Mathematical Model for Early-Aged UHPFRC Compressive Strength Changes

Abstract

:1. Introduction

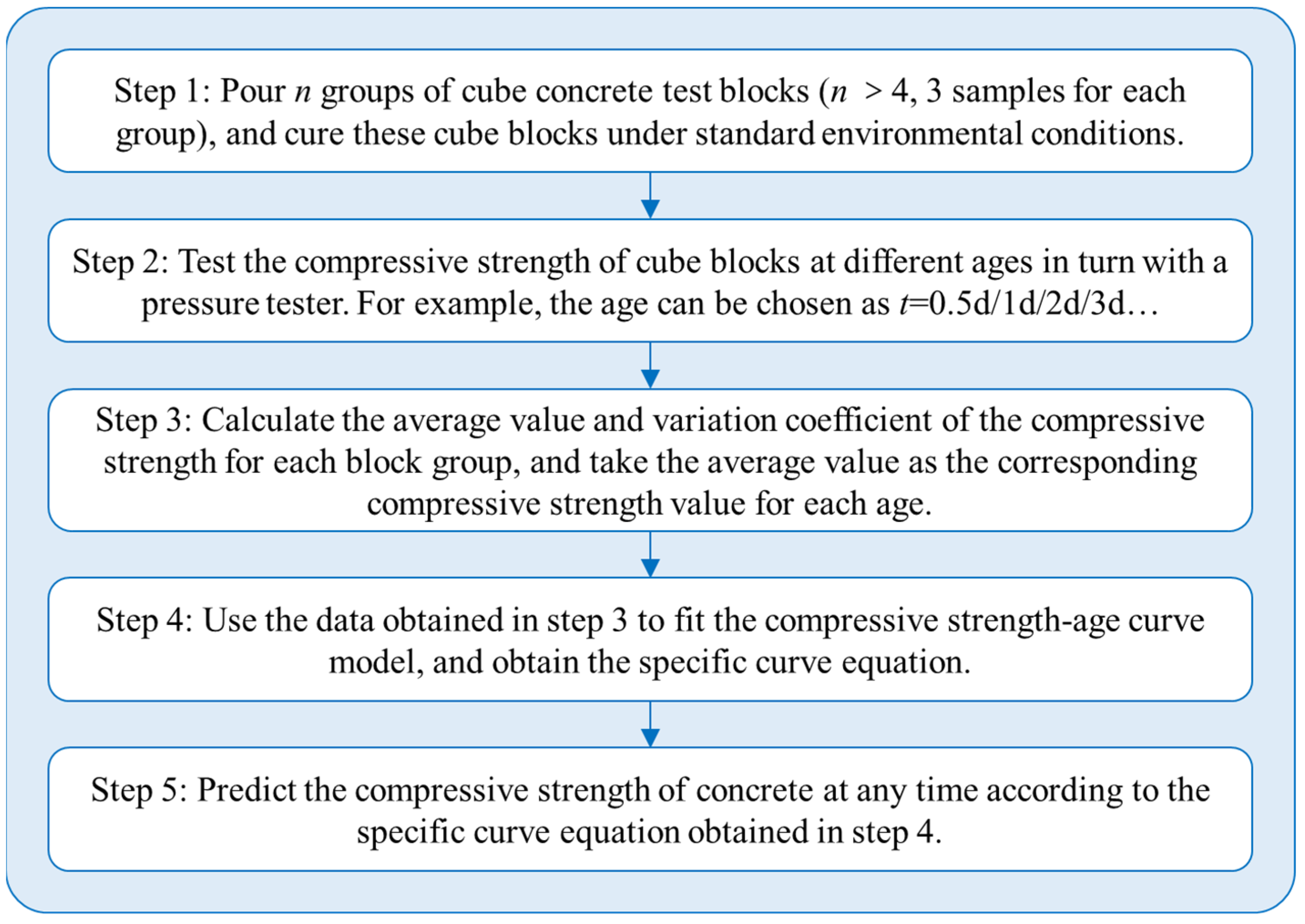

2. Compressive Strength-Time Mathematical Models

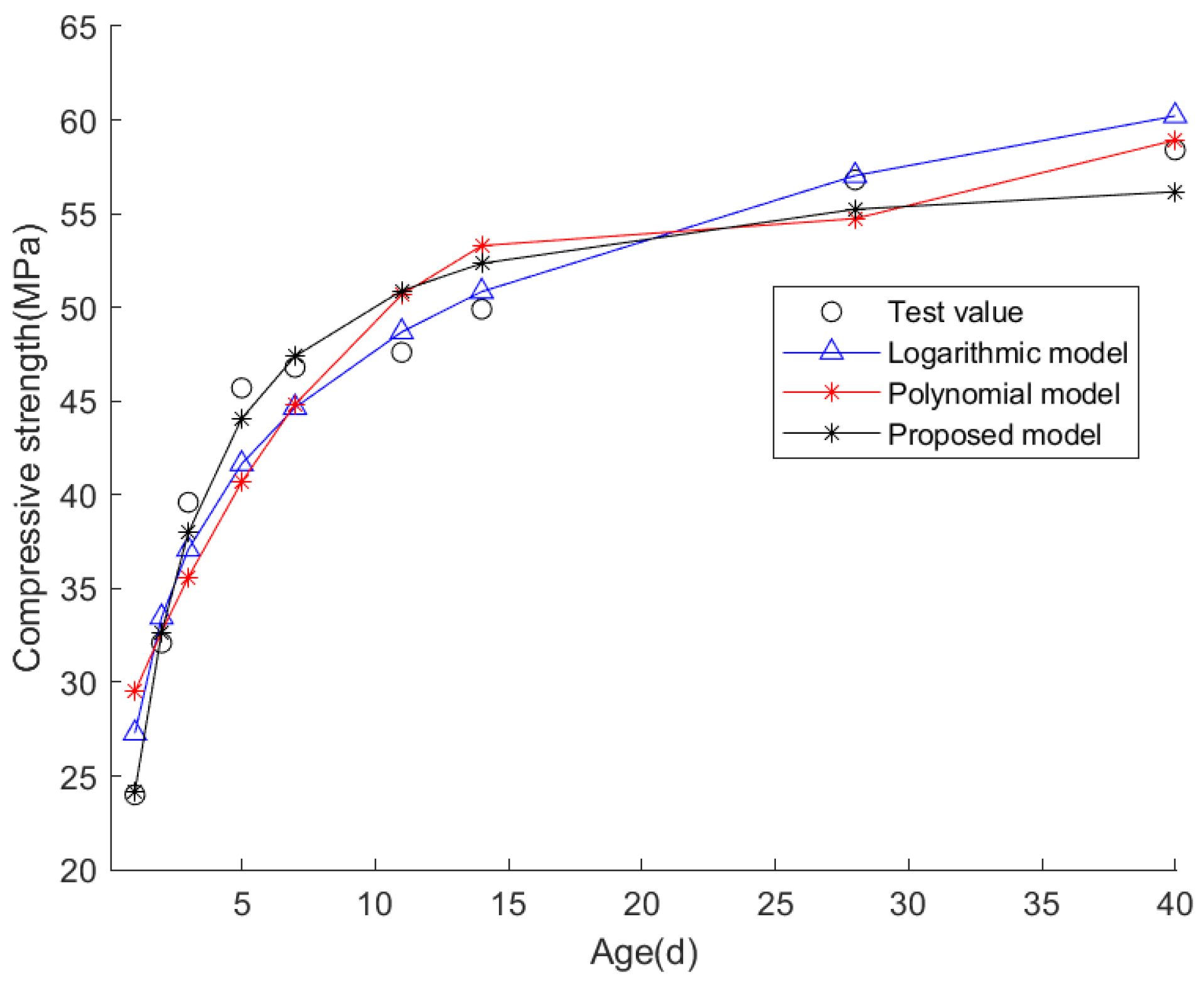

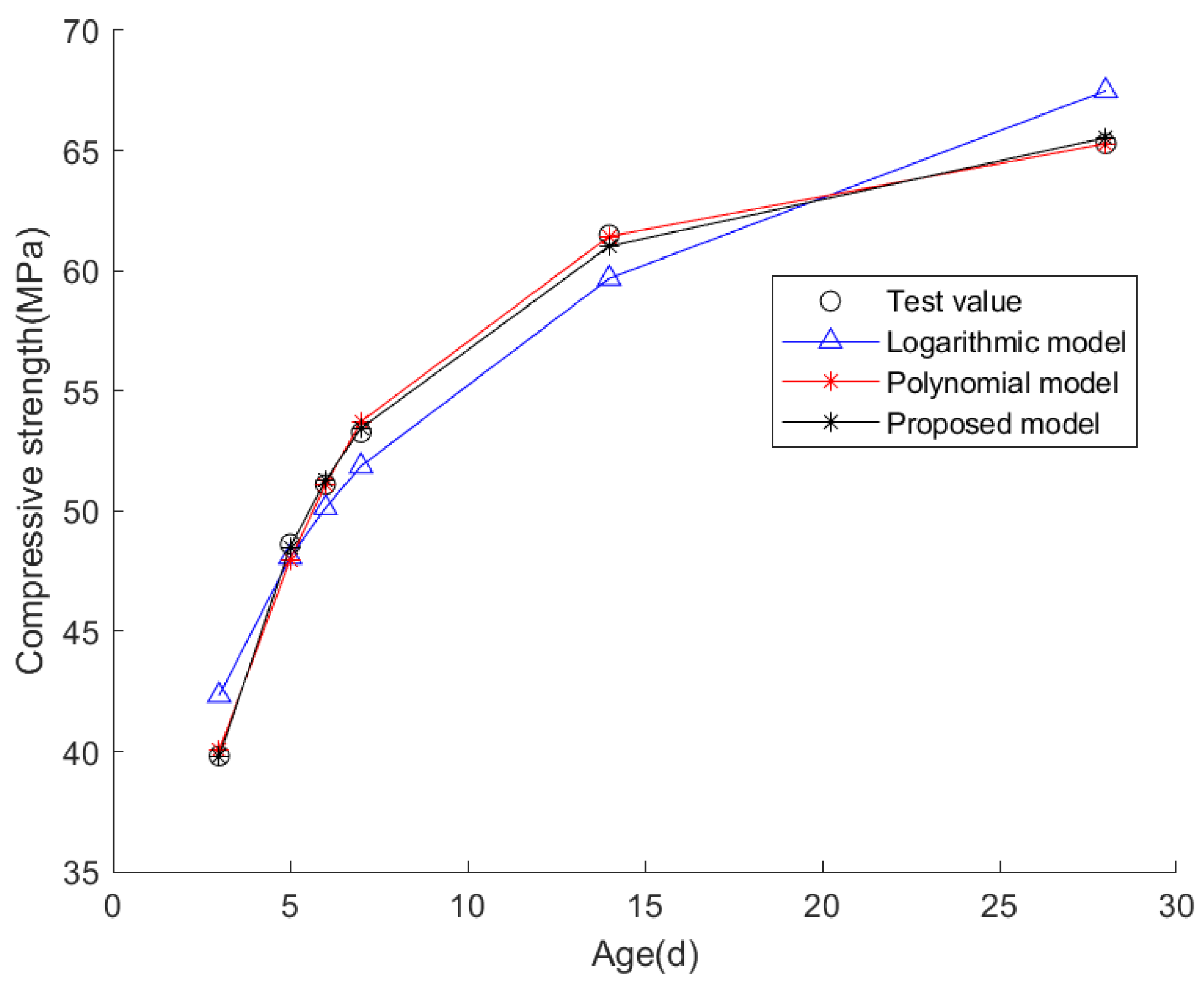

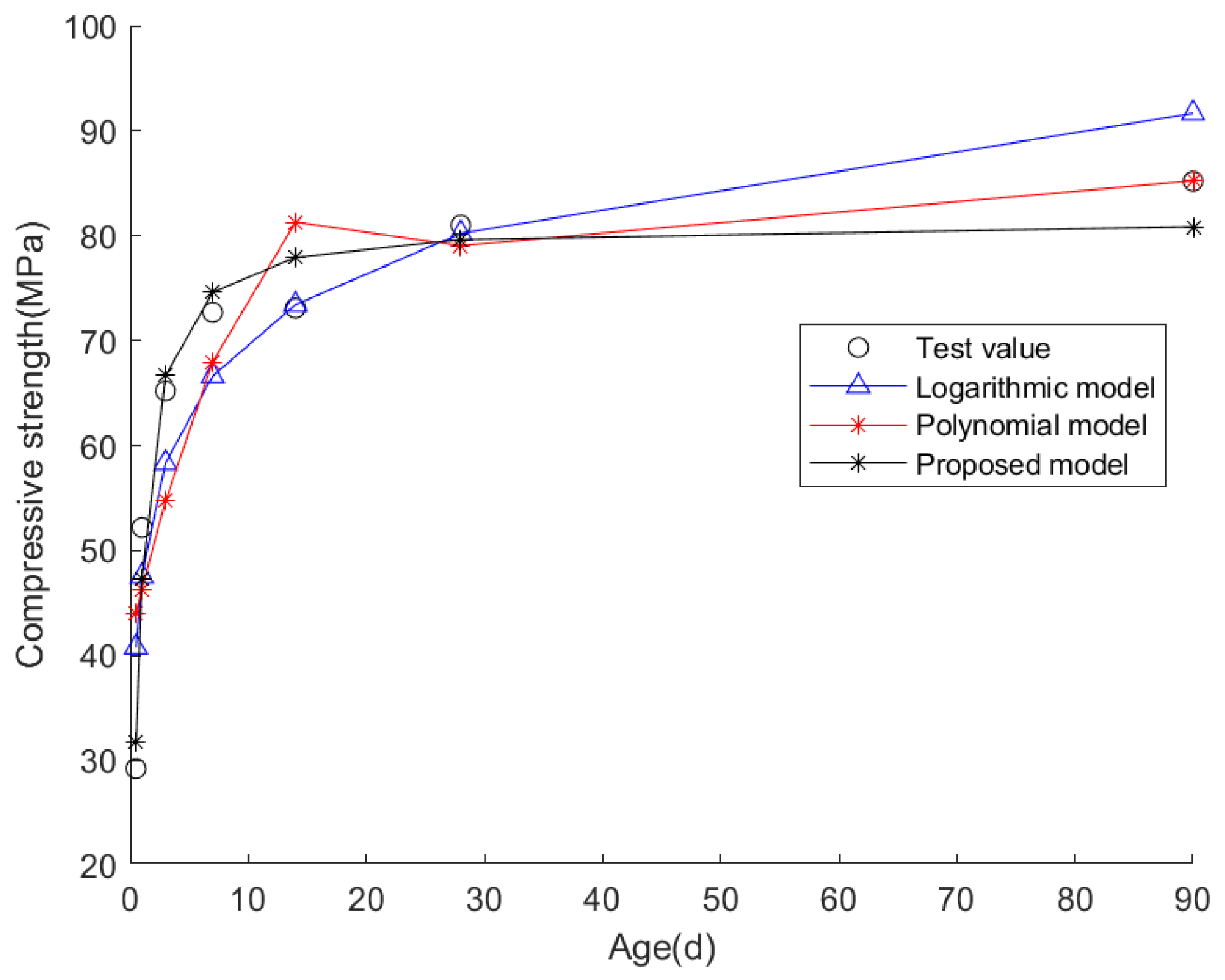

3. Model Verification and Comparison by the Test Data Compiled from Previous Literature

4. UHPFRC Experimental Validation

5. Conclusions

- (1)

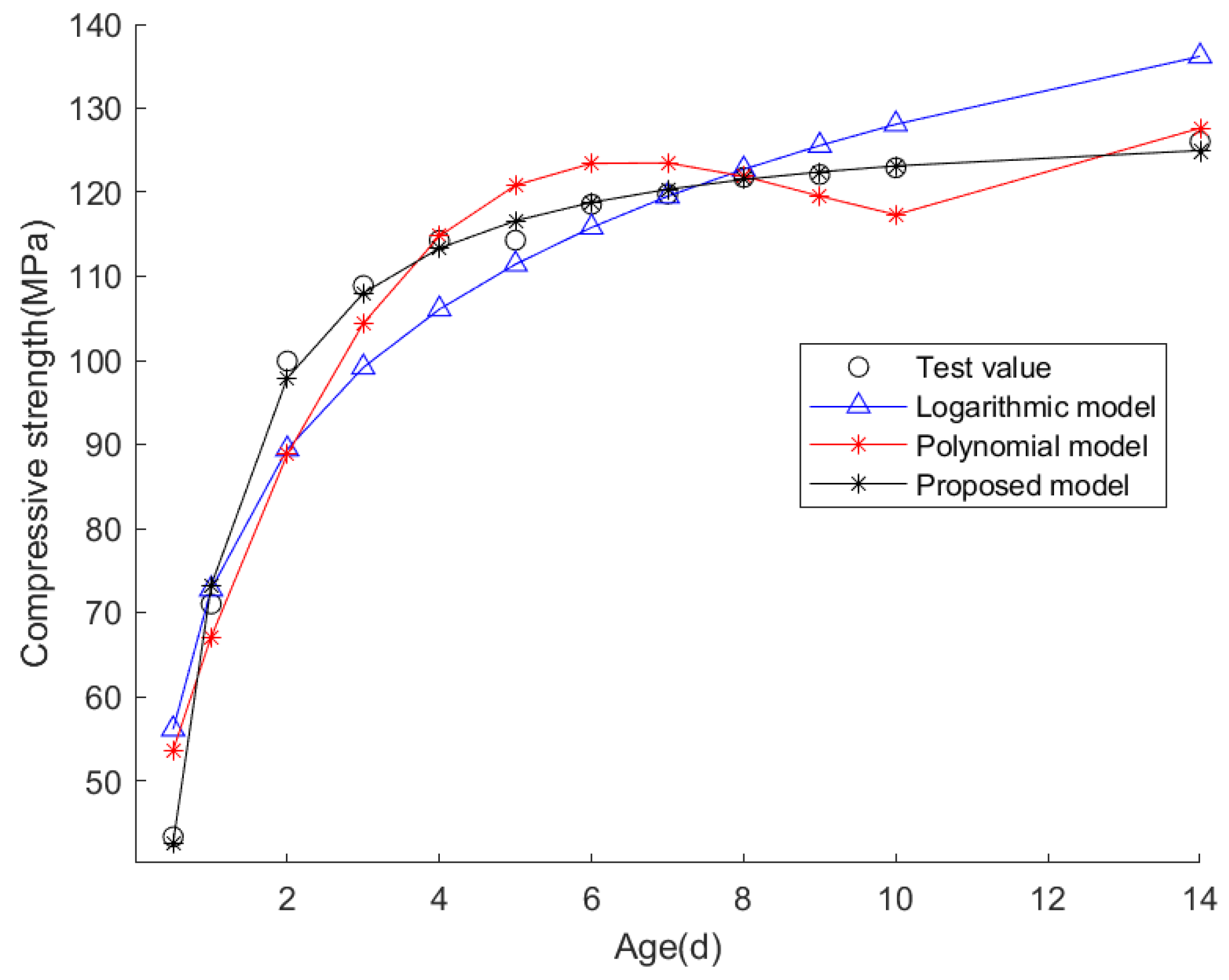

- The existing compression strength–time curve models are not ideal in terms of fitting accuracy or prediction accuracy. The proposed new model can well describe the characteristics of compressive strength increases with time at the early age stage. From the comparison results, it was found that the new model is more accurate and reliable than the logarithmic model and the polynomial model;

- (2)

- From the UHPFRC experiment, it can be seen that the compressive strength of UHPFRC increases very rapidly at the ultra-early age stage, and the compressive strength was very close to that of the strength design grade on about the 7th day. After the 7th day, the compressive strength of UHPFRC increases slowly and gradually maintains a stable value;

- (3)

- Based on the UHPFRC experimental data, it has been shown that the average fitting error and standard deviation of the new model are about 10%~20% of the logarithmic model and the polynomial model. The proposed model has the largest R2 of 0.9974 and the smallest RMSE of 1.2304. The 60-day compressive strength predicted by the proposed model (i.e., 128.36 MPa) is closest to the strength design grade of UHPFRC (i.e., 120 MPa).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Q.W.; Sun, Y.; Peng, X. Experimental study on mechanical properties of concrete at super-early age. Materials 2022, 15, 7582. [Google Scholar] [CrossRef]

- Yang, Q.W.; Peng, X.; Sun, Y. Shear capacity evaluation of the recycled concrete beam. Materials 2022, 15, 3693. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.W.; Ba, Z.; Zhao, Z.; Peng, X.; Sun, Y. Stability evaluation method of hole wall for bored pile under blasting impact. Symmetry 2022, 14, 79. [Google Scholar] [CrossRef]

- Peng, X.; Yang, Q. Damage detection in beam-like structures using static shear energy redistribution. Front. Struct. Civ. Eng. 2023, 16, 1552–1564. [Google Scholar] [CrossRef]

- Yang, S.L.; Millard, S.G.; Soutsos, M.N.; Barnett, S.; Le, T. Influence of aggregate and curing regime on the mechanical properties of ultra-high performance fibre reinforced concrete (UHPFRC). Constr. Build. Mater. 2009, 23, 2291–2298. [Google Scholar] [CrossRef]

- Kwon, S.; Nishiwaki, T.; Kikuta, T.; Mihashi, H. Development of ultra-high-performance hybrid fiber-reinforced cement-based composites. ACI Mater. J. 2014, 111, 309. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Yeh, I.C. Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Bui, D.-K.; Nguyen, T.; Chou, J.S.; Nguyen-Xuan, H.; Ngo, T. A modified firefly algorithm-artificial neural network expert system for predicting compressive and tensile strength of high-performance concrete. Constr. Build. Mater. 2018, 180, 320–333. [Google Scholar] [CrossRef]

- Han, Q.; Gui, C.; Xu, J.; Lacidogna, G. A generalized method to predict the compressive strength of high-performance concrete by improved random forest algorithm. Constr. Build. Mater. 2019, 226, 734–742. [Google Scholar] [CrossRef]

- Anyaoha, U.; Zaji, A.; Liu, Z. Soft computing in estimating the compressive strength for high-performance concrete via concrete composition appraisal. Constr. Build. Mater. 2020, 257, 119472. [Google Scholar] [CrossRef]

- Hameed, M.M.; AlOmar, M.K.; Baniya, W.J.; AlSaadi, M.A. Incorporation of artificial neural network with principal component analysis and cross-validation technique to predict high-performance concrete compressive strength. Asian J. Civ. Eng. 2021, 22, 1019–1031. [Google Scholar] [CrossRef]

- Emad, W.; Mohammed, A.S.; Kurda, R.; Ghafor, K.; Cavaleri, L.; Qaidi, S.M.A.; Hassan, A.; Asteris, P.G. Prediction of concrete materials compressive strength using surrogate models. Structures 2022, 46, 1243–1267. [Google Scholar] [CrossRef]

- Ali, R.; Muayad, M.; Mohammed, A.S.; Asteris, P.G. Analysis and prediction of the effect of Nanosilica on the compressive strength of concrete with different mix proportions and specimen sizes using various numerical approaches. Struct. Concr. 2022, 12. [Google Scholar] [CrossRef]

- Ibrahim, A.K.; Dhahir, H.Y.; Mohammed, A.S.; Omar, H.A.; Sedo, A.H. The effectiveness of surrogate models in predicting the long-term behavior of varying compressive strength ranges of recycled concrete aggregate for a variety of shapes and sizes of specimens. Arch. Civ. Mech. Eng. 2023, 23, 61. [Google Scholar] [CrossRef]

- Mohammed, A.S.; Emad, W.; Sarwar Qadir, W.; Kurda, R.; Ghafor, K.; Kadhim Faris, R. Modeling the impact of liquid polymers on concrete stability in terms of a slump and compressive strength. Appl. Sci. 2023, 13, 1208. [Google Scholar] [CrossRef]

- Moradi, N.; Tavana, M.H.; Habibi, M.R.; Amiri, M.; Moradi, M.J.; Farhangi, V. Predicting the compressive strength of concrete containing binary supplementary cementitious material using machine learning approach. Materials 2022, 15, 5336. [Google Scholar] [CrossRef] [PubMed]

- Rezvan, S.; Moradi, M.J.; Dabiri, H.; Daneshvar, K.; Karakouzian, M.; Farhangi, V. Application of machine learning to predict the mechanical characteristics of concrete containing recycled plastic-based materials. Appl. Sci. 2023, 13, 2033. [Google Scholar] [CrossRef]

- Imran, M.; Khushnood, R.A.; Fawad, M. A Hybrid data-driven and metaheuristic optimization approach for the compressive strength prediction of high-performance concrete. Case Stud. Constr. Mater. 2023, 18, e01890. [Google Scholar] [CrossRef]

- Li, Z.J.; Song, Y.H.; Li, S.H. Prediction of metakaolin high-performance concrete compressive strength. Bull. Chin. Ceram. Soc. 2017, 36, 2963–2968. [Google Scholar]

- Zhang, J.L.; Liu, X.; Zhu, H.B.; Li, C.; Yuan, Y. Model for predicting the mechanical behavior of UHPC based on BP neural network. Concrete 2013, 281, 18–25. [Google Scholar]

- Chen, Q.; Ma, R.; Jiang, Z.W.; Wang, H. Compressive Strength Prediction and Mix Proportion Design of UHPC Based on GA-BP Neural Network. J. Build. Mater. 2020, 23, 176–183. [Google Scholar]

- Zhang, J.; Zhao, Y. Prediction of compressive strength of ultra-high performance concrete (UHPC) containing supplementary cementitious materials. In Proceedings of the 2017 International Conference on Dmart Grid and Electrical Automation (ICSGEA), Changsha, China, 27–28 May 2017; pp. 522–525. [Google Scholar]

- Abuodeh, O.R.; Abdalla, J.A.; Hawileh, R.A. Assessment of compressive strength of Ultra-high Performance Concrete using deep machine learning techniques. Appl. Soft Comput. 2020, 95, 106552. [Google Scholar] [CrossRef]

- Wu, X.G.; Liu, P.C.; Chen, H.Y.; Zeng, T.M.; Xu, W. Characteristic screening and prediction of high-performance concrete compressive strength based on random forest method. Concrete 2022, 387, 17–24. [Google Scholar]

- Roberson, M.M.; Inman, K.M.; Carey, A.S.; Howard, I.L.; Shannon, J. Probabilistic neural networks that predict compressive strength of high strength concrete in mass placements using thermal history. Comput. Struct. 2022, 259, 106707. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, F.Y. Strength development and evaluation of high-strength concrete at early age. China Concr. Cem. Prod. 2004, 137, 1–4. [Google Scholar]

- Zhao, S.B.; Zhao, Y.J.; Chen, J.H.; Liu, S.; Sun, Y.P. Application and study on time-dependent compressive strength and elastic modulus of C50 pumping concrete. Concrete 2015, 303, 98–101. [Google Scholar]

- Yang, W.J.; Wang, Y. Diachronic variation model of compressive strength and elastic modulus of concrete at early age. J. China Foreign Highw. 2007, 27, 149–151. [Google Scholar]

- Wang, M.L.; Wang, X.A. Study on strength development law of high strength concrete at early age in high altitude environment. Build. Struct. 2021, 51, 1311–1315. [Google Scholar]

- Zhao, Z. Proportion design and stregth regularity of high strength concrete. Concrete 2011, 264, 101–103. [Google Scholar]

- Li, X.F.; Ma, W.L.; Pei, S.W.; Sun, S.N. Experimental study on compressive strength of commercial concrete at early age. J. Zhongyuan Inst. Technol. 2006, 17, 59–61. [Google Scholar]

- Li, X.Z.; Han, L.J.; Liu, M.Q. Analysis of early aging prediction method of strength state of high-performance concrete. Shanxi Archit. 2007, 33, 167–168. [Google Scholar]

- Jin, X.Y.; Shen, Y.; Li, Z.J. Experimental study on early aging characteristics of high-strength concrete. China Concr. Cem. Prod. 2003, 133, 5–7. [Google Scholar]

- Ling, J.J. Compressive strength and nonlinear prediction model of high-grade basalt manufactured sand concrete. J. Water Resour. Archit. Eng. 2021, 19, 124–130. [Google Scholar]

- Jia, M.; Han, Z.B. Analysis of compressive test of silicate concrete based on bridge estimation. J. North China Univ. Sci. Technol. (Nat. Sci. Ed.) 2019, 41, 84–89. [Google Scholar]

- Wang, D.Y.; Wang, M.M.; Yang, Z.K.; Wu, Y.G.; Yuan, Q.; Liao, J. Study on mechanical properties of C80 concrete at different ages. Ind. Constr. 2014, 44, 106–111. [Google Scholar]

- Ministry of Construction of China. Test Method Standard for Mechanical Properties of Common Concrete: GB/T 50081-2002 [M]; China Construction Industry Press: Beiging, China, 2003. (In Chinese) [Google Scholar]

| Index | Logarithmic Model | Polynomial Model | Proposed Model |

|---|---|---|---|

| Mean fitting error | 0.1907 | 0.2950 | 0.1133 |

| Fitted standard deviation of error | 0.0410 | 0.0670 | 0.0194 |

| R2 | 0.9541 | 0.8976 | 0.9694 |

| RMSE | 2.2453 | 3.3528 | 1.8317 |

| Predicted day 60 compressive strength | 63.83 MPa | 127.39 MPa | 56.91 MPa |

| Index | Logarithmic Model | Polynomial Model | Proposed Model |

|---|---|---|---|

| Mean fitting error | 0.0847 | 0.0170 | 0.0101 |

| Fitted standard deviation of error | 0.0179 | 0.0054 | 0.0023 |

| R2 | 0.9579 | 0.9984 | 0.9991 |

| RMSE | 1.7148 | 0.339 | 0.2442 |

| Predicted day 60 compressive strength | 76.06 MPa | 550.14 MPa | 68.17 MPa |

| Index | Logarithmic Model | Polynomial Model | Proposed Model |

|---|---|---|---|

| Mean fitting error | 1.4240 | 2.0567 | 0.6167 |

| Fitted standard deviation of error δ | 0.2581 | 0.3783 | 0.0988 |

| R2 | 0.9672 | 0.9639 | 0.9623 |

| RMSE | 3.2636 | 3.4255 | 3.4973 |

| Predicted day 60 compressive strength | 97.73 MPa | 917.90 MPa | 81.56 MPa |

| Index | Logarithmic Model | Polynomial Model | Proposed Model |

|---|---|---|---|

| Mean fitting error | 0.4344 | 0.5604 | 0.1571 |

| Fitted standard deviation of error | 0.1325 | 0.1712 | 0.0314 |

| R2 | 0.8738 | 0.7948 | 0.9639 |

| RMSE | 6.3454 | 8.0907 | 3.3948 |

| Predicted day 60 compressive strength | 87.69 MPa | 24.89 MPa | 80.57 MPa |

| Mix Proportion | Density | Initial Setting Time | Final Setting Time | ||

|---|---|---|---|---|---|

| Powder 2130 kg/m3 | Steel fiber 160 kg/m3 | Water 196 kg/m3 | 2488 kg/m3 | 240 min | 900 min |

| Age (Unit: Day) | Cube 1 | Cube 2 | Cube 3 | Mean Value |

|---|---|---|---|---|

| 0.5 | 44.596 | 41.413 | 43.899 | 43.303 |

| 1 | 65.842 | 71.954 | 75.241 | 71.012 |

| 2 | 101.524 | 100.801 | 97.419 | 99.915 |

| 3 | 106.935 | 110.032 | 109.759 | 108.909 |

| 4 | 120.471 | 109.423 | 112.927 | 114.274 |

| 5 | 122.200 | 116.100 | 104.400 | 114.300 |

| 6 | 125.919 | 107.592 | 122.186 | 118.566 |

| 7 | 120.030 | 123.060 | 116.28 | 119.790 |

| 8 | 121.192 | 122.166 | 121.963 | 121.774 |

| 9 | 124.069 | 116.635 | 125.644 | 122.116 |

| 10 | 117.506 | 122.822 | 128.429 | 122.919 |

| 14 | 121.747 | 136.977 | 119.324 | 126.016 |

| Index | Logarithmic Model | Polynomial Model | Proposed Model |

|---|---|---|---|

| Mean fitting error | 0.3503 | 0.2877 | 0.0480 |

| Fitted standard deviation of error | 0.0797 | 0.0649 | 0.0095 |

| R2 | 0.9130 | 0.9437 | 0.9974 |

| RMSE | 7.0595 | 5.6791 | 1.2304 |

| Predicted day 60 compressive strength | 171.13 MPa | 1192 MPa | 128.36 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, X.; Yang, Q.; Cao, H.; Wang, H. Mathematical Model for Early-Aged UHPFRC Compressive Strength Changes. Coatings 2023, 13, 525. https://doi.org/10.3390/coatings13030525

Peng X, Yang Q, Cao H, Wang H. Mathematical Model for Early-Aged UHPFRC Compressive Strength Changes. Coatings. 2023; 13(3):525. https://doi.org/10.3390/coatings13030525

Chicago/Turabian StylePeng, Xi, Qiuwei Yang, Hongfei Cao, and Haozhen Wang. 2023. "Mathematical Model for Early-Aged UHPFRC Compressive Strength Changes" Coatings 13, no. 3: 525. https://doi.org/10.3390/coatings13030525

APA StylePeng, X., Yang, Q., Cao, H., & Wang, H. (2023). Mathematical Model for Early-Aged UHPFRC Compressive Strength Changes. Coatings, 13(3), 525. https://doi.org/10.3390/coatings13030525