Experimental Study on Preparation of Dry-Mixed Mortar from Coal Gangue

Abstract

:1. Introduction

2. Experiment

2.1. Experimental Raw Materials

- Admxture 1#: Hubei Jinzhu New Material Technology Co., LTD., Wu Han, China,

- Admxture 2#: Henan Xingwei Intelligent Building Material Technology Co., LTD., Gushi, China.

- Function: adjust the consistency and water retention of dry-mixed mortar.

2.2. Experimental Instruments and Equipment

2.3. Experimental Process

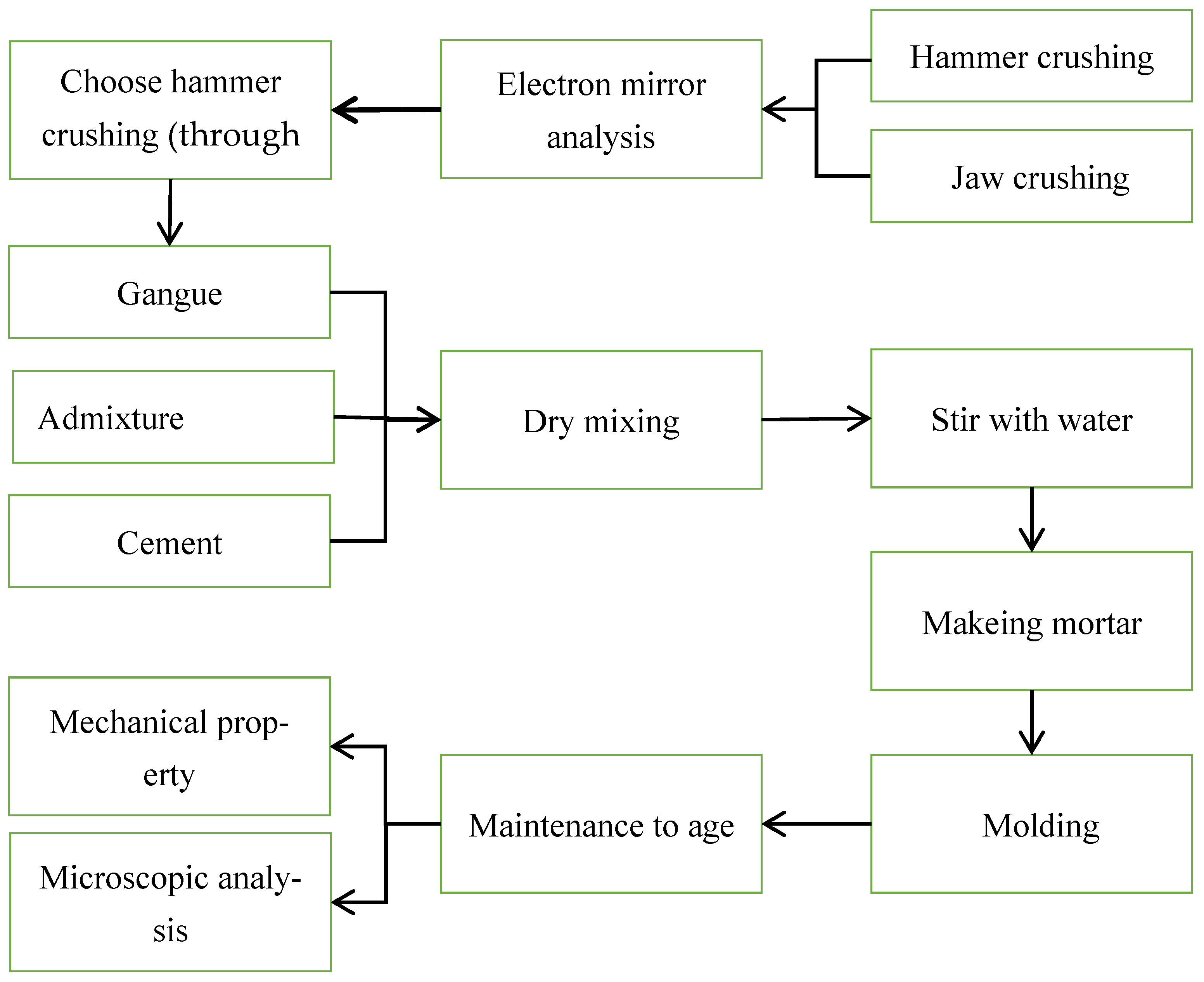

2.3.1. Experimental Flowchart for Preparing Dry-Mix Mortar

2.3.2. Dry-Mixed Mortar Preparation Process

2.4. Experimental Formula Design

2.5. Performance Test

2.5.1. Grain Tickle Grading Experiment

- G—the sieve allowance g on a sieve

- A—screen surface area( mm2)

- d—screen side length (mm)

2.5.2. Consistency Experiments

2.5.3. Water Retention Rate Experiment

- W—mortar water retention ratio (%)

- m1—drying mold mass (g)

- m2—filter paper before absorbing water mass (g)

- m3—mortar and try out total mass (g)

- m4—filter paper after absorbing water mass(g)

- α—mortar moisture content (%)

- —compressive strength (MPa)

- —destructive load (N)

- A—pressure area (mm2)

- K—conversion coefficient, 1.35

3. Results Analysis and Discussion

3.1. Characterization of Gangue Samples

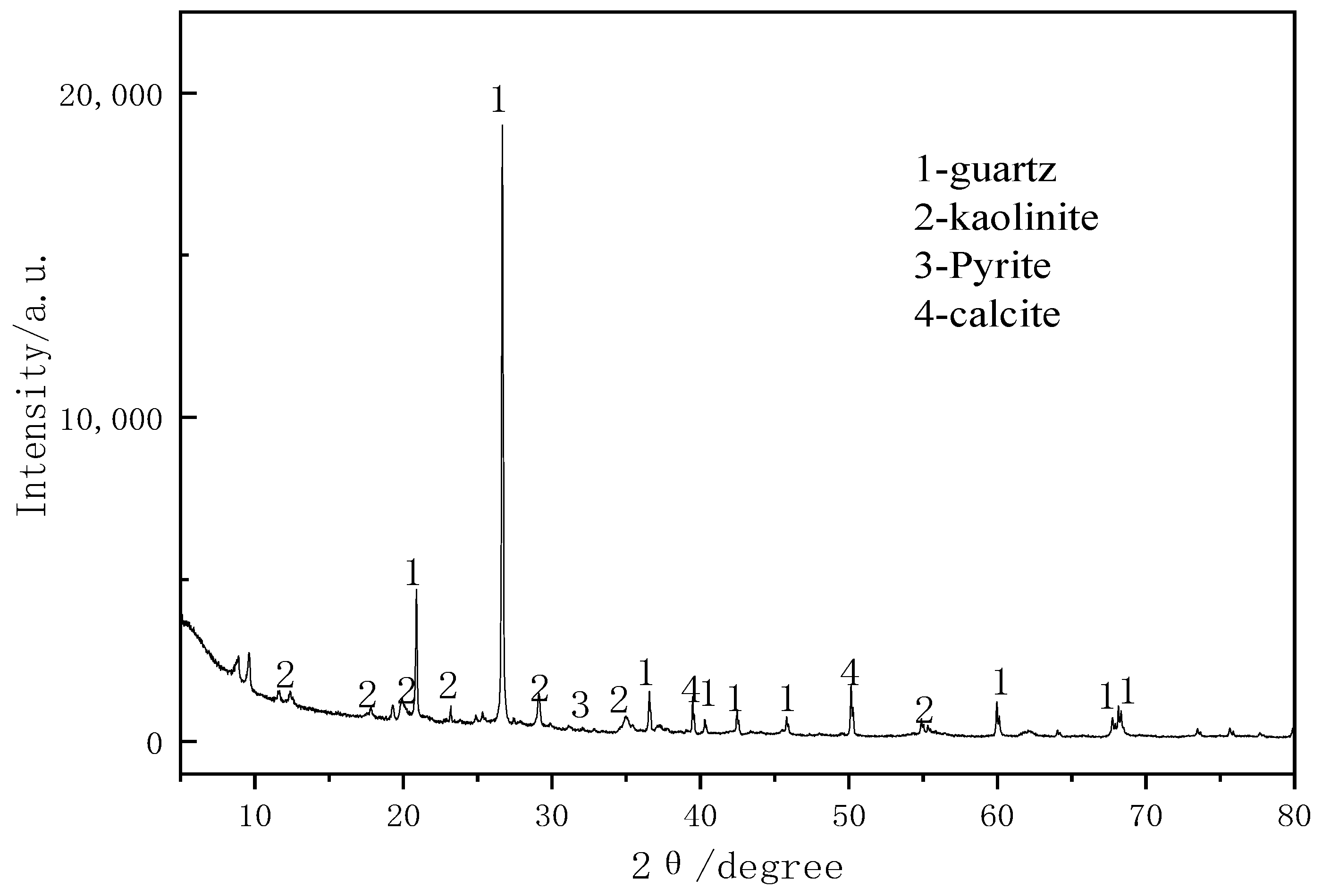

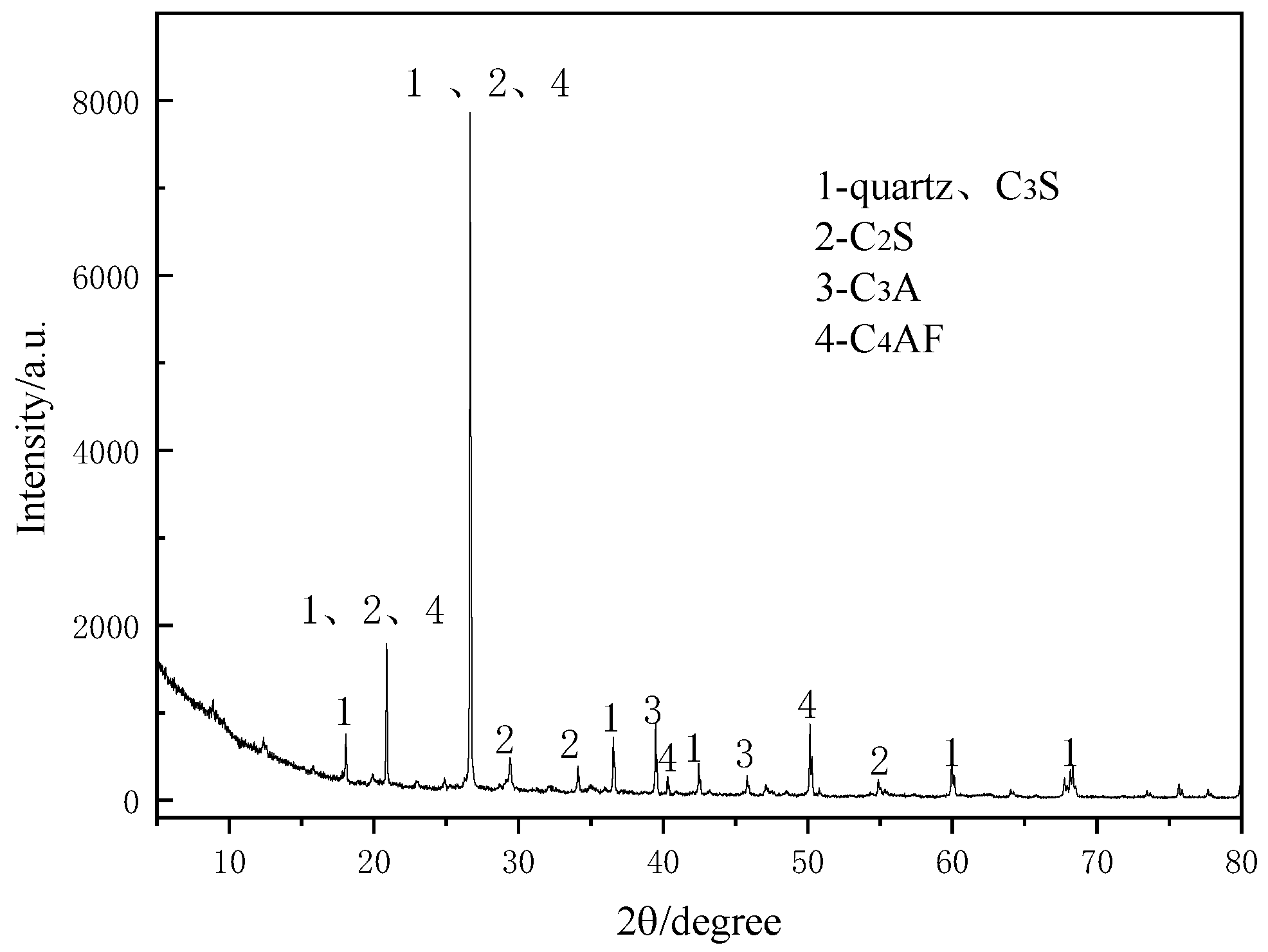

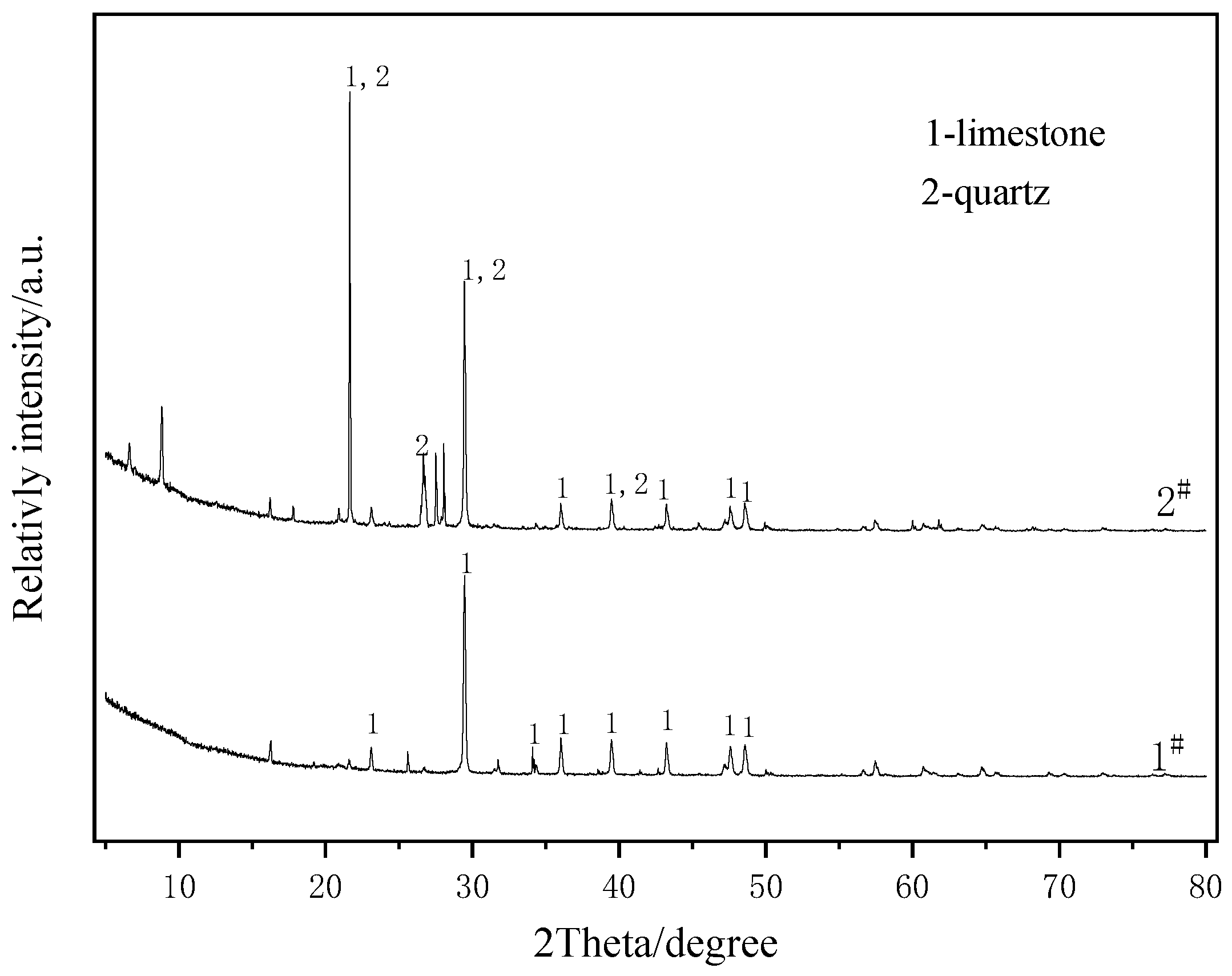

3.1.1. XRD Analysis of Gangue

3.1.2. SEM Analysis of Gangue

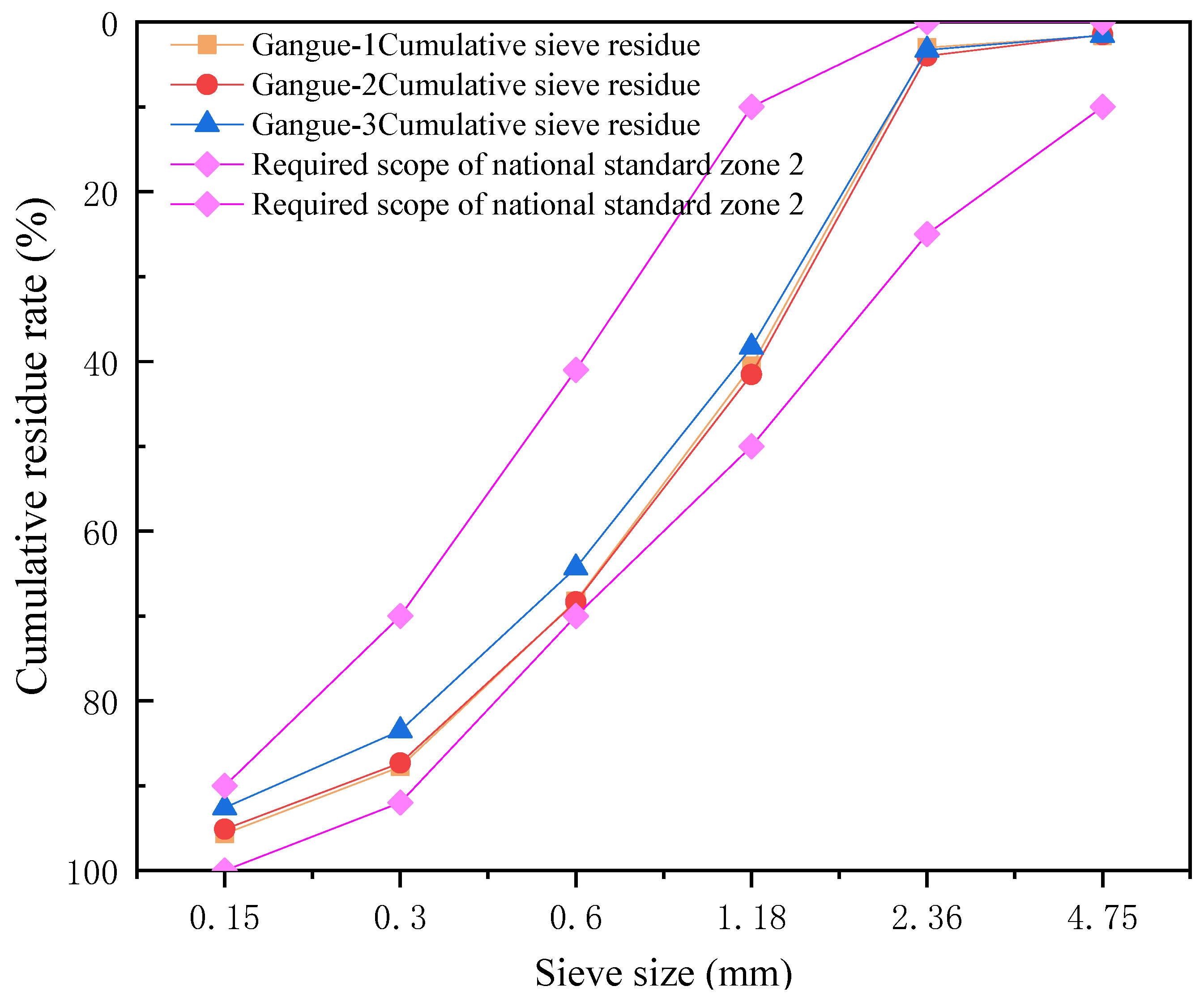

3.2. Performance Effect of Particle Size-Level Paired Dry-Mixed Mortar

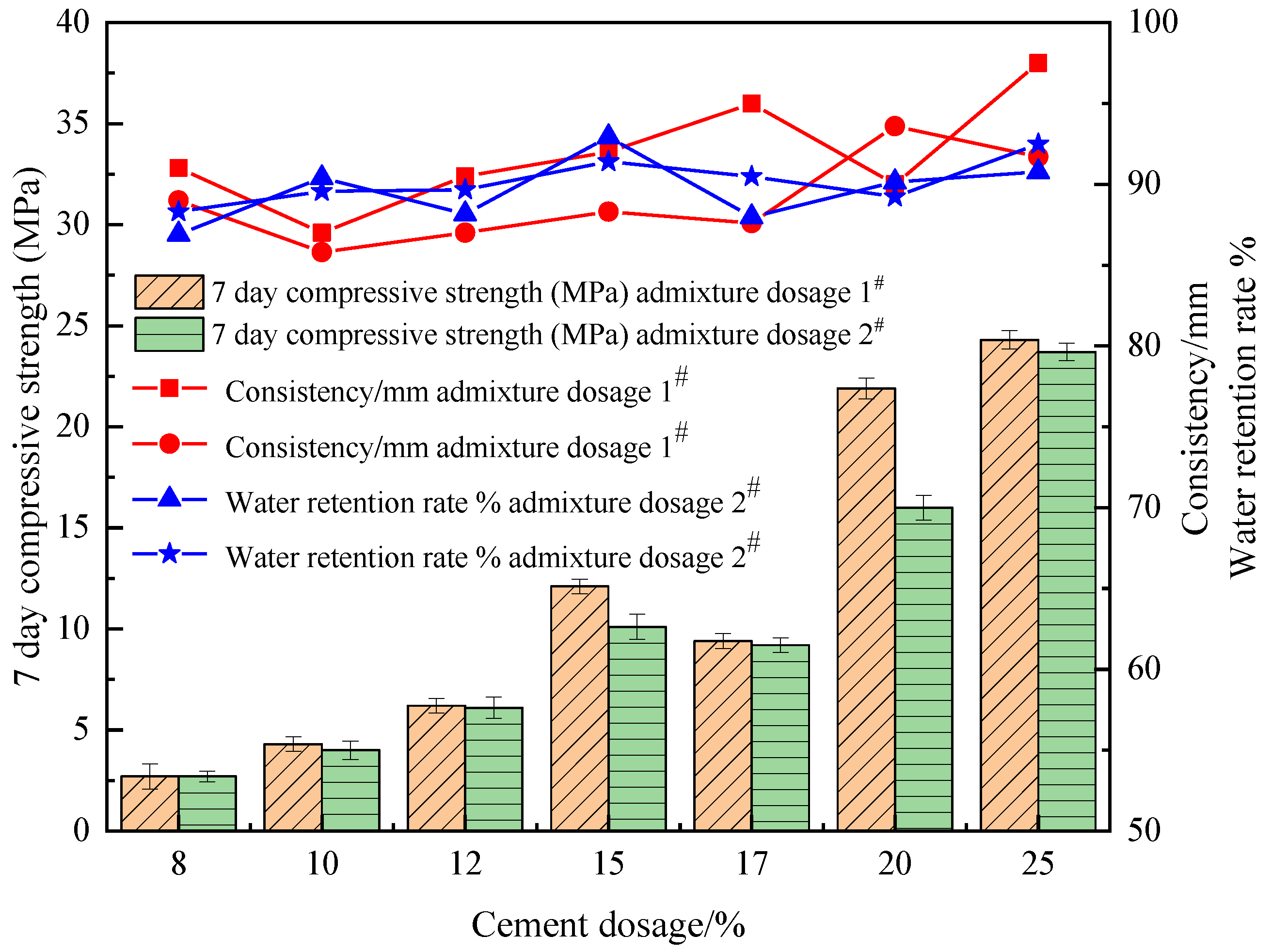

3.3. Analysis of the Effect of Cement Mixing on the Performance of Dry-Mix Mortar

3.4. Analysis of the Effect of Admixture Dosage on the Performance of Dry-Mixed Mortar

3.5. Analysis of the Effect of Water Addition on the Performance of Dry-Mixed Mortar

3.6. Characterization of Dry-Mixed Mortar Samples

3.6.1. XRD Analysis of Dry-Mixed Mortar

3.6.2. SEM Analysis of Dry-Mixed Mortar

3.7. Analysis of the Strengthening Mechanism of Additives

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.L.; He, H.; He, F.X. Effect of slaked lime and aluminum sulfate on the properties of dry-mixed masonry mortar. J. Constr. Build. Mater. 2018, 180, 117–123. [Google Scholar] [CrossRef]

- Yang, S.Y.; Zhao, J.; Chang, S.X.; Collins, C.; Xu, J.M.; Liu, X.M. Status assessment and probabilistic health risk modeling of metals accumulation in agriculture soils across China: A synthesis. Environ. Int. 2019, 128, 165–174. [Google Scholar] [CrossRef] [PubMed]

- Xie, M.Z.; Liu, F.Q.; Zhao, H.L.; Ke, C.Y.; Xu, Z.Q. Mineral phase transformation in coal gangue by high temperature calcination and high-efficiency separation of alumina and silica minerals. J. Mater. Res. Technol. 2021, 14, 2281–2288. [Google Scholar] [CrossRef]

- Liu, Y.X.; Ling, T.C.; Wang, M.; Wu, Y.Y. Synergic performance of low-kaolinite calcined coal gangue blended with limestone in cement mortars. Constr. Build. Mater. 2021, 300, 124012. [Google Scholar] [CrossRef]

- Qin, L.; Gao, X.J.; Su, A.S.; Li, Q.Y. Effect of carbonation curing on sulfate resistance of cement-coal gangue paste. J. Clean. Prod. 2021, 278, 123897. [Google Scholar] [CrossRef]

- Han, R.C.; Guo, X.N.; Guan, J.F.; Yao, X.H.; Hao, Y. Activation Mechanism of Coal Gangue and Its Impact on the Properties of Geopolymers: A Review. Polymers 2022, 14, 3861. [Google Scholar] [CrossRef]

- Lv, B.; Zhao, Z.Y.; Deng, X.W.; Fang, C.J.; Dong, B.B.; Zhang, B. Sustainable and clean utilization of coal gangue: Activation and preparation of silicon fertilizer. J. Mater. Cycles Waste Manag. 2022, 24, 1579–1590. [Google Scholar] [CrossRef]

- Liu, H.Q.; Xu, Q.; Wang, Q.H.; Zhang, Y.Z. Prediction of the elastic modulus of concrete with spontaneous-combustion and rock coal gangue aggregates. J. Struct. 2020, 28, 774–785. [Google Scholar] [CrossRef]

- Yao, Z.S.; Fang, Y.; Kong, W.H.; Huang, X.W.; Wang, X.S. Experimental Study on Dynamic Mechanical Properties of Coal Gangue Concrete. J. Adv. Mater. Sci. Eng. 2020, 2020, 1–16. [Google Scholar] [CrossRef]

- Zhang, Q.S. Performance analysis of coal gangue grinding fine ash and its application in concrete. J. China Build. Mater. Sci. Technol. 2020, 29, 82–83. [Google Scholar] [CrossRef]

- Chen, Q.; Jia, Q.; Wang, Z.J.; Dong, J.X.; Shi, T.J. Research Progress on Mechanical Properties and Durability of Different Lightweight Aggregate Concrete. J. Res. Appli. Build. Mater. 2021, 4, 32–35. [Google Scholar]

- Wang, X.; Zhang, J.X.; Li, M.; Huo, B.B.; Jin, L. Experimental Study on Performance Optimization of Grouting Backfill Material Based on Mechanically Ground Coal Gangue Utilizing Urea and Quicklime. J. Mater. 2023, 16, 1097. [Google Scholar] [CrossRef] [PubMed]

- Qiu, J.S.; Zhou, Y.X.; Guan, X.; Zhu, M.Y. The influence of fly ash content on ITZ microstructure of coal gangue concrete. J. Constr. Build. Mater. 2021, 298, 123562. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, G.H.; Guo, L.H.; Zhou, L.Q.; Yuan, K.K. Utilization of coal gangue as coarse aggregates in structural concrete. J. Constr. Build. Mater. 2021, 268, 121212. [Google Scholar] [CrossRef]

- Yang, S.Q.; Lu, J.X.; Poon, C.S. Recycling of waste glass in dry-mixed concrete blocks: Evaluation of alkali-silica reaction (ASR) by accelerated laboratory tests and long-term field monitoring. J. Constr. Build. Mater. 2020, 262, 120865. [Google Scholar] [CrossRef]

- Hu, Z.W.; Kong, Z.; Cai, G.S.; Li, Q.Y.; Guo, Y.X.; Su, D.L.; Liu, J.Z.; Zheng, S.D. Study of the Properties of Full Component Recycled Dry-Mixed Masonry Mortar and Concrete Prepared from Construction Solid Waste. Sustainability 2021, 13, 8385. [Google Scholar] [CrossRef]

- Qiu, J.S.; Zhu, M.Y.; Zhou, Y.X.; Guan, X. Effect and mechanism of coal gangue concrete modification by fly ash. Constr. Build. Mater. 2021, 294, 123563. [Google Scholar] [CrossRef]

- Jing, L.; Yin, S.P.; Farhad, A. Textile-Reinforced Mortar Strengthening of Masonry Piers Containing Industrial Waste Coal Gangue Sintered Bricks. J. Compos. Constr. 2022, 26, 04022013. [Google Scholar] [CrossRef]

- Jin, J.X.; Qin, Z.F.; Lü, X.L.; Liu, T.; Zhang, G.S.; Shi, J.Y.; Zuo, S.H.; Li, D.Q. Rheology control of self-consolidating cement-tailings grout for the feasible use in coal gangue-filled backfill. Constr. Build. Mater. 2022, 316, 125836. [Google Scholar] [CrossRef]

- Huang, M.; Duan, J.M.; Wang, J.K. Research on Basic Mechanical Properties and Fracture Damage of Coal Gangue Concrete Subjected to Freeze-Thaw Cycles. J. Adv. Mater. Sci. Eng. 2021, 2021. [Google Scholar] [CrossRef]

- Marija, N.; Akis, M.; Virginie, W.; Erik, S.; Jeanette, V. Influence of sand drying and mixing sequence on the performance of mortars with fine recycled concrete aggregates. J. Constr. Build. Mater. 2022, 315, 125750. [Google Scholar]

- Lin, R.-S.; Lee, H.-S.; Han, Y.; Wang, X.-Y. Experimental studies on hydration–strength–durability of limestone-cement-calcined Hwangtoh clay ternary composite. J. Constr. Build. Mater. 2021, 269, 121290. [Google Scholar] [CrossRef]

- Miao, M.; Xue, K.W.; Miao, F.; Jiang, H.W. Influence of Limestone Powder on Hydration Characteristics and Rheological Properties of Cement Paste. J. Hunan Univer. (Nat. Sci. Ed.) 2018, 45, 90–96. [Google Scholar]

- Wang, C.J.S.D.H.; Jia, H.F.; Liu, J.H. Role of Limestone Powder and Its Effect on Durability of Cement-Based Materials. J. Am. Ceram. Soc. 2017, 45, 1582–1593. [Google Scholar]

- Xiao, Z.M.; Guo, J.P. Inhibiting effect of admixture on shrinkage of flexural strength of sulphoaluminate cement and its mechanism. Cement 2017, 44, 10–13. [Google Scholar]

- Hargis, C.W.; Telesca, A.; Monteiro, P.J.M. Calcium sulfoaluminate (Ye’elimite) hydration in the presence of gypsum, calcite, and vaterite. J. Cem. Concr. Compos. 2014, 65, 15–20. [Google Scholar] [CrossRef]

- Liu, J.H.; Li, K.; Song, S.M.; Bian, L.B. Influence of Gypsum on Hydration and Hardening Performance of Limestone Powder in Cement Based Material. J. Mater. Rev. 2017, 31, 105–110+125. [Google Scholar]

- Song, F.; Lü, Y.N.; Yu, W.M.; Liu, Y.F.; Liang, X.S.; Liu, H.; Zhao, H.W. Mechanism of Calcium Carbonate Improving Mechanical Properties of Low Calcium Cement. J. Non-Met. Mines. 2021, 44, 5–8. [Google Scholar]

| Number | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | SO3 | P2O5 |

| GS | 47.46 | 26.19 | 1.24 | 0.08 | 0.69 | 1.90 | 0.25 | 0.40 | 0.05 |

| number | TiO2 | NiO | CuO | ZrO2 | SrO | Cr2O3 | CeO2 | I.L | Σ |

| GS | 1.09 | 0.01 | 0.01 | 0.03 | 0.01 | 0.03 | 0.03 | 20.52 | 99.99 |

| Cement | Standard Consistency% | Condensation Time/Min | Flexural Strength/MPa | Compressive Strength/MPa | |||

|---|---|---|---|---|---|---|---|

| Initial Condensation | Final Condensation | 3d | 28d | 3d | 28d | ||

| P·O42.5 | 27.4 | 186 | 230 | 6.1 | 8.6 | 26.4 | 49.6 |

| Cement | SiO2 | CaO | Al2O3 | Fe2O3 | MgO | SO3 | R2O | Loss |

|---|---|---|---|---|---|---|---|---|

| P·O42.5 | 23.45 | 60.24 | 5.37 | 2.81 | 2.56 | 2.86 | 0.37 | 2.34 |

| Coal Gangue (%) | Cement (%) | Admixture 1# (g/kg) | Admixture 2# (g/kg) | Water (mL/kg) |

|---|---|---|---|---|

| 92 | 8 | 0.045 | - | 185 |

| 90 | 10 | 0.045 | - | 185 |

| 88 | 12 | 0.045 | - | 185 |

| 85 | 15 | 0.045 | - | 185 |

| 83 | 17 | 0.045 | - | 185 |

| 80 | 20 | 0.045 | - | 185 |

| 75 | 25 | 0.045 | - | 185 |

| 92 | 8 | - | 0.045 | 185 |

| 90 | 10 | - | 0.045 | 185 |

| 88 | 12 | - | 0.045 | 185 |

| 85 | 15 | - | 0.045 | 185 |

| 83 | 17 | - | 0.045 | 185 |

| 80 | 20 | - | 0.045 | 185 |

| 75 | 25 | - | 0.045 | 185 |

| Coal Gangue (%) | Cement (%) | Admixture 1# (g/kg) | Water (mL/kg) |

|---|---|---|---|

| 83 | 17 | 0 | 185 |

| 83 | 17 | 0.045 | 185 |

| 83 | 17 | 0.1 | 185 |

| 83 | 17 | 0.2 | 185 |

| 83 | 17 | 0.3 | 185 |

| 83 | 17 | 0.4 | 185 |

| 83 | 17 | 0.45 | 185 |

| Coal Gangue (%) | Cement (%) | Admixture 1#(g/kg) | Water (mL/kg) |

|---|---|---|---|

| 83 | 17 | 0.2 | 185 |

| 83 | 17 | 0.2 | 188 |

| 83 | 17 | 0.2 | 191 |

| 83 | 17 | 0.2 | 194 |

| 83 | 17 | 0.2 | 197 |

| 83 | 17 | 0.2 | 200 |

| mm | 0.15 | 0.3 | 0.6 | 1.18 | 2.36 | 4.75 | Granularity Series | Configure Mortar Intensity Level | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Cumulative Residue Ratio (%) | ||||||||||

| No. | ||||||||||

| Gangue-1 | 95.67 | 87.79 | 68.22 | 40.54 | 3.01 | 1.60 | 2.95 | M7.5 | ||

| Gangue-2 | 95.12 | 87.31 | 68.33 | 41.55 | 3.98 | 1.50 | 2.96 | M7.5 | ||

| Gangue-3 | 92.58 | 83.49 | 64.33 | 38.33 | 3.29 | 1.57 | 2.86 | M7.5 | ||

| National Standard Zone 2 Requirements Scope | 90~100 | 70~92 | 41~70 | 10~50 | 0~25 | 0~10 | medium sand 3.0~2.3 | / | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Zhu, H.; Zhang, S.; Wu, H.; Cong, J.; Luo, Y. Experimental Study on Preparation of Dry-Mixed Mortar from Coal Gangue. Coatings 2023, 13, 518. https://doi.org/10.3390/coatings13030518

Cheng Y, Zhu H, Zhang S, Wu H, Cong J, Luo Y. Experimental Study on Preparation of Dry-Mixed Mortar from Coal Gangue. Coatings. 2023; 13(3):518. https://doi.org/10.3390/coatings13030518

Chicago/Turabian StyleCheng, Yue, Haijie Zhu, Shengjun Zhang, Huiyong Wu, Junjun Cong, and Yuqing Luo. 2023. "Experimental Study on Preparation of Dry-Mixed Mortar from Coal Gangue" Coatings 13, no. 3: 518. https://doi.org/10.3390/coatings13030518

APA StyleCheng, Y., Zhu, H., Zhang, S., Wu, H., Cong, J., & Luo, Y. (2023). Experimental Study on Preparation of Dry-Mixed Mortar from Coal Gangue. Coatings, 13(3), 518. https://doi.org/10.3390/coatings13030518