Study on Microstructure and Mechanical Properties of A100-Y2O3 Coatings on Low-Carbon Steel by Laser Cladding

Abstract

:1. Introduction

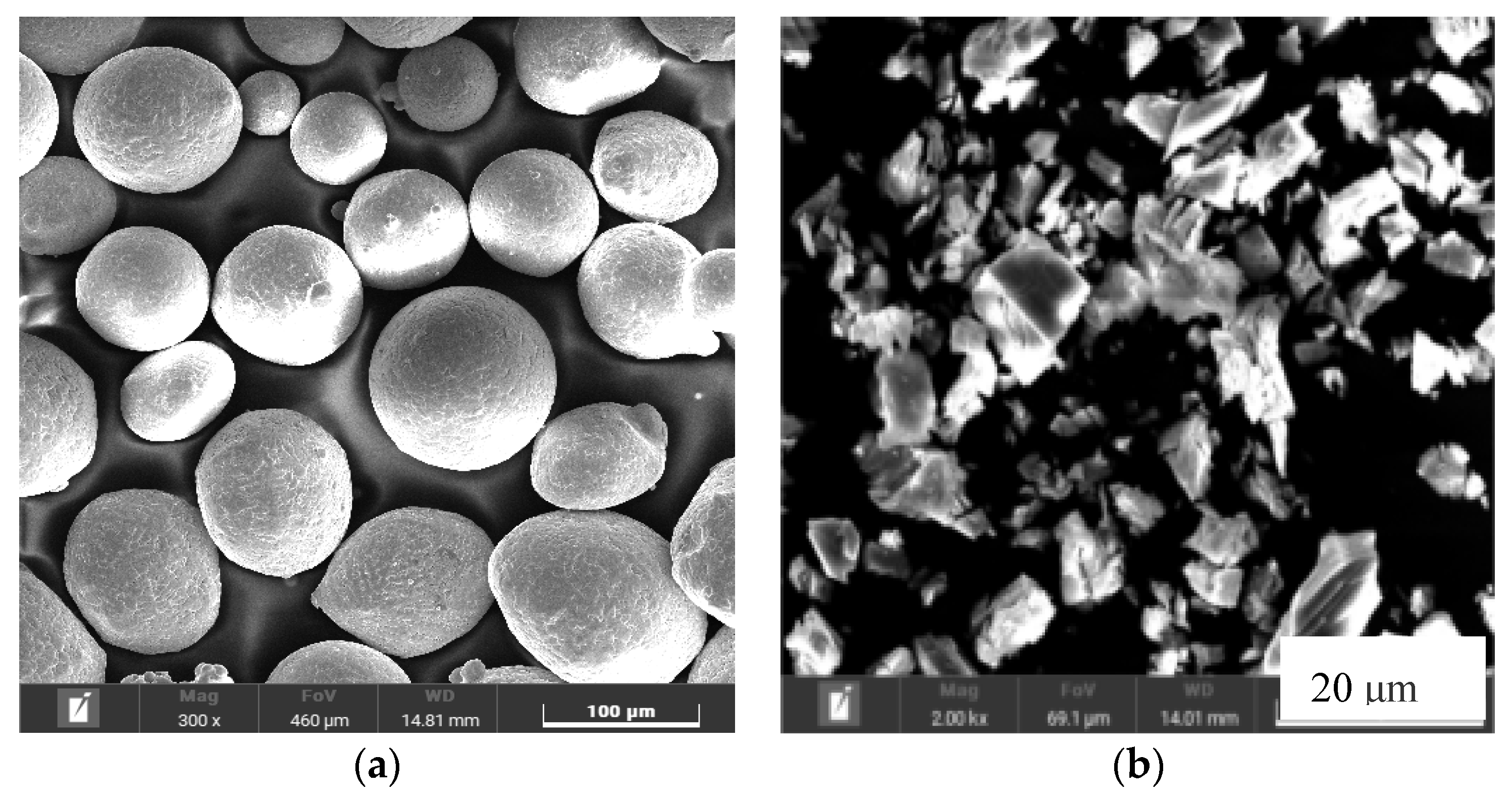

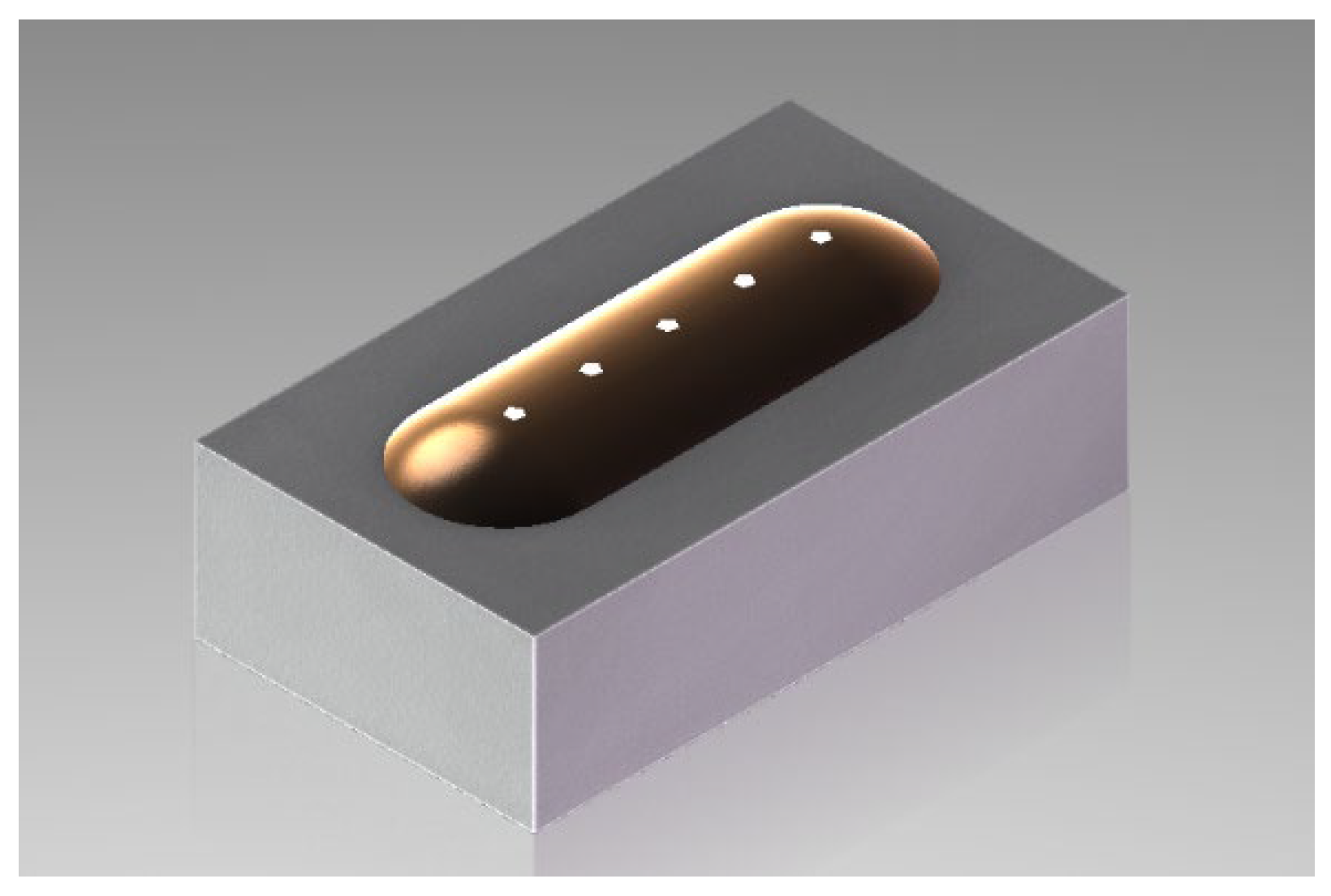

2. Materials and Methods

3. Results and Discussion

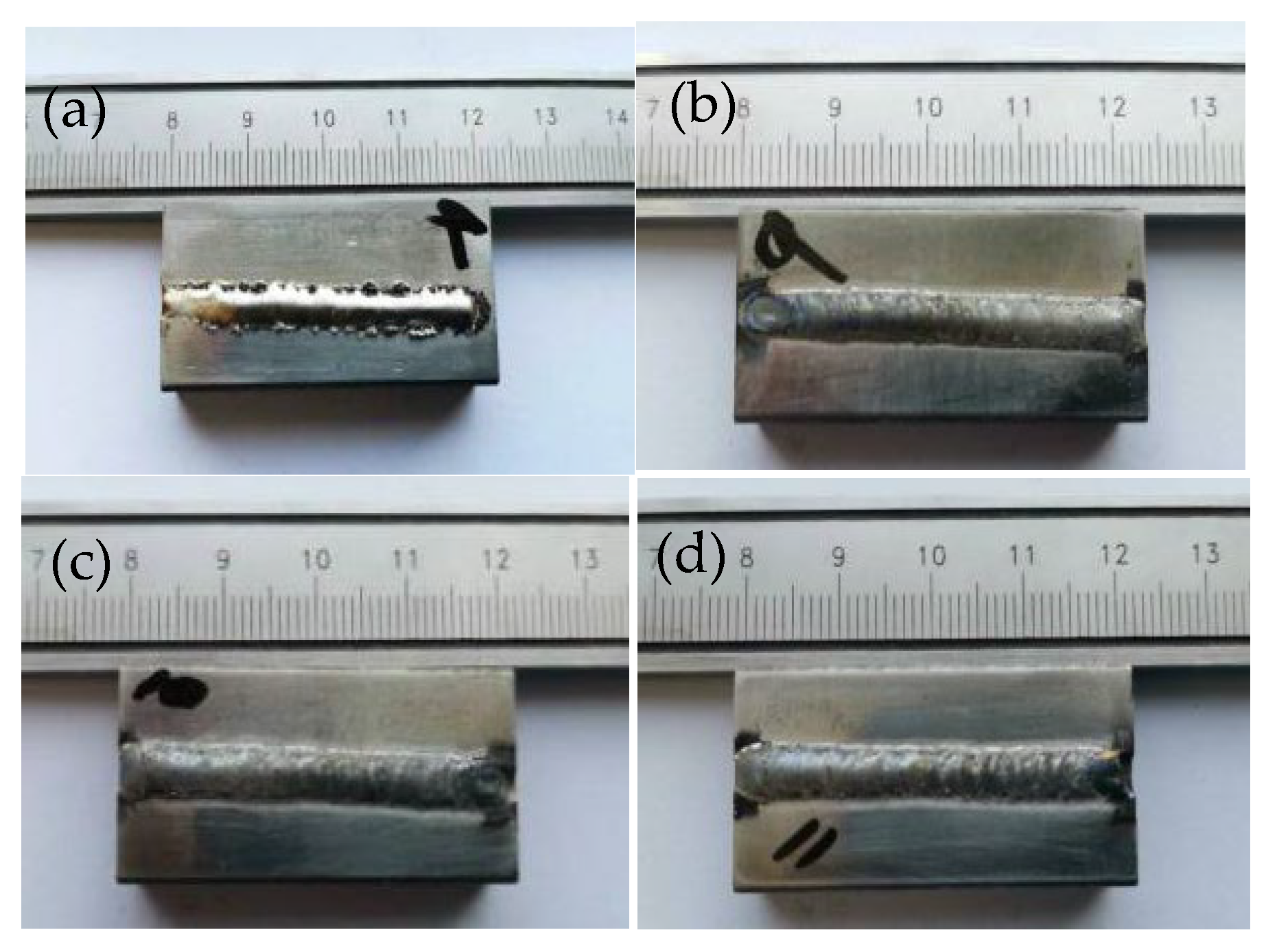

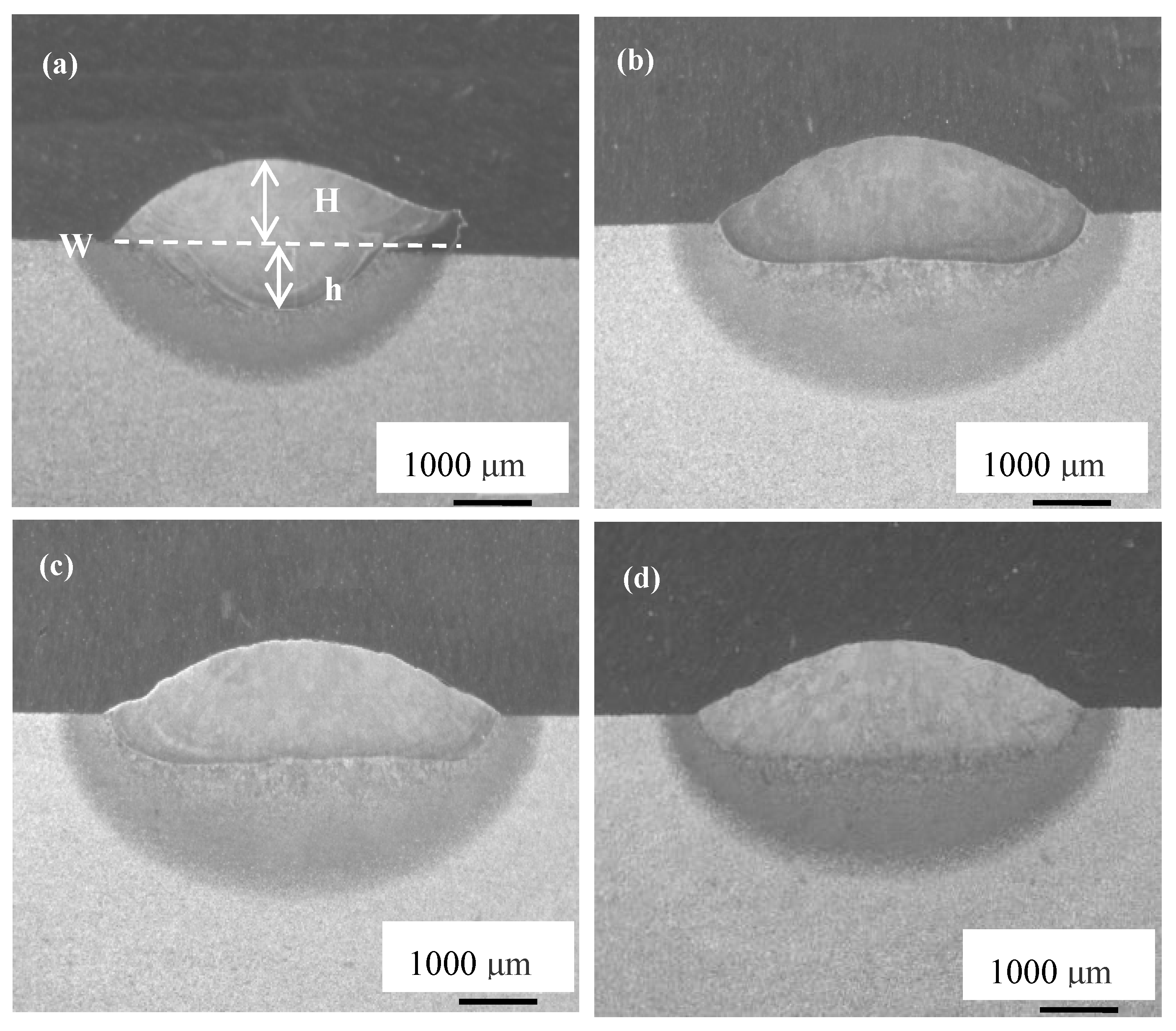

3.1. Macroscopic Morphologies of A100-Y2O3 Cladding Coatings

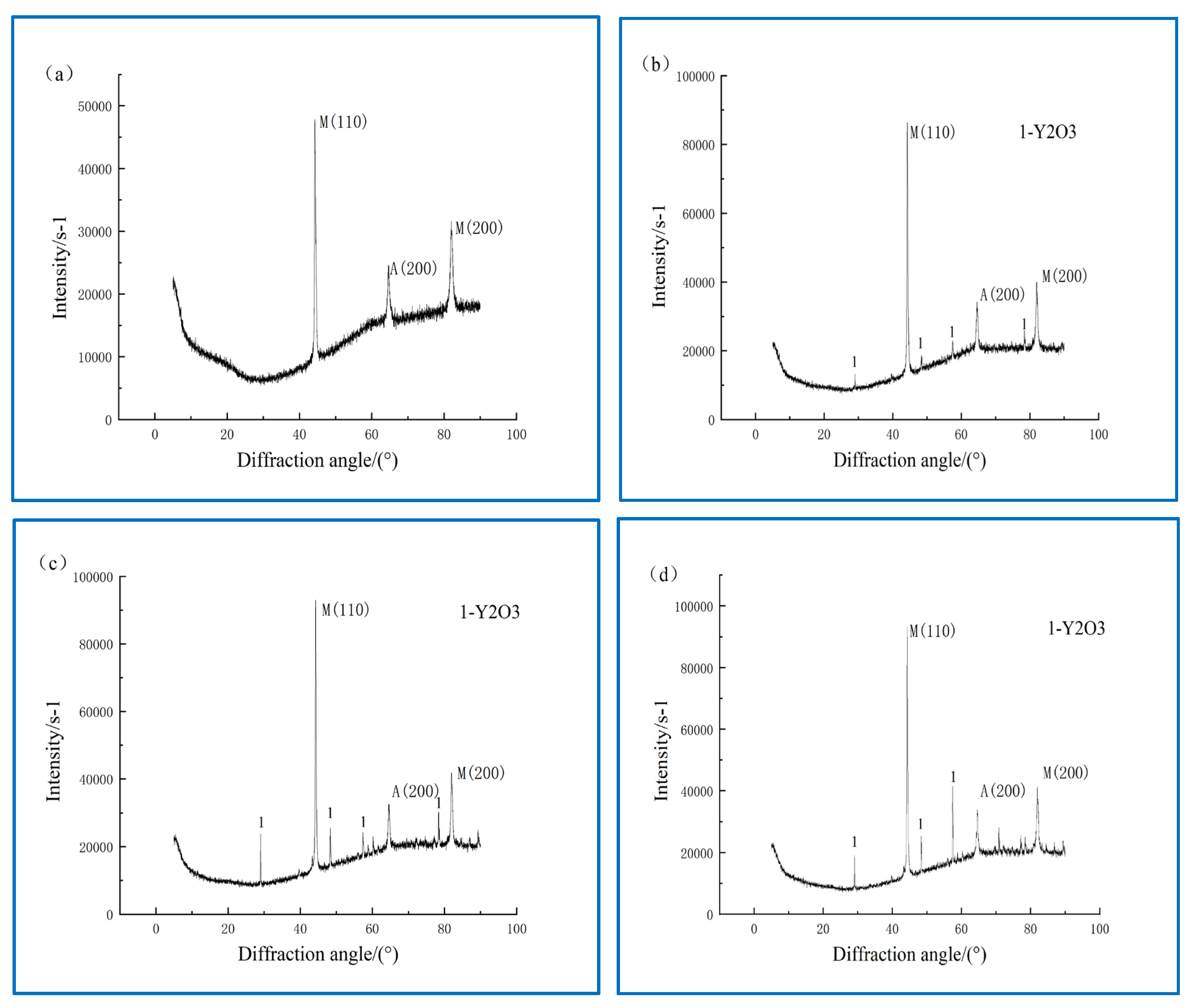

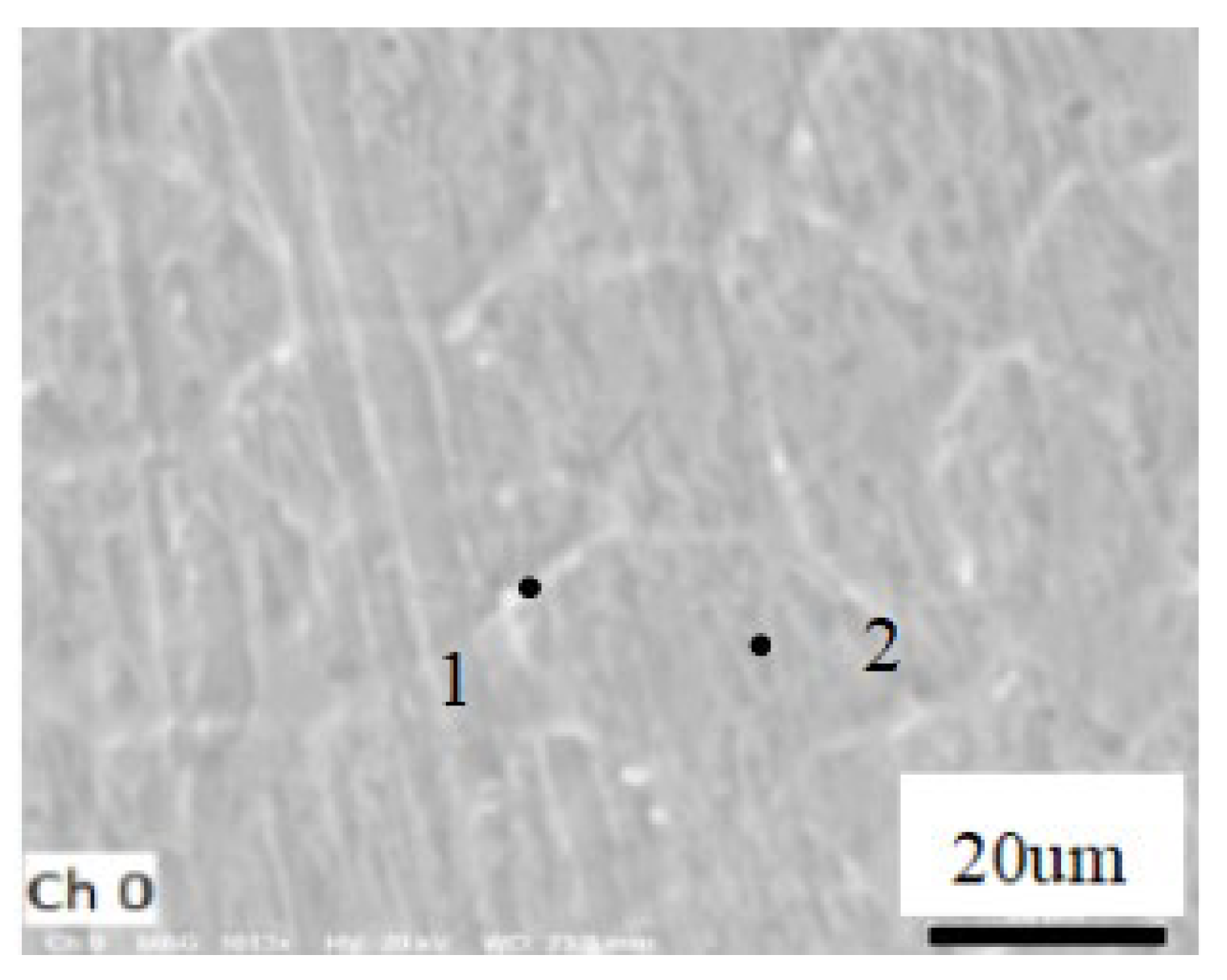

3.2. Phase Composition and Microstructure of A100-Y2O3 Cladding Coatings

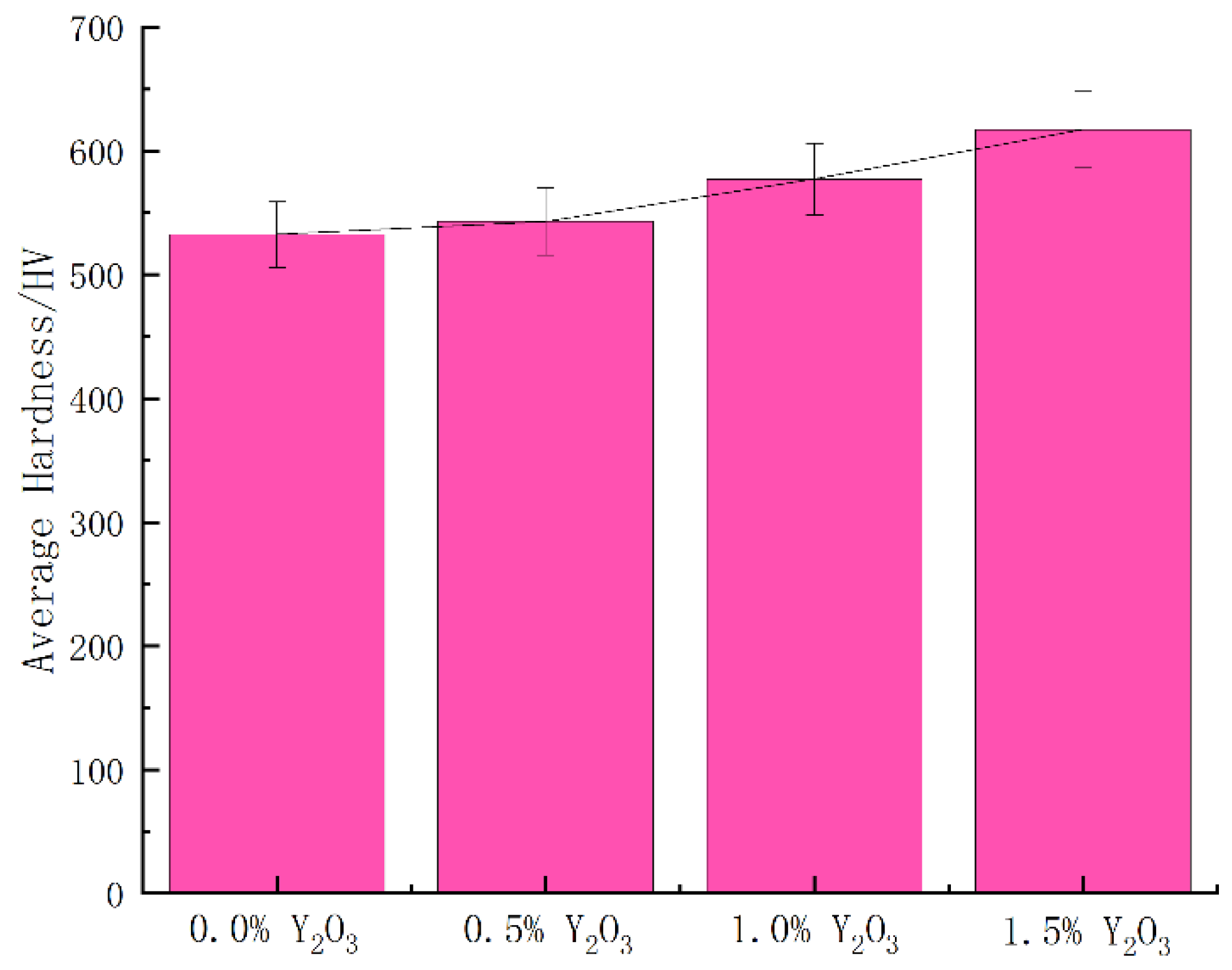

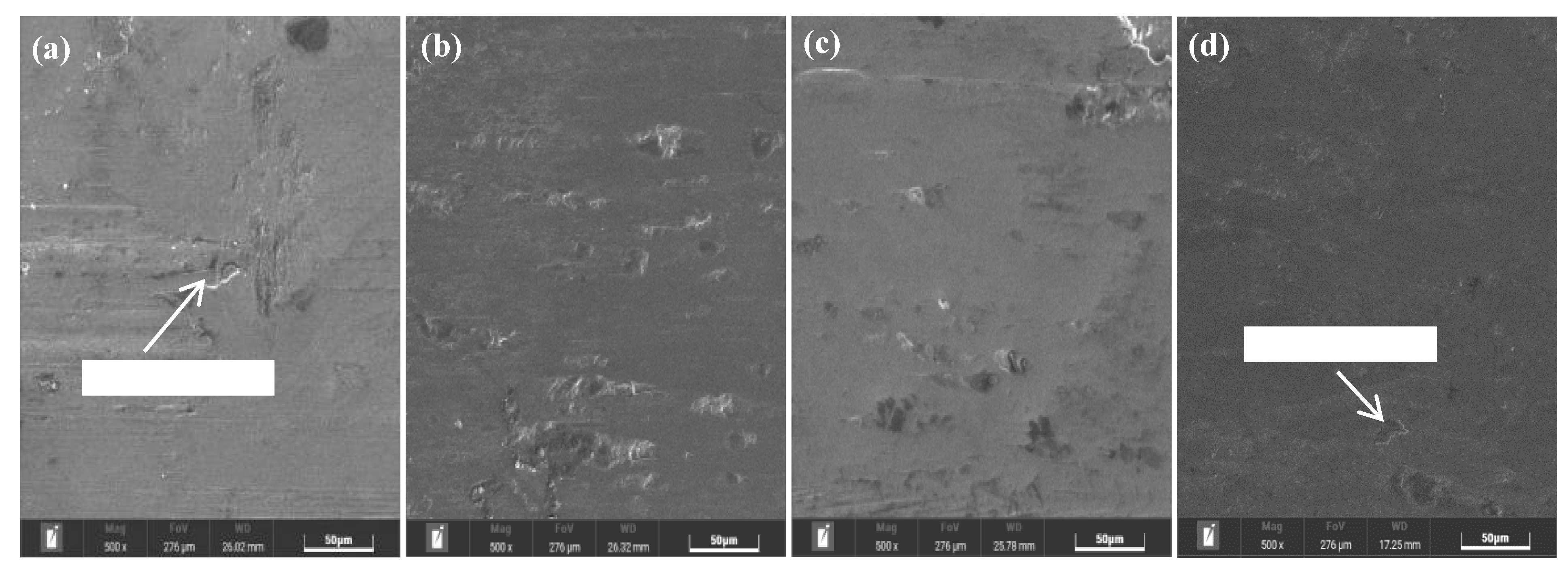

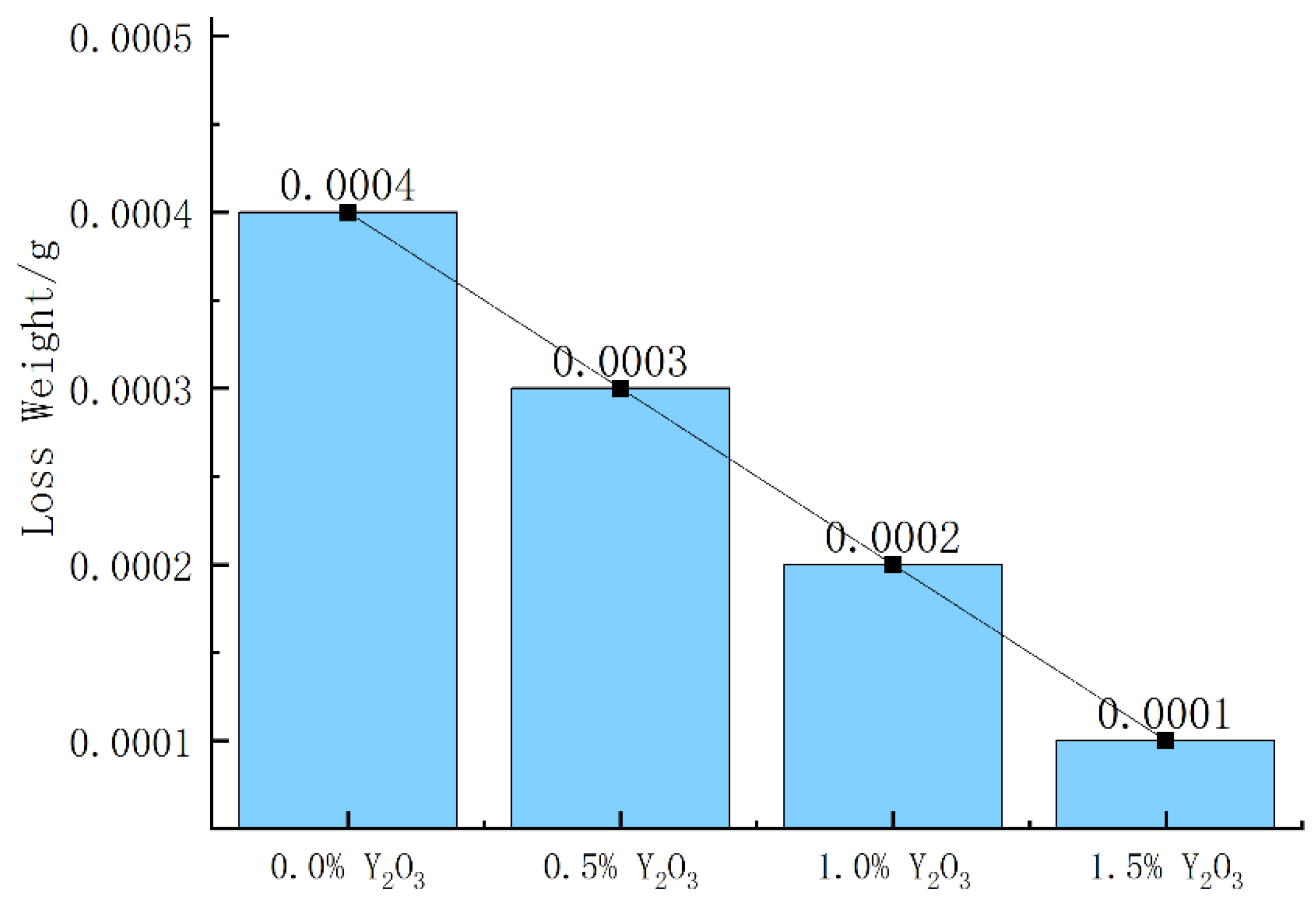

3.3. Microhardness and Wear Resistance of A100-Y2O3 Cladding Coatings

- Increased hardness of the coatings: Y2O3 addition improves the hardness of the A100-Y2O3 cladding coatings, making them more resistant to softening under friction and heat.

- Nailing effect at grain boundaries: Y2O3 concentrates at grain boundaries, inhibiting grain deformation and migration during friction, which helps maintain coating integrity.

- Strengthening effect: Y2O3 acts as a strengthening agent in the coating, further enhancing its wear resistance.

4. Conclusions

- Phase Composition: The A100-Y2O3 cladding coatings contain martensite, austenite and Y2O3 as the main phases. The grain structure varies within the coating, with columnar and coarse equiaxed grains in the middle and fine equiaxed grains at the top. The addition of Y2O3 results in finer grain structures.

- Microhardness: The average microhardness of A100-0%Y2O3 cladding coating is 532.489 HV. As the Y2O3 content increases, the microhardness of the coating gradually rises. When the Y2O3 content reaches 1.5%, the average microhardness of A100-1.5%Y2O3 cladding coating reaches 617.290 HV.

- Wear Resistance: The worn surface of A100-0%Y2O3 cladding coatings exhibits adhesive wear characteristics, indicating significant wear. However, with the addition of Y2O3, the wear resistance of the coatings improves. In particular, A100-1.5%Y2O3 cladding coating displays wear resistance three times higher than A100-0%Y2O3 cladding coating.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, T.; Xiao, M.; Zhang, Y.; Shen, Y. Effects of graphite and graphene spatial structure on the TiC crystal structure and the properties of composite coatings. Surf. Coat. Technol. 2019, 377, 124909. [Google Scholar] [CrossRef]

- Brnic, J.; Balos, S.; Brcic, M.; Dramicanin, M.; Krscanski, S.; Milutinovic, M.; Ding, B.; Gao, Z. Testing and Analysis of Uniaxial Mechanical Fatigue, Charpy Impact Fracture Energy and Microhardness of Two Low-Carbon Steels. Materials 2023, 16, 884. [Google Scholar] [CrossRef] [PubMed]

- Han, T.; Zhou, K.; Chen, Z.; Gao, Y. Research Progress on Laser Cladding Alloying and Composite Processing of Steel Materials. Metals 2022, 12, 2055. [Google Scholar] [CrossRef]

- Okulov, A.; Korobov, Y.; Stepchenkov, A.; Makarov, A.; Iusupova, O.; Korkh, Y.; Kuznetsova, T.; Kharanzhevskiy, E.; Liu, K. Mechanical and Structural Characterization of Laser-Cladded Medium-Entropy FeNiCr-B4C Coatings. Materials 2023, 16, 5479. [Google Scholar] [CrossRef] [PubMed]

- Luo, P.; Li, X.; Zhang, W.; Liang, X.; Tan, Z.; Wang, D.; Jiang, C.; Hou, J.; Sun, L. The Study of Phase Transformation Behaviors for 38MnB5Nb Ultra High-Strength Steel by CCT Curves and TTT Curves. Metals 2023, 13, 190. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, L.; Lu, S.; Lin, Z.; Wen, T.; Chen, Z. Progress and Perspective of Ultra-High-Strength Martensitic Steels for Automobile. Metals 2022, 12, 2184. [Google Scholar] [CrossRef]

- Aditya, Y.N.; Srichandra, T.D.; Tak, M.; Padmanabham, G. To study the laser cladding of ultra high strength AerMet-100 alloy powder on AISI-4340 steel for repair and refurbishment. Mater. Today Proc. 2021, 41, 1146–1155. [Google Scholar] [CrossRef]

- Zhang, B.; He, B.; Wang, H. Microstructural investigation and mechanical performance of laser cladding repaired bainite steel with AerMet100 steel. Surf. Coat. Technol. 2022, 440, 128498. [Google Scholar] [CrossRef]

- Barr, C.; Da Sun, S.; Easton, M.; Orchowski, N.; Matthews, N.; Brandt, M. Influence of macrosegregation on solidification cracking in laser clad ultra-high strength steels. Surf. Coat. Technol. 2018, 340, 126–136. [Google Scholar] [CrossRef]

- Walker, K.; Lourenço, J.; Sun, S.; Brandt, M.; Wang, C. Quantitative fractography and modelling of fatigue crack propagation in high strength AerMet®100 steel repaired with a laser cladding process. Int. J. Fatigue 2017, 94, 288–301. [Google Scholar] [CrossRef]

- Rashid, R.R.; Barr, C.; Palanisamy, S.; Nazari, K.; Orchowski, N.; Matthews, N.; Dargusch, M. Effect of clad orientation on the mechanical properties of laser-clad repaired ultra-high strength 300 M steel. Surf. Coat. Technol. 2019, 380, 125090. [Google Scholar] [CrossRef]

- Rashid, R.R.; Nazari, K.; Barr, C.; Palanisamy, S.; Orchowski, N.; Matthews, N.; Dargusch, M. Effect of laser reheat post-treatment on the microstructural characteristics of laser-cladded ultra-high strength steel. Surf. Coatings Technol. 2019, 372, 93–102. [Google Scholar] [CrossRef]

- Ran, X.; Cheng, H.; Liu, D.; Zhang, S.; Tang, H.; Wang, H. Microstructure and Mechanical Properties of Plasma Arc Welding Joint for Laser Melting-Deposited AerMet100 Ultrahigh-Strength Steel. Mater. Sci. Forum 2014, 789, 424–430. [Google Scholar] [CrossRef]

- Zhang, D.; He, X.; Gao, Y.; Qin, B. Investigation of the Microstructure and Wear Properties of Laser Clad Al-Si Coatings Containing Different Y2O3 Contents. Coatings 2023, 13, 308. [Google Scholar] [CrossRef]

- Chen, T.; Wu, F.; Wang, H.; Liu, D. Laser Cladding In-Situ Ti(C,N) Particles Reinforced Ni-Based Composite Coatings Modified with CeO2 Nanoparticles. Metals 2018, 8, 601. [Google Scholar] [CrossRef]

- Wang, W.; Chen, Z.; Feng, S. Effect of CeO2 on Impact Toughness and Corrosion Resistance of WC Reinforced Al-Based Coating by Laser Cladding. Materials 2019, 12, 2901. [Google Scholar] [CrossRef]

- Chen, T.; Liu, D.; Wu, F.; Wang, H. Effect of CeO2 on Microstructure and Wear Resistance of TiC Bioinert Coatings on Ti6Al4V Alloy by Laser Cladding. Materials 2017, 11, 58. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Liu, D.; Yang, J.; Zhang, H.; Ma, A.; Zhang, X.; Ren, Z.; Zhang, R.; Dong, Y.; Ye, C. Improving plain and fretting fatigue resistance of A100 steel using ultrasonic nanocrystal surface modification. Int. J. Fatigue 2021, 148, 106204. [Google Scholar] [CrossRef]

- Jia, D.; Shi, W.; Zhang, H.; Wu, T.; Diao, Y.; Li, K.; Lu, C. Effects of Y2O3 Content on Wear Resistance and Corrosion Resistance of 316L/TiC Coating Fabricated by Laser Cladding. Coatings 2023, 13, 1348. [Google Scholar] [CrossRef]

- Liu, J.; Guan, Y.; Xia, X.; Peng, P.; Ding, Q.; Liu, X. Laser Cladding of Al0.5CoCrCuFeNiSi High Entropy Alloy Coating without and with Yttria Addition on H13 Steel. Crystals 2020, 10, 320. [Google Scholar] [CrossRef]

- Wan, X.; Tian, C.; Li, Y.; Zhou, J.; Qian, S.; Su, L.; Wang, L. Effect of Y2O3 Addition on Microstructure and Properties of Laser Cladded Al-Si Coatings on AZ91D Magnesium Alloy. Materials 2022, 16, 338. [Google Scholar] [CrossRef] [PubMed]

- Han, T.; Xiao, M.; Zhang, Y.; Shen, Y. Effect of Cr content on microstructure and properties of Ni-Ti-xCr coatings by laser cladding. Optik 2019, 179, 1042–1048. [Google Scholar] [CrossRef]

- Jiang, H.; Zhao, X.; Wang, D.; Zhu, Q.; Li, T.; Lei, Y. Effects of Y2O3 Addition on the Microstructure and Static Lead-Bismuth Eutectic Thermal Corrosion Behaviors of FeCrAlTiC-xY2O3 Laser Clade Coatings. Coatings 2022, 12, 1759. [Google Scholar] [CrossRef]

- Gao, Y.; Lu, P.; Bai, S.; Qin, B.; Zhang, D. Influence of Laser Power on Microstructure and Properties of Al-Si+Y2O3 Coating. Coatings 2023, 13, 1289. [Google Scholar] [CrossRef]

| Elements | Fe | Co | Ni | Cr | Mo |

|---|---|---|---|---|---|

| Content | 69.69 | 14.35 | 11.27 | 3.07 | 1.62 |

| Coatings | H (μm) | h (μm) | W (μm) | W/H |

|---|---|---|---|---|

| A100-0%Y2O3 | 1105 | 982 | 4762 | 4.31 |

| A100-0.5%Y2O3 | 1080 | 705 | 5167 | 4.78 |

| A100-1.0%Y2O3 | 983 | 757 | 5986 | 6.09 |

| A100-1.5%Y2O3 | 997 | 745 | 5914 | 5.93 |

| Point | Fe | Co | Ni | Cr | Mo | Y |

|---|---|---|---|---|---|---|

| 1 | 68.23 | 12.89 | 11.04 | 4.48 | 2.18 | 1.18 |

| 2 | 73.48 | 12.73 | 10.15 | 3.03 | 0.35 | 0.26 |

| Samples | Max Value | Min Value | Average | Variance |

|---|---|---|---|---|

| A100-0%Y2O3 | 552.266 | 494.131 | 532.489 | 26.396 |

| A100-0.5%Y2O3 | 589.803 | 507.176 | 542.204 | 33.166 |

| A100-1.0%Y2O3 | 630.387 | 525.481 | 577.314 | 35.169 |

| A100-1.5%Y2O3 | 650.180 | 570.446 | 617.290 | 26.213 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, K.; Han, T.; Zhu, X.; Chen, Z.; Zhou, C.; Cao, H.; Shen, Y. Study on Microstructure and Mechanical Properties of A100-Y2O3 Coatings on Low-Carbon Steel by Laser Cladding. Coatings 2023, 13, 1702. https://doi.org/10.3390/coatings13101702

Zhou K, Han T, Zhu X, Chen Z, Zhou C, Cao H, Shen Y. Study on Microstructure and Mechanical Properties of A100-Y2O3 Coatings on Low-Carbon Steel by Laser Cladding. Coatings. 2023; 13(10):1702. https://doi.org/10.3390/coatings13101702

Chicago/Turabian StyleZhou, Kexin, Tengfei Han, Xinghui Zhu, Zhongyu Chen, Chao Zhou, Hanbo Cao, and Yifu Shen. 2023. "Study on Microstructure and Mechanical Properties of A100-Y2O3 Coatings on Low-Carbon Steel by Laser Cladding" Coatings 13, no. 10: 1702. https://doi.org/10.3390/coatings13101702

APA StyleZhou, K., Han, T., Zhu, X., Chen, Z., Zhou, C., Cao, H., & Shen, Y. (2023). Study on Microstructure and Mechanical Properties of A100-Y2O3 Coatings on Low-Carbon Steel by Laser Cladding. Coatings, 13(10), 1702. https://doi.org/10.3390/coatings13101702