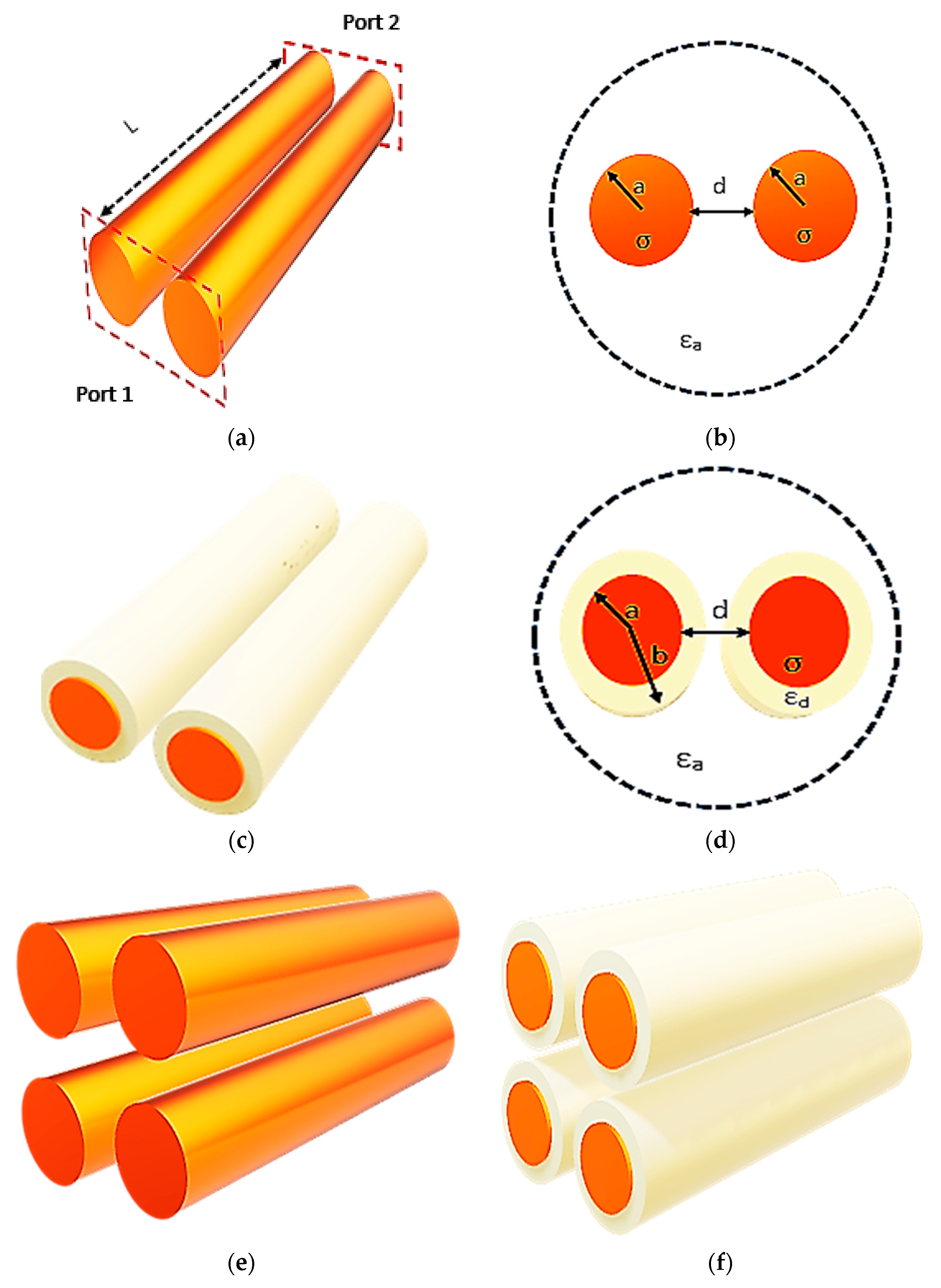

4.1. Two-Wire Waveguide Analysis

In the design and investigation of transmission lines, return loss and transmission coefficient are essential factors. They are used to determine a transmission line’s performance and assure us that there is no signal loss during transmission. In the initial study, a metallic copper two-wire waveguide for efficient propagation of THz waves was analyzed. Its return loss S(1, 1), as well as transmission coefficient S(2, 1) for three different gaps, 200 µm, 400 µm, and 600 µm, are given in

Figure 2.

The return loss for the 200 µm gap was an average of about − 30 dB, while for an increased

d of 400 µm and 600 µm, the averages obtained were about −25 dB and −23 dB. The same occurred in the case of the transmission coefficient: narrower gaps had better matching than larger values of

d; the best case was for the wires at 200 µm. This is because the tighter the coupling between the surface waves and the wires, the less power is being reflected to the source, and the more power is transported up the line. Moreover, the frequency and the conductivity of the wires also determine the optimum spacing between two parallel bare copper wires operating in the THz range. It was seen that the spacing between the wires had an impact on the return loss and transmission coefficient for two parallel bare copper wires operating in the THz band. A narrower spacing resulted in a reduced return loss and an improved transmission coefficient. The attenuation constant (α) was a measure of how much the power of a signal decreased as it traveled along a two-wire waveguide, and the attenuation constant for two bare wires for various values of

d is shown in

Figure 3.

The attenuation constant for 200 µm was about 25 dB/m, while for 400 µm and 600 µm, it was much more of an average, 36 dB/m and 44 dB/m. The signal’s frequency influences the attenuation constant. The attenuation constant of two wires increases with the increase in frequency. This is due to decreased skin depth at higher frequencies, such as the THz range. The electric field between the wires is greater with a smaller gap between them, which improves the efficiency of surface wave propagation. Thus, the signal transmits with less power along the two-wire waveguide as a result. Additionally, the repetitive pattern can be seen in s-parameters and the attenuation constant plot, which is due to the resonance behavior in the proposed wire waveguide, which is not uncommon in waveguide designs. Resonance is a common phenomenon in waveguides, and it may lead to small fluctuations (increases or decreases) in alpha; this shows the complex interaction of two-wire geometry with THz waves.

4.2. Two-Coated-Wire Waveguide Analysis

Despite the bare metal wire waveguide’s low loss and low dispersion advantages, there are some practical implications, such as weakly guided SPP [

5,

13]. The above-discussed two bare wires were dielectrically coated, and their effect on the s-parameters and the attenuation constant was analyzed. The changes in these parameters due to coating, seen in the percentages for various gap sizes, are shown in

Table 2. Rather than showing all the s-parameters and attenuation for two coated wires, only the amount of percentage change is shown for simplification in analysis.

It can be noted that coating has a significant effect on the THz propagation through two wires. The return loss is reduced by about −39% and the transmission coefficient is increased by about 84% for the very small

d of 200 µm, a near about double increment. However, it can also be noticed that as the

d is increased between the two coated wires, the amount of matching and improvement in the s-parameters increases; S(2, 1) increment of 53% for 400 µm, 16% for 600 µm while there is a S(1, 1) decrement of −12% for 400 µm, and −8% for 600 µm, respectively. Thus, the transmission coefficient and the return loss are improved after coating. This is due to the fact that reflection at the wire waveguide interface is reduced, as the dielectric layer acts as a transition layer between the metal and the surrounding medium. Also, radiation losses are reduced due to the dielectric coating leading to the improvement of s-parameters. Coating the bare wire also influences the propagation characteristics, such as the attenuation constant of the waveguide and the effect of dielectric coating on the attenuation, which can also be seen in

Table 2. For the smaller value of

d of 200 µm, the reduction in the attenuation is about −84.40% after applying the dielectric coating to the two bare copper wires. However, with the increase in the

d between the wires, this downfall rate in the attenuation decreases by −52% and −15% for 400 µm and 600 µm, respectively. Thus, it can be considered that there is a major reduction in the attenuation constant after the application of the dielectric coating, leading to a longer propagation length, as experimentally demonstrated and proved in [

28,

29].

Two coated and uncoated wires were analyzed for the 3D visualization analysis, and the effect of coating on the THz wire waveguide is shown in

Figure 4. The maximum electric field intensity of the dielectric coated wires is more than the bare wire; therefore, an average electric field of 6 × 10

4 was taken for better visualization and analysis.

The electric field strength in the bare wire is spread on one side and between the wires. However, the addition of the dielectric layer between the metallic wires improves the confinement of electric fields inside the waveguide as verified in [

17,

30]. This improves the coupling between the wires and the effectiveness of energy transfer. Due to the greater energy confinement within the waveguide and the increased electric field, there is a low power loss and better transmission efficiency overall. Power leakage from the waveguide is decreased because of the dielectric coating. The observed increase in the electric field intensity is due to the electric field confinement inside the waveguide, as well as less energy leaking out. That indicates low radiation losses and other losses, which improve signal transmission.

The performance characteristics of the wire waveguide mainly depend on the operating frequency, surface structure, and gap between the wires; therefore, the variation in electric field at different frequencies and gaps is shown in

Table 3, with the difference in percentage value after coating the bare wires.

The surface current intensity plot of the two bare and coated wires is shown in

Figure 5. This analysis is an important parameter to be analyzed, as it facilitates the researchers identifying the areas with maximum current in a waveguide and identifying any leakage. The maximum surface currents of bare and coated wire waveguides are different due to their geometry; however, the average maximum of both designs selected is 180 A/m for uniform scaling and better visualization of surface current flow and the most intensive areas.

It can be noted in both cases that the maximum current is in between the wires, where the electric field is strongest. After coating the bare wires, the surface current intensity in the dielectric gap between the two wires was increased, as can be seen in

Figure 5b. This is due to the fact that dielectric coating increases the effective dielectric constant of the waveguide, which causes the surface current to flow more efficiently, which in turn leads to the high surface current in the waveguide. Also, radiation losses are mitigated due to dielectric coating, leading to better propagation of waves. The electric and magnetic fields in the region between the wires are strongly confined and concentrated, which is clear evidence of a guided mode propagating along the wires. The variation in surface current at different frequencies and

d is shown in

Table 4.

As can be noticed in

Table 4, as the frequency of operation increases, the percentage increment in surface current increases. As the operating frequency is increased, the skin depth is decreased, making the surface more concentrated.

By looking at the analysis of two-wire waveguides for efficient propagation of THz waves, it can be concluded that two bare wires can propagate THz waves efficiently, and when applying the dielectric coating, their performance is significantly improved. Scattering parameters and attenuation constants are much improved after coating. Electric field and surface currents in the two-wire waveguides with and without coating indicate that there is a significant rise in these parameters due to coating, due to the concentration of waves in the region between the wires. Additionally, the d between the two wires and the operating frequency affects the propagation characteristics of THz waves through the two wires.

4.3. Four-Wire Waveguide Analysis

Two-wire waveguides with and without the coating were studied to analyze their feasibility for utilization in next-generation THz transmission systems. Practical and commercially available cables and copper binders consists of more than two wires. Therefore, in this section, the analysis is extended for the four parallel wires with and without coating. For the THz wave transmission through four parallel bare wires, the simulated s-parameters are shown in

Figure 6.

The best average return loss achieved was about −34.1 dB with a transmission coefficient of −1.2 dB for

d = 200 µm. It can be noticed that, compared to the two bare parallel wires, four-wire waveguides have better transmission coefficients and return loss for all values of

d. This is due to the fact that the coupling efficiency of four wires is better than that of the wire waveguide. The main benefit of a four-wire waveguide is that it may support additional propagation modes, which can result in better performance in terms of signal transmission and reflection characteristics, as well as supporting higher-order modes along with the fundamental mode. Similarly, in the case of attenuation constant, four bare wire waveguides have a lower attenuation constant as compared to the two-wire waveguide of the same size and

d, as can be seen in

Figure 7. The additional wires in the four-wire waveguide as compared to two wires enable more effective confinement of the electric and magnetic fields, resulting in a reduction in energy losses using radiation and leakage. Better transmission efficiency and less attenuation are benefits of this improved confinement. Similarly, as in the case of two wires, four-wire s-parameters and attenuation also experienced periodic picks due to the resonance effect.

4.4. Coated Four-Wire Waveguide Analysis

Usually, in the infrastructure, already installed wires are coated for several advantages, such as radiation leakage prevention, environmental protection, etc. For the realization of TDSL and the utilization of coated wires for their efficient propagation, its analysis is important.

The four bare wires discussed above were dielectrically coated, and their effects on the s-parameters and the attenuation constant were analyzed. The percentage change in these parameters at various values of

d due to coating is shown as percentages in

Table 5.

As the d between the wires increased, the effect or the change in the percentage of s-parameters and attenuation constant decreased. As for d = 200 µm, the percentage change was 76% for attenuation as well as transmission coefficient, but for the gap of 600 µm, the percentage change was reduced to only 10%. The return loss was also decreased after coating, −30% in the case of d = 200 µm, and the percentage change was reduced with an increment in d. It can again be validated after two-wire coating analyses that in the four-wire analysis, after coating the bare wires, there was a significant improvement in the s-parameters and the attenuation constant of the THz wire waveguide.

Electric field and surface current at the THz frequency range were investigated in a four-wire waveguide with and without coating.

Figure 8 shows a 3D representation of the four-wire waveguide’s bare and dielectrically coated electric field distribution pattern.

For better visualization and analysis, the average electric field was set at 3 × 104 V/m. It can be seen in the 3D analysis of the electric field distribution that for the gap of 200 µm, dielectrically coating the bare wire increased the electric field intensity, thus improving the field confinement. The maximum electric field intensity can be seen in the red area, and the concentration is in the inner portion between the wires, showing that the THz waves are propagating through the surface and dielectric gap between the wires.

The performance of the waveguide is mainly affected by the operating frequency, as in the THz range, waves are too short that it approaches to the size of gap between wires and dielectric coating thickness. So, it is important to analyze the four-wire waveguide at the lowest, center, and highest frequencies of the proposed band for better analysis. For various d and center frequencies, changes were observed in the electric field of the four-wire waveguides with and without dielectric coating. Therefore, for simplification, only the percentage differences in the electric field for different gaps and three different frequencies are summarized in

Table 6.

The above percentage difference table clearly shows the rise and fall in the electric field due to

d and frequency. For the gap sizes of 200 µm and 400 µm, there was an increase in electric field. This is because the effective dielectric constant of the waveguide was increased as a result of the dielectric coating. Since surface waves propagate more effectively due to the higher dielectric constant, the electric field between the wires obtained was stronger as a result. Also, the dielectric layer reduced the radiation losses, thus confining the electric field to the waveguide. Moreover, when the

d between the wires was increased further to 600 µm, there was a downfall of the electric field, as the

d is large and the electric field force is weak.

Figure 9 shows the surface current for the center frequency of 270 GHz and a

d of 200 µm.

The same phenomenon as in the case of two wires with and without coating occurred in four wires with and without coating; the maximum surface current was in the gap between the wires, as can be seen in both cases of four wires (

Figure 9a,b). However, the concentration value is greater in the case of dielectric coating. This parameter is also affected by the frequency propagating; therefore, only the percentage differences in the surface current for different

d and three different frequencies, i.e., 220, 270, and 320 GHz, are summarized in

Table 7.