Influence of the Nitrogen Flux Ratio on the Structural, Morphological and Tribological Properties of TiN Coatings

Abstract

:1. Introduction

2. Experimental Section

2.1. Deposition of TiN Coatings

2.2. Characterization of TiN Coatings

3. Results and Discussion

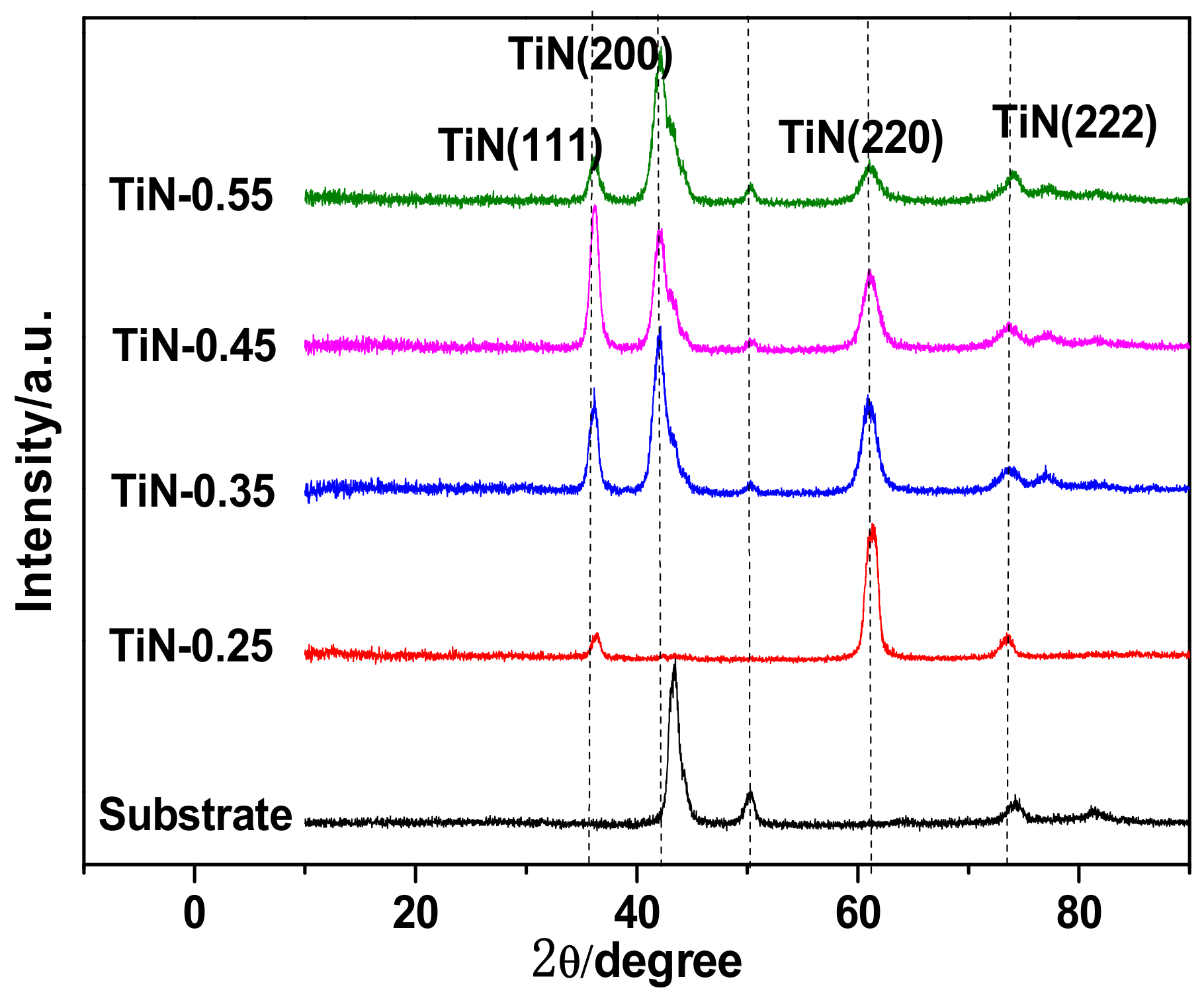

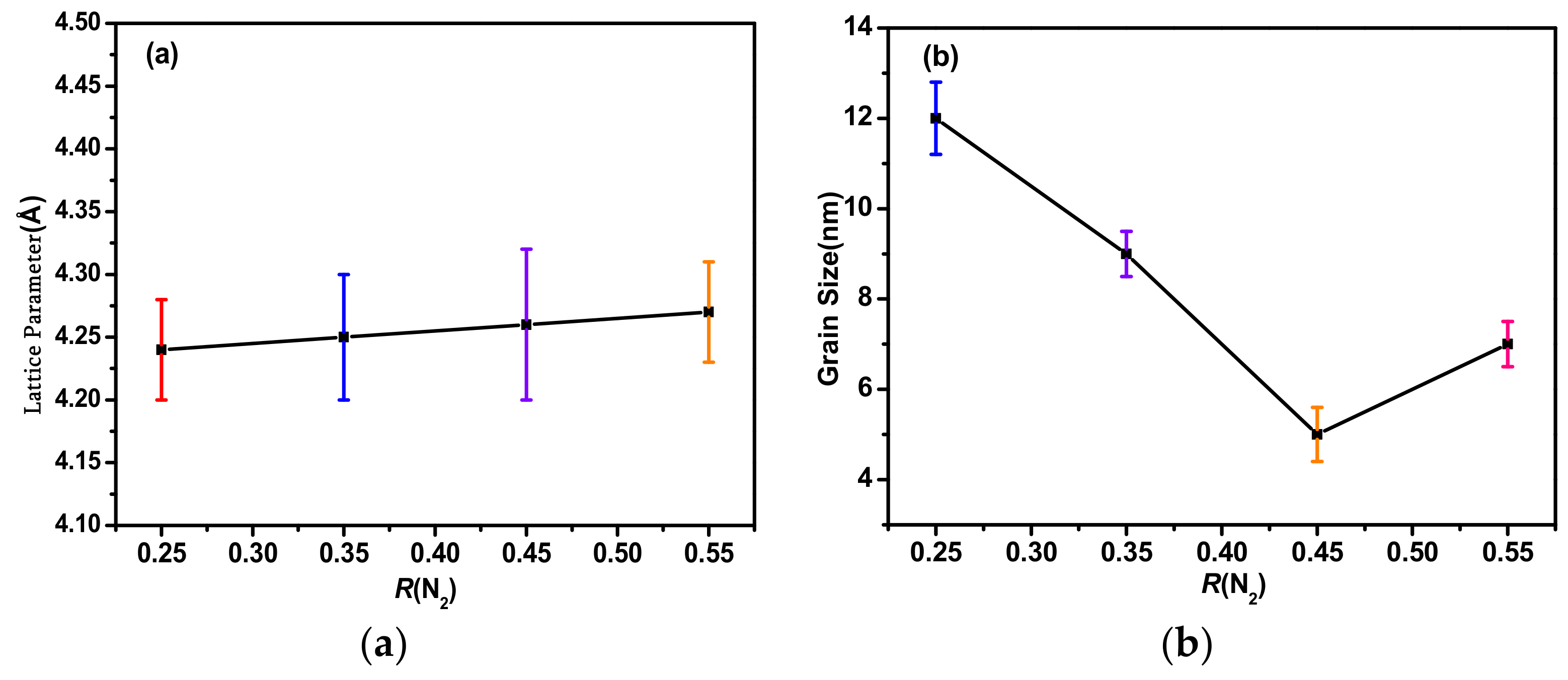

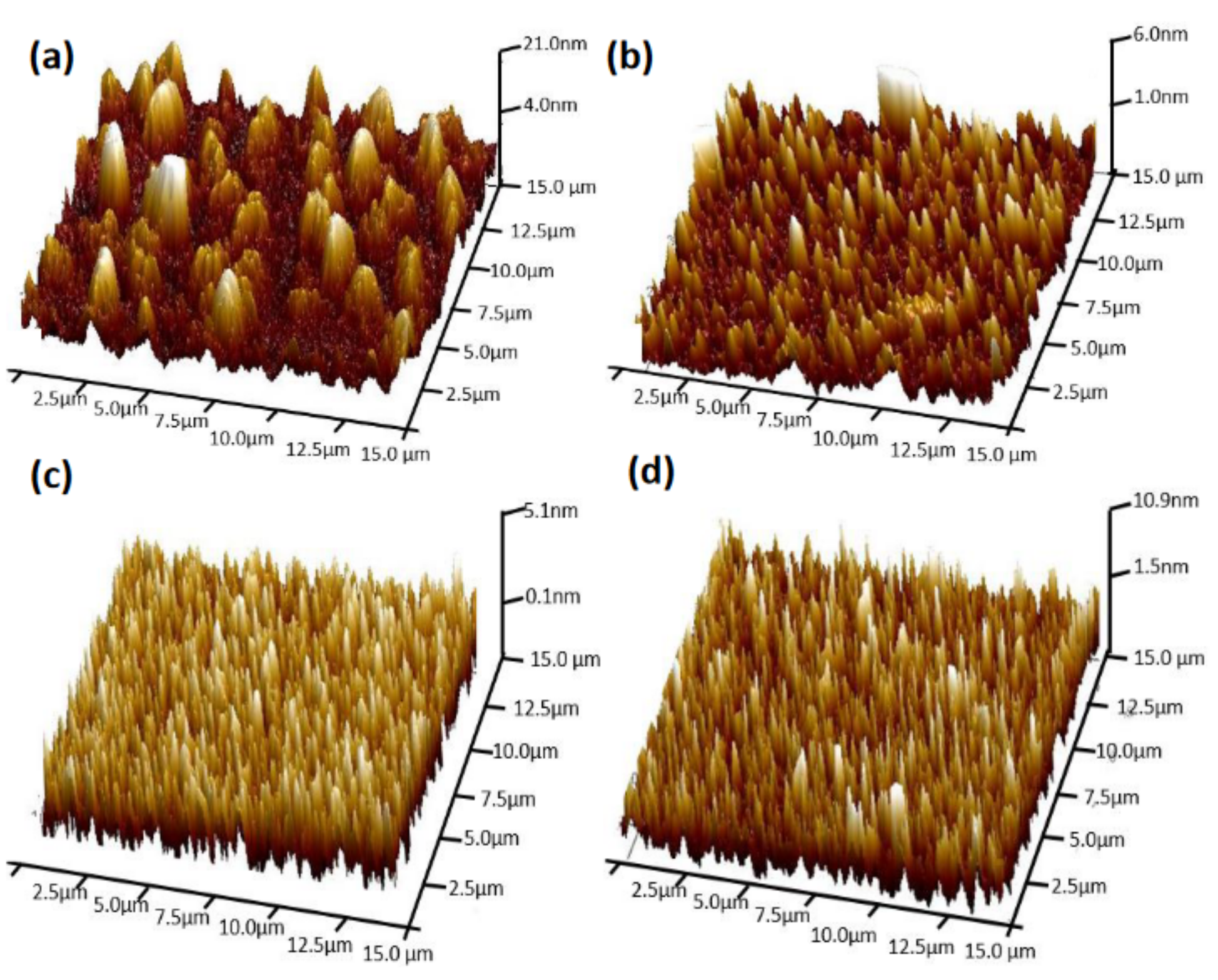

3.1. Microstructure and Morphology of TiN Coatings

3.2. Mechanical Performance of TiN Coatings

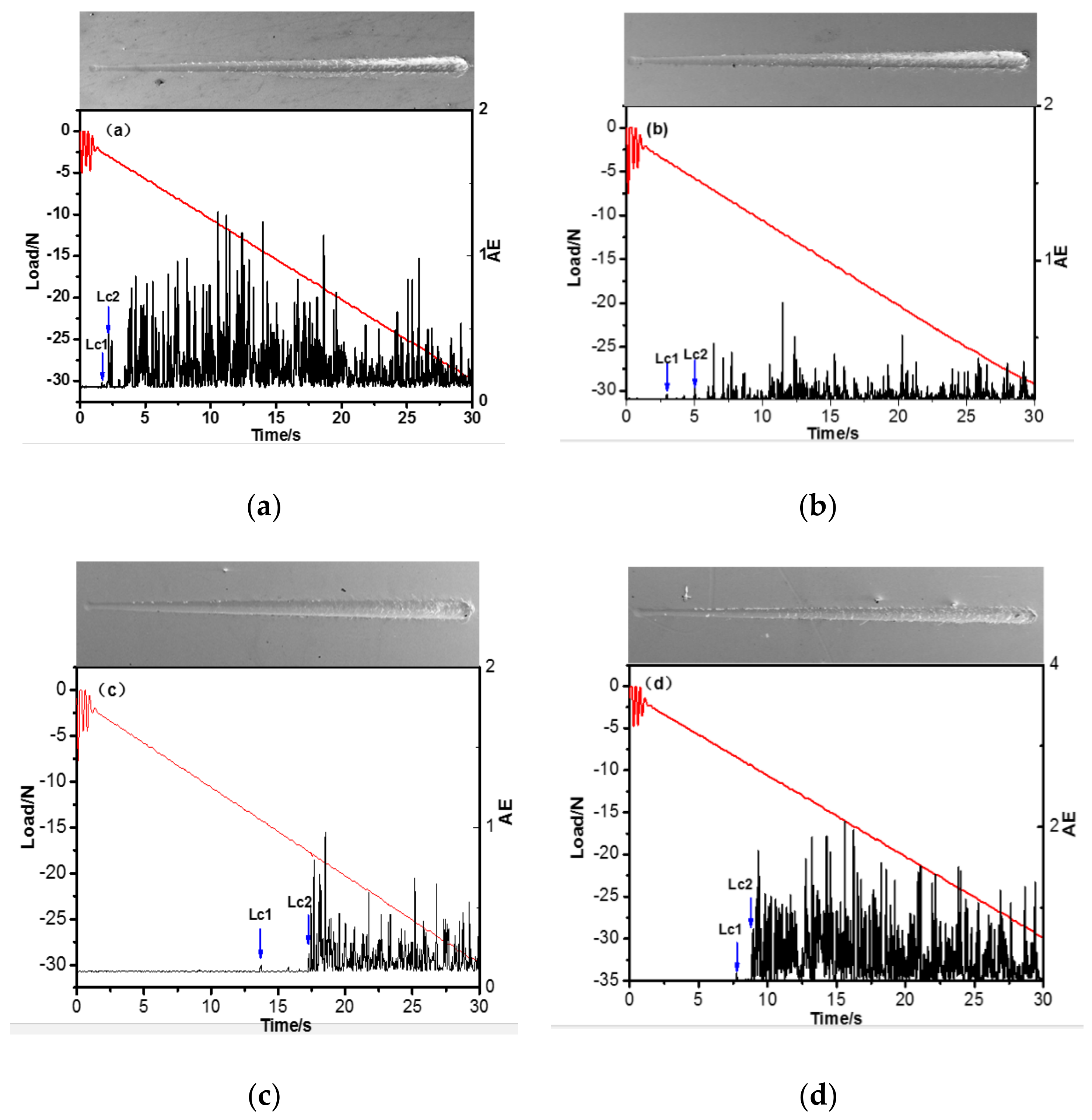

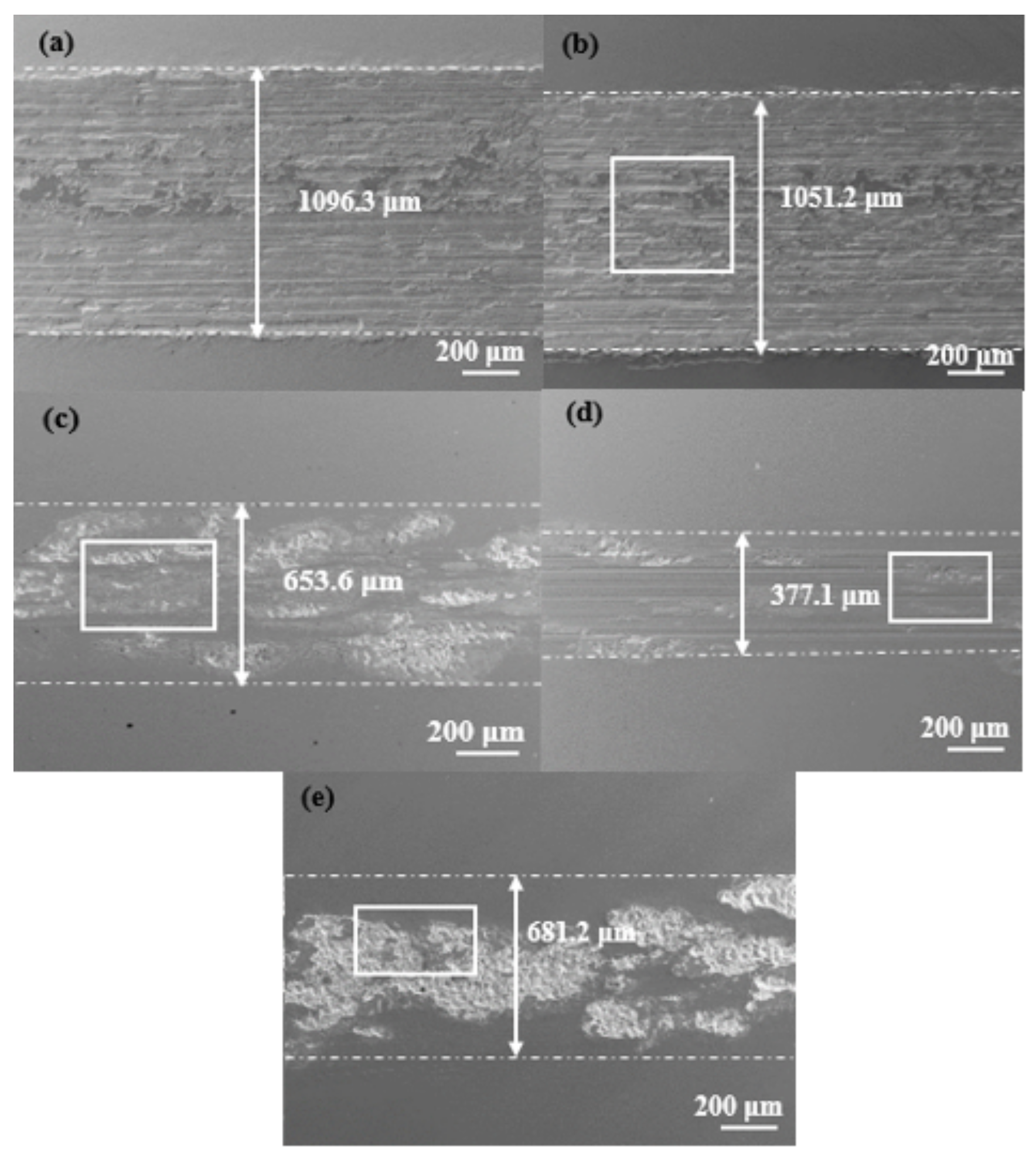

3.3. Tribological Performance

4. Conclusions

- The phase structure of the TiN coatings deposited at R(N2) = 0.25, 0.35, 0.45, and 0.55 was mainly face-centered cubic TiN. All TiN coatings had obvious columnar crystals. The TiN-0.45 coating possessed the densest columnar microstructure of the four TiN coatings.

- The nitrogen flux ratio strongly affected the mechanical properties of the coating, and the TiN-0.45 coating had the best mechanical properties (hardness, elasticity modulus, H/E, and H3/E2) due to its minimum grain size and (111) orientation. In addition, the thickness of the TiN coating was inversely correlated with R(N2) and decreased from 772 nm to 509 nm as R(N2) decreased.

- The TiN-0.45 coating had the largest values of H/E and H3/E2 and, therefore, the best wear resistance among the four TiN coatings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xi, Y.; Bai, Y.; Gao, K.; Pang, X.; Yang, H.; Yan, L.; Volinsky, A.A. Residual stress and microstructure effects on mechanical, tribological and electrical properties of TiN coatings on 304 stainless steel. Ceram. Int. 2018, 44, 15851–15858. [Google Scholar] [CrossRef]

- Bobzin, K. High-performance coatings for cutting tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Sawada, S.; Tamai, T.; Hattori, Y. Effect of contact force on the friction coefficient of electroplated TiN films for automotive applications. J. Jpn. Inst. Met. 2009, 73, 659–665. [Google Scholar] [CrossRef] [Green Version]

- Lousa, A.; Esteve, J.; Mejia, J.P.; Devia, A. Influence of deposition pressure on the structural mechanical and decorative properties of TiN thin films deposited by cathodic arc evaporation. Vacuum 2007, 81, 1507–1510. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, X.; Gu, X.; Zhang, H.; Lu, J.; Liu, H. Fabrication of Metallic Micro-Parts Reinforced with Nano-and Micro-Sized TiN Particles via Laser Shock Processing. J. Mater. Eng. Perform. 2022, 31, 786–800. [Google Scholar] [CrossRef]

- Franks, W.; Schenker, I.; Schmutz, P.; Hierlemann, A. Impedance characterization and modeling of electrodes for biomedical applications. IEEE Trans. Biomed. Eng. 2005, 52, 1295–1302. [Google Scholar] [CrossRef]

- Jeyachandran, Y.; Narayandass, S.; Mangalaraj, D.; Areva, S.; Mielczarski, J. Properties of titanium nitride films prepared by direct current magnetron sputtering. Mater. Sci. Eng. A 2007, 445, 223–236. [Google Scholar] [CrossRef]

- Toth, L.E. Refractory Materials, Transition Metal Carbides and Nitrides; Academic Press Inc.: New York, NY, USA, 1971; Volume 7, p. 88. [Google Scholar]

- Shukla, K.; Rane, R.; Alphonsa, J.; Maity, P.; Mukherjee, S. Structural, mechanical and corrosion resistance properties of Ti/TiN bilayers deposited by magnetron sputtering on AISI 316L. Surf. Coatings Technol. 2017, 324, 167–174. [Google Scholar] [CrossRef]

- Hua, M.; Ma, H.; Li, J.; Mok, C. Tribological behaviours of patterned PVD TiN spot coatings on M2 steel coated with different bias voltages. Surf. Coat. Technol. 2006, 200, 3612–3625. [Google Scholar] [CrossRef]

- Pihosh, Y.; Goto, M.; Kasahara, A.; Oishi, T.; Tosa, M. Influence of reacting nitrogen gas consistence on the properties of TiN films prepared by rf. magnetron sputtering. Appl. Surf. Sci. 2005, 244, 244–247. [Google Scholar] [CrossRef]

- Gerlach, J.; Höche, T.; Frost, F.; Rauschenbach, B. Ion beam assisted MBE of GaN on epitaxial TiN films. Thin Solid Film. 2004, 459, 13–16. [Google Scholar] [CrossRef]

- Chen, G.S.; Guo, J.J.; Lin, C.K.; Hsu, C.-S.; Yang, L.C.; Fang, J.S. Evaluation of radio-frequency sputter-deposited textured TiN thin films as diffusion barriers between copper and silicon. J. Vac. Sci. Technol. A Vac. Surf. Film. 2002, 20, 479–485. [Google Scholar] [CrossRef]

- Arshi, N.; Lu, J.; Joo, Y.K.; Lee, C.G.; Yoon, J.H.; Ahmed, F. Study on structural, morphological and electrical properties of sputtered titanium nitride films under different argon gas flow. Mater. Chem. Phys. 2012, 134, 839–844. [Google Scholar] [CrossRef]

- Stanishevsky, A.; Lappalainen, R. Tribological properties of composite Ti (N, O, C) coatings containing hard amorphous carbon layers. Surf. Coatings Technol. 2000, 123, 101–105. [Google Scholar] [CrossRef]

- Bin, D.; Tao, Y.; Hu, Z. The microstructure, mechanical and tribological properties of TiN coatings after Nb and C ion implantation. Appl. Surf. Sci. 2013, 284, 405–411. [Google Scholar] [CrossRef]

- Pelleg, J.; Zevin, L.Z.; Lungo, S.; Croitoru, N. Reactive-sputter-deposited TiN films on glass substrates. Thin Solid Film. 1991, 197, 117–128. [Google Scholar] [CrossRef]

- Lu, G.; Yu, L.; Ju, H.; Zuo, B.; Xu, J. Influence of nitrogen content on the thermal diffusivity of TiN films prepared by magnetron sputtering. Surf. Eng. 2020, 36, 192–198. [Google Scholar] [CrossRef]

- Banerjee, R.; Singh, K.; Ayyub, P.; Totlani, M.K.; Suri, A.K. Influence of the Ar/N2 ratio on the preferred orientation and optical reflectance of reactively sputter deposited titanium nitride thin films. J. Vac. Sci. Technol. A Vac. Surf. Film. 2003, 21, 310–317. [Google Scholar] [CrossRef]

- Li, T.Q.; Noda, S.; Tsuji, Y.; Ohsawa, T.; Komiyama, H. Initial growth and texture formation during reactive magnetron sputtering of TiN on Si (111). J. Vac. Sci. Technol. A Vac. Surf. Film. 2002, 20, 583–588. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Tang, W.; Zhang, L. Crystalline size effects on texture coefficient, electrical and optical properties of sputter-deposited Ga-doped ZnO thin films. J. Mater. Sci. Technol. 2015, 31, 175–181. [Google Scholar] [CrossRef]

- Material Data Inc. MDI Jade 6 User’s Manual; Material Data Inc.: Livermore, CA, USA, 2004. [Google Scholar]

- Arshi, N.; Lu, J.; Koo, B.H.; Lee, C.G.; Ahmed, F. Effect of nitrogen flow rate on the properties of TiN film deposited by e beam evaporation technique. Appl. Surf. Sci. 2012, 258, 8498–8505. [Google Scholar] [CrossRef]

- Sundgren, J.E. Structure and properties of TiN coatings. Thin Solid Film. 1985, 128, 21–44. [Google Scholar] [CrossRef]

- Warren, B.E. X-ray Diffraction; Addison Wesley Publishing Co.: London, UK, 1969. [Google Scholar]

- Chawla, V.; Jayaganthan, R.; Chandra, R. Structural characterizations of magnetron sputtered. Mater. Charact. 2008, 59, 1015–1020. [Google Scholar] [CrossRef]

- Mohapatra, S.S.; Ranjan, S.; Dasgupta, N.; Mishra, R.K.; Thomas, S. Nano-Carriers for Drug Delivery: Nanoscience and Nanotechnology in Drug Delivery; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Kiahosseini, S.R.; Larijani, M.M. Effects of nitrogen gas ratio on the structural and corrosion properties of ZrN thin films grown on biodegradable magnesium alloy by ion-beam sputtering. Appl. Phys. A 2017, 123, 759. [Google Scholar] [CrossRef]

- Qasmi, M.; Delobelle, P. Influence of the average roughness Rms on the precision of the Young’s modulus and hardness determination using nanoindentation technique with a Berkovich indenter. Surf. Coat. Technol. 2006, 201, 1191–1199. [Google Scholar] [CrossRef]

- Lee, J.H.; Nathanael, A.J.; Hong, S.I. Effect of nitrogen flow rate on the structure and properties of TiN thin films deposited onto β-type Ti-15Mo-3Nb-3Al-0.2Si alloy Substrates by Reactive Magnetron Sputtering. Adv. Mater. Res. 2012, 557, 1998–2001. [Google Scholar] [CrossRef]

- Lia, J.; Zheng, H.; Sinkovits, T.; Hee, A.C.; Zhao, Y. Mono and multiple TiN(/Ti) coating adhesion mechanism on a Ti–13Nb–13Zr alloy. Appl. Surf. Sci. 2015, 355, 502–508. [Google Scholar] [CrossRef]

- Huang, J.H.; Lau, K.W.; Yu, G.P. Effect of nitrogen flow rate on structure and properties of nanocrystalline TiN thin films produced by unbalanced magnetron sputtering. Surf. Coat. Technol. 2005, 191, 17–24. [Google Scholar] [CrossRef]

- Huang, J.H.; Ho, C.H.; Yu, G.P. Effect of nitrogen flow rate on the structure and mechanical properties of ZrN thin films on Si(1 0 0) and stainless steel substrates. Mater. Chem. Phys. 2007, 102, 31–38. [Google Scholar] [CrossRef]

- Ali, R.; Sebastiani, M.; Bemporad, E. Influence of Ti–TiN multilayer PVD-coatings design on residual stresses and adhesion. Mater. Des. 2015, 75, 47–56. [Google Scholar] [CrossRef]

- He, C.; Zhang, J.; Xie, L.; Ma, G.; Du, Z.; Wang, J.; Zhang, D. Microstructure, mechanical and corrosion properties of TiN/Ni nano-multilayered films. Rare Metals. 2019, 38, 979–988. [Google Scholar] [CrossRef]

| R(N2) | Roughness (nm) | Hardness (GPa) | Elasticity modulus (GPa) | H/E | H3/E2 (GPa) |

|---|---|---|---|---|---|

| 0.25 | 26.03 ± 0.15 | 18.50 ± 4.10 | 278.0 ± 28.7 | 0.067 ± 0.008 | 0.082 ± 0.012 |

| 0.35 | 6.81 ± 0.12 | 23.32 ± 2.21 | 315.2 ± 31.1 | 0.074 ± 0.012 | 0.128 ± 0.017 |

| 0.45 | 1.46 ± 0.08 | 26.14 ± 2.07 | 329.5 ± 28.7 | 0.080 ± 0.007 | 0.165 ± 0.025 |

| 0.55 | 3.90 ± 0.14 | 20.87 ± 3.52 | 296.8 ± 30.1 | 0.007 ± 0.006 | 0.103 ± 0.009 |

| R(N2) | Element (at.%) | |||

|---|---|---|---|---|

| Ti | N | Fe | Cr | |

| 0.25 | 22.57 | 4.40 | 30.77 | 42.26 |

| 0.35 | 52.98 | 24.26 | 17.94 | 4.82 |

| 0.45 | 60.45 | 28.76 | 10.01 | 0.78 |

| 0.55 | 56.33 | 16.81 | 23.08 | 3.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, X.; Guo, S.; Wan, Y.; Li, Q.; Liu, B.; Zheng, H. Influence of the Nitrogen Flux Ratio on the Structural, Morphological and Tribological Properties of TiN Coatings. Coatings 2023, 13, 78. https://doi.org/10.3390/coatings13010078

Fu X, Guo S, Wan Y, Li Q, Liu B, Zheng H. Influence of the Nitrogen Flux Ratio on the Structural, Morphological and Tribological Properties of TiN Coatings. Coatings. 2023; 13(1):78. https://doi.org/10.3390/coatings13010078

Chicago/Turabian StyleFu, Xiaojing, Shuming Guo, Yong Wan, Qiang Li, Bingchang Liu, and Hui Zheng. 2023. "Influence of the Nitrogen Flux Ratio on the Structural, Morphological and Tribological Properties of TiN Coatings" Coatings 13, no. 1: 78. https://doi.org/10.3390/coatings13010078

APA StyleFu, X., Guo, S., Wan, Y., Li, Q., Liu, B., & Zheng, H. (2023). Influence of the Nitrogen Flux Ratio on the Structural, Morphological and Tribological Properties of TiN Coatings. Coatings, 13(1), 78. https://doi.org/10.3390/coatings13010078