Experimental Study on Flexural Bearing Characteristics of Ceramsite Concrete Beams after Creep at Different Curing Ages

Abstract

:1. Introduction

2. Experimental Materials and Basic Mechanical Properties

2.1. Experimental Materials

- (1)

- The coarse aggregate is 900-grade crushed stone shale granules produced by Yichang Guangda Ceramic Granules Products Co. Prewetting ceramsite before concrete mixing can effectively improve the workability of concrete. Its physical properties are shown as Table 1. The ceramsite is prewetted for 4 h, and then dried for 12 h to remove the water on the ceramsite surface (shown in Figure 1).

- (2)

- Fine aggregate was ordinary river sand, which was sieved before the test to avoid the influence of impurities in the sand. The filter sieve used for the test was a 4.75 mm side length square hole sieve. The physical properties are shown in Table 2.

- (3)

- The cement was P.O. 42.5 ordinary silicate cement produced by Hubei Huaxin Cement Company Limited, Wuhan, China and its physical indices all met the requirements of the test specification, as shown in Table 3.

- (4)

- The water-reducing agent is HsC polycarboxylat-type superplasticizers produced by Qingdao Hongxia. The technical specifications of the water-reducing agent are shown in Table 4.

- (5)

- The water was Wuhan tap water.

2.2. Mix Proportion

2.3. Basic Mechanical Properties of Concrete

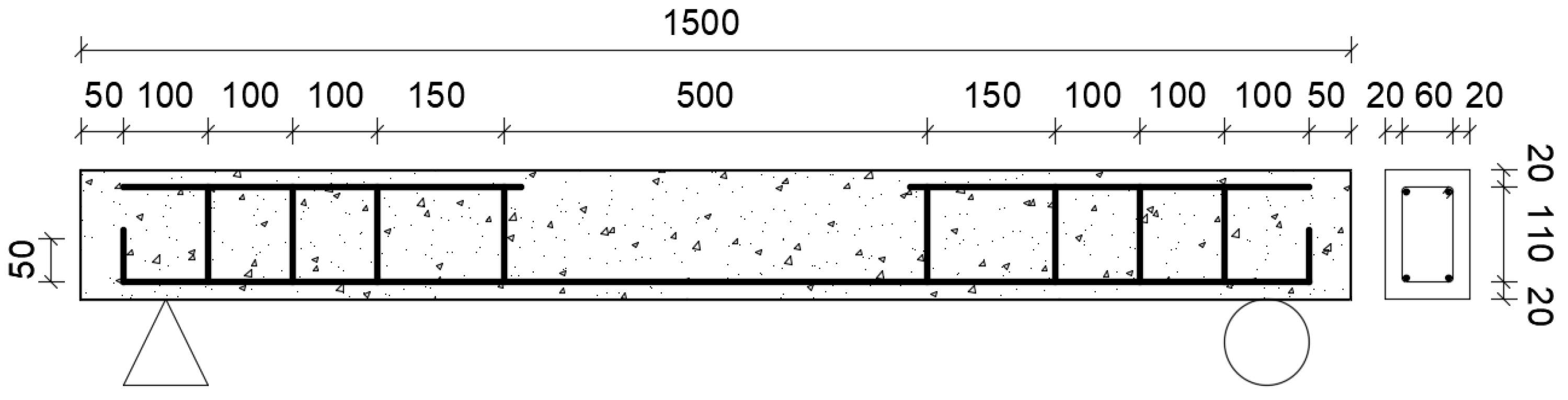

3. Design of the Test

4. Experimental Results and Analysis

4.1. Effect of Ceramsite Concrete Beam Performance after Creep

4.2. Effect of Age of Maintenance on Ceramsite Concrete Beams after Creeping

5. Conclusions

- (1)

- Creep will increase the deformation capacity of ceramsite concrete beams and enhance the toughness and energy-absorption capacity. L2D1 exhibits higher flexural strength than L1D1, with a reinforcement value of 11%.

- (2)

- The law of load-bearing capacity of the ceramsite concrete beams was unaffected by creep loading. However, the ultimate load-bearing capacity of the ceramsite concrete beams was promoted by creep loading. The ultimate load-bearing capacity of the test beams increased by about 10% after 200 d of creep loading at the same curing age.

- (3)

- Creep loading affected the development of cracks. The long-term creep effect reduced the maximum crack width and crack depth. Moreover, it increased the number and average crack spacing of cracks in ceramsite concrete beams.

- (4)

- With the increase of loading age, the initial deflection value and the creep deflection value in the same holding time also gradually decreased. In addition, the decreasing trend was less and less noticeable. As the age of loading increases, the reduction rate tended to zero.

- (5)

- The age of curing also affected the ultimate bearing capacity of ceramsite concrete beams influenced by creep. The growth rate of the ultimate bearing capacity is faster in the early stages of curing ages, slower after 120 d, and slower and more stable in the 228–320 d range. The ultimate load capacity of L2D4 has increased by only 1.81% compared to L2D1.

- (6)

- The age of loading affected the ability of the ceramsite concrete beams to develop cracks after creep. The shorter the age of loading, the fewer the cracks in the ceramsite concrete beams subjected to bending damage, the greater the maximum crack width, the depth of the cracks and the average crack spacing. The longer the loading age, the more dense the cracks in the concrete beams subjected to flexural damage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yin, Y.; Hu, S.; Wang, Y. Influence of self-weight on the fracture properties of three-point bending concrete beams. Eng. Mech. 2019, 36, 48–56. [Google Scholar]

- Sofia Real, M.; Glória Gomes, A.; Moret Rodrigues, J.; Bogas, A. Contribution of structural lightweight aggregate concrete to the reduction of thermal bridging effect in buildings. Constr. Build. Mater. 2016, 121, 460–470. [Google Scholar] [CrossRef]

- Zhu, H.; Fu, Z.; Liu, P.; Li, Y.; Zhao, B. Shear behavior of stud-PBL composite shear connector for steel–ceramsite concrete composite structure. Coatings 2022, 12, 583. [Google Scholar] [CrossRef]

- Xie, J.; Zhao, J.; Wang, J.; Huang, P.; Liu, J. Investigation of the high-temperature resistance of sludge ceramsite concrete with recycled fine aggregates and GGBS and its application in hollow blocks. J. Build. Eng. 2021, 34, 101954. [Google Scholar] [CrossRef]

- Jiang, W.; Yang, Z. Compressive creep of lightweight aggregate concrete at early age. J. Build. Mater. 2016, 19, 40–44. [Google Scholar]

- Zhuang, Y.; Chen, C.; Ji, T. Effect of shale ceramsite type on the tensile creep of lightweight aggregate concrete. Constr. Build. Mater. 2013, 46, 13–18. [Google Scholar] [CrossRef]

- Ji, T.; Chen, C.; Chen, Y. Effect of ceramsite prewetting degree on tensile creep characteristics of lightweight aggregate concrete. J. Build. Mater. 2012, 15, 690–696. [Google Scholar]

- Zhang, Y.; Mao, J.; Jin, W.; Zhang, J. Creep model of high-performance concrete at different loading ages. Constr. Build. Mater. 2022, 357, 129379. [Google Scholar] [CrossRef]

- Wang, S.; Wu, X.; Yang, J.; Zhu, S. Acoustic emission characteristics and dynamic damage constitutive relation of shale-ceramsite concrete subjected to loading Tests. J. Mater. Civ. Eng. 2020, 32, 76. [Google Scholar] [CrossRef]

- Hwang, E.; Kim, G.; Koo, K.; Moon, H.; Choe, G.; Suh, D.; Nam, J. Compressive creep and shrinkage of high-strength concrete based on limestone coarse aggregate applied to high-rise buildings. Materials 2021, 14, 5026. [Google Scholar] [CrossRef]

- Liang, S.; Wei, Y. Effects of water-to-cement ratio and curing age on microscopic creep and creep recovery of hardened cement pastes by microindentation. Cement. Concr. Comp. 2020, 113, 103619. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Q.; Chen, S.; Zhou, X.; Liu, H. The influence of persistent curing-loading temperature on the basic creep of early-age concrete: Experimental investigation. Constr. Build. Mater. 2020, 261, 119950. [Google Scholar] [CrossRef]

- Li, K.; Yang, C.; Huang, W.; Zhao, Y.; Wang, Y.; Pan, Y.; Xu, F. Effects of hybrid fibers on workability, mechanical, and time-dependent properties of high strength fiber-reinforced self-consolidating concrete. Constr. Build. Mater. 2021, 277, 122325. [Google Scholar] [CrossRef]

- Cai, X.; Jiang, M.; Guo, X.; Chen, J.; Zhao, Q. Experimental study on the creep behaviour of cemented sand and gravel (CSG) and temperature stress prediction of CSG dam under seasonal temperature change. Adv. Civ. Eng. 2020, 1, 8289520. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.; Zheng, W.; Wang, Y.; Chang, W. Analysis and Modelling of Shrinkage and Creep of Reactive Powder Concrete. Appl. Sci. 2018, 85, 732. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Dong, J.; Tan, K.H. Reliability Analysis of SFRC Beams Under Ultimate Limit States of Long-Term Load. J. Northeast. Univ. (Nat. Sci.) 2017, 38, 1055–1059. (In Chinese) [Google Scholar]

- Tošić, N.; Aidarov, S.; de la Fuente, A. Systematic review on the creep of fiber-reinforced concrete. Materials 2020, 13, 5098. [Google Scholar] [CrossRef] [PubMed]

- Szydłowski, R.; Łabuzek, B. Experimental evaluation of shrinkage, creep and prestress losses in lightweight Aggregate concrete with sintered fly ash. Materials 2021, 14, 3895. [Google Scholar] [CrossRef]

- Zheng, Z.; Hu, D.; Liu, P.; Sha, F.; Liu, L.; Yu, Z. Considering the effect of the randomness of concrete strength and relative humidity on concrete creep. Struct. Concr. 2020, 10, 201900435. [Google Scholar] [CrossRef]

- Wei, Y.; Huang, J.; Liang, S. Measurement and modeling concrete creep considering relative humidity effect. Mech. Time-Depend. Mat. 2020, 24, 161–177. [Google Scholar] [CrossRef]

- Yu, Q.; Bazant, Z.; Wendner, R. Improved algorithm for efficient and realistic creep analysis of large creep-sensitive concrete structures. ACI Struct. J. 2012, 109, 665. [Google Scholar]

- Wang, W.; Gong, J. New relaxation function and age-adjusted effective modulus expressions for creep analysis of concrete structures. Eng. Struct. 2019, 188, 1–10. [Google Scholar] [CrossRef]

- Dong, W.; Zhang, X.; Zhang, B.; Wu, Q. Influence of sustained loading on fracture properties of concrete. Eng. Fract. Mech. 2018, 200, 134–145. [Google Scholar] [CrossRef] [Green Version]

- Dong, W.; Li, J.; Zhang, X.; Zhang, B. Evolutions of SIFs of concrete under sustained loading by considering the effects of stress relaxations. J. Mater. Civil. Eng. 2019, 31, 04019287. [Google Scholar] [CrossRef] [Green Version]

- Rong, H.; Dong, W.; Zhang, X.; Zhang, B. Size effect on fracture properties of concrete after sustained loading. Mater. Struct. 2019, 52, 16. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, C.; Fan, J.; Bai, G.; Xiao, J. Experimental study on recycled concrete beam subjected to long-term loading and its flexural performance after unloading. Chin. J. Build. Struct. 2020, 41, 56–63. (In Chinese) [Google Scholar]

- Saliba, J.; Loukili, A.; Grondin, F.; Regoin, J.-P. Experimental study of creep-damage coupling in concrete by acoustic emission technique. Mater. Struct. 2012, 45, 1389–1401. [Google Scholar] [CrossRef]

- Omar, M.; Loukili, A.; Pijaudier-Cabot, G.; Le Pape, Y. Creep-damage coupled effects: Experimental investigation on bending beams with various sizes. J. Mater. Civ. Eng. 2009, 21, 65–72. [Google Scholar] [CrossRef] [Green Version]

- JGJ/T 12-2019; Technical Standard for Application of Lightweight Aggregate Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, July 2019; pp. 17–24. (In Chinese)

- Chen, M.; Li, Z.; Wu, J.; Wang, J. Shear behaviour and diagonal crack checking of shale ceramsite lightweight aggregate concrete beams with high-strength steel bars. Constr. Build. Mater. 2020, 249, 118730. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Rural Development of the people’s Republic of China: Beijing, China, June 2019; pp. 8–43. (In Chinese)

- Sun, G.; Xue, S. Experimental investigation of creep and shrinkage of reinforced concrete with influence of reinforcement ratio. Adv. Concr. Constr. 2019, 7, 211–218. [Google Scholar]

- Bažant, Z.P.; Baweja, S. Justification and refinements of model B3 for concrete creep and shrinkage 1. statistics and sensitivity. Mater. Struct. 1995, 28, 415–430. [Google Scholar] [CrossRef]

- GB/T 50152-2012; Standard for Test Method of Concrete Structures. Ministry of Housing and Urban-Rural Development of the people’s Republic of China: Beijing, China, January 2012; pp. 11–63. (In Chinese)

- Chen, P.; Zhou, X.; Zheng, W.; Wang, Y.; Bao, B. Influence of high sustained loads and longitudinal reinforcement on long-term deformation of reinforced concrete beams. J. Build. Eng. 2020, 30, 101241. [Google Scholar] [CrossRef]

- Altoubat, S.A.; Lange, D.A. Creep, shrinkage, and cracking of restrained concrete at early age. ACI. Mater. J. 2001, 98, 323–331. [Google Scholar]

- Micelli, F.; Candido, L.; Vasanelli, E.; Aiello, M.; Plizzari, G. Effects of short fibers on the long-term behavior of RC/FRC beams aged under service loading. Appl. Sci. 2019, 9, 2540. [Google Scholar] [CrossRef] [Green Version]

- Candido, L.; Micelli, F.; Vasanelli, E.; Aiello, M.; Plizzari, G. Cracking behaviour of FRC beams under long-term loading. Concreep 2015, 10, 1147–1156. [Google Scholar]

- Knaack, A.; Kurama, Y. Sustained Service Load Behavior of Concrete Beams with Recycled Concrete Aggregates. ACI Struct. J. 2015, 112, 565–577. [Google Scholar] [CrossRef]

- Hu, C.; SI, B. Experimental investigation on the cracks of existing concrete beams repaired with SHCC under sustained load. Chinese Concrete 2017, 2, 15–20. (In Chinese) [Google Scholar]

| Particle Size (mm) | Volume Density (kg/m3) | Apparent Density (kg/m3) | Compressive Strength of Concrete Cylinder (MPa) | Water Absorption in 1 h (%) |

|---|---|---|---|---|

| 5~20 | 814 | 1517 | 6.8 | 2.42 |

| Volume Density (kg/m3) | Apparent Density (kg/m3) | Mud Ration (%) | Fineness |

|---|---|---|---|

| 1570 | 2650 | ≤2 | 2.7 |

| Density (g/cm3) | Mineral Composition of Clinker | Fineness(Sieve Allowance by 80 μm Square Hole)/% | |||

|---|---|---|---|---|---|

| C3S | C2S | C3A | C3AF | ||

| 3.15 | 45 | 25 | 12 | 8 | 6.5 |

| Color | PH | Relative Density | Solid Content (%) | Water-Reducing Rate (%) |

|---|---|---|---|---|

| Pale yellow | 6~8 | 1.08 ± 0.02 | 40 | 25–35 |

| Cement | Ceramsite | Sand | Water-Reducing Agent | Water | Sand Ratio |

|---|---|---|---|---|---|

| 510 | 554 | 730 | 5.1 | 152 | 43% |

| Mechanical Parameters | Strength | |||

|---|---|---|---|---|

| Specimen No. 1 | Specimen No. 2 | Specimen No. 3 | Test Results | |

| Compressive strength/MPa | 40.04 | 38.77 | 42.47 | 40.43 |

| Flexural strength/MPa | 6.92 | 7.05 | 6.43 | 6.80 |

| Elasticity modulus/GPa | 24.45 | 24.01 | 24.18 | 24.21 |

| Group No. | Curing Age/d | Loading Duration/d | Purpose | Ultimate Bearing Capacity/kN | Loading Force/kN | Ultimate Bearing Capacity after Creep/kN |

|---|---|---|---|---|---|---|

| L0D1 | 28 | 0 | Used to confirm creep loading force. | 48.0 | – | – |

| L0D2 | 60 | 50.0 | – | – | ||

| L0D3 | 90 | 52.5 | – | – | ||

| L0D4 | 120 | 53.5 | – | – | ||

| L1D1 | 228 | 0 | The reference group of creep test beams. | 55.9 | – | – |

| L1D2 | 260 | 56.4 | – | – | ||

| L1D3 | 290 | 56.8 | – | – | ||

| L1D4 | 320 | 57.2 | – | – | ||

| L2D1 | 228 | 200 | Control group to study the influence of curing age. | – | 14.40 | 61.9 |

| L2D2 | 260 | – | 15.00 | 61.8 | ||

| L2D3 | 290 | – | 15.75 | 62.8 | ||

| L2D4 | 320 | – | 16.05 | 63.1 |

| Specimen Beam Grouping Number | Extreme Load Condition | Maximum Crack Depth at Damage (cm) | Average Crack Spacing at Damage (cm) | ||

|---|---|---|---|---|---|

| Load (kN) | Maximum Crack Width (mm) | Number of Cracks | |||

| L1D1 | 55.9 | 2.99 | 14 | 14.1 | 4.4 |

| L1D2 | 56.4 | 2.73 | 16 | 13.5 | 4.3 |

| L1D3 | 56.8 | 2.55 | 14 | 13.6 | 3.9 |

| L1D4 | 57.2 | 2.41 | 17 | 13.2 | 3.6 |

| L2D1 | 61.9 | 2.58 | 16 | 14.2 | 4.0 |

| L2D2 | 61.8 | 2.41 | 17 | 13.3 | 3.6 |

| L2D3 | 62.8 | 2.05 | 20 | 12.4 | 3.3 |

| L2D4 | 63.1 | 1.95 | 22 | 12.2 | 3.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Chen, J.; Wu, Y.; Li, J.; Fu, Z.; Liu, P. Experimental Study on Flexural Bearing Characteristics of Ceramsite Concrete Beams after Creep at Different Curing Ages. Coatings 2023, 13, 158. https://doi.org/10.3390/coatings13010158

Zhu H, Chen J, Wu Y, Li J, Fu Z, Liu P. Experimental Study on Flexural Bearing Characteristics of Ceramsite Concrete Beams after Creep at Different Curing Ages. Coatings. 2023; 13(1):158. https://doi.org/10.3390/coatings13010158

Chicago/Turabian StyleZhu, Hongbing, Jingyi Chen, Yuxin Wu, Jiapeng Li, Zhenghao Fu, and Peng Liu. 2023. "Experimental Study on Flexural Bearing Characteristics of Ceramsite Concrete Beams after Creep at Different Curing Ages" Coatings 13, no. 1: 158. https://doi.org/10.3390/coatings13010158