Microstructure and Mechanical Properties of Magnetron Sputtering TiN-Ni Nanocrystalline Composite Films

Abstract

:1. Introduction

2. Experimental

2.1. Film Preparation

2.2. Film Characterization

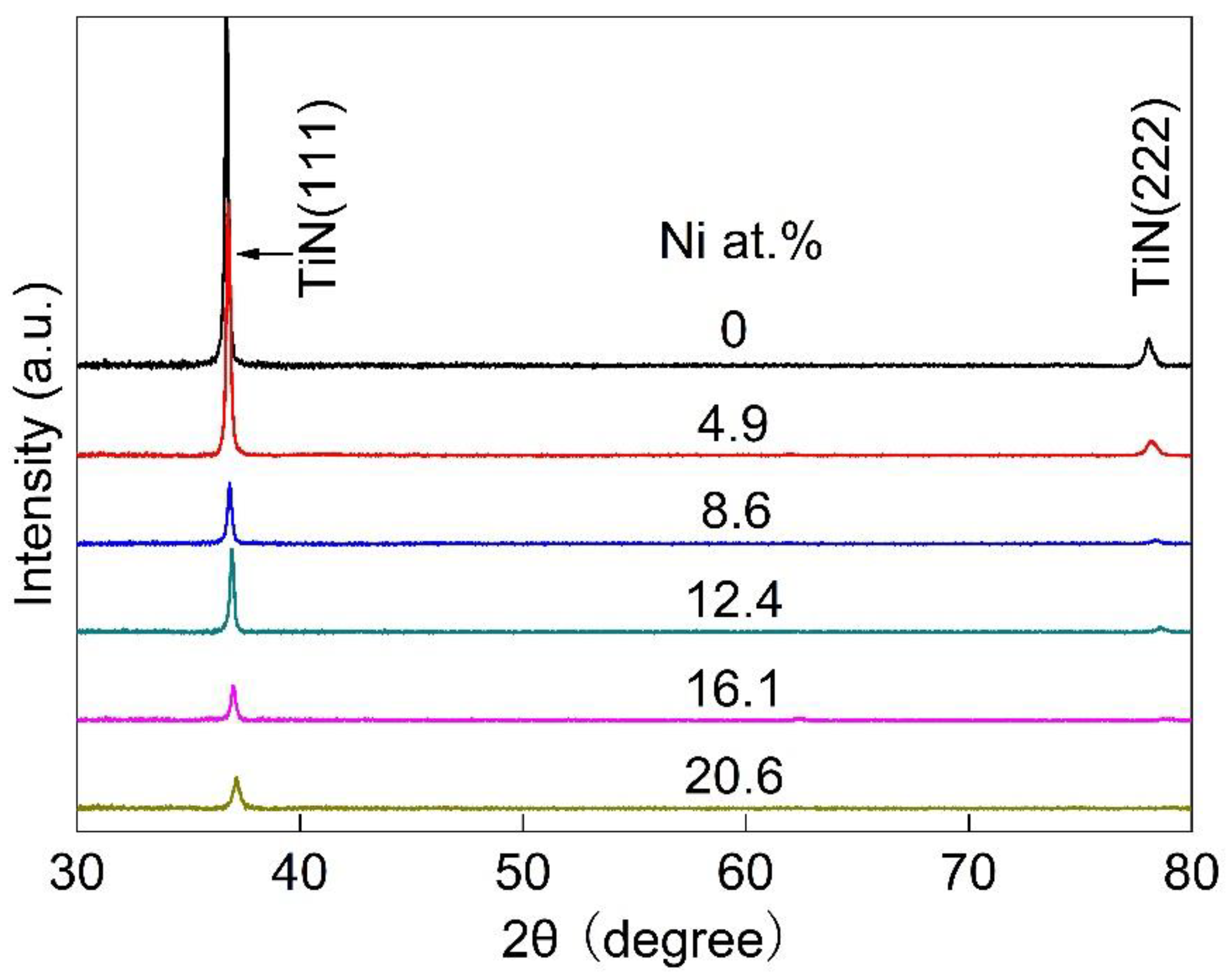

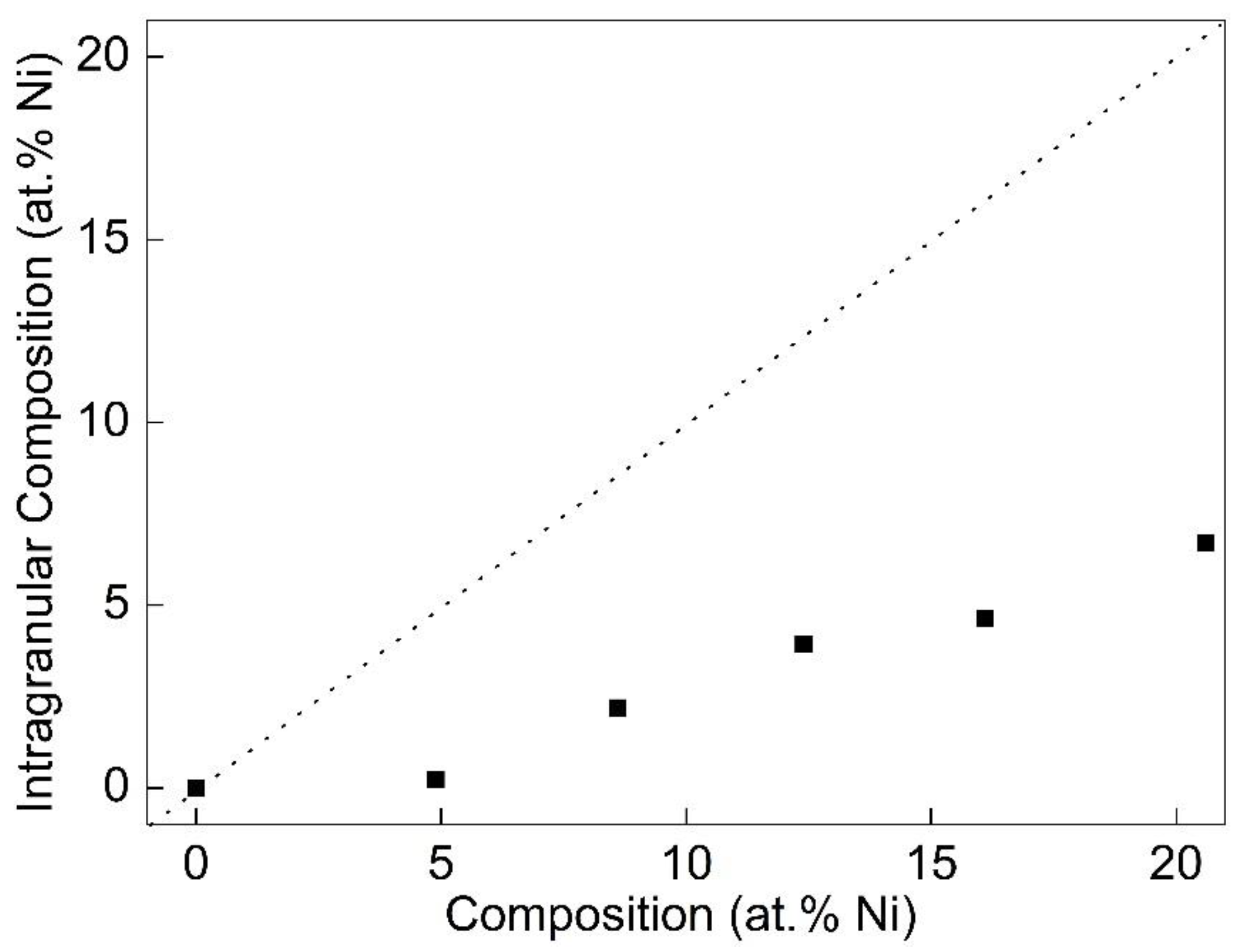

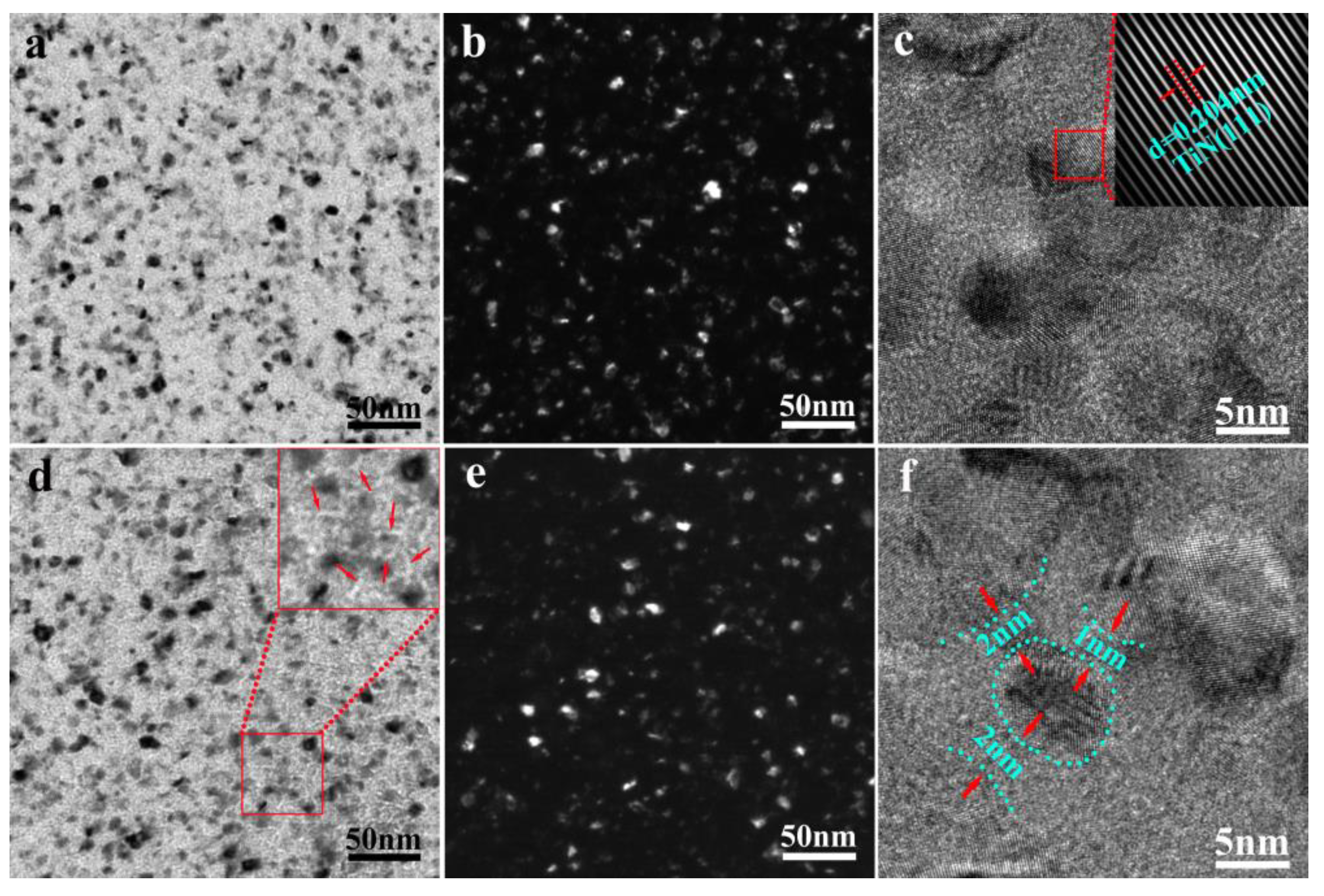

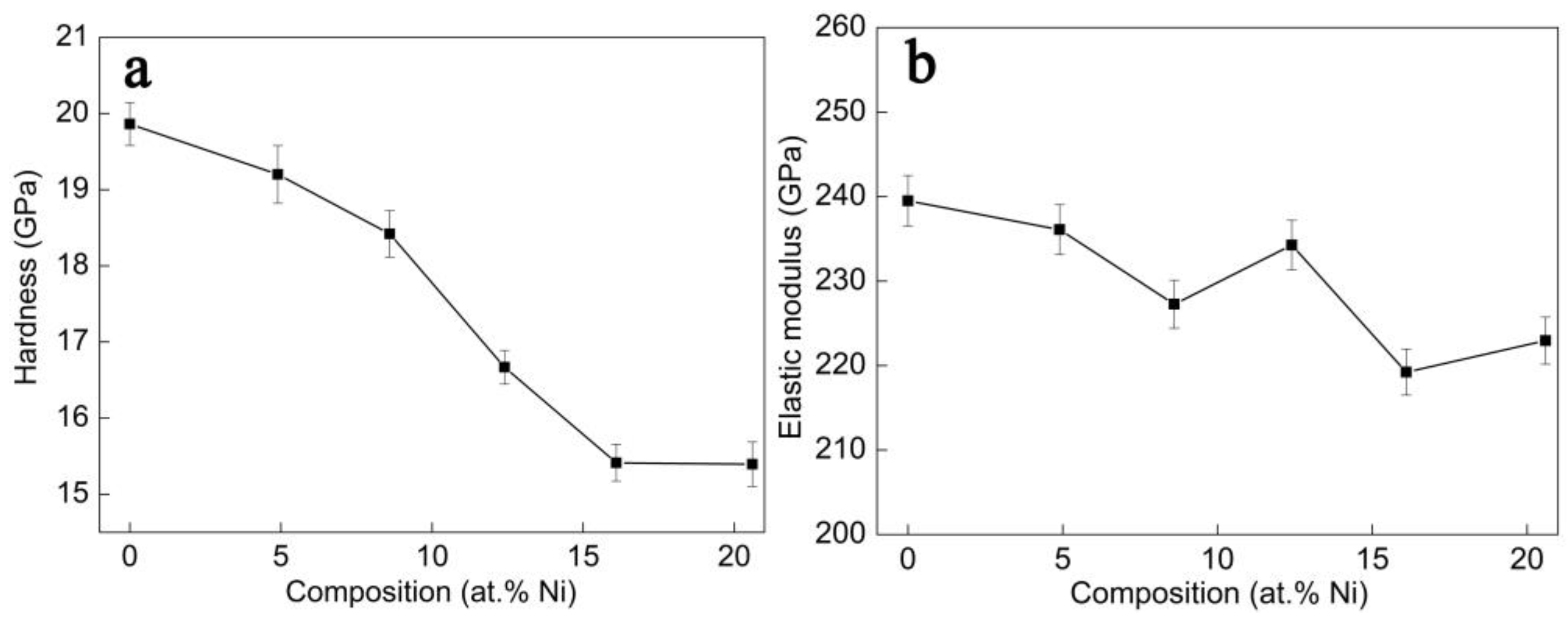

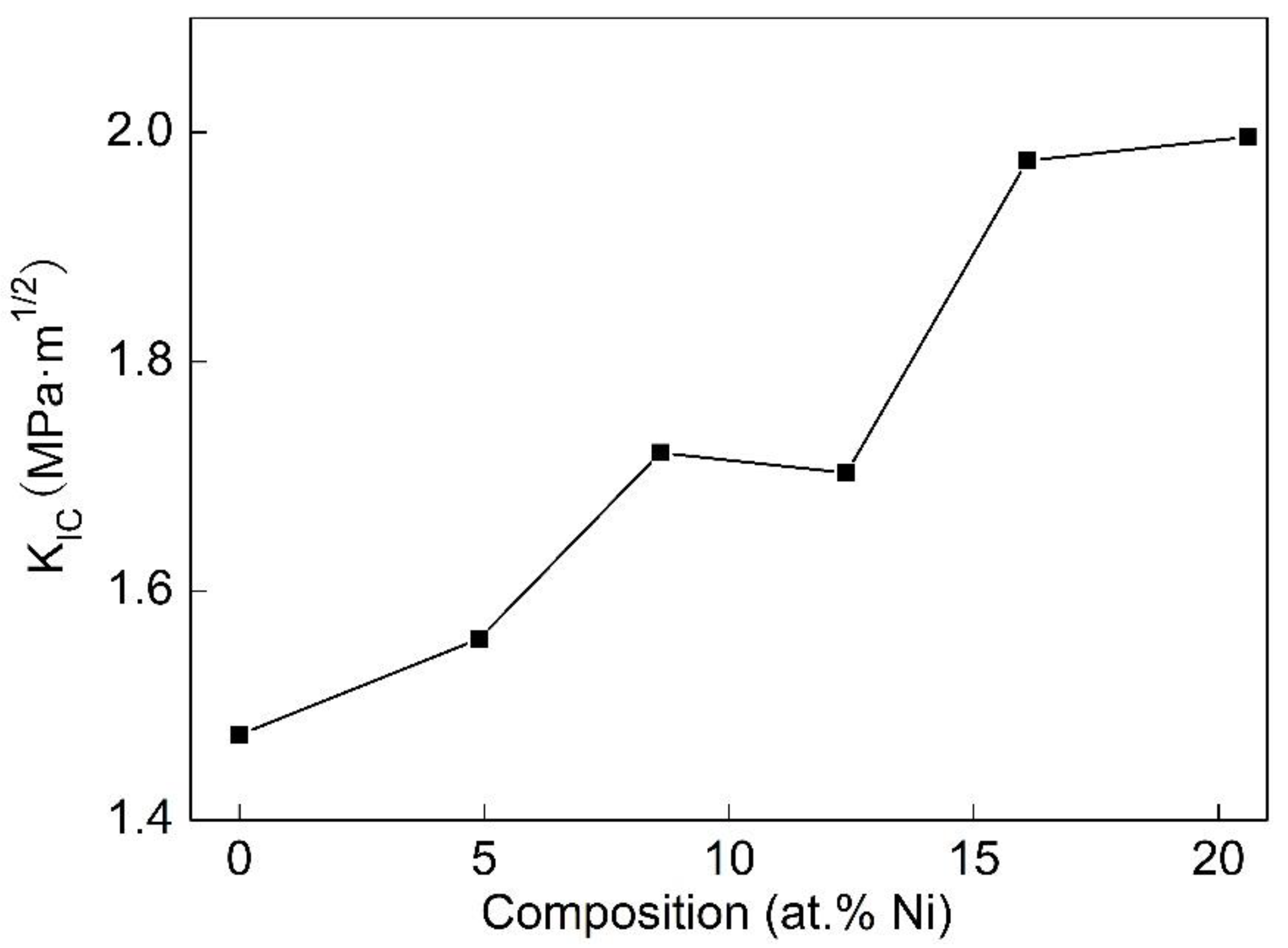

3. Results

4. Discussion

4.1. Microstructure

4.2. Mechanical Behavior

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bondarev, A.; Al-Rjoub, A.; Yaqub, T.B.; Polcar, T.; Fernandes, F. TEM study of the oxidation resistance and diffusion processes in a multilayered TiSiN/TiN(Ag) coating designed for tribological applications. Appl. Surf. Sci. 2023, 609, 155319. [Google Scholar] [CrossRef]

- Tian, C.X.; Wang, Z.S.; Zou, C.W.; Tang, X.S.; Xie, X.; Li, S.Q.; Liang, F.; Li, Z.J.; Liu, Y.F.; Su, F.H. Ternary and quarternary TiBN and TiBCN nanocomposite coatings deposited by arc ion plating. Surf. Coat. Technol. 2019, 359, 445–450. [Google Scholar] [CrossRef]

- Wan, Q.; Wu, Z.Y.; Liu, Y.; Yang, B.; Liu, H.D.; Ren, F.; Wang, P.; Xiao, Y.Y.; Zhang, J.; Zhang, G.D. Lead-bismuth eutectic (LBE) corrosion mechanism of nano-amorphous composite TiSiN coatings synthesized by cathodic arc ion plating. Corros. Sci. 2021, 183, 109264. [Google Scholar] [CrossRef]

- Wan, Q.; Yang, B.; Chen, Y.M.; Liu, H.D.; Ren, F. Grain size dependence of the radiation tolerances of nano-amorphous Ti-Si-N composite coatings. Appl. Surf. Sci. 2019, 466, 179–184. [Google Scholar] [CrossRef]

- Zhou, S.; Zhao, W.; Qiu, Z.; Lin, S.; Zheng, Z.; Zeng, D.C. Improvedload-bearing capacity of Mo-doped Ti-N coatings: Effects of Mo alloying and GB plasticity. Surf. Coat. Technol. 2021, 424, 127630. [Google Scholar] [CrossRef]

- Das, C.R.; Rangwala, M.; Ghosh, A. Influence of substrate bias voltage on microstructure and mechanical characteristics of TiAlSiN coating deposited by High Power Impulse Magnetron Sputtering (HiPIMS). Surf. Coat. Technol. 2023, 458, 129351. [Google Scholar] [CrossRef]

- Ma, S.L.; Ma, D.Y.; Guo, Y.; Xu, B.; Wu, G.Z.; Xu, K.W.; Chu, P.K. Synthesis and characterization of superhard, self-lubricating Ti–Si–C–N nanocomposite coatings. Acta Mater. 2007, 55, 6350–6355. [Google Scholar] [CrossRef]

- Musil, J.; Zeman, P.; Hrubý, H.; Mayrhofer, P.H. ZrN/Cu nanocomposite film—A novel superhard material. Surf. Coat. Technol. 1999, 120–121, 179–183. [Google Scholar] [CrossRef]

- Kmar, M.; Mishra, S.; Mitra, R. Effect of Ar:N2 ratio on structure and properties of Ni-TiN nanocomposite thin films processed by reactive RF/DC magnetron sputtering. Surf. Coat. Technol. 2013, 228, 100–114. [Google Scholar] [CrossRef]

- Akhter, R.; Bendavid, A.; Munroe, P. Effect of Ni content on the microstructure and mechanical properties of TiNiN coatings. Appl. Surf. Sci. 2022, 573, 151536. [Google Scholar] [CrossRef]

- Akhter, R.; Bendavid, A.; Munroe, P. Tailoring the scratch adhesion strength and wear performance of TiNiN nanocompositecoatings by optimizing substrate bias voltage during cathodic arc evaporation. Surf. Coat. Technol. 2022, 445, 128707. [Google Scholar] [CrossRef]

- Sahu, B.P.; Ray, M.; Mitra, R. Structure and properties ofNi1-xTixN thin films processed by reactive magnetronco-sputtering. Mater. Charact. 2020, 169, 110604. [Google Scholar] [CrossRef]

- Kumar, M.; Mitra, R. Effect of substrate bias on microstructure and properties of Ni-TiN nanocomposite thin films deposited by reactive magnetron co-sputtering. Surf. Coat. Technol. 2014, 251, 239–246. [Google Scholar] [CrossRef]

- Akhter, R.; Bendavid, A.; Munroe, P. The influence of substrate bias on the surface morphology, microstructure and mechanical behavior of TiNiN coatings. Appl. Surf. Sci. 2022, 590, 153107. [Google Scholar] [CrossRef]

- Irie, M.; Ohara, H.; Tsujioka, M.; Nomura, T. The production and properties ofTiN-Ni nanostructure films by filtered vacuum arc deposition. Mater. Chem. Phys. 1998, 54, 317–320. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique or determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 2011, 7, 1564–1583. [Google Scholar] [CrossRef]

- Denton, A.R.; Ashcroft, N.W. Vegard’s law. Phys. Rev. A 1991, 43, 3161–3164. [Google Scholar] [CrossRef]

- Ju, H.; Yu, D.; Yu, L.; Ding, N.; Xu, J.; Zhang, X.; Zheng, Y.; Yang, L.; He, X. The influence of Ag contents on the microstructure, mechanical and tribological properties of ZrN-Ag films. Vacuum 2018, 148, 54–61. [Google Scholar] [CrossRef]

- Ren, P.; Zhang, K.; He, X.; Du, S.; Yang, X.; An, T.; Wen, M.; Zheng, W. Toughness enhancement and tribochemistry of the Nb-Ag-N films actuated by solute Ag. Acta Mater. 2017, 137, 1–11. [Google Scholar] [CrossRef]

- Milman, Y.V.; Galanov, B.A.; Chugunova, S.I. Plasticity characteristic obtained through hardness measurement. Acta Metall. Mater. 1993, 41, 2523–2532. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, X. Toughness evaluation of hard coatings and thin films. Thin Solid Film. 2012, 520, 2375–2389. [Google Scholar] [CrossRef]

- Ju, H.; Yu, L.; Yu, D.; Asempah, I.; Xu, J. Microstructure, mechanical and tribological properties of TiN-Ag films deposited by reactive magnetron sputtering. Vacuum 2017, 141, 82–88. [Google Scholar] [CrossRef]

- Domingues, R.P.; Rodrigues, M.S.; Lopes, C.; Pedrosa, P.; Alves, E.; Barradas, N.P.; Borges, J.; Vaz, F. Thin films composed of metal nanoparticles (Au, Ag, Cu) dispersed in AlN: The influence of composition and thermal annealing on the structure and plasmonic response. Thin Solid Film. 2019, 676, 12–25. [Google Scholar] [CrossRef]

- Figueiredo, N.M.; Vaz, F.; Cunha, L.; Rodil, S.E.; Cavaleiro, A. Structural, chemical, optical and mechanical properties of Au doped AlN sputtered coatings. Surf. Coat. Technol. 2014, 255, 130–139. [Google Scholar] [CrossRef]

- Wang, H.; Wang, B.; Li, S.; Xue, Q.; Huang, F. Toughening magnetron sputtered TiB2 coatings by Ni addition. Surf. Coat. Technol. 2013, 232, 767–774. [Google Scholar] [CrossRef]

- Xiao, P.; Derby, B. Wetting of titanium nitride and titanium carbide by liquid metals. Acta Mater. 1996, 44, 307–314. [Google Scholar] [CrossRef]

- Taranets, N.Y.; Naidich, Y.V. Wettability of aluminum nitride by molten metals. Powder Metall. Met. Ceram. 1996, 35, 282–285. [Google Scholar]

- Wang, C.; Li, S.; Zhang, T.; Pan, Y. The effect of silicon on the wettability and interfacial reaction in AlN/Cu alloy systems. Mater. Sci. Eng. B 2011, 176, 53–59. [Google Scholar] [CrossRef]

- Xi, L.; Kaban, I.; Nowak, R.; Bruzda, G.; Sobczak, N.; Eckert, J. Wetting, reactivity, and phase formation at interfaces betweenNi–Al melts and TiB2 ultrahigh-temperature ceramic. J. Am. Ceram. Soc. 2018, 101, 911–918. [Google Scholar] [CrossRef]

- Binder, S.; Lengauer, W.; Ettmayer, P. The Ti-N-Ni system: Investigations relevant for cermet sintering. J. Alloys Compd. 1991, 177, 119–127. [Google Scholar] [CrossRef]

- Koyama, M.; Zhang, Z.; Wang, M.; Ponge, D.; Raabe, D.; Tsuzaki, K.; Noguchi, H.; Tasan, C.C. Bone-like crack resistance in hierarchical metastable nanolaminate steels. Science 2017, 355, 1055–1057. [Google Scholar] [CrossRef] [PubMed]

- Pineau, A.; Benzerga, A.A.; Pardoen, T. Failure of metals I: Brittle and ductile fracture. Acta Mater. 2016, 107, 424–483. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, B.; Yuan, H.; He, Z.; Shang, H.; Hou, Y.; Ju, H.; Fernandes, F. Microstructure and Mechanical Properties of Magnetron Sputtering TiN-Ni Nanocrystalline Composite Films. Coatings 2023, 13, 1902. https://doi.org/10.3390/coatings13111902

Ma B, Yuan H, He Z, Shang H, Hou Y, Ju H, Fernandes F. Microstructure and Mechanical Properties of Magnetron Sputtering TiN-Ni Nanocrystalline Composite Films. Coatings. 2023; 13(11):1902. https://doi.org/10.3390/coatings13111902

Chicago/Turabian StyleMa, Bingyang, Haitian Yuan, Zongqian He, Hailong Shang, Yanjie Hou, Hongbo Ju, and Filipe Fernandes. 2023. "Microstructure and Mechanical Properties of Magnetron Sputtering TiN-Ni Nanocrystalline Composite Films" Coatings 13, no. 11: 1902. https://doi.org/10.3390/coatings13111902

APA StyleMa, B., Yuan, H., He, Z., Shang, H., Hou, Y., Ju, H., & Fernandes, F. (2023). Microstructure and Mechanical Properties of Magnetron Sputtering TiN-Ni Nanocrystalline Composite Films. Coatings, 13(11), 1902. https://doi.org/10.3390/coatings13111902