double glow plasma alloying process and preoxidation treatment as SOFC interconnect. Int. J. Hydrogen Energy 2019, 44, 18415–18424. [Google Scholar] [CrossRef]

- Sun, Z.; Cao, Y.; Zhang, L.; Feng, J. Carbothermal reduction reaction enhanced wettability and brazing strength of AgCuTi-SiO2f/SiO2. J. Eur. Ceram. Soc. 2020, 40, 1488–1495. [Google Scholar] [CrossRef]

- Xin, C.; Li, N.; Jia, J.; Du, J.; Yan, J. Interfacial microstructures formation mechanism between SiO2 substrate and AgCuTi braze alloys. Ceram. Int. 2018, 44, 17784–17791. [Google Scholar] [CrossRef]

- Lee, J.G.; Lee, M.K. Microstructure and mechanical behavior of a Titanium-to-stainless steel dissimilar joint brazed with Ag-Cu alloy filler and an Ag interlayer. Mater. Charact. 2017, 129, 98–103. [Google Scholar] [CrossRef]

- Yuan, X.; Kang, C.Y.; Kim, M.B. Microstructure and XRD analysis of brazing joint for duplex stainless steel using a Ni–Si–B filler metal. Mater. Charact. 2009, 60, 923–931. [Google Scholar] [CrossRef]

- Yang, J.; Xu, Y.; Zhang, S.; Zhang, M. Brazing of Mn–Cu alloy and 430 stainless steel with Cu–34Mn–6Ni–10Sn filler metal. Mater. Trans. 2019, 60, 1674–1679. [Google Scholar] [CrossRef]

- Yang, J.; Xu, Y.; Zhang, S.; Zhang, M. Joining of Mn-Cu alloy and 430 stainless steel using Cu-based filler by SIMA-imitated brazing process. Mater. Lett. 2019, 253, 401–404. [Google Scholar] [CrossRef]

- Shi, H.; Yan, J.; Ning, L.; Xin, Z.; Chen, K.; Yu, L. Microstructure and properties of FeCrMo damping alloy brazing joint using Mn-based brazing filler. Vacuum 2019, 159, 209–217. [Google Scholar] [CrossRef]

- Lin, C.; Shiue, R.K.; Wu, S.K.; Lin, Y.S. Dissimilar infrared brazing of CoCrFe(Mn)Ni equiatomic high entropy alloys and 316 stainless steel. Crystals 2019, 9, 518. [Google Scholar] [CrossRef]

- Li, Y.; Parfitt, D.; Flewitt, P.E.J.; Hou, X.; Fonseca, J.Q.D.; Chen, B. Microstructural considerations of enhanced tensile strength and mechanical constraint in a copper/stainless steel brazed joint. Mater. Sci. Eng. A Struct. 2020, 796, 139992. [Google Scholar] [CrossRef]

- Jameson, G.J.; Cerro, M. Theory for the equilibrium contact angle between a gas, a liquid and a solid. J. Chem. Soc. Faraday Trans. 1976, 1, 883–895. [Google Scholar] [CrossRef]

- Gao, Y.; Liang, Y.; Shi, C. Microstructure of laser remelted Ni-base alloy coating on stainless steel. J. Mater. Sci. Technol. 1998, 1, 49–52. [Google Scholar] [CrossRef]

- Si, X.Q.; Cao, J.; Kiebach, R.; Xu, Y.; Xu, H.; Talic, B.; Feng, J. Joining of solid oxide fuel/electrolysis cells at low temperature: A novel method to obtain high strength seals already at 300 °C. J. Power Sources 2018, 400, 296–304. [Google Scholar] [CrossRef]

- Molleda, F.; Mora, J.; Molleda, J.R.; Carrillo, E.; Mora, E.; Mellor, B.G. Copper coating of carbon steel by a furnace brazing process using brass as the braze. Mater. Charact. 2008, 59, 613–617. [Google Scholar] [CrossRef]

- Li, J.; Pan, L.; Fu, Q.; Zhou, Y.; Guo, N. Wettability and corrosion behavior of a Ni coating on 304 stainless steel surface. Surf. Coat. Technol. 2018, 357, 740–747. [Google Scholar] [CrossRef]

- Yu, G.; Zou, T.; Chen, S.; Huang, J.; Zhao, Z. Effect mechanism of Ni coating layer on the characteristics of Al/steel dissimilar metal brazing. Mater. Charact. 2020, 167, 110518. [Google Scholar] [CrossRef]

- Zhao, X.; Tan, C.; Xiao, L.; Xia, H.; Bo, C.; Song, X.; Li, L.; Feng, J. Effect of the Ni coating thickness on laser welding-brazing of Mg/steel. J. Alloy. Compd. 2018, 769, 1042–1058. [Google Scholar] [CrossRef]

- Kim, C.; Suh, B.L.; Yun, H.; Kim, J.; Lee, H. Surface plasmon aided ethanol dehydrogenation using Ag-Ni binary nanoparticles. ACS Catal. 2017, 7, 2294–2302. [Google Scholar] [CrossRef]

- Bracq, G.; Laurent-Brocq, M.; Perrière, L.; Pirès, R.; Joubert, J.M.; Guillot, I. The FCC solid solution stability in the Co-Cr-Fe-Mn-Ni multi-component system. Acta Mater. 2018, 128, 327–336. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, X.; Yuan, Q.; Xue, J.; Lu, G.; Liu, Z.; Wang, H.; Ding, F.; Yu, Q. Fast growth of inch-sized single-crystalline graphene from a controlled single nucleus on Cu-Ni alloys. Nat. Mater. 2015, 15, 43–48. [Google Scholar] [CrossRef] [PubMed]

- Venkateswaran, T.; Vincent, X.; Sivakumar, D.; Bhanu, P.; Janaki, G.D.R. Brazing of stainless steels using Cu-Ag-Mn-Zn braze filler: Studies on wettability, mechanical properties, and microstructural aspects. Mater. Des. 2017, 121, 213–228. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Khodaei, M.; Shadmani, S. Superhydrophobicity on aluminum through reactive etching and TEOS/GPTMS/nano-Al2O3 silane-based nanocomposite coating. Surf. Coat. Technol. 2019, 374, 1078–1090. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, Y.; Jin, J.; Tian, L.; Han, Z.; Ren, L. Facile fabrication of biomimetic superhydrophobic surface with anti-frosting on stainless steel substrate. Appl. Surf. Sci. 2015, 355, 1238–1244. [Google Scholar] [CrossRef]

- Mirski, Z.; Piwowarczyk, T. Wettability of hardmetal surfaces prepared for brazing with various methods. Arch. Civ. Mech. Eng. 2011, 11, 411–419. [Google Scholar] [CrossRef]

- Ma, Q.; Tong, Z.; Wang, W.; Dong, G. Fabricating robust and repairable superhydrophobic surface on carbon steel by nanosecond laser texturing for corrosion protection. Appl. Surf. Sci. 2018, 455, 748–757. [Google Scholar] [CrossRef]

- Wang, H.; Zhuang, J.; Qi, H.; Yu, J.; Ma, Y. Laser-chemical treated superhydrophobic surface as a barrier to marine atmospheric corrosion. Surf. Coat. Technol. 2020, 401, 126255. [Google Scholar] [CrossRef]

- Wang, C.X.; Zhang, X.F. A non-particle and fluorine-free superhydrophobic surface based on one-step electrodeposition of dodecyltrimethoxysilane on mild steel for corrosion protection. Corros. Sci. 2020, 163, 108284. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, Y.; Hu, Z.; Zhang, X.; Wu, S.; Wang, R.; Zhu, Y. A novel electrodeposition route for fabrication of the superhydrophobic surface with unique self-cleaning, mechanical abrasion and corrosion resistance properties. Chem. Eng. J. 2016, 303, 37–47. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, J.; Ming, P.; Zhao, D.; Song, J. Wire electrochemical etching of superhydrophobic 304 stainless steel surfaces based on high local current density with neutral electrolyte. Appl. Surf. Sci. 2022, 571, 151269. [Google Scholar] [CrossRef]

- Li, H.; Xu, W.; Li, L.; Xia, H.; Chen, X.; Chen, B.; Song, X.; Tan, C. Enhancing the wettability for 4043 aluminum alloy on 301L stainless steel via chemical-etched surface texturing. J. Mater. Process. Technol. 2022, 305, 117577. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, J.; Li, Y.; Li, W.; Chen, J.; Shen, L.; Zhang, P.; Yu, Z. Wetting and spreading behaviors of Al-Si alloy on surface textured stainless steel by ultrafast laser. Appl. Surf. Sci. 2020, 520, 146316. [Google Scholar] [CrossRef]

- Roy, R.K.; Panda, A.K.; Govind, S.K.D.; Mitra, A. Development of a copper-based filler alloy for brazing stainless steels. Mater. Sci. Eng. A Struct. 2009, 523, 312–315. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, N.; Yan, J.; Cao, Y. The microstructure and mechanical properties of 1Cr17Ni2/QAl7 brazed joints using Cu-Mn-Ni-Ag brazing alloy. Mater. Sci. Eng. A Struct. 2016, 661, 25–31. [Google Scholar] [CrossRef]

- Miao, W.; Zheng, S.; Zhou, J.; Zhang, B.; Fang, R.; Hao, D.; Sun, L.; Wang, D.; Zhou, Z.; Xu, J.; et al. Microchannel and nanofiber array morphology enhanced rapid superspreading on animals’ corneas. Adv. Mater. 2021, 33, 2007152. [Google Scholar] [CrossRef]

| Element | Fe | Ni | Cr | Mn | Si | Ti | C |

|---|---|---|---|---|---|---|---|

| 1Cr18Ni9Ti | Bal. | 8~11 | 17~19 | ≤2.0 | ≤1.0 | 0.8 | ≤0.12 |

| Mn70NiCr | - | 24.0~26.0 | 4.5~5.5 | Bal. | - | - | - |

| 1Cr18Ni19Ti No. | Surface States | Contact Angle/Brazing Alloy Spreading Area (mm2) | ||

|---|---|---|---|---|

| 1150 °C/15 min | 1170 °C/15 min | 1190 °C/15 min | ||

| 1 | Acid treatment | 15.4°/26.463 | 19.5°/25.092 | 20.6°/21.264 |

| 2 | Acid treatment + 4 μm Ni | 6.1°/49.662 | 7.7°/38.031 | 11.8°/37.532 |

| 3 | Acid treatment + 10 μm Ni | 15.3°/42.318 | 18°/31.408 | 14°/28.142 |

| 4 | Sandblasting + 4 μm Ni | 10.4°/36.121 | 13.3°/30.121 | 15.3°/26.044 |

| 5 | Acid treatment | 18.9°/26.248 | 24.7°/18.511 | 22.4°/23.681 |

| 6 | Acid treatment + 4 μm Ni | 11.6°/39.246 | 6.4°/45.595 | 6.6°/41.073 |

| 7 | Acid treatment + 10μm Ni | 7.9°/39.581 | 12.0°/39.173 | 11.9°/31.660 |

| 8 | Sandblasting + 4 μm Ni | 13.0°/31.944 | 11.7°/27.681 | 8.9°/32.523 |

| 9 | Acid treatment | 20.9°/26.892 | 24.2°/22.125 | 20°/23.647 |

| 10 | Acid treatment + 4 μm Ni | 10.1°/38.905 | 6.3°/51.458 | 6.6°/43.396 |

| 11 | Acid treatment + 10 μm Ni | 8.2°/40.169 | 8.6°/45.662 | 6.3°/57.521 |

| 12 | Sandblasting + 4 μm Ni | 15.1°/32.660 | 9.1°/39.551 | 10.1°/32.533 |

| Element (At.%) | Ti | Cr | Mn | Fe | Ni |

|---|---|---|---|---|---|

| A | - | 17.05 | 2.59 | 24.19 | 56.17 |

| B | - | 15.95 | 24.66 | 13.88 | 45.52 |

| C | 0.59 | 12.60 | 0.39 | 76.28 | 10.14 |

| D | 0.57 | 19.56 | 1.9 | 70.10 | 7.95 |

| Element (At.%) | Ti | Cr | Mn | Fe | Ni |

|---|---|---|---|---|---|

| A | - | 16.06 | 5.50 | 21.92 | 56.53 |

| B | - | 14.44 | 22.37 | 15.87 | 47.32 |

| C | 1.38 | 8.21 | 0.33 | 49.16 | 40.91 |

| D | 0.65 | 19.07 | 1.73 | 70.69 | 7.87 |

| Element (At.%) | Ti | Cr | Mn | Fe | Ni |

|---|---|---|---|---|---|

| A | - | 18.38 | 3.09 | 22.04 | 56.49 |

| B | - | 13.77 | 25.23 | 12.69 | 48.32 |

| C | 1.13 | 7.73 | 0 | 42.4 | 48.90 |

| D | 0.45 | 19.01 | 1.67 | 70.75 | 8.12 |

| Element (At.%) | Ti | Cr | Mn | Fe | Ni |

|---|---|---|---|---|---|

| A | - | 19.06 | 7.66 | 21.04 | 52.25 |

| B | - | 10.07 | 34.57 | 7.83 | 47.53 |

| C | 6.51 | 19.52 | 8.35 | 52.77 | 12.84 |

| D | 0.65 | 19.18 | 1.76 | 70.20 | 8.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Chen, H.; Yang, W.; Zhang, Q.; Yang, B.; Hu, Y.; Li, C.; Gao, D.; Si, X.; Qi, J.; et al. Effect of the Surface States of 1Cr18Ni9Ti Stainless Steel on Mn-Based Brazing Alloy Wetting. Coatings 2022, 12, 1328. https://doi.org/10.3390/coatings12091328

Zhang C, Chen H, Yang W, Zhang Q, Yang B, Hu Y, Li C, Gao D, Si X, Qi J, et al. Effect of the Surface States of 1Cr18Ni9Ti Stainless Steel on Mn-Based Brazing Alloy Wetting. Coatings. 2022; 12(9):1328. https://doi.org/10.3390/coatings12091328

Chicago/Turabian StyleZhang, Chenghao, Huize Chen, Weipeng Yang, Qinlian Zhang, Bo Yang, Yazhen Hu, Chun Li, Dejun Gao, Xiaoqing Si, Junlei Qi, and et al. 2022. "Effect of the Surface States of 1Cr18Ni9Ti Stainless Steel on Mn-Based Brazing Alloy Wetting" Coatings 12, no. 9: 1328. https://doi.org/10.3390/coatings12091328

APA StyleZhang, C., Chen, H., Yang, W., Zhang, Q., Yang, B., Hu, Y., Li, C., Gao, D., Si, X., Qi, J., & Cao, J. (2022). Effect of the Surface States of 1Cr18Ni9Ti Stainless Steel on Mn-Based Brazing Alloy Wetting. Coatings, 12(9), 1328. https://doi.org/10.3390/coatings12091328