Assessment of Efficiency and Anilox-Roll Condition after Ultrasonic Cleaning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Anilox Rolls

2.2. Printing Procedure

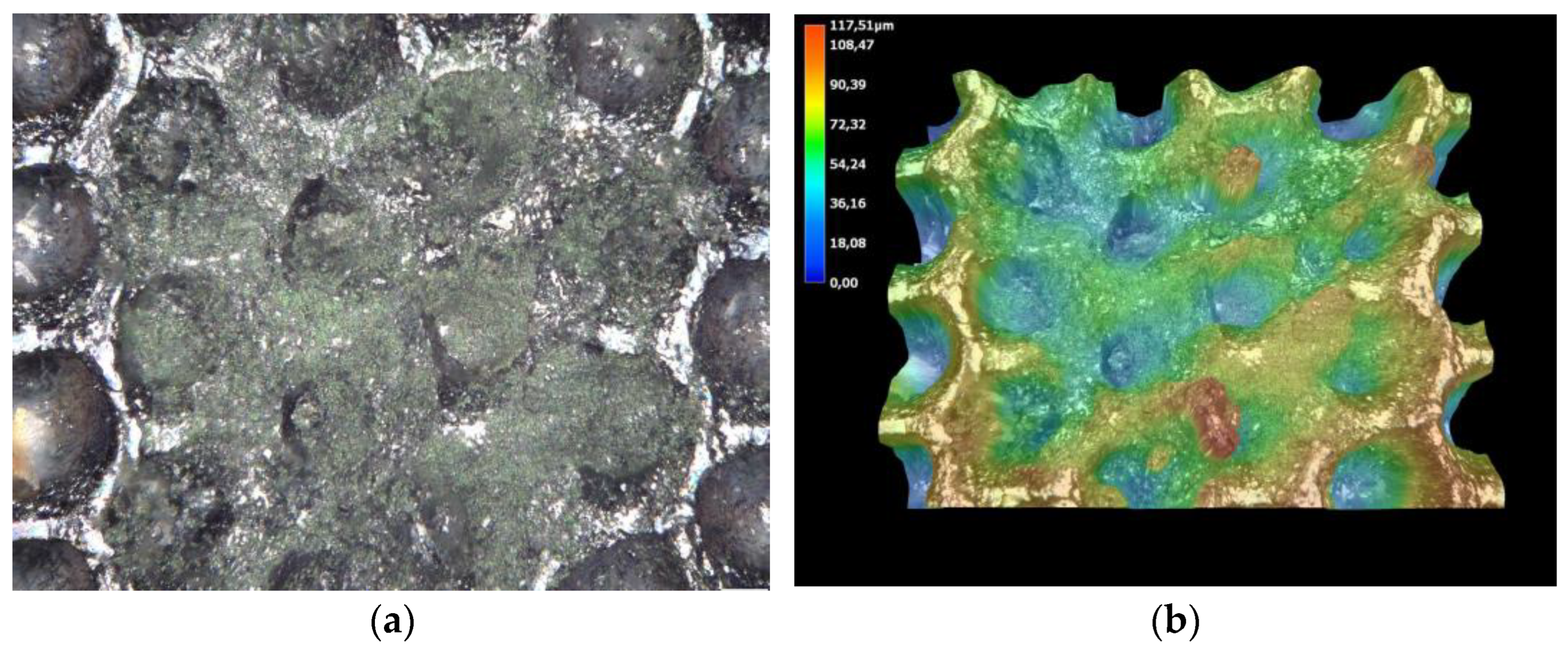

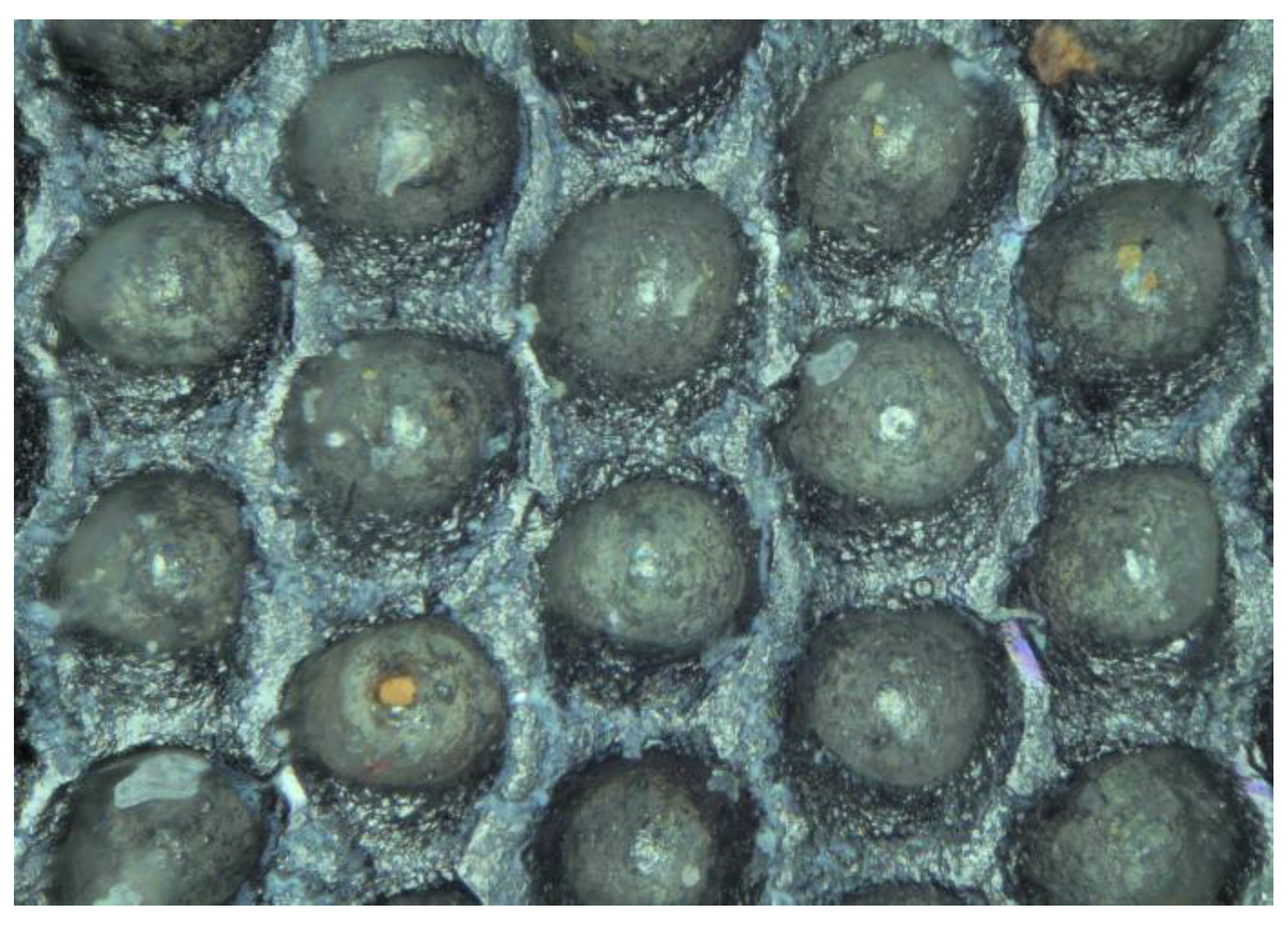

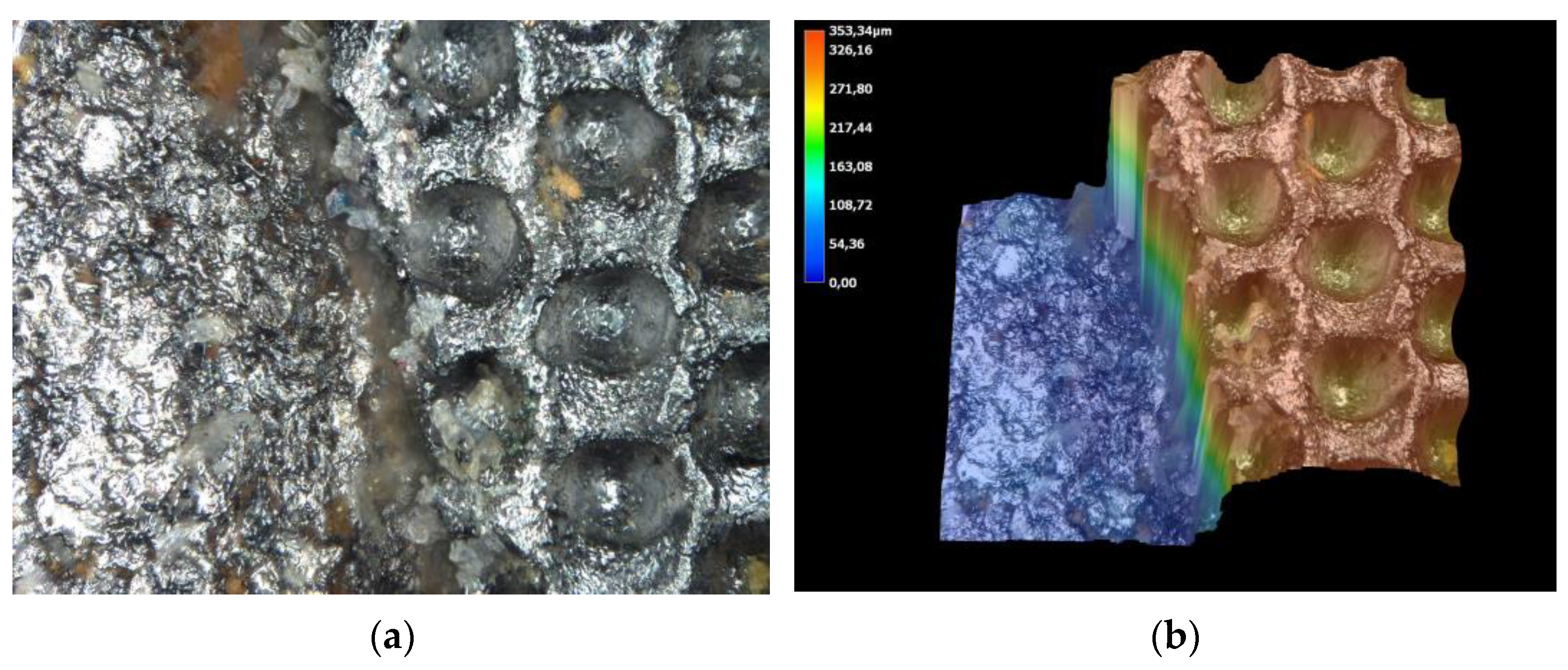

2.3. Mechanical Damages

2.4. Cleaning Procedure

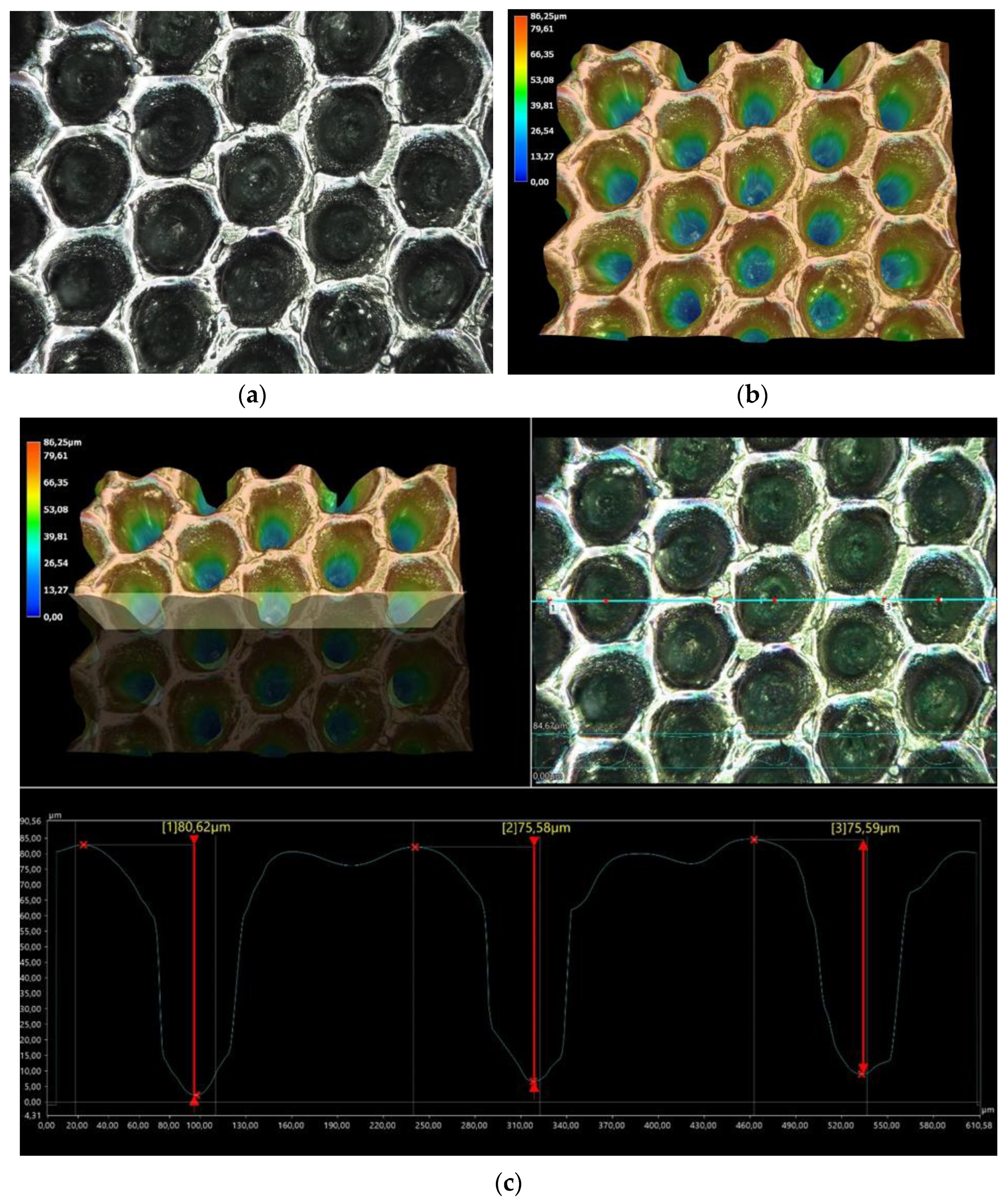

2.5. Analysis of Anilox Rolls

- Ratio of the inkwell opening to the width of the threshold;

- Capacity, i.e., the volume of inkwell collected on a unit area of a raster mesh;

- Inkwell depth.

- Reference: brand new anilox roll, no mechanical damages, not printing, no cleaning;

- No mechanical damages, printing, cleaning with a cleaning agent;

- Mechanical damages, no printing, no cleaning;

- Mechanical damages, printing, cleaning with a cleaning agent;

- Mechanical damages, printing, cleaning with distilled water.

3. Results and Discussion

- Depth of the inkwell;

- Diameter of the inkwell;

- Volume of the inkwell;

- Surface area of the inkwell.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Flexographic Technical Association. Flexographic Image Reproduction Specifications & Tolerances 7.0, FIRST 7.0 Kindle Edition; Flexographic Technical Association: Bohemia, NY, USA, 2022. [Google Scholar]

- Izdebska, J. 11-Flexographic printing. In Printing on Polymers Fundamentals and Applications; William Andrew Applied Science Publishers: Norwich, NY, USA, 2016; pp. 179–197. [Google Scholar] [CrossRef]

- Flexography: Principles & Practices 6.0; Flexographic Technical Association. Available online: https://www.flexography.org/training-resources/resource-library/flexography-principles-and-practices/ (accessed on 27 July 2023).

- Hamblyn, A. Effect of Plate Characteristics on Ink Transfer in Flexographic Printing. Ph.D. Thesis, Swansea University, Swansea, UK, 2015. [Google Scholar]

- Abusaq, Z.; Zahoor, S.; Habib, M.S.; Rehman, M.; Mahmood, J.; Kanan, M.; Mushtaq, R.T. Improving energy performance in flexographic printing process through lean and AI techniques: A case study. Energies 2023, 16, 1972. [Google Scholar] [CrossRef]

- Joshi, A.V. Optimization of flexo process parameters to reduce the overall manufacturing cost. Int. J. Optim. Control Theor. Appl. 2022, 12, 66–78. [Google Scholar] [CrossRef]

- The Secret to Print Consistency: Maintaining Anilox Roll Volume. Available online: https://www.flexography.org/industry-news/print-consistency-maintain-anilox-roll-volume/ (accessed on 28 July 2023).

- Döring, J.E.; De Schoulepnikoff, L. Review on the art of anilox-manufacturing—From the coated cylinder up to the gravure. In Proceedings of the Thermal Spray 2011: Proceedings from the International Thermal Spray Conference, Hamburg, Germany, 27–29 September 2011; Volume 83713, pp. 542–549. [Google Scholar] [CrossRef]

- Savickas, A.; Stonkus, R.; Jurkonis, E.; Iljin, I. Assessment of the condition of anilox rollers. Coatings 2021, 11, 1301. [Google Scholar] [CrossRef]

- Damaged Anilox Rollers—How to Save On Repairs Case Study. Available online: https://www.daetwyler-usa.com/daetwyler-value-of-expertise/ (accessed on 28 July 2023).

- The problem of Scoring Lines on Anilox Rolls. Available online: https://flexopedia.net/scoring-lines-on-anilox-rolls/ (accessed on 28 July 2023).

- Anilox Scoring Prevention. Available online: https://www.harperimage.com/AniloxRolls/Anilox-Guides/Anilox-Damage-Prevention (accessed on 28 July 2023).

- Scrubbing the Cells. Available online: https://www.flexotechmag.com/key-articles/24074/scrubbing-the-cells/ (accessed on 28 July 2023).

- Bould, D.C.; Hamblyn, S.M.; Gethin, D.T.; Claypole, T.C. Effect of impression pressure and anilox specification on solid and halftone density. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2011, 225, 699–709. [Google Scholar] [CrossRef]

- Żołek-Tryznowska, Z. 6-Rheology of printing inks. Print. Polym. Fundam. Appl. 2016, 87–99. [Google Scholar] [CrossRef]

- Anilox Selection: The Impact on Ink Strength, Drying & Curing. Available online: https://www.flexography.org/industry-news/anilox-selection-ink-strength-drying-curing/ (accessed on 28 July 2023).

- Saad, A.A.E.-R.E. Environmental Pollution Reduction by Using VOC-Free Water-Based Gravure Inks and Drying Them with a New Drying System Based on Dielectric Heating. Ph.D. Thesis, Bergische Universität Wuppertal, Wuppertal, Germany, 2007. [Google Scholar]

- Savickas, A.; Stonkus, R.; Jurkonis, E. Investigation of anilox roller cell clogging. J. Graph. Eng. Des. 2021, 11, 61–67. [Google Scholar] [CrossRef]

- Żołek-Tryznowska, Z.; Rombel, M.; Petriaszwili, G.; Dedijer, S.; Kašiković, N. Influence of some flexographic printing process conditions on the optical density and tonal value increase of overprinted plastic films. Coatings 2020, 10, 816. [Google Scholar] [CrossRef]

- Instructions for the Cleaning and Care of Anilox Rollers. Available online: https://www.zecher.com/media/Zecher_Cleaning_and_Care_Anilox_Rollers.pdf (accessed on 30 July 2023).

- Anilox Roll Cleaning. Available online: https://www.draychem.co.uk/anilox-roll-cleaning.php (accessed on 30 July 2023).

- Specifying the Right Anilox Roll. Available online: https://www.harperimage.com/AniloxRolls/Anilox-Guides/Specifying-the-Right-Anilox- (accessed on 30 July 2023).

- Ultrasonic Tanks: Frequently Asked Questions. Cheshire Anilox Technology-Ultrasonic Tanks-FAQ. Available online: https://cheshireanilox.co.uk/wp-content/uploads/2017/08/Ultrasonic-tanks-FAQ.pdf (accessed on 30 July 2023).

- 5 Methods of Anilox Roller Cleaning—Advantages and Disadvantages. Available online: https://www.printsystems.pl/en/2016/11/29/5-methods-of-anilox-roller-cleaning/ (accessed on 30 July 2023).

- Industry News. How to Clean Anilox Roller. Available online: https://www.jctprinting.com/news/en/News-20181225-013243.html (accessed on 30 July 2023).

- Correct Use of Laser Cleaning for Anilox Rollers. Available online: https://flexopedia.net/laser-cleaning-for-anilox-rollers/ (accessed on 30 July 2023).

- Jin, H. Use the Laser Engraving Machines to Achieve Laser Cleaning, Laser Post-Melting and Roughness Control of the Anilox Rolls; Internship Report; Apex Europe B.V.: Hapert, The Netherlands, 2015. [Google Scholar]

- Anilox Cleaning Systems. Available online: https://www.researchgate.net/publication/293631262_Anilox_cleaning_systems (accessed on 30 July 2023).

- Anilox Development and the Need to Clean. Available online: https://www.researchgate.net/publication/296541896_Anilox_development_and_the_need_to_clean (accessed on 30 July 2023).

- How to Clean Anilox Rolls & Understanding the Chemicals Involved, Flexographic Technical Association. Available online: https://www.flexography.org/industry-news/how-to-clean-anilox-rolls-understanding-chemicals/ (accessed on 30 July 2023).

- Ceramic Anilox Roll Care and Maintenance. Available online: https://www.praxairsurfacetechnologies.com/-/media/corporate/praxairsurface/us/documents/brochures/p9125_aniloxrollmaintenance_lr.pdf?la=en (accessed on 30 July 2023).

- Anilox Cleaning Systems: Preserving Roll Life. Available online: https://docplayer.net/20815633-Anilox-cleaning-systems-preserving-roll-life.html (accessed on 30 July 2023).

- Shape, Volume, Count: Standard Anilox Specifications in Flexographic Packaging. Available online: https://www.flexography.org/industry-news/shape-volume-count-standard-anilox-specifications-in-flexographic-packaging/ (accessed on 30 July 2023).

- Anilox Roll Specifications: Line Count or Volume? Available online: https://www.labelandnarrowweb.com/issues/2008-07/view_features/anilox-roll-specifications/ (accessed on 30 July 2023).

- ISO 25178-1:2016; Geometrical Product Specifications (GPS)-Surface Texture: Areal-Part 1: Indication of Surface Texture. International Organization for Standardization: Geneva, Switzerland, 2016.

| Sample Number | Inkwell Depth [µm] | Inkwell Volume [µm3] | Inkwell Area [µm] | Capacity [µm] |

|---|---|---|---|---|

| 1 (brand new) | 80.42 (3.39) * | 331,500 (12,600) | 25,520 (1010) | 15.6 (0.6) |

| 2 (undamaged, after printing) | 62.9 (2.89) | 285,090 (11,400) | 24,860 (980) | 12.5 (0.5) |

| 3 (undamaged, printing, cleaning) | 78.61 (2.97) | 325,900 (14,800) | 25,650 (1220) | 15.4 (0.7) |

| 4 (damaged, printing, cleaning) | 77.26 (3.06) | 330,500 (12,900) | 25,010 (1130) | 15.3 (0.6) |

| 5 (damaged, printing, cleaning—water) | 70.29 (3.86) | 302,000 (17,600) | 24,360 (860) | 13.6 (0.8) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Przybysz, K.; Lipkiewicz, A.; Małachowska, E.; Dubowik, M.; Przybysz, P. Assessment of Efficiency and Anilox-Roll Condition after Ultrasonic Cleaning. Coatings 2023, 13, 1699. https://doi.org/10.3390/coatings13101699

Przybysz K, Lipkiewicz A, Małachowska E, Dubowik M, Przybysz P. Assessment of Efficiency and Anilox-Roll Condition after Ultrasonic Cleaning. Coatings. 2023; 13(10):1699. https://doi.org/10.3390/coatings13101699

Chicago/Turabian StylePrzybysz, Kamila, Aneta Lipkiewicz, Edyta Małachowska, Marcin Dubowik, and Piotr Przybysz. 2023. "Assessment of Efficiency and Anilox-Roll Condition after Ultrasonic Cleaning" Coatings 13, no. 10: 1699. https://doi.org/10.3390/coatings13101699

APA StylePrzybysz, K., Lipkiewicz, A., Małachowska, E., Dubowik, M., & Przybysz, P. (2023). Assessment of Efficiency and Anilox-Roll Condition after Ultrasonic Cleaning. Coatings, 13(10), 1699. https://doi.org/10.3390/coatings13101699