An Experimental Study and Adaptability Evaluation of Chain Extender Component in Water Reducer on the Sulfate Corrosion Resistance of Ordinary Concrete

Abstract

:1. Introduction

2. Test

2.1. Raw Materials Overview

- (1)

- (2)

- (3)

- (4)

- The water reducer was produced by Shanxi Shanda Hesheng New Materials Co., Ltd. in Taiyuan City, Shanxi Province, China. It includes two formulations of polycarboxylic acid high-performance water reducers, distinguished as Water Reducer 3 (with chain extender) and Water Reducer 3#–1 (without chain extender). The specific formulations are detailed in Table 6.

- (5)

- Fly ash is a Class II fly ash, produced by the Taiyuan Second Power Plant, with a fineness of 11%, water demand ratio of 101%, and moisture content of 0.2%.

- (6)

- Slag was produced by the Shanxi Taiyuan Iron and Steel Group, with a specific surface area of 450 m2/kg, a flowability ratio of 103%, and an ignition loss of 2.3%.

- (7)

- The water was drinking water.

- (8)

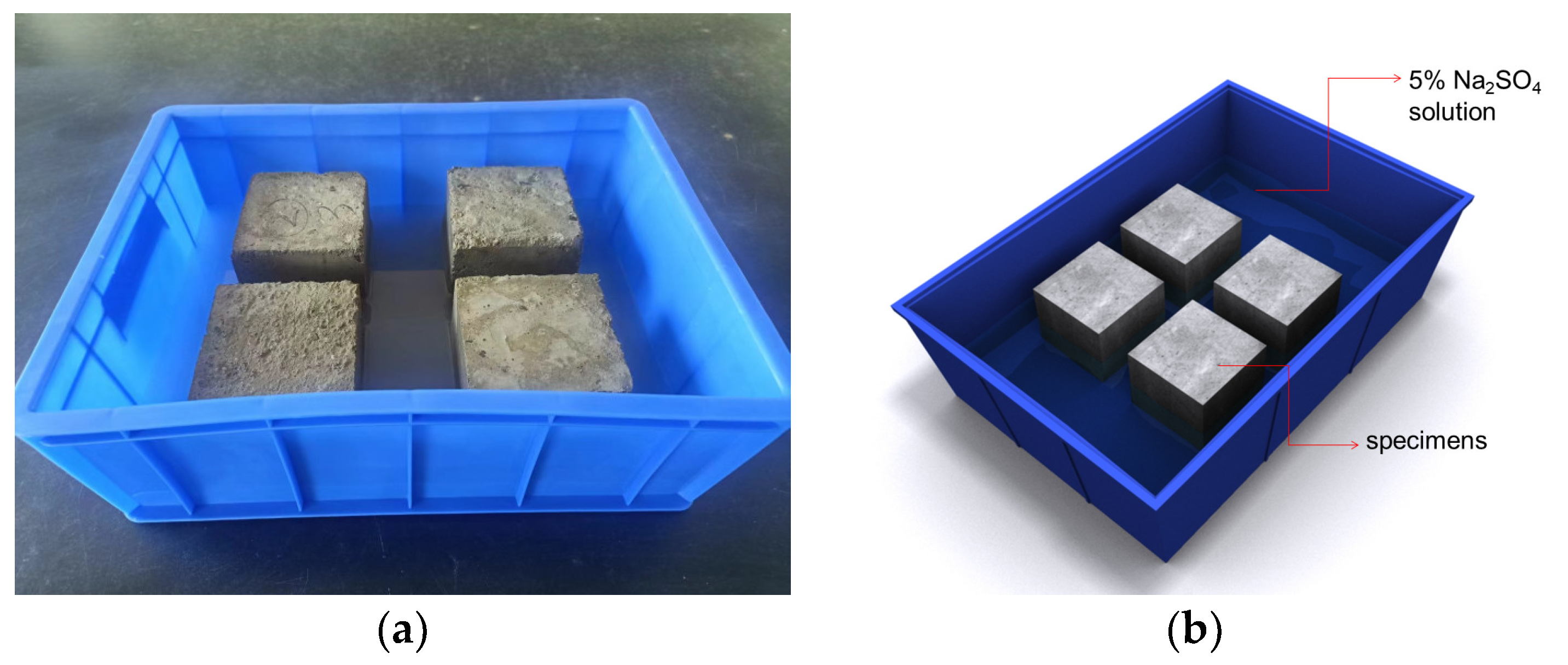

- Anhydrous sodium sulfate was used for preparing a 5% concentration Na2SO4 solution.

2.2. Test Research Method

2.2.1. Workability and Mechanical Properties of the Concrete Mixture

2.2.2. Alkali Aggregate Reactivity of Concrete

2.2.3. Sulfate Resistance of Concrete

2.2.4. Evaluation of the Adaptability of the Chain Extender Component to Concrete

3. Results and Discussion

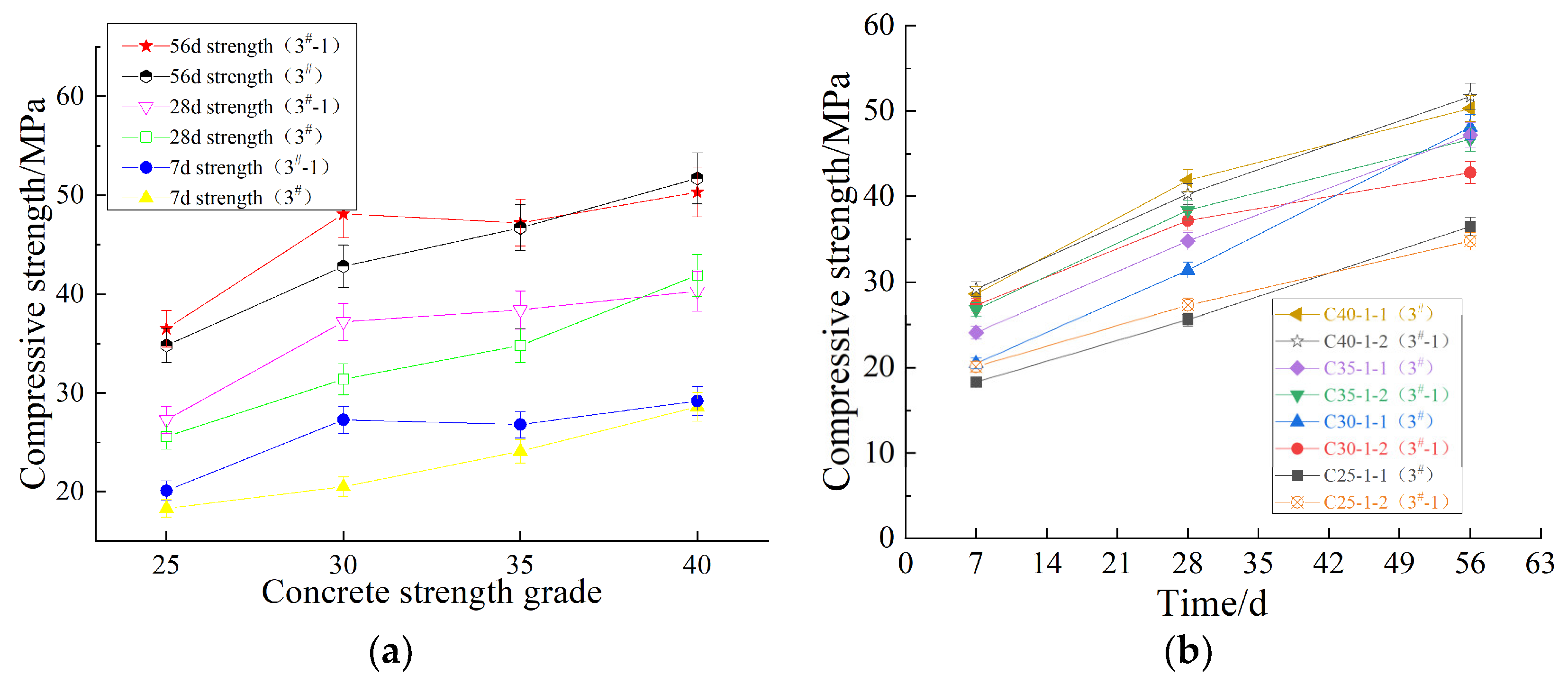

3.1. Workability and Mechanical Properties of the Concrete Mixtures

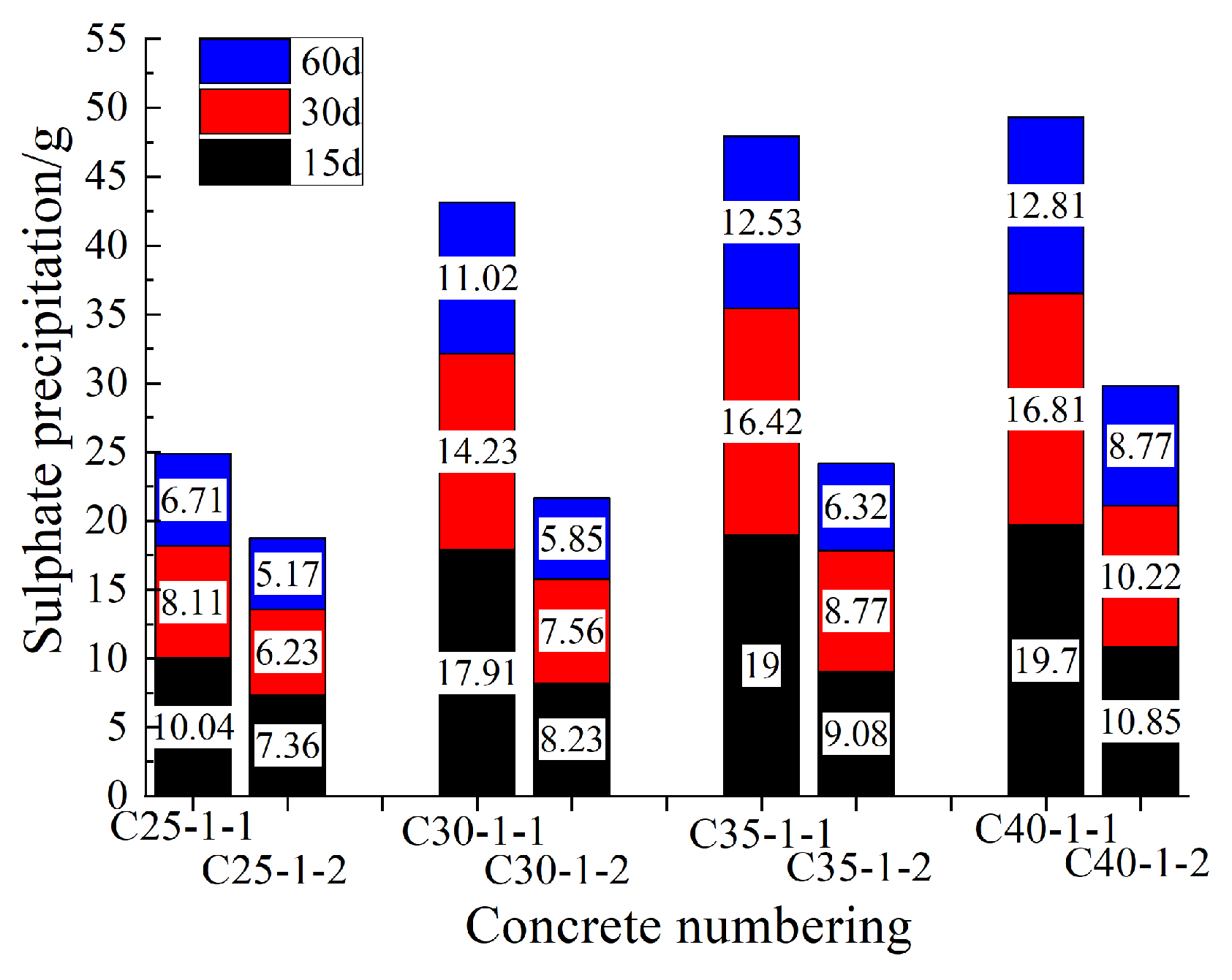

3.2. Sulfate Resistance of Concrete

3.3. SEM Microscopic Analysis of Concrete

3.4. Concrete Specimen Semi-Immersion and XRD Test Failure Mechanism

3.5. Study on the Adaptability of the Chain Extender Component to Ordinary Concrete

4. Evaluation Method Validity Verification

4.1. Mix Proportions of Concrete with Fly Ash and Slag as Dual Admixtures

4.2. Mix Performance and Mechanical Properties of Concrete with Fly Ash and Slag as Dual Admixtures

4.3. Sulfate Resistance of Concrete with Fly Ash and Slag as Dual Admixtures

4.4. Adaptability Evaluation of the Chain Extender Component to Concrete with Fly Ash and Slag as Dual Admixtures

5. Conclusions

- (1)

- Through the SEM analysis, it was evident that the internal pores in concrete were significantly reduced by the chain extender component. The chain extender component improved the internal porosity of the concrete, resulting in a denser microstructure. As a result, the concrete’s impermeability and sulfate corrosion resistance was enhanced, while the impact on the properties of the mixture was minimal.

- (2)

- Based on the analysis of erosion products from specimens using the semi-immersion method, it was observed that chemical erosion primarily occurred in the immersion zone, while both chemical and physical erosion were present in the alternate wet–dry zone.

- (3)

- Although the chain extender component improved the internal pore structure of the concrete, further research is needed to assess the impact on concrete strength.

- (4)

- According to the evaluation using the 0–1 scoring method, Water Reducer 3 received a score of 20, while Water Reducer 3#–1 received a score of 4. Considering these results comprehensively, the chain extender component exhibited good adaptability to ordinary concrete.

- (5)

- To validate the effectiveness of the 0–1 scoring method, it was applied to evaluate the adaptability of fly ash and slag blended cement concrete. Water Reducer 3 obtained a score of 13, while Water Reducer 3#–1 received a score of 10. Considering these results comprehensively, the chain extender component demonstrated good adaptability to fly ash and slag blended cement concrete.

- (6)

- Overall, this method takes into consideration workability, strength, as well as impermeability, sulfate attack resistance, and alkali–aggregate reactions. It serves as a comprehensive evaluation method for assessing the adaptability of water reducers to concrete. This method can provide a reference for future research on the adaptability of water reducers to concrete.

- (7)

- In order to improve the sulfate corrosion resistance of concrete and to prepare sulfate corrosion resistant concrete, it is necessary to study the influence of other water reducers and admixtures on the sulfate corrosion resistance of concrete and the adaptability between the water reducers and admixtures. In addition, in order to further validate the effectiveness of the evaluation method, this method should be applied to fly ash, slag and silica fume three-admixture concrete and high-performance concrete (HPC). These findings will be the subject of subsequent publications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, B.; Ji, S.; Zhang, A.; Gong, T. Experimental Study on Efflorescence of High Performance Concrete and Design Suggestions for Mixture Ratio. J. Electr. Power 2017, 32, 504–510. [Google Scholar]

- Jiang, J.; Weng, W.; Qiu, J. Study on sulfate corrosion behavior of concrete under simulated groundwater pressure. J. Hebei Eng. Univ. 2019, 36, 11–15. [Google Scholar]

- Qiao, H.; Qiao, G.; Lu, C. Damage degradation model of concrete based on COMSOL under sulfate environment. J. Huazhong Univ. Sci. Technol. 2021, 49, 119–125. [Google Scholar]

- Yan, C.; Cao, Y.; Liu, S.; Wang, X.; Pang, P. Experimental study on salt corrosion resistance of PVA fiber concrete. Concrete 2020, 56–60. [Google Scholar]

- Hou, Y. Study on the mechanical and corrosion resistance of hybrid fiber reinforced concrte. Funct. Mater. 2020, 51, 11116–11120+11213. [Google Scholar]

- Zhang, H.; Zhu, Y.; Han, J. Durability of partially-exposed concrete in sulfate saline soil area. Concrete 2015, 4–8. [Google Scholar]

- Li, H.; Sun, W.; Zuo, X. Effect of mineral admixtures on sulfate attack resistance of cement-based materials. Bull. Silic. 2018, 1120–1126. [Google Scholar]

- Niu, D.; Wang, J.; Ma, R. Sulfate attack test of shotcrete under dry-wet alternation. China J. Highw. Transp. 2016, 29, 82–89. [Google Scholar]

- Wang, H.; Dong, Y.; Sun, X.; Jin, W. Damage mechanism of concrete deteriorated by sulfate attack in wet-dry cycle environment. J. Zhejiang Univ. 2012, 46, 1255–1261. [Google Scholar]

- Yang, Y.; Zhang, Y.; She, W.; Qian, R. Deterioration mechanism of concrete with initial damage exposed to sulfate attack. J. Build. Mater. 2017, 20, 705–711. [Google Scholar]

- Yang, W.; Ye, X.; Li, R.; Yang, J. Effect of Stray Current on Corrosion and Calcium IonCorrosion of Concrete Reinforcement. Materials 2022, 15, 7287. [Google Scholar] [CrossRef] [PubMed]

- Golewski, G.L. The Effect of the Addition of Coal Fly Ash (CFA) on the Control of Water Movement within the Structure of the Concrete. Materials 2023, 16, 5218. [Google Scholar] [CrossRef]

- Zhu, M.; Liu, S.; Ren, Z.; Zhao, S. Experimental study on mineral admixture improving sulfate resistance of high strength concrete. North China Univ. Water Resour. Hydropower 2020, 41, 67–72. [Google Scholar]

- Geng, O.; Sun, Q.; Li, D. Study on inhibition effect of chloride on sulfate corrosion of recycled concrete. J. Build. Sci. Eng. 2020, 37, 108–116. [Google Scholar]

- Wang, M.; Huang, S.; Li, X. Experimental study on polycarboxylic acid series high performance water reducer modified by chain extender. Concr. Cem. Prod. 2015, 1–5. [Google Scholar]

- Santhanam, M.; Cohen, M.D.; Olek, J. Sulfate attack research—Whither now? Cem. Concr. Res. 2001, 31, 845–851. [Google Scholar] [CrossRef]

- Santhanam, M. Studies on Sulfate Attack: Mechanisms, Test Methods, and Modeling. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2001. [Google Scholar]

- Neville, A. The confused world of sulfate attack on concrete. Cem. Concr. Res. 2004, 34, 1275–1296. [Google Scholar] [CrossRef]

- Schmidt, T.; Lothenbach, B.; Romer, M.; Neuenschwander, J.; Scrivener, K. Physical and microstructural aspects of sulfate attack on ordinary and limestone blended Portland cements. Cem. Concr. Res. 2009, 39, 1111–1121. [Google Scholar] [CrossRef]

- Liu, K.; Mo, L.; Deng, M. Influence of pH on the formation of gypsumin cement materials during sulfate attack. Adv. Cem. Res. 2015, 27, 487–493. [Google Scholar] [CrossRef]

- Bellmann, F.; Moser, B.; Stark, J. Influence of sulfate solution concentration on the formation of gypsum in sulfate resistance test specimen. Cem. Concr. Res. 2006, 36, 358–363. [Google Scholar] [CrossRef]

- Xie, C.; Wang, Q.; Yu, B.; Zhang, R.; Dai, J.; Guo, Y. Analysis of sulfate corrosion resistance of cement-based composite cementitious at different erosion temperatures. J. Mater. Sci. Eng. 2020, 38, 571–578+584. [Google Scholar]

- Zhang, M. Influence of sulfate corrosion on microstructure characteristics of concrete. Bull. Silic. 2020, 39, 1160–1165. [Google Scholar]

- Zhang, X.; Zhang, R.; Ning, G.; Li, H.; Dou, X.; Xiong, Z. Influence of water-cement ratio on sulfate corrosion resistance of concrete. J. Railw. Sci. Eng. 2021, 18, 1471–1478. [Google Scholar]

- Xie, C.; Wang, Q.; Yu, B.; Zhang, R.; Dai, J.; Wang, Y. Experimental study on sulfate attack resistance of nano SiO2-Slag-Cement composite cementitious material. J. Mater. Sci. Eng. 2020, 38, 88–93. [Google Scholar]

- Tian, S. Experimental Research on Sulfate Corrosion Resistance of Concrete under Dry and Wet Environment. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2019. [Google Scholar]

- Wang, Y. Study on Sulfate Attack Mechanism Andmodifications of Concrete in West of China. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2016. [Google Scholar]

- Grzegorz, L.G. Combined effect of coal fly ash (CFA) and nanosilica (nS) on the strength parameters and microstructural properties of eco-friendly concrete. Energies 2023, 16, 452. [Google Scholar]

- Yang, C. Synergetic Effect of superabsorbent polymer and CaO-based expansive agent on mitigating autogenous shrinkage of UHPC matrix. Materials 2023, 16, 2814. [Google Scholar]

- Wei, H. Compound effects of sodium chloride and gypsum on the compressive strength and sulfate resistance of slag-based geopolymer concrete. Buildings 2023, 13, 675. [Google Scholar]

- Dong, Y.; Ma, Y.; Zhu, J.; Qiu, J. Study on Impermeability of Foamed Concrete Containing Municipal Solid Waste Incineration Powder. Materials 2022, 15, 5176. [Google Scholar] [CrossRef]

- Kang, J. Some basic problems in the research of sulfate corrosion of concrete. Concrete 1995, 7–16. [Google Scholar]

- Yang, D.; Zhou, J.; Wang, H.; Liu, R.; Nie, C. Study on the effectiveness of admixtures and mineral admixtures on sulfate resistance of concrete. Concrete 2003, 12–15. [Google Scholar]

- He, X.; Ma, B.; Chen, Y. Research and evaluation of mineral admixture on sulfate resistance of concrete. Concrete 2003, 8–11. [Google Scholar]

- Ban, K. Inhibition of Admixture on TSA Corrosion of Concrete. Master’s Thesis, Chongqing University, Chongqing, China, 2010. [Google Scholar]

- Feng, L. Effect of silica fume and water reducer on sulfate corrosion resistance of cement. J. Southwest Jiaotong Univ. 1988, 5–14. [Google Scholar]

- Qiao, H. Experimental Study on Sulfate Resistance of High Performance Concrete. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, 2003. [Google Scholar]

- Zhang, M.; Guo, C.; Jia, J. Preparation and properties research of high compatibility and multi-branch chain polycarboxylate superplasticizer. Bull. Silic. 2019, 38, 1274–1277. [Google Scholar]

- Wu, W.; Liu, Z.Y.; Ye, Z.; Wang, Y. Synthesis and characterization of phosphonate polycarboxylate superplasticizer with high adaptability. New Build. Mater. 2016, 43, 39–41+57. [Google Scholar]

- Jiang, Z.; Fang, Y.; Guo, Y.; Lin, T. Study on Synthesis and Properties of Vinyl Polyoxyethylene Ether Type Polycarboxylate Superplasticizer. IOP Conf. Ser. Earth Environ. Sci. 2020, 571, 012135. [Google Scholar] [CrossRef]

- Lin, Z. Synthesis and performance study of a highly dispersed HPEG-type polycarboxylate superplasticizer. J. Phys. Conf. Ser. 2022, 2194, 012028. [Google Scholar] [CrossRef]

- Song, Z.; Yao, Y.; Li, T.; Li, X.; Wu, M. Molecular structure design and preparation of slow release polycarboxylic superplasticizer. J. Build. Mater. 2017, 20, 563–568+574. [Google Scholar]

- Zhang, M. Preparation and Properties of low air-entraining and shrinkage-reducing polycarboxylate superplasticizer. Bull. Silic. 2017, 36, 369–373. [Google Scholar]

- Tan, L.; Yan, W.; Zhong, K.; Yang, H.; Tian, M.; Liu, Y. Research on synthesis at room temperature and performance of a high adaptable polycarboxylate superplasticizer. New Build. Mater. 2022, 49, 136–139. [Google Scholar]

- Zhu, X.; Li, X. Synthesis and properties of novel ester monomers and polycarboxylate superplasticizer. Funct. Mater. 2022, 53, 2182–2186. [Google Scholar]

- Lai, H. Preparation and properties of highly adaptive polycarboxylate superplasticizer. Polym. Notif. 2022, 107–112. [Google Scholar]

- Guo, F.; Lu, J.; Liu, J.; Qiu, J. Study on the adaptability of polycarboxylate superplasticizer and cement and its mechanism. New Build. Mater. 2018, 45, 103–107. [Google Scholar]

- Tang, X.; Sun, Z.; Liu, Y. Influence of Triethanolamine Grinding Aid on the Compatibility Between Cement and Polycarboxylate Superplasticizer and Its Mechanism. Mater. Guide 2018, 32, 641–645. [Google Scholar]

- Lu, C. Study on the Adaptability of Polycarboxylate Water Reducer in UHPC. Master’s Thesis, Hunan University of Technology, Zhuzhou, China, 2020. [Google Scholar]

- Tang, H. Corrosion-Resistant Concrete Admixture Study. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2007. [Google Scholar]

- Cai, P. Synthesis and Application of Polycarboxylic Acid Water Reducer. Master’s Thesis, Shenyang Jianzhu University, Shenyang, China, 2019. [Google Scholar]

- Su, J. Preparation of Polyether Polycarboxylic Acid Water Reducer and Its Adaptability to Cement. Master’s Thesis, Shijiazhuang Tiedao University, Shijiazhuang, China, 2019. [Google Scholar]

- GB/T 1345-2005; The Test Sieving Method for Fineness of Cement. Standards Publishing House: Beijing, China, 2005.

- GB/T1346-2011; Test Methods for Water Consumption, Setting Time, and Soundness of Cement for Standard Consistency. Standards Publishing House: Beijing, China, 2011.

- GB/T 1346-2011; Method of Testing Cements-Determination of Strength. Standards Publishing House: Beijing, China, 2021.

- JGJ55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Construction Industry Press: Beijing, China, 2011.

- GB/T50080-2016; Standard for Test Methods of Performance on Ordinary Fresh Concrete. Construction Industry Press: Beijing, China, 2016.

- GB /T 50081-2019; Standard for Test Methods of Physical and Mechanical Properties of Concrete. Construction Industry Press: Beijing, China, 2019.

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Construction Industry Press: Beijing, China, 2009.

- Peng, X.; Yi, C.; Zhang, Z.; Ouyang, X.; Qiu, X. Effect of polycarboxylate-type water-reducer on dispersion and hydration products of cement. J. Build. Mater. 2010, 13, 578–583. [Google Scholar]

- Hamada, D.; Hamai, T.; Shonaka, M. New superplasticizer providing ultimate workability. Spec. Publ. 2006, 28, 185–190. [Google Scholar]

- Chen, F.; Gao, J.; Qi, B.; Shen, D. Deterioration mechanism of plain and blended cement mortars partially exposed to sulfate attack. Constr. Build. Mater. 2017, 154, 849–856. [Google Scholar] [CrossRef]

- Toyoda, M.; Sakagami, K.; Okano, M.; Okuzono, T.; Toyoda, E. Improved sound absorption performance of three-dimensional MPP space sound absorbers by filling with porous materials. Appl. Acoust. 2017, 116, 311–316. [Google Scholar] [CrossRef]

- El-Hachem, R.; Rozière, E.; Grondin, F.; Loukili, A. Multi-criteria analysis of the mechanism of degradation of Portland cement based mortars exposed to external sulphate attack. Cem. Concr. Res. 2012, 42, 1327–1335. [Google Scholar] [CrossRef]

- Xiong, C.; Jiang, L.; Xu, Y.; Chu, H.; Jin, M.; Zhang, Y. Deterioration of pastes exposed to leaching, external sulfate attack and the dual actions. Constr. Build. Mater. 2016, 116, 52–62. [Google Scholar] [CrossRef]

| Specific Surface Area/m2/kg | Setting Time/Min | 3d Strength/MPa | 28d Strength/MPa | |||

|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | Flexural | Compression Resistance | Flexural | Compression Resistance | |

| 324 | 167 | 218 | 5.0 | 22.1 | 8.5 | 49.2 |

| Apparent Density/kg/m3 | Clay Content/% | Clay Lump Content/% | Alkali Activity (14 d Expansion Rate)/% | Firmness/% |

|---|---|---|---|---|

| 2670 | 2.2 | 0.1 | 0.04 | 6 |

| Sieve Hole Size/mm | 4.75 | 2.36 | 1.18 | 0.60 | 0.30 | 0.15 | Chassis | |

| Cumulative Screen Sieve/% | Experiment 1 | 9.0 | 20.2 | 34.1 | 62.3 | 78.6 | 97.8 | 99.8 |

| Experiment 2 | 8.7 | 19.8 | 34.4 | 60.8 | 80.6 | 98.1 | 98.7 | |

| Apparent Density/kg/m3 | Clay Content/% | Clay Lump Content/% | Firmness/% | Crushing Index/% | Alkali Activity (14 d Expansion Rate)/% |

|---|---|---|---|---|---|

| 2580 | 0.1 | 0.1 | 1 | 9.6 | 0.03 |

| Sieve Hole Size/mm | 26.5 | 19 | 16 | 9.5 | 4.75 | 2.36 | Chassis | |

| Cumulative Screen Sieve/% | Experiment 1 | 4.5 | 20.8 | 40.8 | 85.0 | 93.1 | 98.5 | 100 |

| Experiment 2 | 4.2 | 21.3 | 45.7 | 85.1 | 92.4 | 97.8 | 100 | |

| Recipe No. | Polycarboxylic Acid | Gluconic Acid, Sodium Salt | Sodium Tripolyphosphate | Sodium Hexametaphosphate | Sodium Bicarbonate | Chain Extender | Sodium Dodecyl Sulfate | Water | Water Reducing Rate |

|---|---|---|---|---|---|---|---|---|---|

| 3# | 140 | 15 | 5 | 70 | 4 | 3 | 0.3 | 762.7 | ≥25% |

| 3#–1 | 140 | 15 | 5 | 70 | 4 | 0 | 0.3 | 762.7 | ≥25% |

| Numbering | Water Reducer | Strength Grade | W/B Ratio | Sand-Aggregate/% | Mix Proportion/kg/m3 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Cement | Sand | Gravel | Water | Water Reducer | |||||

| C25-1-1 | 3# | C25 | 0.53 | 38 | 320 | 725 | 1185 | 170 | 6.4 |

| C25-1-2 | 3#–1 | C25 | 0.53 | 38 | 320 | 725 | 1185 | 170 | 6.4 |

| C30-1-1 | 3# | C30 | 0.50 | 38 | 340 | 720 | 1170 | 170 | 6.8 |

| C30-1-2 | 3#–1 | C30 | 0.50 | 38 | 340 | 720 | 1170 | 170 | 6.8 |

| C35-1-1 | 3# | C35 | 0.45 | 39 | 370 | 719 | 1126 | 167 | 7.4 |

| C35-1-2 | 3#–1 | C35 | 0.45 | 39 | 370 | 719 | 1126 | 167 | 7.4 |

| C40-1-1 | 3# | C40 | 0.40 | 40 | 400 | 728 | 1092 | 160 | 8.0 |

| C40-1-2 | 3#–1 | C40 | 0.40 | 40 | 400 | 728 | 1092 | 160 | 8.0 |

| Numbering | Slump/mm | Slump Loss/mm | Air Content/% | Initial Setting Time/min | Final Setting Time/min | |

|---|---|---|---|---|---|---|

| Initiation | 1 h | |||||

| C25-1-1 | 220 | 195 | 25 | 2.0 | 341 | 472 |

| C25-1-2 | 220 | 190 | 30 | 2.1 | 348 | 476 |

| C30-1-1 | 220 | 190 | 30 | 2.1 | 345 | 470 |

| C30-1-2 | 215 | 185 | 30 | 2.2 | 334 | 464 |

| C35-1-1 | 225 | 190 | 35 | 2.2 | 328 | 462 |

| C35-1-2 | 230 | 180 | 50 | 2.2 | 336 | 460 |

| C40-1-1 | 215 | 190 | 25 | 2.3 | 343 | 474 |

| C40-1-2 | 210 | 180 | 30 | 2.3 | 325 | 453 |

| Numbering | Impervious Grade | Sulfate Resistance Rating | Sulphate Precipitation/g | Mass Difference/g | |||

|---|---|---|---|---|---|---|---|

| 15d | 30d | 60d | Ʃ60d | ||||

| C25-1-1 | P8 | KS30 | 10.04 | 8.11 | 6.71 | 24.86 | 5.85 |

| C25-1-2 | P7 | KS30 | 7.36 | 6.23 | 5.17 | 18.76 | 9.78 |

| C30-1-1 | P9 | KS60 | 17.91 | 14.23 | 11.02 | 43.16 | 7.53 |

| C30-1-2 | P8 | KS30 | 8.23 | 7.56 | 5.85 | 21.64 | 10.52 |

| C35-1-1 | P10 | KS60 | 19.00 | 16.42 | 12.53 | 47.95 | 7.64 |

| C35-1-2 | P10 | KS30 | 9.08 | 8.77 | 6.32 | 24.17 | 14.53 |

| C40-1-1 | P11 | KS60 | 19.70 | 16.81 | 12.81 | 49.32 | 6.55 |

| C40-1-2 | P11 | KS30 | 10.85 | 10.22 | 8.77 | 29.84 | 14.59 |

| Type of Water Reducer | Slump Loss Value | P | KS | Pan Alkali | Compressive Strength | Total Score | ||

|---|---|---|---|---|---|---|---|---|

| 7d | 28d | 56d | ||||||

| 3# | 3 | 2 | 3 | 4 | 3 | 3 | 2 | 20 |

| 3#–1 | 0 | 0 | 0 | 0 | 1 | 1 | 2 | 4 |

| Numbering | Water Reducer | Strength Grade | W/B Ratio | Sand-Aggregate/% | Mix Proportion/kg/m3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | Fly Ash | Slag | Sand | Gravel | Water | Water Reducer | |||||

| C25-2-1 | 3# | C25 | 0.50 | 43 | 260 | 70 | 40 | 793 | 1052 | 185 | 7.4 |

| C25-2-2 | 3#–1 | C25 | 0.50 | 43 | 260 | 70 | 40 | 793 | 1052 | 185 | 7.4 |

| C30-2-1 | 3# | C30 | 0.45 | 42 | 290 | 70 | 30 | 770 | 1063 | 176 | 7.8 |

| C30-2-2 | 3#–1 | C30 | 0.45 | 42 | 290 | 70 | 30 | 770 | 1063 | 176 | 7.8 |

| C35-2-1 | 3# | C35 | 0.42 | 41 | 320 | 60 | 30 | 743 | 1069 | 172 | 8.2 |

| C35-2-2 | 3#–1 | C35 | 0.42 | 41 | 320 | 60 | 30 | 743 | 1069 | 172 | 8.2 |

| C40-2-1 | 3# | C40 | 0.38 | 40 | 350 | 60 | 30 | 710 | 1066 | 167 | 8.8 |

| C40-2-2 | 3#–1 | C40 | 0.38 | 40 | 350 | 60 | 30 | 710 | 1066 | 167 | 8.8 |

| Numbering | Slump/mm | Slump Loss/mm | Air Content/% | Initial Setting Time/min | Final Setting Time/min | |

|---|---|---|---|---|---|---|

| Initiation | 1 h | |||||

| C25-2-1 | 235 | 200 | 35 | 2.3 | 365 | 490 |

| C25-2-2 | 230 | 190 | 40 | 2.1 | 380 | 495 |

| C30-2-1 | 220 | 205 | 15 | 2.1 | 348 | 478 |

| C30-2-2 | 210 | 195 | 25 | 2.3 | 371 | 474 |

| C35-2-1 | 225 | 195 | 30 | 2.5 | 355 | 487 |

| C35-2-2 | 225 | 190 | 35 | 2.4 | 359 | 500 |

| C40-2-1 | 205 | 190 | 15 | 2.6 | 300 | 474 |

| C40-2-2 | 210 | 180 | 30 | 2.1 | 320 | 493 |

| Numbering | Impervious Grade | Sulfate Resistance Rating | Sulphate Precipitation/g | Mass Difference/g | |||

|---|---|---|---|---|---|---|---|

| 15d | 30d | 60d | Ʃ60d | ||||

| C25-2-1 | 8 | 60 | 9.52 | 8.01 | 6.52 | 24.05 | 4.98 |

| C25-2-2 | 8 | 60 | 8.84 | 7.64 | 5.82 | 22.30 | 7.60 |

| C30-2-1 | 9 | 90 | 10.11 | 8.23 | 6.31 | 24.65 | 7.08 |

| C30-2-2 | 8 | 90 | 9.8 | 8.07 | 6.28 | 24.15 | 5.77 |

| C35-2-1 | 11 | 90 | 10.09 | 8.46 | 6.82 | 25.37 | 8.73 |

| C35-2-2 | 10 | 90 | 9.95 | 8.16 | 6.12 | 24.23 | 9.39 |

| C40-2-1 | 12 | 90 | 10.07 | 9.02 | 6.33 | 25.42 | 12.78 |

| C25-2-1 | 8 | 60 | 9.52 | 8.01 | 6.52 | 24.05 | 4.98 |

| Type of Water Reducer | Slump Loss Value | P | KS | Pan Alkali | Compressive Strength | Total Score | ||

|---|---|---|---|---|---|---|---|---|

| 7d | 28d | 56d | ||||||

| 3# | 4 | 3 | 0 | 4 | 0 | 1 | 1 | 13 |

| 3#–1 | 0 | 0 | 0 | 0 | 4 | 3 | 3 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, B.; Li, X.; Meng, X.; Zhang, Y.; Zhao, L.; Zhang, Q. An Experimental Study and Adaptability Evaluation of Chain Extender Component in Water Reducer on the Sulfate Corrosion Resistance of Ordinary Concrete. Coatings 2023, 13, 1958. https://doi.org/10.3390/coatings13111958

Wu B, Li X, Meng X, Zhang Y, Zhao L, Zhang Q. An Experimental Study and Adaptability Evaluation of Chain Extender Component in Water Reducer on the Sulfate Corrosion Resistance of Ordinary Concrete. Coatings. 2023; 13(11):1958. https://doi.org/10.3390/coatings13111958

Chicago/Turabian StyleWu, Bin, Xianjun Li, Xianjie Meng, Yuanyaun Zhang, Lijun Zhao, and Qiang Zhang. 2023. "An Experimental Study and Adaptability Evaluation of Chain Extender Component in Water Reducer on the Sulfate Corrosion Resistance of Ordinary Concrete" Coatings 13, no. 11: 1958. https://doi.org/10.3390/coatings13111958

APA StyleWu, B., Li, X., Meng, X., Zhang, Y., Zhao, L., & Zhang, Q. (2023). An Experimental Study and Adaptability Evaluation of Chain Extender Component in Water Reducer on the Sulfate Corrosion Resistance of Ordinary Concrete. Coatings, 13(11), 1958. https://doi.org/10.3390/coatings13111958