Precise Characterization of CNF-Coated Microfibers Using Transmission Electron Microscopy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Characterization of Hierarchical Materials

2.3. Characterization of the Samples

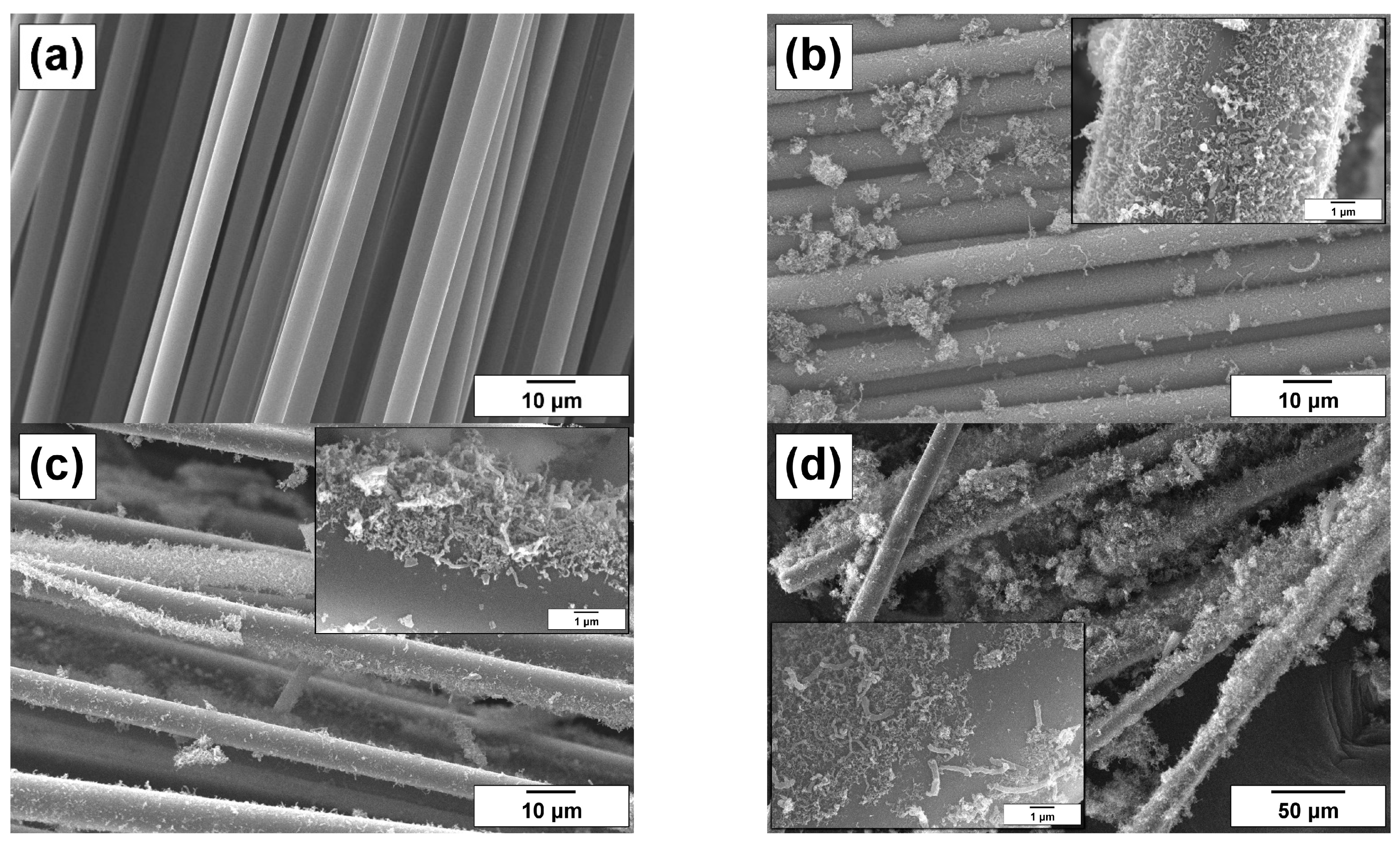

2.3.1. Scanning Electron Microscopy Studies

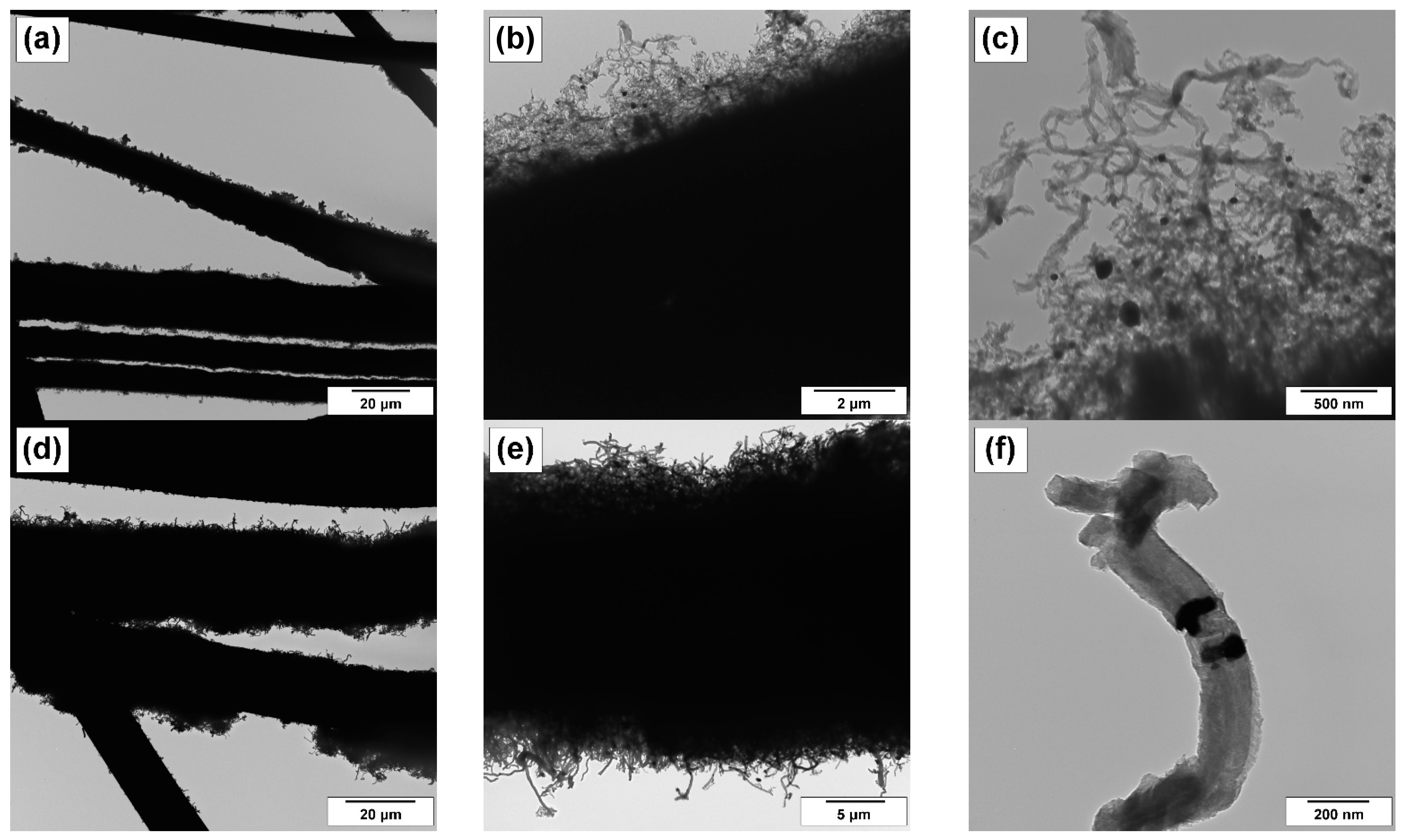

2.3.2. Methodology of “TEM-Sonication” Studies

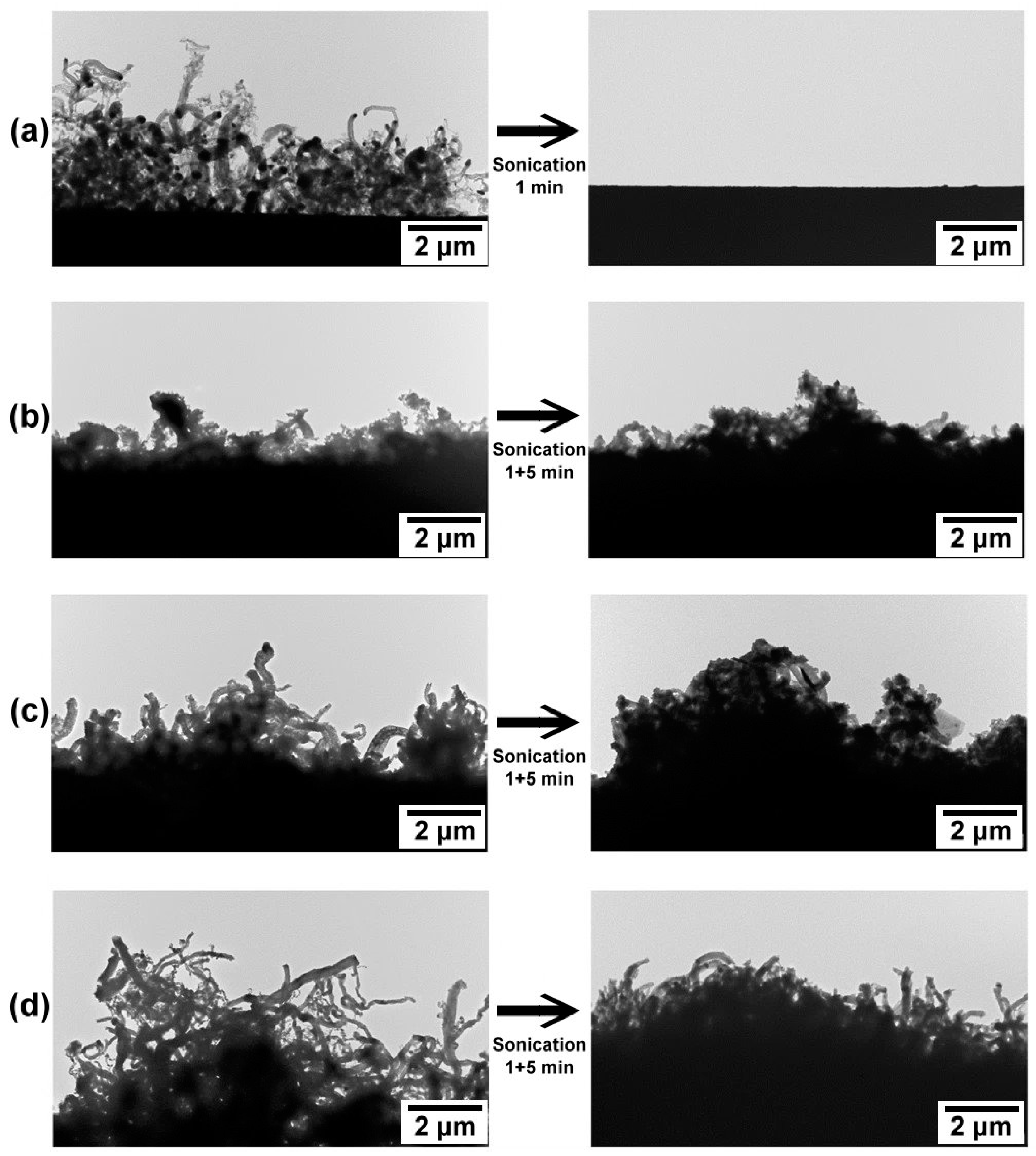

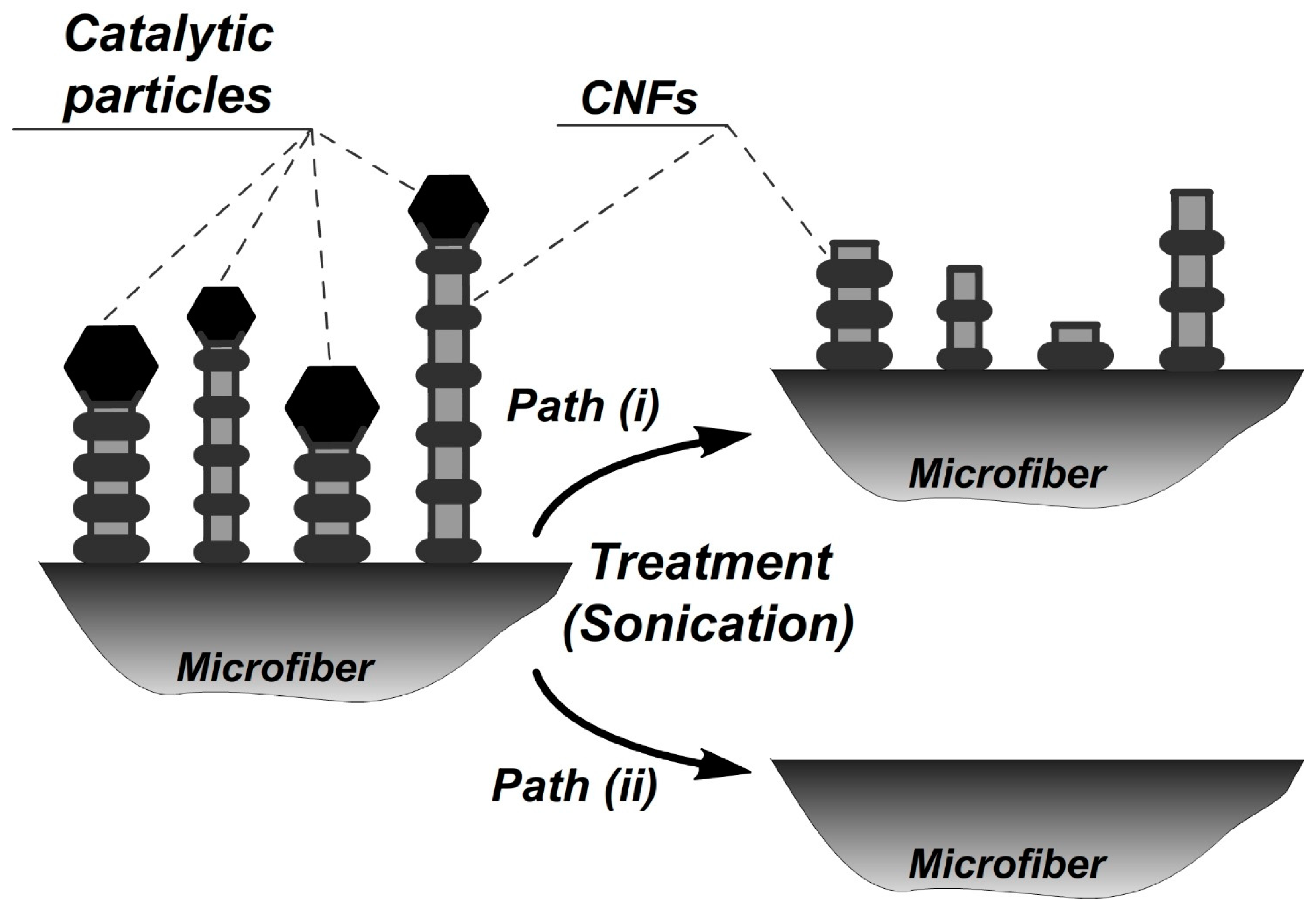

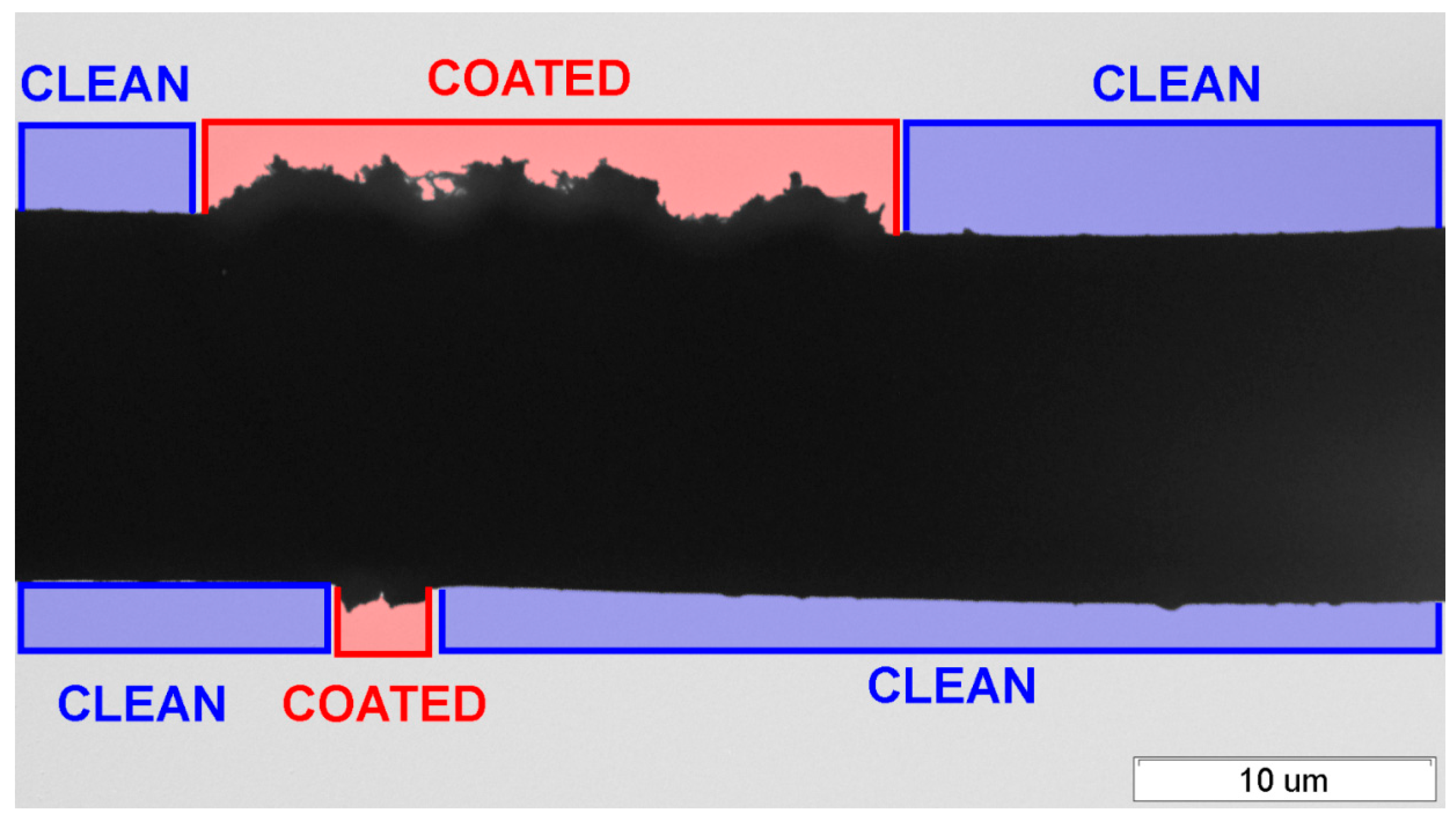

2.3.3. Examination of the Adhesion Strength between Microfibers and CNF

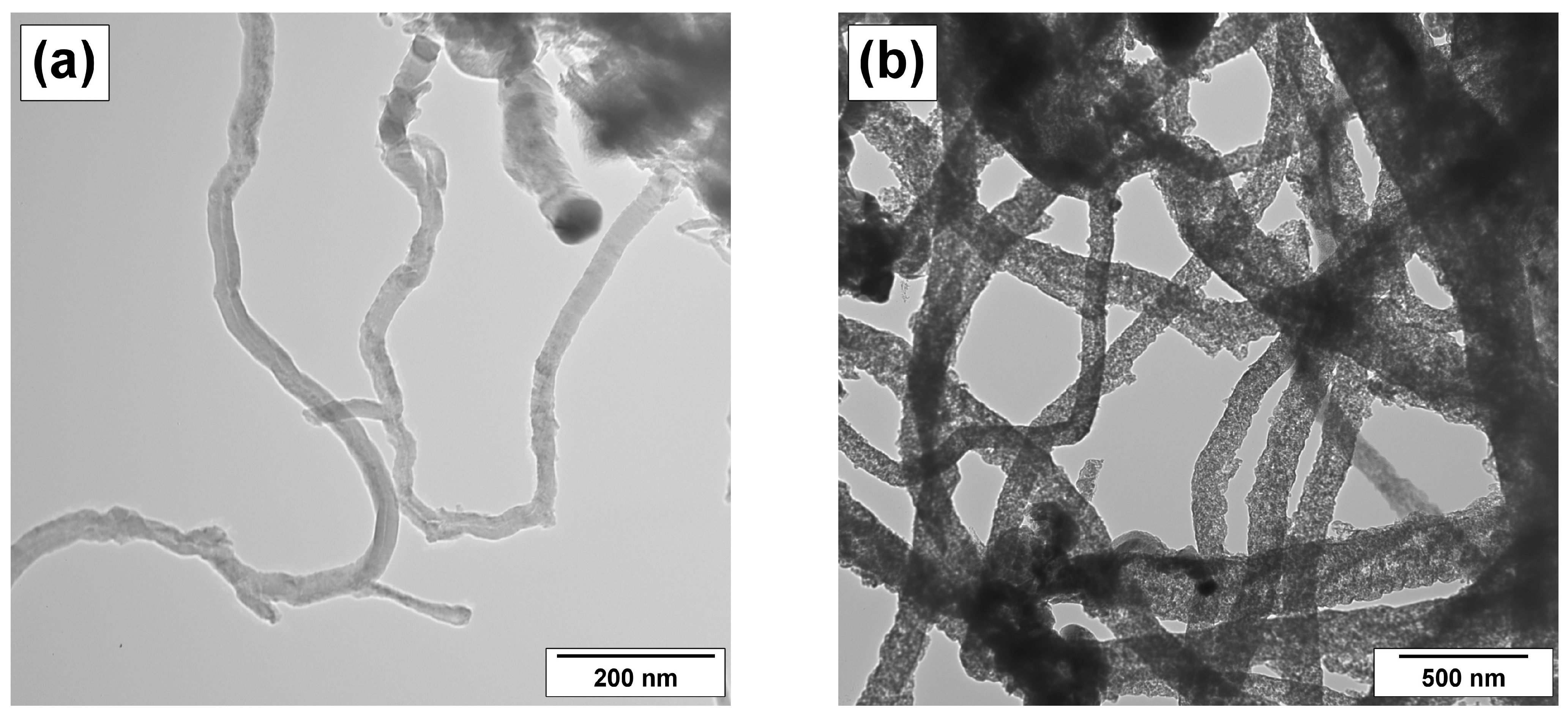

2.3.4. TEM Visualization

3. Results and Discussion

3.1. Examination of Hierarchical Materials by SEM and TEM Techniques

3.2. Examination of the Adhesion Strength in Hierarchical Materials by TEM Technique Coupled with the Sonication Treatment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.; Cai, S.; Li, Y.; Wang, Z.; Long, Y.; Yu, T.; Shen, Y. High performances of plant fiber reinforced composites—A new insight from hierarchical microstructures. Compos. Sci. Technol. 2020, 194, 108151. [Google Scholar] [CrossRef]

- Valorosi, F.; De Meo, E.; Blanco-Varela, T.; Martorana, B.; Veca, A.; Pugno, N.; Kinloch, I.A.; Anagnostopoulos, G.; Galiotis, C.; Bertocchi, F. Graphene and related materials in hierarchical fiber composites: Production techniques and key industrial benefits. Compos. Sci. Technol. 2020, 185, 107848. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mahmood, H.; Pegoretti, A. All-carbon multi-scale and hierarchical fibers and related structural composites: A review. Compos. Sci. Technol. 2020, 186, 107932. [Google Scholar] [CrossRef]

- Farina, I.; Goodall, R.; Hernández-Nava, E.; di Filippo, A.; Colangelo, F.; Fraternali, F. Design, microstructure and mechanical characterization of Ti6Al4V reinforcing elements for cement composites with fractal architecture. Mater. Des. 2019, 172, 107758. [Google Scholar] [CrossRef]

- Li, Y.; Yi, X.; Yu, T.; Xian, G. An overview of structural-functional-integrated composites based on the hierarchical microstructures of plant fibers. Adv. Compos. Hybrid Mater. 2018, 1, 231–246. [Google Scholar] [CrossRef]

- Nepal, D.; Kang, S.; Adstedt, K.M.; Kanhaiya, K.; Bockstaller, M.R.; Brinson, L.C.; Buehler, M.J.; Coveney, P.V.; Dayal, K.; El-Awady, J.A. Hierarchically structured bioinspired nanocomposites. Nat. Mater. 2022, 22, 18–35. [Google Scholar] [CrossRef]

- Hagnell, M.K.; Åkermo, M. The economic and mechanical potential of closed loop material usage and recycling of fibre-reinforced composite materials. J. Clean. Prod. 2019, 223, 957–968. [Google Scholar] [CrossRef]

- Kerber, M.L.; Vinogradov, V.M.; Golovkin, G.S.; Gorbatkina, Y.A.; Kryzhanovskii, V.K.; Kuperman, A.M.; Simonov-Emel’yanov, I.D.; Khaliulin, V.I.; Bunakov, V.A. Polymeric Composite Materials: Structure, Properties, and Technology: A Textbook; Profession: St. Petersburg, Russia, 2008. (In Russian) [Google Scholar]

- Ponomareva, E.; Shkinev, V.; Zaglyadova, S.; Krasnikova, I.; Egorova, E. Copper Catalysts based on carbon–carbon fibrous materials for ethanol dehydrogenation. Russ. J. Appl. Chem. 2016, 89, 598–602. [Google Scholar] [CrossRef]

- Ponomareva, E.A.; Krasnikova, I.V.; Egorova, E.V.; Mishakov, I.V.; Vedyagin, A.A. Ethanol dehydrogenation over copper supported on carbon macrofibers. Mendeleev Commun. 2017, 27, 210–212. [Google Scholar] [CrossRef]

- Ponomareva, E.A.; Krasnikova, I.V.; Egorova, E.V.; Mishakov, I.V.; Vedyagin, A.A. Dehydrogenation of ethanol over carbon-supported Cu–Co catalysts modified by catalytic chemical vapor deposition. React. Kinet. Mech. Catal. 2017, 122, 399–408. [Google Scholar] [CrossRef]

- Petukhova, E.S.; Krasnikova, I.V. The effect of surface nanostructuring on the behavior of a fiber-reinforced polyethylene composite. AIP Conf. Proc. 2016, 1785, 030021. [Google Scholar] [CrossRef]

- Rahaman, A.; Kar, K.K. Carbon nanomaterials grown on E-glass fibers and their application in composite. Compos. Sci. Technol. 2014, 101, 1–10. [Google Scholar] [CrossRef]

- He, X.; Wang, C.; Tong, L.; Wang, R.; Cao, A.; Peng, Q.; Moody, S.; Li, Y. Direct measurement of grafting strength between an individual carbon nanotube and a carbon fiber. Carbon 2012, 50, 3782–3788. [Google Scholar] [CrossRef]

- Cooper, C.A.; Cohen, S.R.; Barber, A.H.; Wagner, H.D. Detachment of nanotubes from a polymer matrix. Appl. Phys. Lett. 2002, 81, 3873–3875. [Google Scholar] [CrossRef]

- Barber, A.H.; Cohen, S.R.; Wagner, H.D. Measurement of carbon nanotube–polymer interfacial strength. Appl. Phys. Lett. 2003, 82, 4140–4142. [Google Scholar] [CrossRef]

- Strus, M.C.; Cano, C.I.; Pipes, R.B.; Nguyen, C.V.; Raman, A. Interfacial energy between carbon nanotubes and polymers measured from nanoscale peel tests in the atomic force microscope. Compos. Sci. Technol. 2009, 69, 1580–1586. [Google Scholar] [CrossRef]

- Chen, L.; Yu, Z.; Yin, D.; Cao, K. Preparation and anticorrosion properties of BTA@HNTs-GO nanocomposite smart coatings. Compos. Interfaces 2020, 28, 1–16. [Google Scholar] [CrossRef]

- Xu, W.; Lan, R.; Du, D.; Humphreys, J.; Walker, M.; Wu, Z.; Wang, H.; Tao, S. Directly growing hierarchical nickel-copper hydroxide nanowires on carbon fibre cloth for efficient electrooxidation of ammonia. Appl. Catal. B-Environ. 2017, 218, 470–479. [Google Scholar] [CrossRef]

- Ji, D.; Peng, S.; Safanama, D.; Yu, H.; Li, L.; Yang, G.; Qin, X.; Srinivasan, M.; Adams, S.; Ramakrishna, S. Design of 3-dimensional hierarchical architectures of carbon and highly active transition metals (Fe, Co, Ni) as bifunctional oxygen catalysts for hybrid lithium–air batteries. Chem. Mater. 2017, 29, 1665–1675. [Google Scholar] [CrossRef]

- Krasnikova, I.V.; Mishakov, I.V.; Vedyagin, A.A.; Bauman, Y.I.; Korneev, D.V. Surface modification of microfibrous materials with nanostructured carbon. Mater. Chem. Phys. 2017, 186, 220–227. [Google Scholar] [CrossRef]

- Beaumont, P.W.R.; Soutis, C.; Hodzic, A. The Structural Integrity of Carbon Fiber Composites: Fifty Years of Progress and Achievement of the Science, Development, and Applications; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar]

- Qian, H.; Bismarck, A.; Greenhalgh, E.S.; Kalinka, G.; Shaffer, M.S.P. Hierarchical composites reinforced with carbon nanotube grafted fibers: The potential assessed at the single fiber level. Chem. Mater. 2008, 20, 1862–1869. [Google Scholar] [CrossRef]

- Taheri, M.L.; Stach, E.A.; Arslan, I.; Crozier, P.A.; Kabius, B.C.; LaGrange, T.; Minor, A.M.; Takeda, S.; Tanase, M.; Wagner, J.B. Current status and future directions for in situ transmission electron microscopy. Ultramicroscopy 2016, 170, 86–95. [Google Scholar] [CrossRef] [PubMed]

- Flannigan, D.J.; Zewail, A.H. 4D electron microscopy: Principles and applications. Acc. Chem. Res. 2012, 45, 1828–1839. [Google Scholar] [CrossRef]

- Ayache, J.; Beaunier, L.; Boumendil, J.; Ehret, G.; Laub, D. Sample Preparation Handbook for Transmission Electron Microscopy: Techniques; Springer Science & Business Media: Cham, Switzerland, 2010; Volume 2. [Google Scholar]

- Rao, D.S.; Muraleedharan, K.; Humphreys, C. TEM specimen preparation techniques. Microsc. Sci. Technol. Appl. Educ. 2010, 2, 1232. [Google Scholar]

- Bauman, Y.I.; Mishakov, I.V.; Buyanov, R.A.; Vedyagin, A.A.; Volodin, A.M. Catalytic properties of massive iron-subgroup metals in dichloroethane decomposition into carbon products. Kinet. Catal. 2011, 52, 547–554. [Google Scholar] [CrossRef]

- Mishakov, I.V.; Vedyagin, A.A.; Bauman, Y.I.; Shubin, Y.V.; Buyanov, R.A. Synthesis of Carbon Nanofibers via Catalytic Chemical Vapor Deposition of Halogenated Hydrocarbons. In Carbon Nanofibers: Synthesis, Applications and Performance; Chang-Seop, L., Ed.; Nova Science Publishers: Hauppauge, NY, USA, 2018; pp. 77–181. [Google Scholar]

- Tokareva, I.V.; Mishakov, I.V.; Korneev, D.V.; Vedyagin, A.A.; Golokhvast, K.S. Nanostructuring of the carbon macrofiber surface. Nanotechnol. Russ. 2015, 10, 158–164. [Google Scholar] [CrossRef]

- Chesnokov, V.V.; Buyanov, R.A. The formation of carbon filaments upon decomposition of hydrocarbons catalysed by iron subgroup metals and their alloys. Russ. Chem. Rev. 2000, 69, 623–638. [Google Scholar] [CrossRef]

- Mishakov, I.V.; Chesnokov, V.V.; Buyanov, R.A.; Chuvilin, A.L. Morphology and structure of carbon resulting from decomposition of chlorohydrocarbons on nickel and cobalt containing catalysts. Reac. Kinet. Catal. Lett. 2002, 76, 361–367. [Google Scholar] [CrossRef]

| # | Sample Designation | Type of Microfiber | Characteristics * of Microfiber | Coating Conditions | Carbon Yield (YC), wt% | ||

|---|---|---|---|---|---|---|---|

| d, μm | L, mm | WH2O, mL/g | |||||

| 1 | CNF/CMF | Chopped carbon microfiber (CMF) | 5–6 | 5–7 | 0.90 | 600 °C C2H4 30 min | 40 |

| 2 | CNF/CMF(DCE) | 600 °C C2H4Cl2 ** 30 min | 50 | ||||

| 3 | CNF/BMF | Chopped basalt microfiber (BMF) | 20 | 9 | 0.30 | 500 °C C2H4 *** 15 min | 50 |

| 4 | CNF/FGC(DCE) | Fiberglass cloth (FGC) | 10 | 10 | 0.36 | 600 °C C2H4Cl2 ** 120 min | 36 |

| Sonication Time, min | CNF/CMF | CNF/BMF | CNF/FGC |

|---|---|---|---|

| 1 | 0.75 | 0.74 | 0.2 |

| 5 | 0.56 | 0.23 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korneev, D.V.; Krasnikova, I.V.; Afonnikova, S.D.; Vedyagin, A.A.; Mishakov, I.V. Precise Characterization of CNF-Coated Microfibers Using Transmission Electron Microscopy. Coatings 2023, 13, 256. https://doi.org/10.3390/coatings13020256

Korneev DV, Krasnikova IV, Afonnikova SD, Vedyagin AA, Mishakov IV. Precise Characterization of CNF-Coated Microfibers Using Transmission Electron Microscopy. Coatings. 2023; 13(2):256. https://doi.org/10.3390/coatings13020256

Chicago/Turabian StyleKorneev, Denis V., Irina V. Krasnikova, Sofya D. Afonnikova, Aleksey A. Vedyagin, and Ilya V. Mishakov. 2023. "Precise Characterization of CNF-Coated Microfibers Using Transmission Electron Microscopy" Coatings 13, no. 2: 256. https://doi.org/10.3390/coatings13020256

APA StyleKorneev, D. V., Krasnikova, I. V., Afonnikova, S. D., Vedyagin, A. A., & Mishakov, I. V. (2023). Precise Characterization of CNF-Coated Microfibers Using Transmission Electron Microscopy. Coatings, 13(2), 256. https://doi.org/10.3390/coatings13020256