Abstract

Liquid impingement erosion has been known as mechanical degradation, where the original material is removed progressively from a solid surface due to continued exposure to impacts by high-speed liquid droplets. This is a major issue in many industries, including aerospace and aviation and power generation, particularly gas and steam turbines, nuclear power plants, and wind energy. Tremendous numerical and experimental studies have been performed so far to understand the physical phenomena involved in this process and to improve the erosion resistance of different surfaces. In this review paper, first, the liquid–solid impact in a wide range of relative velocities is reviewed fundamentally. Then, the liquid impingement erosion of metals, including damage regimes and damage accumulation mechanisms, as well as the role of solid properties on erosion performance are explained. Finally, promising water droplet erosion-resistant materials and surface treatments are discussed. This review paper is intended to summarize the present knowledge of the different mechanisms involved in the liquid impingement erosion process.

1. Introduction

The name “erosion” comes from the Latin word “rodere,” which means “to gnaw”. This term is commonly used to explain water and wind wear on rocks, seashores, and soil; however, in material and mechanical engineering, it refers to mechanical damage caused by sufficiently high-speed impingements [1]. Erosion is the outcome of interactions between either solid and solid or liquid and solid. Solid particle erosion, cavitation erosion, liquid impingement erosion, and slurry erosion are all examples of erosion phenomena [2,3,4,5,6,7,8,9,10,11]. They are all linked to cyclic loading and high-intensity pressure pulses [12,13,14]. In general, liquid impingement erosion has received less attention than solid particle and cavitation erosion.

Water droplet erosion (WDE) is the gradual loss of material owing to the collision of water droplets at sufficiently high speeds [14,15]. WDE is a sub-category of liquid impingement erosion. Studying and understanding the liquid droplet impingement erosion of metals, compared to other classes of materials, have been a major portion of the erosion literature [12,14,16,17,18,19,20,21]. This is because the blades of several machineries subjected to droplet impacts are made of metals. These include the blades of the compressor of a gas turbine, steam turbine blades, aeroengine fan blades, and turbocharger fan blades [22,23,24,25,26]. Moreover, aircraft body and steam pipelines are also subject to liquid droplet impacts [27,28]. As such, the behavior of metallic alloys such as stainless steels [20,21,29], titanium alloys [16,18,30], and aluminum alloys [31,32,33] have extensively been studied under droplet impact loading. Table 1 lists some of the industrial applications where various components are subject to liquid impingement erosion.

Table 1.

Examples of applications where different components are subject to liquid impingement erosion [22].

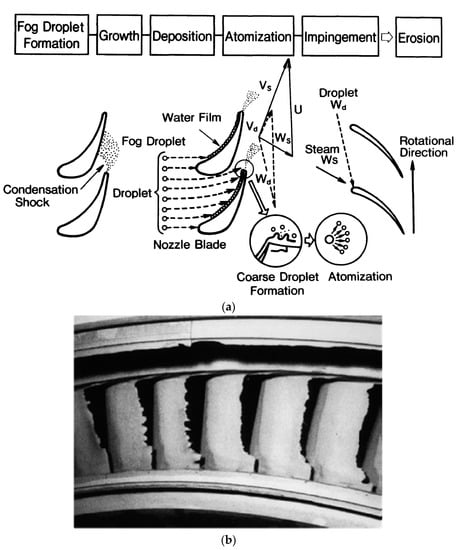

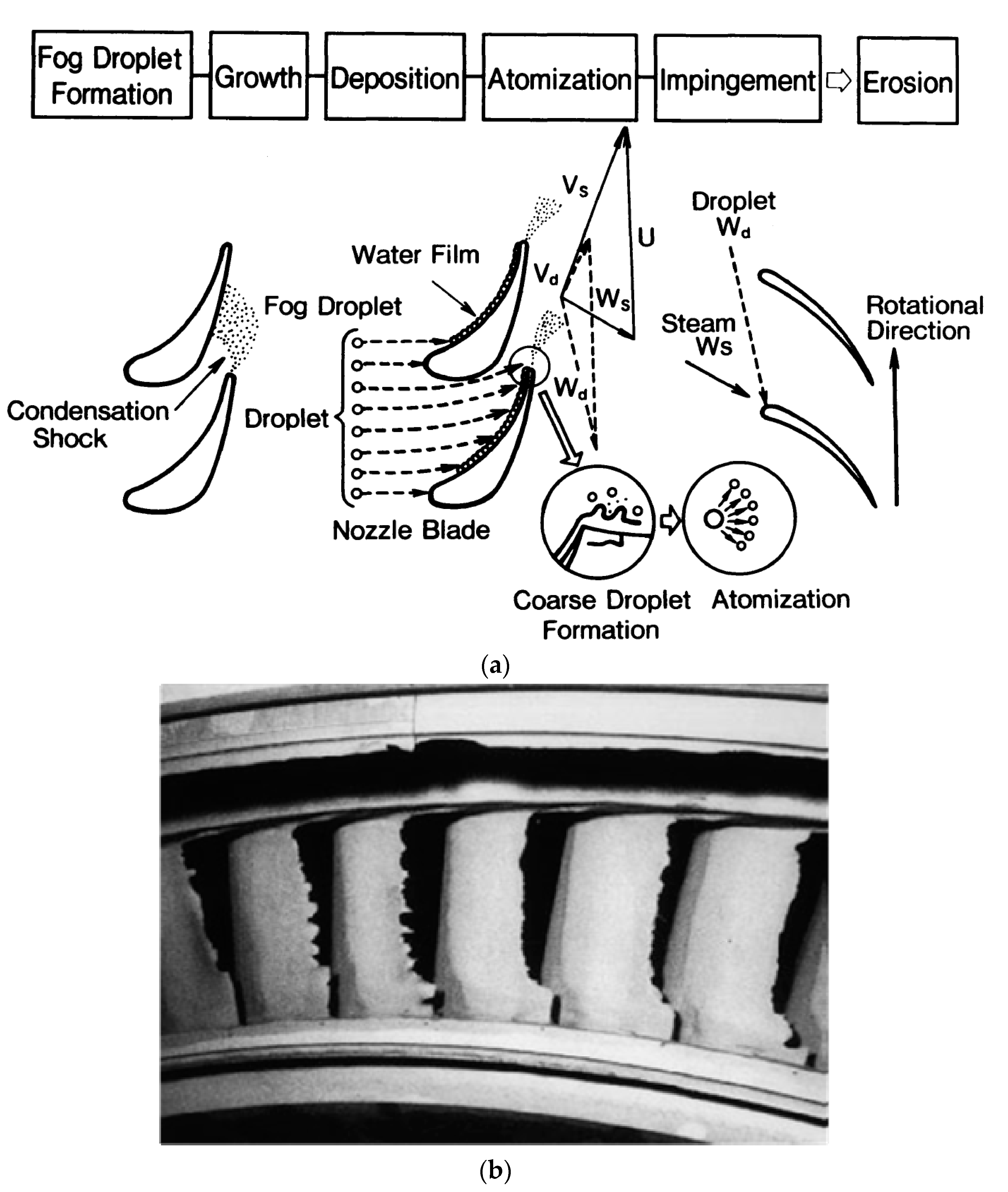

As mentioned, many industries such as aerospace/aviation and power generation are concerned about WDE. As an example, Figure 1 shows prominent damage to steam turbine blades caused by WDE. Because of the low pressure and temperature in the last stages of the turbine, a small percentage of the steam falls below the saturation line, resulting in the creation of very minute primary water droplets known as fog droplets. On the stationary blades, these droplets coalesce and produce a water film. An accumulation of water on these blades causes the water film to become unstable, resulting in the development of relatively large droplets (>1 mm). The large droplets are atomized and subsequently carried toward the rotating blades by the steam flow [20,38]. Figure 1a depicts a schematic of droplet generation in steam turbines. Figure 1b demonstrates that WDE is a result of the supersonic impact of the rotating blades and the produced water droplets.

This kind of erosion has also been detected on the blades of gas turbine compressors when a fog cooling system is utilized [15,39]. It has been shown that increasing the ambient temperature by 1 °F causes the turbine efficiency to be reduced by 0.3–0.5% [40]. Fog cooling, which involves spraying minute water droplets into the intake air to cool it (i.e., to reduce the air temperature), is proposed as a feasible way to improve turbine performance by increasing the air density. Although the sprayed water droplets are mostly evaporated during fog cooling, some of the droplets remain and come into the compressor with the intake air (this is known as overspraying) [15,39,41]. WDE damage occurs as a result of repeated high-speed impingements between these droplets and the rotating blades. Material loss, profile distortion, and reduced aerodynamic performance are all consequences of this damage. Furthermore, the weight loss of the blades may affect the compressor′s balance and generate large vibrations, which is a serious problem for the engine [38]. As a result, the power generation and aerospace sectors are keen to understand more about WDE and how to minimize the damage it causes.

Figure 1.

(a) Schematic of formation and impingement of water droplets in steam turbines (reproduced from Reference [42] with permission (Copyright Elsevier 1990)) and (b) severe water droplet erosion on the suction side of steam turbine blades [43].

Figure 1.

(a) Schematic of formation and impingement of water droplets in steam turbines (reproduced from Reference [42] with permission (Copyright Elsevier 1990)) and (b) severe water droplet erosion on the suction side of steam turbine blades [43].

Over the last few decades, tremendous investigations have been conducted to better understand the physics behind the WDE phenomenon and the intricacies of the damage it causes (for instance, see [12,14,16,17,18,19,20,21]). In the current work, the goal is to review the most important studies in this field. In that regard, a wide range of phenomena and processes involved in the WDE from fluid mechanics, solid mechanics, and material engineering points of view has been reviewed. The study plan is to review the following topics in order:

- the low-speed liquid–solid impact

- the high-speed liquid–solid impact

- the liquid impingement erosion of metals

- the erosion-mitigation materials and techniques

It is apparent that understanding the low-speed droplet impact dynamics is beneficial because it provides fundamental insights into the nature of high-speed droplet impact. Therefore, the low-speed droplet impact is discussed before the high-speed droplet impact. It should be pointed out that the broadness of the topics considered in the present paper is its most significant advantage and novelty. In that regard, different factors that affect the erosion phenomenon are explored. Moreover, the most recent approaches to mitigate or prevent erosion are discussed.

2. Low-Speed Liquid–Solid Impact

Numerous studies on the dynamics of droplet impact are mostly related to its inevitable effect in nature and industrial applications such as inkjet technology [44], thermal spray coating [45,46,47,48,49,50], and cooling systems [51,52]. For instance, as mentioned, a continuous droplet impact on steam turbine blades results in erosion [20,38,42,43] and wear or ice accretion that can compromise the safety of aircraft [53,54]. Various physical scenarios can arise upon the impact of a liquid droplet on a solid surface, such as spreading, fingering, deposition, receding, bouncing, and splashing [52,55]. Moghtadernejad et al. [56] reported a thorough review on the influence of different parameters including the surface temperature and wettability, impact velocity, droplet shape, and size on droplet impact dynamics and heat transfer. Other parameters such as normal and tangential velocities for impact on moving walls were also discussed.

More complicated phenomena may occur if the substrate is wetted with a liquid layer or if the droplet is undergoing a phase change. It has been illustrated that parameters such as the liquid properties of the droplet (density, viscosity, and surface tension), and surface characteristics (coating, materials, and surface structure and roughness) can define the outcome and physical behavior of a droplet during the impingement. Thus, the effect of various parameters has been defined by dimensionless numbers such as the Reynolds number (), Weber number (), Bond number (), Ohnesorge number () and Froud number ():

where , , , , and are the impact velocity, droplet diameter, density, dynamic viscosity, surface tension, and gravity, respectively. The physical behavior of droplet dynamics can be specified based on these non-dimensional numbers, depending on the dominant force. Various phenomena related to droplet impact as well as the onset and transition between the mentioned stages have been explored in several studies [51,52,55,57,58,59,60,61,62]. In the next sections, a comprehensive review of the most important scenarios of droplet impact is outlined.

2.1. Surface Wetting, Static and Dynamic Contact Angle, Surface Texture, and Hydrophobicity

Once a droplet comes into contact with a substrate, the outcome can be predicted based on several parameters including surface tension, capillary length, surface texture, and chemistry. Depending on the capillary length (), the shape of the droplet can either be a spherical droplet or might spread on the surface. For instance, if the radius of the water droplet is less than 2.7 mm, the droplet is governed by the interfacial tension force rather than the gravitational force. Another important factor is the wettability, which is conventionally evaluated by the equilibrium contact angle (due to the interaction between all three interfacial tensions in the horizontal direction characterized by Young′s equation):

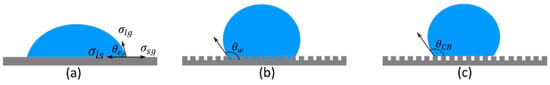

where , , and are the surface tension between solid–gas, liquid–solid, and liquid–gas, respectively (see Figure 2a). Moreover, the droplet form is defined by the surface energy (the required energy for bringing out the molecules of the material to the surface). When the surface energy is high, droplets tend to spread on the surface (contact angle <90°) and therefore the surface is considered a hydrophilic surface. It should be noted that if the contact angle is less than 30°, the wettability becomes more significant. For low-energy surfaces (contact angle >90°), the surface is known as a hydrophobic surface. In cases where the surface has extremely low energy, the contact angle of the droplet can be greater than 150° (superhydrophobic surface).

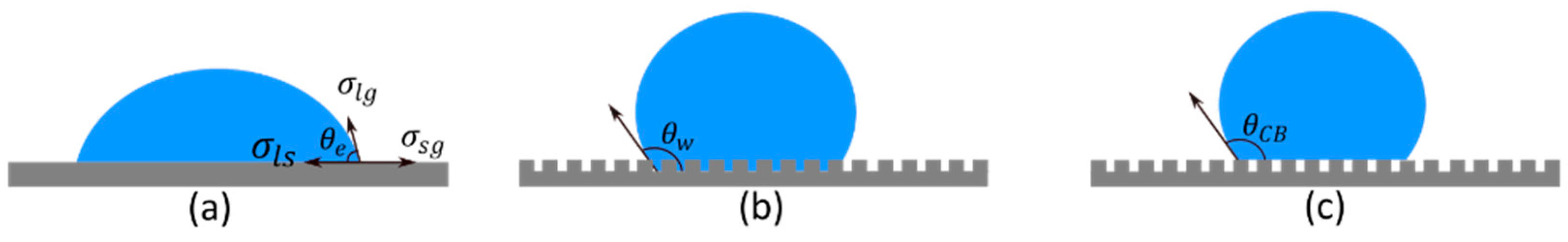

Figure 2.

Schematic of a droplet on a flat solid surface in an equilibrium state (a), rough surface/Wenzel state (b), rough surface/Cassie–Baxter state (c).

The surface texture and its pattern are quite significant in contributing to the wetting behavior of a surface. Generally, there are two possibilities when a droplet is in contact with a rough surface: Wenzel and Cassie–Baxter states [63]. In Wenzel states, the apparent contact angle would be higher, as the droplet penetrates the roughness. Accordingly, Young’s equation is modified as

where and are the apparent contact angle (Figure 2b) and the contact angle on a smooth surface, respectively. is the roughness factor, which is defined as the ratio of an actual contact area of the solid–liquid interface to its projection on a flat surface. The philic/phobic behavior can be enhanced by surface roughness [64]. On the other hand, in a Cassie–Baxter state, air pockets can be trapped within the textured surface, and consequently, a droplet can remain on top of the surface asperities and form a higher apparent contact angle (Figure 2c). For a Cassie–Baxter state (), the contact angles would be demonstrated as

where is the solid–liquid fraction. The transition of Cassie–Baxter to Wenzel state is possible if sufficient activation energy is provided [65,66] (for instance, by applying enough pressure to the droplet or if the droplet has a low surface tension). If the droplet tends to stay in the Cassie–Baxter state, its energy should be lower than that in the Wenzel state (). Therefore, the contact angle should be greater than a critical value, i.e., .

The contact angle hysteresis (CAH) is considered as another wetting parameter in predicting the mobility of droplets. The CAH is measured by taking the difference between advancing () and receding contact angles (), which are mostly related to parameters of surface roughness and chemical heterogeneity. Measuring the advancing and receding contact angles is based on observing the angle of a droplet as it begins to condense (until it advances with a constant contact angle) and evaporates (until it recedes with a constant contact angle). In general, measuring these angles precisely is quite challenging, as indicated by a previous study [67]. In recent studies [67,68], the and are estimated by adding and withdrawing a droplet through a syringe or by locating a droplet on a surface and tilting the surface until the surface reaches a certain inclination angle and the droplet deforms into a tear shape before the detachment/movement.

As stated earlier, the pattern of structured surfaces would be a significant factor in Cassie–Baxter and Wenzel states of wetting [69]. In superhydrophobic surfaces, the low surface energy of the material is an important parameter that enables the droplet to completely rebound from the surface. Superhydrophobic surfaces (SHSs) can been fabricated with different methods such as lithography, plasma treatment, etching, micro-machining, chemical vapor deposition, sol-gel processing, etc. [70,71,72,73,74]. It has been shown that the droplet contact time on a SHS, , does not depend on the impact velocity for a wide range of velocities (20–230 cm.s−1) [75]. The following equation can be used to estimate the contact time:

where is the droplet radius. The contact time can be affected by parameters such as the internal dissipation and surface–liquid adhesion during the spreading and recoiling stages [76]. On a moving SHS, the dimensionless contact time depends on the capillary number where . Here, is the air viscosity and is the tangential velocity of the surface [61,77].

Several experimental, numerical, and theoretical investigations have been dedicated to droplet impact on SHSs in order to evaluate the effect of surface roughness and its topology on droplet spreading, contact time, and impact dynamics [75,78,79,80,81,82]. A comprehensive review of recent advances in superhydrophobic surfaces can be found in [70,76]. It is worth noting that there have been only a few experimental and numerical studies conducted to explore how air shear flow influences the droplet dynamics on SHSs [83,84]. In addition, it should be pointed out that when it comes to the impact of micro-scale droplets, the dynamics are different from those at the macro-scale because the surface tension (capillary force) becomes the dominant force over the inertial force. As a result, the effect of the topology and pattern of micro-structured surfaces on droplet dynamics becomes more significant for micro-droplets, as demonstrated by Gomaa et al. [85]. While there have been numerous experimental and numerical studies examining macro-scale droplet impact on SHSs, only a few studies have focused on the impact of micro-scale droplets on these surfaces [85,86,87]. Regarding the numerical simulation of the process, a review by Afkhami [88] highlights the challenges in studying dynamic wetting phenomena and the interaction between liquid droplets and solid surfaces at the molecular scale.

Balancing the hydrodynamic momentum of droplet impact can lead to complete bouncing, partial bouncing, and complete wetting situations. The capillary pressure () and dynamic pressure () due to the inertia effect have significant effect on droplet dynamics. At very high impact velocities, the water hammer pressure () can be important at the contact area (because of droplet compression by the shock wave) [89]. Regarding these generated pressures, the conditions for complete bouncing, partial bouncing, and non-bouncing are , and , respectively. It is important to note that superhydrophobic surfaces face a challenge known as the Cassie–Wenzel transition, which can cause the non-wetting property of these surfaces to fail and prevent droplets from bouncing. Factors such as exposure to high-pressure conditions or frost formation [90] can cause the non-wetting characteristic in SHSs to collapse. This transition can be influenced by various parameters, such as the evaporation of a sessile droplet, enlarging the size of a droplet, and the arrangement and configuration of micro-structures (height, shape, or pitch of pillars). Additionally, SHSs only repel water droplets and may not work effectively against low-surface-tension liquids such as oils. To overcome these limitations, new surfaces have been developed, including superomniphobic and slippery lubricant-infused porous surfaces (SLIPS) [84,87,91,92,93], which can work with a wide range of liquids.

2.2. Air Bubble Entrapment, Splashing, Fingering, and Crown Formation

For droplet impact on dry surfaces, the following events can occur: air bubble entrapment, spreading deposition, or, it might be accompanied by prompt and corona splash if the impact velocity is sufficiently high. Prior to droplet impingement on a substrate, a pressure build-up in the air region starts developing, which leads to air entrapment beneath the liquid droplet. Depending on the Weber number, the air gap can be retained during the whole impingement process (typically on the order of micro/nanometers). It has been observed that the air layer exerts a lubrication force that results in dimple formation in a droplet and eventually droplet bouncing (as long as the air layer sustained its action as a lubrication force) [94,95,96,97,98]. This phenomenon can be observed in Leidenfrost droplets due to the heated surface [99,100,101]. In the case of a liquid surface, the entrapped air would be more complicated as the liquid film thickness can affect the impact and air layer dynamics [97,102,103]. The trapping of an air bubble under a droplet has been simulated by Mehdi-Nejad et al. [104], more recently by Shetabivash and Dolatabadi [96] on flat surfaces, and by Yeganehdoust et al. [97] on immiscible liquid films at low Weber numbers. Hicks and Purvis [105] reported on the effect of gas cushioning (due to the gas compression and viscosity) during liquid–solid impact, which can lead to gas bubble entrapment. The size of the resulting air pocket was determined in this study.

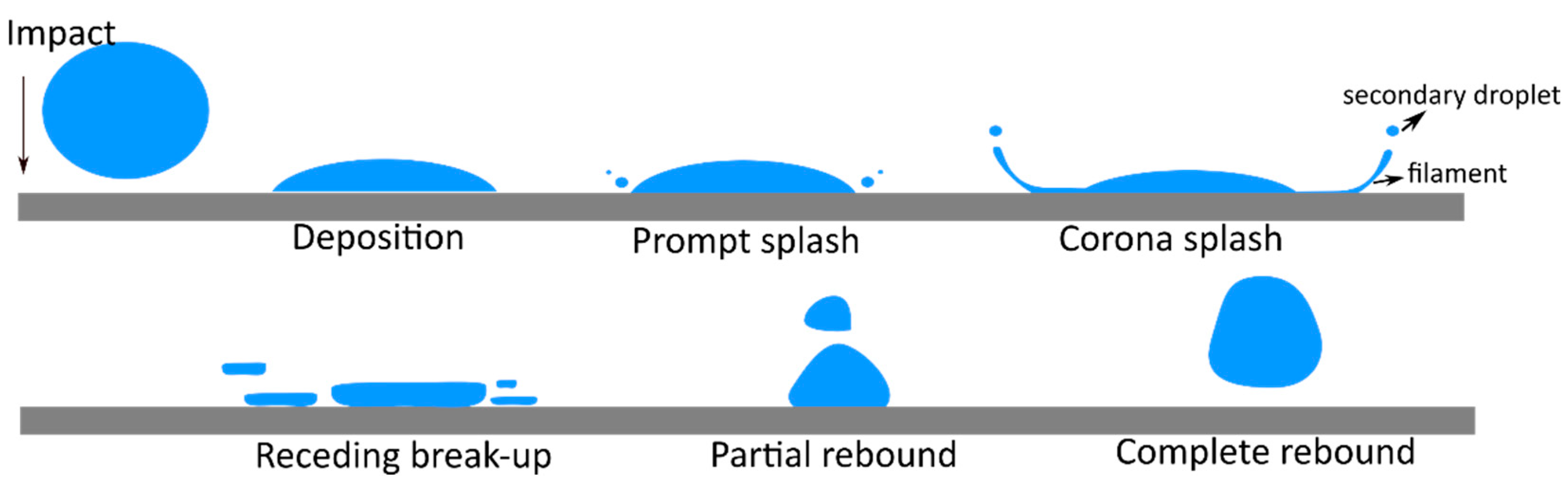

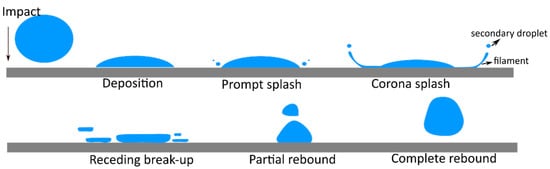

In situations where the droplet impact velocity is high, a prompt splash might happen, which results in the generation of several small droplets. The splashing of a droplet can be in the form of a prompt splash, corona splash, receding breakup, or partial rebound (see Figure 3), and thus there is no unique definition for the splashing phenomenon. Generally, it is perceived by the fragmentation of the liquid into secondary droplets. Prior to the creation of secondary droplets, ligament formation and fingering might be observed. In a corona splash, small droplets are mainly formed around the rim after the collision occurs [55,62]. In addition to the parameters related to the droplet impact, a new parameter, , which incorporates the inertia, viscous stress, and surface tension, is defined to demonstrate the transition from spreading to splashing regime (also known as the splashing threshold). This threshold would be useful in order to predict the splashing behavior, which mostly refers to prompt and corona splashes [55,62]. In general, the surface roughness and the properties of the surrounding gas have significant effects on this threshold.

Figure 3.

Schematic of droplet impact outcome.

During the splashing, different instabilities can be formed that are responsible for destabilizing the crown and rims and for the growth of fingers [106,107]. For instance, Rayleigh–Taylor instability may happen at the interface of the fluids. Rayleigh–Plateau instability is considered the most feasible driving mechanism of secondary droplet formation in splashing cases [108]. Another possible mechanism for secondary droplet generation is the Richtmyer–Meshkov instability [109]. It should be noted that the spreading of a droplet at low impact velocities has been studied comprehensively by Fukai et al. [110], Chandra and Avedisian [111], Pasandideh-Fard et al. [112], and more recently by Roisman et al. [113]. However, to better understand the mechanism behind the formation of fingers, the work of Kim et al. [114] should be considered in which a linear perturbation model based on Rayleigh–Taylor instability theory was used. Moreover, the formation of fingers upon the impact of water droplets on stationary and moving surfaces was experimentally investigated by Mehdizadeh et al. [115] and Moghtadernejad et al. [60]. Numerous numerical simulations have also analyzed the splashing behavior [116,117,118,119].

The splashing phenomenon is more discernible if a liquid film exists on the surface. Zhang et al. [120] used numerical simulation to illustrate the effect of micro-droplet size on the onset of splashing for impact on both dry and wet surfaces. For impact on dry surfaces, it was found that lowering the ambient air density or pressure can delay the splashing at high speeds [121]. Other important parameters that can affect the onset of splashing and its behavior are the gas viscosity, surface elasticity, and roughness [122,123]. Cossali et al. [124] presented certain modifications on the correlation (K) for splashing behavior that entails the effect of surface roughness. Additionally, the chance and extent of splashing can be enhanced by increasing the surface roughness and impinging velocity while the splashing can be delayed or completely avoided for an ideally smooth surface. In general, on solid stationary substrates, the value of changes between 3300 and 54,000 depending on the surface type and roughness [125,126,127,128]. On a moving surface, the tangential velocity has a significant influence on the splashing threshold. Bird et al. [57] and Moghtadernejad et al. [61] showed that for spinning aluminum and superhydrophobic surfaces, the splashing threshold becomes

where and are constants dependent on parameters such as the surface roughness. is the droplet impact velocity and is the tangential velocity of the surface.

Yarin [62] presented a review of the splashing behavior of droplet impact on dry and thin liquid surfaces and provided details on phenomena related to splashing, fingering, jetting, recoiling, and depositing. Ersoy and Eslamian [106] provided a comparative review to observe and analyze the impact of a droplet on dry, thin liquid film, and shallow pool surfaces. They concluded that the maximum spreading factor would be the fastest on the thin liquid film, even faster than the impact on dry surfaces. Depending on the Weber number and the film thickness, different outcomes such as crown formation and splash, surface waves, and the formation and breakup of the central Worthington jet (secondary droplets and aerosols splash into the air by a collapse of an air cavity formed at the center of the deformed droplet) were observed. Guo et al. [121] recently investigated the impact of the density of the surrounding air on drop splashing on dry surfaces and liquid films with impact speeds over 50 m/s. Their findings suggest that reducing the air density can decrease splashing on dry surfaces, but it does not′t have a significant impact on wet surfaces. Blake and De Conick [129] have extended the molecular-kinetic theory of dynamic wetting by including the effects of fluid–solid interaction. Pegg et al. [123] demonstrated that splashing can occur due to substrate oscillation resulting from solid elasticity. Vander Wal et al. [130] investigated the transition of non-splashing/splashing for a range of fluids for droplet impact on dry and thin liquid film surfaces with different impact velocities. They showed that splashing occurs for Ca = > 0.35 and We > 20 on dry and thin liquid film surfaces, respectively. Therefore, a larger viscosity and smaller surface tension can lead to splashing behavior. On the other hand, a larger density and smaller surface tension promote splashing. Several studies [102,106,116,130,131] have been dedicated to the droplet impact on thin liquid films and solid surfaces. For the thin liquid film, a droplet can retract if the droplet does not wet the substrate.

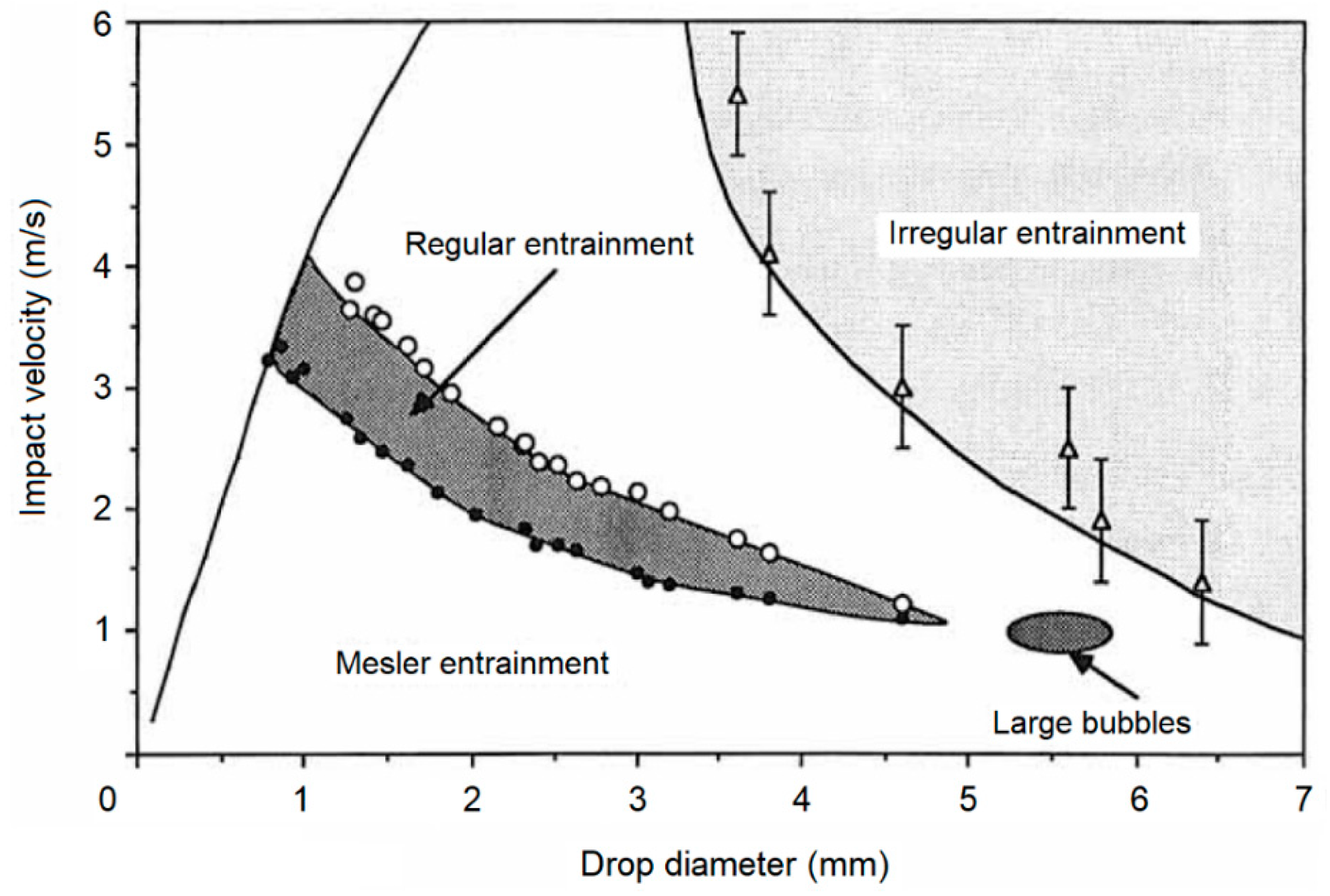

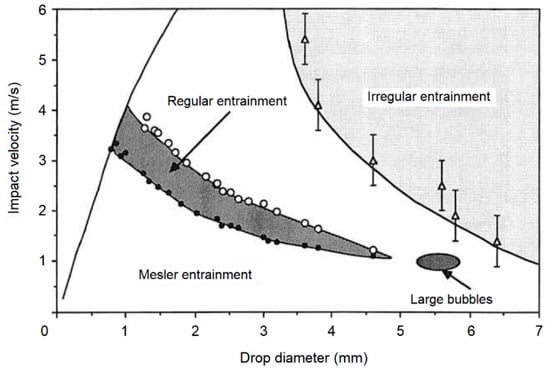

In the case of droplet impact on a liquid surface, besides the factors that were discussed in the previous paragraphs, another key parameter is the height of the liquid film, which significantly affects the outcome of the droplet. The transition between various flow regimes has been described thoroughly based on - numbers or V-D (droplet impact velocity and diameter) diagram (see Figure 4) [132,133]. One of the significant incidents during impact on a liquid pool is the formation of bubble entrapment. Several types of bubble entrapment might form during the impact on liquid, which are mostly classified as Mesler entrapment [134,135], regular bubble entrapment, and irregular bubble entrapment (due to the impact of large droplets) [136]. Finding the transition of droplet bouncing to Mesler bubble is quite challenging. Recently, Mirjalili and Mani [137] carried out a thorough numerical investigation on droplet bouncing and Mesler entrainment for low impact velocities on liquid pool surfaces. Ray et al. [138] investigated the thin/thick jet formation and bubble entrapment for flow regimes during the transition from coalescing to splashing. It was observed in the literature that the thin high jet formation after bubble entrapment gradually transformed into a thick high jet.

Figure 4.

Pumphrey′s diagram based on droplet impact velocity and diameter for droplet impact on a liquid pool (reproduced from Reference [133] with permission (Copyright Cambridge University Press 1990)).

2.3. Impact on Non-Flat, Inclined Surfaces and Multiple-Droplet Impact and Coalescence

The impingement of a droplet on non-flat surfaces such as curved solid surfaces (e.g., spherical and cylindrical) is more applicable in nature and industrial applications. Several studies investigated the effect of the surface curvature on the wettability of droplets after impingement [139,140,141]. For an impact on a solid sphere, it was found that a droplet can completely engulf the solid sphere if the ratio of the solid sphere diameter to the droplet diameter is small enough. However, it deforms into a hat-like shape if the stated ratio is large [142]. Liu et al. [143] comprehensively investigated the effect of the impact conditions and wettability of surfaces on spreading diameters. It was observed that the maximum spreading diameter was independent of the Weber number and wettability for extremely large sphere sizes. However, the curvature of surfaces can affect the formation of liquid films and lamellae [141]. The effect of a solid sphere’s impact on hydrophobic and superhydrophobic surfaces has been studied as well [144] and it was concluded that the droplet induced a larger contact area compared to the flat surfaces. Li et al. [145] evaluated the dynamics of droplet impact on a solid sphere for different surface wettability and droplet sizes using numerical simulation. It was shown that droplets formed a semi-spherical shape for low impact velocities, while at high speeds, the droplets engulfed the sphere. Šikalo et al. [146] focused on the dynamics of droplet impact on inclined surfaces for different liquid viscosities and surface roughness and observed an asymmetrical behavior in the droplet spreading. Several studies evaluated the effect of surface wettability for droplet impact on inclined surfaces [57,147,148]. Buksh et al. [149] performed a comparison between drop impact onto moving surfaces and drop impact onto inclined surfaces, using different liquids with various viscosities and surface tensions. Their findings indicated that both the moving and inclined surfaces produced similar results in terms of the initial spreading of the droplets and splashing, suggesting that the two systems are equivalent.

Multiple droplet impact and coalescence exhibit more complex dynamics and have been observed mostly in nature and engineering applications such as spray cooling, inkjet printing, and microfluidic and nanofluidic technologies [83,150,151,152,153,154,155,156]. The coalescence can be due to the impact of multiple droplets on a solid/liquid surface, because of the presence of air shear flow, or related to condensation. Although several studies have been performed to understand the collision of a droplet on solid and liquid surfaces, there have been few studies for successive multiple impacts and coalescence. Kumar et al. [156] conducted an experiment to investigate the impact of an ethanol droplet onto a stationary ethanol droplet. They found that when the volume of the stationary droplet is more than twice that of the impacting droplet, the partial coalescence phenomenon occurs. Cheng et al. [155] conducted a numerical simulation of the coalescence process of multiple droplets into a line pattern on a solid surface using the Lattice Boltzmann approach. They observed that the equilibrium contact angle and droplet spacing play a significant role in controlling the coalescence moment of multiple droplets.

3. High-Speed Liquid–Solid Impact

High-speed droplet impact is a phenomenon that is observed in multiple industries, in particular, power generation and aerospace, and is of great importance due to the blade erosion in both gas and steam turbines, thus increasing the maintenance cost. For instance, in industrial gas/steam turbines, the high rotational speed of 3000/3600 RPM (compatible with a 50/60 Hz electrical grid) can lead to a linear velocity of up to 350 m/s. As mentioned, the water droplets that are formed through the coalescence of smaller droplets on compressor vanes and shed downstream or due to the condensation of water vapor in the nozzle of steam turbines can reach a diameter of 0.1–1 mm. The repetitive and stochastic nature of the impact between the impinging water droplets and the rotating blades makes it extremely difficult to quantify the impact outcome. Experimental and analytical studies in this field are somewhat limited due to the intricate nature of droplet impact in these circumstances. Therefore, the use of numerical analysis is an effective approach to explore this phenomenon. In most practical applications, a spray of liquid droplets impacts the solid; nonetheless, the droplets coalescence and the overlap between the impacted areas renders the spray impingement a complex phenomenon to study. Hence, almost all studies found in the literature analyze single-droplet impacts and utilize the superimposition of multiple droplets to model the spray effect.

There is a very limited number of experiments conducted to examine the entire physical phenomenon of droplet impact at high impingement velocities, due to the shutter time limitation of high-speed cameras, e.g., Visser et al. [157]. It is noteworthy that for a droplet impact at velocities above 100 m/s, the time scale is on the order of one nanosecond. Thus, capturing the events during the early phase of the impingement requires a temporal resolution that is equivalent to one billion frames per second. Consequently, many researchers have developed analytical and computational tools to quantify the droplet impact outcome. To that end, a brief historical background of water hammer pressure is presented first. Next, the events occurring upon high-speed liquid–solid impact are discussed according to their sequence of appearance, including compression wave formation, lateral jetting, expansion waves, cavitation, and air bubble entrapment. Finally, a review of fluid–solid interaction (FSI) models, including both one-way and two-way coupling, is reported.

3.1. Compression Waves, High-Pressure Front Formation, and Lateral Jetting

Von Kármán [158] developed one of the earliest analytical models for liquid–solid impact in 1929, specifically for seaplane floats landing on water. Moreover, the initial stages of liquid–solid impact were mathematically addressed by Korobkin [159], using the method of matched asymptotic expansions and by assuming an incompressible fluid and a rigid solid. The effects of liquid compressibility during the entry of a solid body into an ideal incompressible and compressible fluid were also investigated by Korobkin and Pukhnachov [160] and Korobkin [161]. Asymptotic solutions were obtained for various stages of flow such as supersonic, transonic, subsonic, inertia, and developed flow stages. It is worth noting that the impact of a circular droplet on a flat plate is similar to the penetration of a blunt body into a fluid with a flat surface. Additionally, Korobkin and Iafrati [162] developed a two-dimensional hydrodynamic model to study the sudden start of a floating wedge on a liquid with weak compressibility, resulting in the ejection of liquid jets.

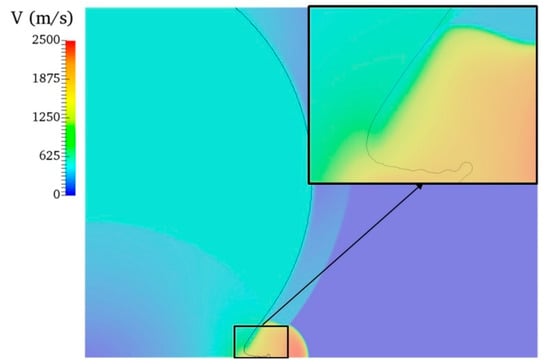

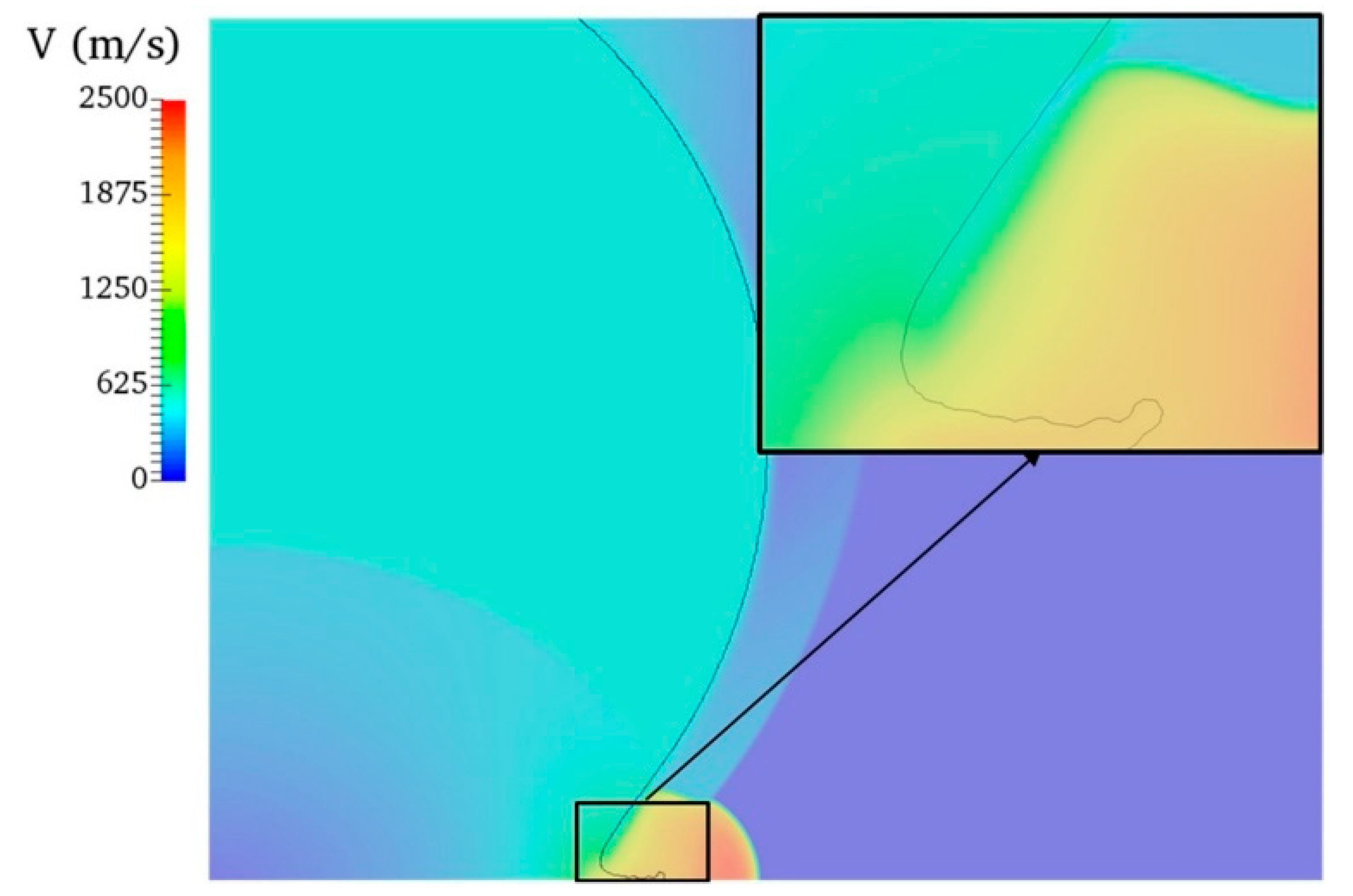

When a liquid droplet impacts a solid surface at a high velocity, compression waves propagate within the droplet because of fluid compressibility. These waves cause a high-density area in the liquid close to the solid surface and break away from the edge of the droplet [163], which result in the generation of lateral jets, as described by Heymann [164] and verified by the experiments of Dear and Field [165] and Field et al. [5]. The pressure waves found in the liquid accumulate over time and create a high-pressure front as the sound speed varies in the compressed region. Figure 5 depicts the evolution of the compressed region and the lateral jet formation for a spherical droplet impacting a rigid solid at various impingement velocities. Compression waves move through the compressed area at the speed of sound in the liquid; consequently, the rest of the droplet, outside the disturbed zone, is not influenced by the impact yet. In other words, the pressure and density inside the undisturbed area stay unaffected because it is totally unaware of the impact. Lesser [166] investigated liquid droplet impacts on rigid and elastic targets analytically and to find out the precise location of the high-pressure front, he suggested an envelope of individual wavelets emanated from the expanding contact edge. In this model, the velocity of the compression wave is assumed to be equal to the speed of sound in ambient conditions. Although this assumption is appropriate for the acoustic limit, Haller [167] and Haller et al. [168,169] showed that it is not valid for high impact velocities where the liquid compressibility plays a significant role. For instance, he showed analytically and numerically that, at an impact velocity of 500 m/s, the speed of the compression wave during the initial phase of the impingement is about 2600–3000 m/s, which is considerably higher than the speed of sound in water under ambient conditions, i.e., 1430 m/s. Thus, in simulations of the compressible droplet impact, it is important to consider the variations in the sound speed, via the changes in liquid density, with an appropriate equation of state. Recently, Marzbali and Dolatabadi [170] and [171] used a compressible volume-of-fluid (VOF) model together with proper equations of state to determine the interfacial gas–liquid flow in high-speed droplet impingements. In [170], they studied the impact of a 200 µm droplet at a velocity of 500 m/s on a dry rigid surface, and in [171] they focused on the impingement of a 500 µm droplet at a velocity of 350 m/s on a 100 µm thick liquid film. They compared their numerical results for lateral jet speed, liquid density, and maximum pressure with the data obtained by Haller [167] for the droplet impingement on a rigid surface [172].

As the liquid droplet moves downwards towards the solid, the high-pressure front penetrates further into the liquid bulk, causing the compressed region to become larger. Simultaneously, the contact line of the droplet starts to move radially outward from the center axis of the droplet, immediately after the droplet comes into contact with the surface. In the beginning, the contact periphery spreads out at a much faster rate than the high-pressure front. As the contact line begins to slow down due to viscosity dissipation, it is eventually overtaken by the high-pressure front that is expanding outward. At this moment, the high-pressure front detaches and begins to travel along the free surface resulting in the creation of lateral jets. In other words, the lateral jetting occurs when the high-pressure front, which separates the compressed region from the undisturbed region within the liquid, reaches the liquid–gas interface. The liquid lamella is raised upward because of the shear stress generated by the resistance of the air around the droplet periphery, as illustrated in Figure 6. A similar phenomenon, obtained from the growth of the boundary layer within the liquid area between the stagnation point and the root of the ejected lamella which results in its thickening, was observed by Riboux and Gordillo [173,174] for low impact speeds. This jetting eruption is due to a significant difference between the pressure and density across the free surface of the droplet in the contact line area. When lateral jetting takes place, the impact pressure reaches its temporal highest value, as experimentally measured by Rochester and Brunton [175]. Soulard et al. [176] analyzed the jet properties using molecular dynamics simulations at high speeds, which agreed well with theoretical predictions prior to the jet breakup.

Figure 5.

Dimensionless velocity distribution (top) and dimensionless pressure gradient distribution (bottom) around the droplet for different impact velocities at different dimensionless times (). The pressure gradient fronts are indicated by dotted curved lines. is the water hammer pressure (one-dimensional liquid–rigid-solid impact pressure) [177].

Figure 5.

Dimensionless velocity distribution (top) and dimensionless pressure gradient distribution (bottom) around the droplet for different impact velocities at different dimensionless times (). The pressure gradient fronts are indicated by dotted curved lines. is the water hammer pressure (one-dimensional liquid–rigid-solid impact pressure) [177].

Figure 6.

Velocity contour of water droplet and escaping air at the time of lateral jetting for a liquid–solid impact speed of 500 m/s (reproduced from Reference [172] with permission (Copyright AIP Publishing 2020)).

Figure 6.

Velocity contour of water droplet and escaping air at the time of lateral jetting for a liquid–solid impact speed of 500 m/s (reproduced from Reference [172] with permission (Copyright AIP Publishing 2020)).

3.2. Expansion Waves, Cavitation, and Vapor Bubble Collapse

It has been shown by Heymann [164], Lesser [166], and Lesser and Field [178] that the pressure within the compressed region is not uniform and the point where the pressure is at its highest is situated behind the contact line. The eruption of the lateral jet only happens on the surface at the gas–liquid–solid intersection point and does not take place elsewhere on the droplet’s free surface. This is because compression waves that propagate towards the free surface of the liquid are reflected as rarefaction waves back into the droplet, leading to a reduction in pressure in the region they pass through. Chizov and Takayama [179] presented a method that utilizes a finite element technique for the impact of 2D unheated droplets, together with a heat transfer equation that was discretized based on a finite difference approach to investigate the cavitation phenomenon. As experimentally demonstrated by Field et al. [180], these expansion waves would cause the creation of a cavity in the liquid, which accelerates the erosion of the solid subjected to continuous impacts [181].

The numerical simulation of the collapse of a single bubble and two-bubble array was reported by Betney et al. [182], which demonstrated that the collapse of both bubbles contained in spherical droplets is 20% faster compared to cylindrical (2D) droplets. This would result in the formation of strong shock-induced cavitation and lead to point-like erosion (owing to the collapse of vapor bubbles close to the surface) according to the work of Obreschkow et al. [183]. Kondo and Ando [184] reproduced the experiments performed by Field et al. [5] numerically by simulating cylindrical gelatin drops (12 wt.%) containing micron/submicron-sized gas bubble nuclei that grow to submillimeter-sized bubbles, impinged at 110 m/s on a deformable alloy, and reported that the pressure arising from cavitation bubble collapse can be orders of magnitude larger than the water hammer pressure. Niu and Wang [185] developed a two-fluid inviscid model to simulate the size of the cavitation zone and found out that, although the growth rate of the cavitation zone does not depend on the impingement velocity, the impact pressure due to the primary and secondary cavitation bubble eruption has a strong dependence on the impact speed. A numerical model for a compressible liquid jet was developed by Vasilakis et al. [186], and they were able to validate the vapor formation as well as cavitation with the experiments conducted by Field et al. [180]. Most recently, the formation of vapor cavities inside spherical droplets impacting curved surfaces was reported by Wu et al. [187].

3.3. Liquid Droplet Impact on Shallow Liquid Pools and Air Bubble Entrapment

The initial stages of the high-speed impact of a cylindrical (2D) droplet on a thin water layer were reported by Howison et al. [188] and asymptotic solutions for splashing jets were obtained. When a droplet collides with a thin liquid film, low-pressure stripes are visible within the liquid owing to the reflection of the compression waves on the liquid surface as expansion fans and their cancellation effect [172]. Moreover, the emergence of the lateral jet is delayed because of the damping effect and the stagnation zone is not developed until the pressure front reaches the solid surface. An improved model with interface sharpening and filtering of the capillary forces to capture the lamella formation was published by Tretola and Vogiatzaki [189].

Upon the droplet impact, air bubbles that are compressed because of the high impact pressure are trapped between the droplet interface and the liquid film surface. The analysis of droplet impacts on initially stationary liquid layers with a finite depth, reported by Hicks and Purvis [105], suggests the following approximation for the bubble volume, ,

where , , , and are the droplet radius, liquid density, gas viscosity, and droplet impact velocity, respectively. It should be noted that increasing the film thickness () causes the maximum pressure produced on the solid to decrease substantially, since the impact force is partially absorbed by the liquid film. An empirical relation was developed by Sasaki et al. [190] for carbon steel, as follows:

Here, the impingement damping coefficient () is defined as the ratio of the maximum equivalent stress (determined using the von Mises criterion) in the solid as a result of the drop impact on wet and dry surfaces.

3.4. Fluid–Solid Interaction (FSI) Modelling; One-Way vs. Two-Way Coupling

It is believed that the first FSI model with a one-way coupling assumption was put forward by Cook [191] and Honegger [192], in which a liquid jet impacts a solid surface generating a consistent pressure, commonly referred to as the water hammer pressure. Engel [193] reported the steady-state solution for spherical droplets. Another pressure model was suggested by Blowers [194] to calculate the stress field in rigid solids, which was independent of the pressure field in the liquid. Besides analytical methods, numerical simulations have been widely utilized to simulate the impact of droplets on solid surfaces at high speeds. As an example, Adler [195] employed the finite element approach to investigate the impact of a water droplet on a deformable solid surface at high speed. In addition, several detailed studies were conducted to model the high-speed impact of droplets on rigid solids, as demonstrated by Huang et al. [196] and Haller et al. [169]. Nonetheless, their analysis was limited to the fluid dynamics of the phenomenon, and they did not explore the stress field in the solid, which is essential to understand liquid erosion. Recently, Li et al. [197] numerically investigated the liquid droplet impingement (LDI) onto rigid substrates and developed a 1D fully coupled FSI model to explain the initial phases of impact (this pertains to the stage prior to the formation of lateral jets and droplet disintegration on the surface). Zhou et al. [198,199] expanded the 1D model proposed by Li et al. [197] into a 2D model. It is worth mentioning that although these numerical models have several limitations and deficiencies, they provide valuable information regarding the physical aspects of droplet impingement.

One- and two-dimensional models can only represent liquid columns and cylinders, respectively, and not a spherical droplet. Hence, a two-dimensional, axisymmetric, two-way coupled FSI framework for rigid and elastic Ti-6Al-4V surfaces was developed in [200,201,202]. It was shown that the impact of fluid compressibility on the accumulation of pressure and the resulting solid stress cannot be disregarded for impingement speeds exceeding 100 m/s. Furthermore, the solid elasticity leads to a decrease in the impact pressure. It is noteworthy that WDE for most solids occurs at impingement speeds above 100 m/s (see Table 1). Since the solid deformation, even under high impact velocities, is negligible for metals [202], it is possible to decouple the fluid and solid domains in order to reduce the computational cost in the simulations. To that end, a 2D axisymmetric geometry for spherical droplets with a compressible VOF model [170,171] (in which the ideal gas assumption for the air and Tait’s equation of state (EOS) for water were used [203]) was employed parametrically for a wide range of impingement scenarios on both dry and wetted substrates [172] to obtain a correlation for the maximum impact pressure.

The pressure generated in the fluid during the liquid–solid impact on walls with no penetration is extracted from the literature and tabulated in Table 2. In these equations, , , and , are defined as the impingement velocity, the speed of sound in an undisturbed liquid, and the density of an undisturbed liquid. For instance, for liquid water, = 1430 m/s and = 1000 kg/m3 at standard conditions. A comparison between 1D, 2D, and 2D axisymmetric models of the maximum impact pressure on a rigid substrate demonstrates that the maximum pressure values are confined between the predicted 1D and 2D shock wave theories. It was demonstrated by Xiong et al. [204] that the average impact pressure is reduced by 12% when 3D effects are considered. In many studies, the maximum pressure is nondimensionalized with respect to the one-dimensional water hammer pressure (), calculated based on the properties of an undisturbed liquid. Reference [205] provides a good review of the available models of the maximum pressure developed during the impact of a spherical droplet on a solid surface.

Table 2.

Pressure generated in the fluid during liquid–solid impact (impermeable wall).

It should be noted that the maximum pressure is independent of the droplet diameter for millimeter-sized droplets; however, the transient pressure history and its spatial distribution are affected by the size of the droplet. Furthermore, the erosion damage that is caused by the repetitive impact is influenced by the diameter of the droplets; however, the highest generated pressure does not change considerably with the droplet size. This can be attributed to the fact that when the size of a droplet increases, the impact area it affects also increases. Consequently, the impact pressure would have a longer temporal and a broader spatial distribution, which enhances the loading on the solid substrate. Indeed, Hattori and Lin′s experimental results [209] demonstrated that the loss of material volume is directly related to the diameter of the droplet, following a power law equation with an exponent of 4.7, owing to the higher kinetic energy upon impact, assuming that the total volume of the injected water remains constant.

4. Liquid Impingement Erosion of Metals

As mentioned in the introduction section, several studies have been conducted to understand the liquid droplet impingement erosion of metals and metallic alloys (for example, see [12,14,16,17,18,19,20,21]). In general, the WDE is a complex phenomenon and covers a wide range of topics including fluid mechanics, solid mechanics, and material science. In the previous sections, the focus was on fluid mechanics and understanding the dynamics of droplet impact. In this section and the following subsections, the mechanics of metallic erosion and the influence of mechanical and surface properties are discussed.

4.1. Threshold Conditions and Erosion Damage Regimes in Metals

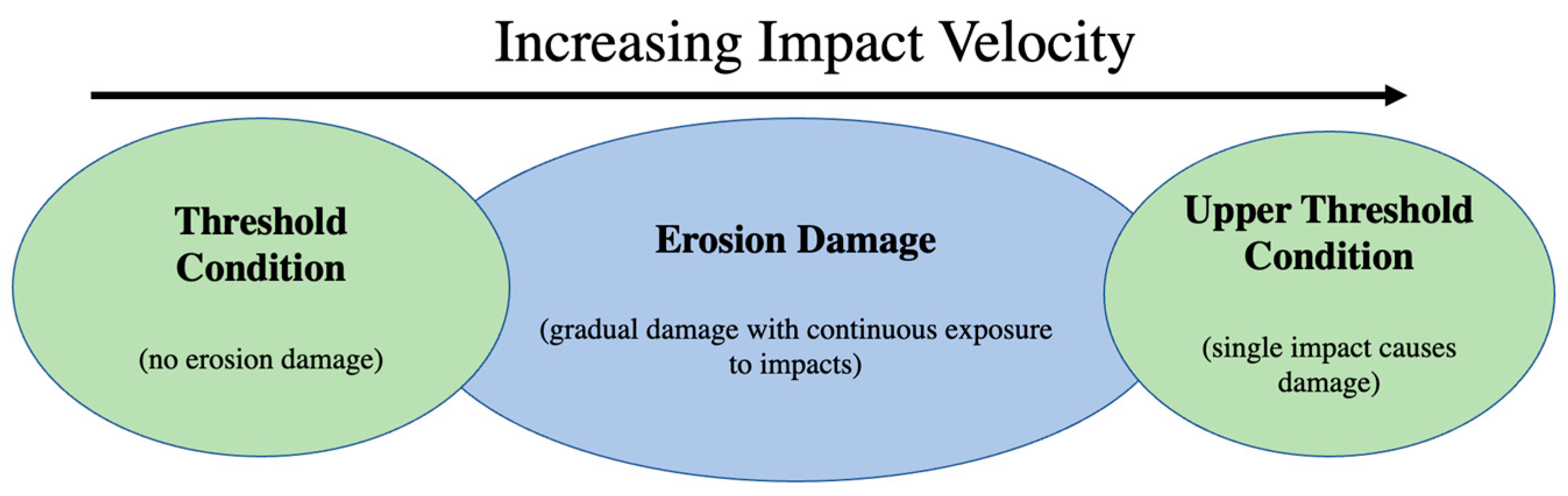

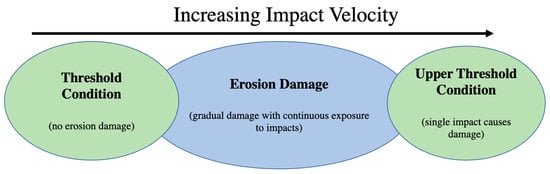

The interaction of a liquid droplet with a metallic surface creates an impact pressure as described in Section 3. In most cases, however, the stresses generated by the impingement of a single droplet are insufficient to induce erosion damage. Multiple and repetitive droplet impacts on the same spot are needed to result in erosion damage in a way akin to fatigue failure [14,210,211]. The mechanisms by which the stresses from the individual droplet impacts sum up to cause erosion damage is not well understood [22]. Nevertheless, it is empirically established that the outcome of the droplet impact process depends markedly on the impact velocity and that different ranges of impact velocity result in different liquid impingement erosion “regimes” [210,212]. These consist of an erosion damage regime bounded by two thresholds (lower threshold and upper threshold), as illustrated in Figure 7. The most important of these is the lower threshold condition and erosion damage regime.

Figure 7.

Different regimes in water droplet erosion.

The threshold condition, sometimes referred to as the lower or absolute threshold [213], indicates the condition where the intensity of the erosion attack, represented by the impact velocity at a certain droplet size, is so low that the material will never experience erosion damages for any practical exposure time. As such, in the threshold condition, erosion is completely avoided. It is likely that the threshold regime is controlled by the elastic and mechanical properties of the target materials [214]. The threshold velocity is often used to refer to the threshold condition, and models to estimate the threshold velocity of materials have been developed [31,213,214]. Ibrahim and Medraj [31] have recently developed an experimental procedure to assess the threshold velocity of metals in rotating erosion test rigs.

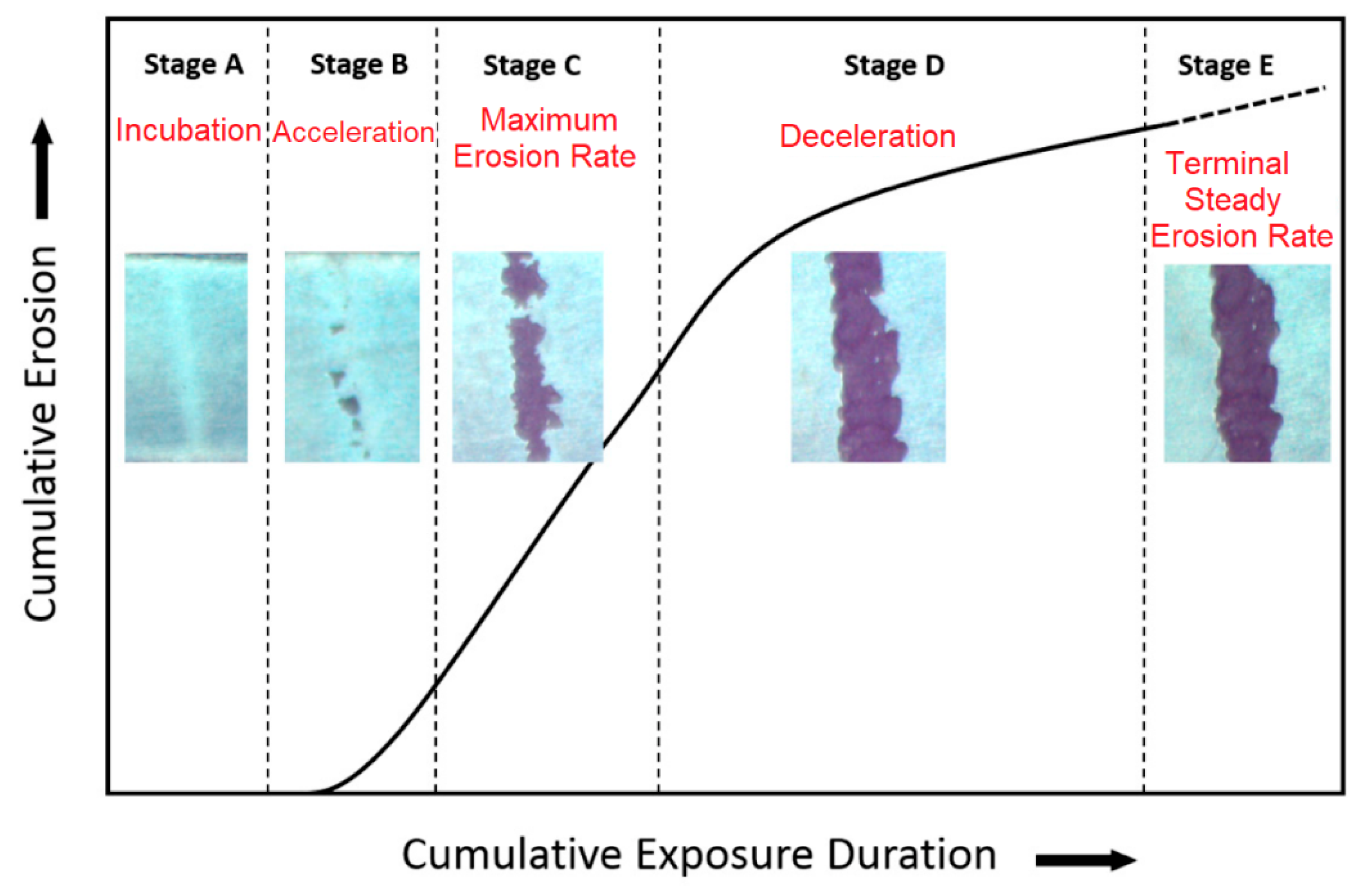

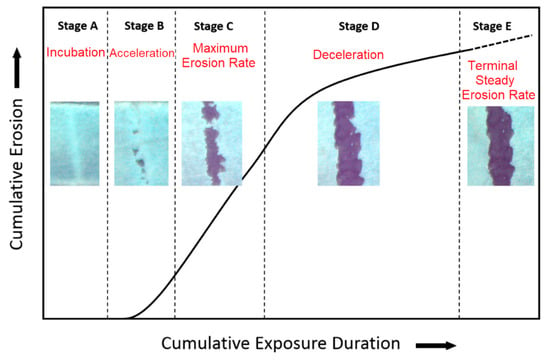

When the impact velocity is higher than the threshold velocity, the erosion damage regime is activated. For bulk metallic materials, erosion damage in this regime shows a significant time-dependent behavior, displaying varying rates of erosion at different time intervals, which leads to a non-linear pattern of damage progression [212]. The erosion graphs are typically used to illustrate this behavior. In Figure 8, the typical erosion curve, often referred to as S-shaped, is schematically illustrated. It should be pointed out that this behavior is commonly seen in water droplet erosion (WDE) of nearly all bulk materials. The erosion curve is conventionally divided into five different regions or stages, as shown in Figure 8. These stages are referred to as the incubation period (stage A), during which the surface roughness increases because of the repetitive impact of water droplets but with no measurable material loss; the acceleration stage (stage B); the steady-state maximum erosion rate (stage C), where the erosion rate reaches its peak and remains constant for a considerable amount of time; the attenuation or deceleration stage (stage D), where the erosion rate begins to decline; and the terminal stage (stage E), where the erosion rate becomes constant once again. The incubation period (stage A) and the steady-state maximum erosion (stage C) are recognized as the most crucial stages in this regime [212]. This is because the length of the incubation period indicates the resistance of the material to water droplet impacts, whereas the linear relationship between the erosion rate and exposure duration over the steady-state maximum erosion rate stage allows for the anticipation of the amount of erosion damage over a certain period of time. Therefore, metallic materials are usually considered to have superior erosion performance when they have a longer incubation period or a smaller steady-state erosion rate.

Figure 8.

Typical erosion curve and stages of damage [22].

4.2. Erosion Damage Accumulation Mechanisms in Metals

As far as metals are concerned, there are two hypotheses proposed to explain the process of damage accumulation during the liquid droplet impingement erosion: fatigue and the accumulation of plastic strain. Fatigue has been the focus of considerable attention as the primary mechanism responsible for the accumulation of erosion damage in metals subjected to WDE [214,215,216]. This is mainly due to the fact that fatigue striation marks are usually observed in eroded metallic surfaces [16,217,218,219,220,221]. Moreover, there are similarities between WDE and fatigue, such as the repetitive nature of the two damage processes and the existence of endurance conditions in both (i.e., the WDE threshold impact velocity and the fatigue endurance limit) [31]. For these reasons, incubation prediction models that solely rely on fatigue have been proposed [215,216]. Notably, Springer′s model [215] remains one of the most-used incubation prediction models throughout the water droplet erosion literature. However, some literature findings seem to undermine the role of fatigue in water droplet erosion. In the 1970s, Adler [210] performed a thorough microstructural examination of the eroded surface of Ti-6Al-4V and noted that fatigue only plays a subordinate role in the initiation of damage. He arrived at the conclusion that the initial impacts are responsible for altering the surface topography, such as roughness and surface depressions, whereas the damage is primarily induced by lateral jetting and hydraulic penetration. Additionally, according to Gujba et al. [30,222] and Ma et al. [223], various surface treatments that are known to significantly enhance fatigue life, such as deep rolling, laser shock peening, and ultrasonic nanocrystalline modification, did not provide a substantial improvement in the erosion resistance of metals, or had very little effect. Hence, they concluded that fatigue is likely to have a limited contribution to the way in which damage accumulates during the incubation period of metallic materials. Moreover, fatigue-based models [215,216], when used to predict erosion data beyond the data used in their derivation, result in remarkable prediction errors [31].

Another hypothesis that has been proposed to explain the damage accumulation during the incubation period is the accumulation of plastic strain leading to the fracture of surface fragments. This concept can be traced back to Rieger′s study [217], who suggested that when ductile metals are repeatedly subjected to droplet impacts, they undergo plastic deformation and accumulate plastic strains as an initial response. The plastic deformation caused by droplet impingement is often indicated by the hardening of the impact region, especially for metals. For instance, it has been demonstrated in previous studies [218,221,224] that metals do experience strain and hardening due to droplet impact before signs of erosion become noticeable. Hardness has been found to rise until the end of the incubation period [218]. Once there are enough liquid–solid collisions, a state of deformation is obtained where the density and concentration of dislocations increase to a great extent. When the internal stresses exceed the metal′s fracture strength at these points, cracks start to appear. Then, the propagation and joining of these cracks is considered to be the reason for the material elimination process.

4.3. Role of Solid Properties on Erosion Performance of Metals

The mechanical and surface properties play an important role in repetitive multiple-impact erosion damage in metals [12]. This is because solid properties are responsible for the materials’ resistance to WDE. Many studies have attempted to correlate erosion resistance with individual properties or a combined group of mechanical properties. Hardness, in particular, has received considerable attention [37,217,218,225,226] due to the fact that it indicates the surface resistance to plastic deformation and has been successfully correlated with a metal′s resistance to other wear phenomena [227,228,229]. The length of the incubation period was found to increase linearly with the hardness of the same alloy systems [230]. Heymann [226] also reported that the inverse of the steady-state erosion rate is related to the hardness raised to power 2. However, Hammit and Heymann [230] argued that correlating the hardness to erosion resistance withholds when different alloy systems are considered. The same conclusion has recently been affirmed by the experimental results and the analysis in the work of Ahmad et al. [231]. Studies seeking to relate the erosion resistance of materials to the fatigue strength were reported in the literature as well [214,229,232]. Thiruvengadam et al. [214,233] correlated the threshold velocity in WDE to the endurance limit of metals. Bedkowski et al. [234] noted that cavitation erosion and fatigue can be described with a theoretical model of the same kind. In addition, several studies have been conducted to determine how tensile properties (such as yield, tensile, and fracture strength) affect the ability of metallic materials to resist erosion [218,235,236,237,238]. The significance of the tensile properties and the stress–strain curve are emphasized in studies that consider the accumulation of plastic strain as the mechanism causing erosion. The initial research in this area has concentrated on individual tensile properties. For example, Hoff et al. [218] demonstrated that the erosion resistance of metals is proportional to the tensile strength to the power of 1.8 (the tensile strength can be linked to the hardness). Thiruvengadam et al. also considered the yield strength in their work [214]. However, combining multiple tensile properties instead of a single one appears to be more indicative of the erosion resistance of materials. To this end, the strain energy and resilience have drawn a great deal of attention. Thiruvengadam [233] concluded that the erosion rate in both cavitation and droplet impingement is inversely proportional to the strain energy to fracture. However, Hobbs [237] showed that ultimate resilience corresponds better to metals′ erosion resistance than strain energy or tensile strength alone. Additionally, Ahmad et al. [231] recently found that elastic resilience most closely fits the erosion resistance of several metals such as stainless steel and titanium alloys.

The surface roughness also influences the response of metals to water droplet impact [26,32,238,239]. Fujisawa et al. [32] illustrated that roughness greatly affects the distribution of the impact pressure on the contact zone. Kirols et al. [239] performed erosion tests on Ti-6Al-4V samples having various initial surface roughness values. It was determined that pre-existing surface irregularities on roughened surfaces led to shorter incubation periods in comparison to those of smooth surfaces [239]. This is due to the fact that a rough surface takes the material a step forward in the damage process by removing the roughening phase that is a crucial part of the incubation period [238,239].

5. Water Droplet Erosion Mitigation Materials and Techniques

WDE can be an issue in a variety of applications and industries, some of which are presented in Table 1. Accordingly, the materials to be protected against this type of erosion will be different, and thus the corresponding method for protection. In this section, the efforts and the materials used as solutions to WDE and related examples will be presented. Although the following is not a wholistic view of all the investigations, an effort was made to cover as a large number as possible.

Generally, when an engineering part fails the service due to a lack of some properties, the first list of actions would include: 1. Find alternative materials; 2. Bulk or surface treatment to modify the fabricated phase or microscopic structure; 3. Apply materials systems rather than using a single material, e.g., using coatings to protect the substrates against the surface effect such as corrosion or erosion threats, including water droplet erosion. Accordingly, we will present the efforts towards the mitigation of WDE in these three categories.

5.1. Materials and Process Selection

The adoption of new materials for highly regulated industrial applications such as aerospace is a long and challenging process. Hence, there is a great tendency for improvements and amendments of the established materials before trying to change them. Among a few alternative materials for the established Ti6Al4V blade materials, TiAl has been recognized as a high-potential alternative which is the subject of interest for aerospace engine producers such as Rolls-Royce [219]. TiAl has been studied particularly with regard to its WDE resistance and was compared with Ti6Al4V blades by Mahdipoor et al. [219]. In this study, a nearly fully lamellar microstructure formed from TiAl and Ti3Al phases was generated through the process of casting followed by hot isostatic pressing (HIP) of Ti45Al2Nb2Mn0.8TiB2(45-2-2XD). The study was a systematic evaluation of the failure mechanisms under water droplet erosion of the material.

Apart from metallic-based materials for blades, the industry tends to move toward thermoplastic-composite materials for many applications, including turbine blades [240]. The US National Renewable Energy Laboratory has funded this research as the belief is that thermoplastics may be beneficial for wind turbine blade composites as they are recyclable, they can have lower manufacturing costs compared with their epoxy counterparts, and thermally joining them is possible. Therefore, they need many validations before being accepted by the industry and, for example, the performance, environmental, and financial risks associated with using such materials should be well evaluated. In addition, to the knowledge of the authors, the performance of these materials under water droplet erosion has not been much investigated.

It is noteworthy that the fabrication process of the material can influence the response of the material. Kamkar et al. [220] chose a rolled microstructure of Ti6Al4V for their WDE study as a highly anisotropic structure to investigate the effects of the microstructure on the erosion mechanism. The results indicate that under the specific conditions of their test, the micro-cracks that form in the early stages of exposure to droplet impacts and are responsible for the eventual mass removal process have a non-random distribution in both inclination and distribution. These micro-cracks also have a tendency to propagate in a particular direction, which in this case is the rolling direction. They also showed the effect of macro-zones (the strongly textured regions normally observed in α or α/β titanium alloys) formed in a forged titanium duplex alloy [18]. As opposed to the previous work, the forged structure consists of a homogeneous globular (rather than elongated) grain microstructure and has a large proportion (around 70%) of equiaxed primary α-grains. The damage sites were randomly distributed (as opposed to rolled specimens). One of these sites was micro-scale surface protrusions that are out of the plane. This observation is in contrast with the common understanding of damage initiation sites being the surface depressions, micro-voids, or pit formations at the surface. We assume that this difference in the materials’ response should be related to the fabrication process.

5.2. Surface Treatment

Due to the common (though debated) belief in the importance of the surface hardness, especially on the incubation of the water erosion damage, well-known traditional methods of surface hardening against erosion damage could be applied to this goal, processes such as shot peening, laser shock peening, heat treatment, and water-jet peening [241]. Some of the traditional methods for reducing WDE damage are processes such as flame hardening and induction hardening following to manufacturing of the parts. These processes suffer from some disadvantages, such as distortions in the part due to the high temperature, alterations of the microstructure, low control of the depth and homogeneity of the hardened region, and short life. Laser treatment is a lower-temperature process with better control of the parameters.

5.2.1. Laser Surface Treatment

Laser surface treatment generates an increased hardness through remelting and rapid cooling, which results in the formation of fine-grained and/or martensitic phases owing to the fast heating and cooling rates associated with this process. Selective local hardening of the blade’s leading edges using laser treatment is known as a favorable solution that, for example, Siemens has used for its steam turbines [242]. A high protection effect combined with high process stability is among the advantages of this technique, plus low heat input and the low corresponding potential geometrical change. A controlled hardening of the inlet edges of such steam turbine blades with other conventional techniques such as flame hardening does not provide the desired results.

A high-power diode laser (HPDL) surface treatment technique was studied by Mann et al. [243] to reduce water droplet erosion of low-pressure steam turbine (LPST) moving blades used in high-rating conventional, critical, and supercritical thermal power plants. The major materials utilized in steam turbines, such as titanium alloy (Ti6Al4V), stainless steel (17Cr-4Ni PH), X20Cr13, and X10CrNiMoV1222 steels were investigated. The results in all cases (except for non-precipitation hardened 17Cr-4Ni PH steel) showed a clear improvement in the WDE performance along with compressive residual stresses at the central portion of the steel samples that changed to tensile toward the edge of the laser-beam-affected area. A still better result was observed for Ti6Al4V, which included compressive residual stresses throughout the entire area exposed to the laser beam.

An effective method for increasing the hardening depth of the laser-treated surface was suggested by Mann [244], through texturing the surface before the treatment. Surface texturing was simply performed by the shot-peening process. They reported the improvement of mainly the first stage (incubation) of WDE damage. This is considered to be due to the peening effect, which increased the surface roughness, which consisted of cavities with a comparable dimension to the laser wavelength. This caused an enhanced absorption of the laser energy and a deeper hardening effect.

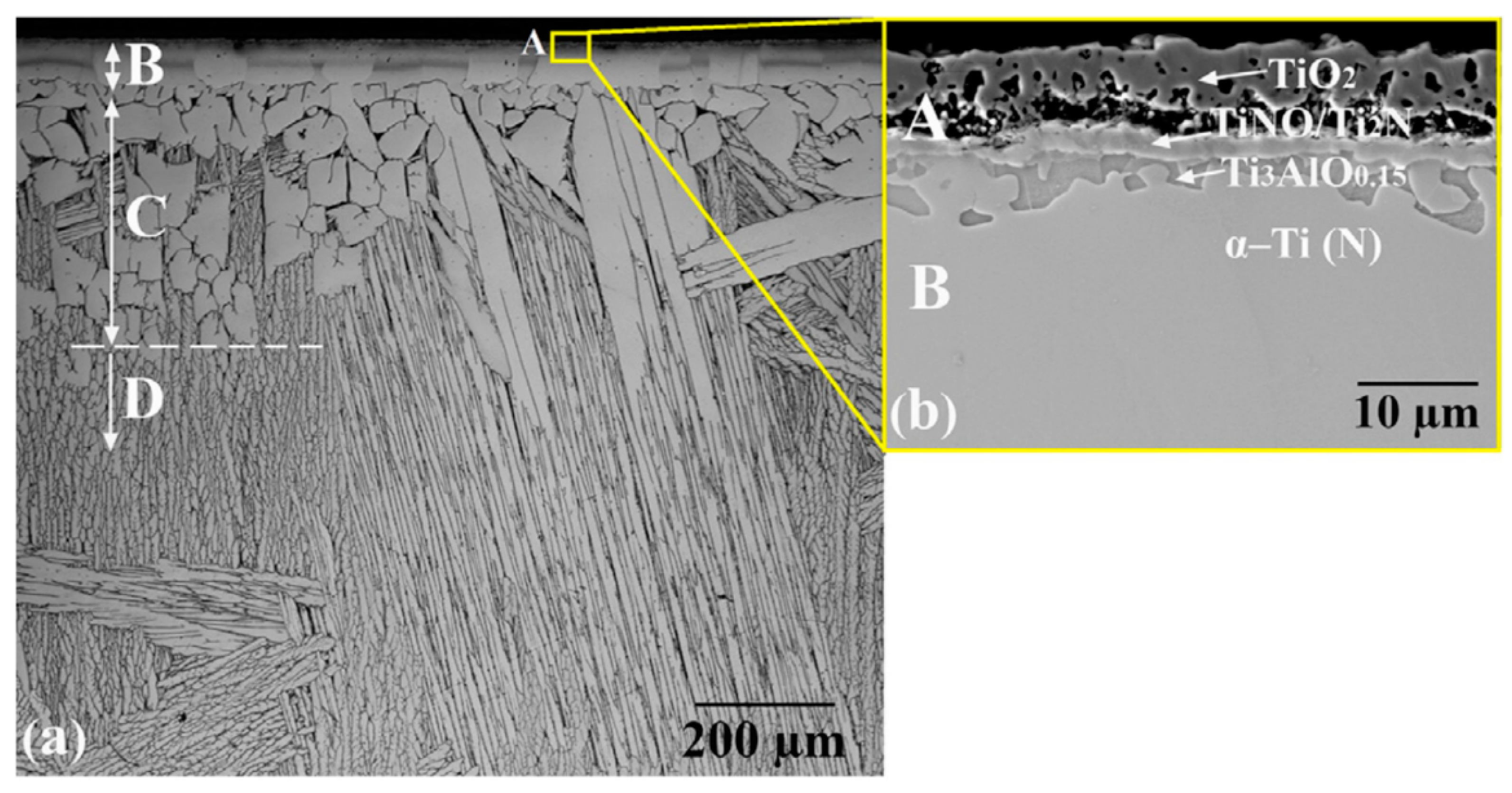

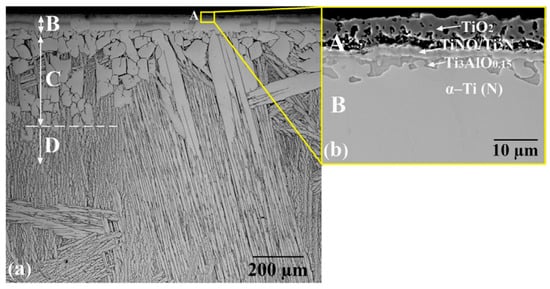

5.2.2. Gas Nitriding and Nitro-Carburizing

Gas nitriding and nitro-carburizing are old hardening techniques that increase the surface hardness through the diffusion of nitrogen and/or carbon to some depth below the surface and the formation of hard nitrides and/or carbides of the substrate elements. The nitriding process was used for strengthening Ti6Al4V against WDE [245] as a cost-effective and geometry-insensitive method. Nitriding was performed at 1173 and 1323 K temperatures using two different nitriding atmospheres, N2 and N2–4%H2 for 5 and 10 h. The results showed that the process conveys an improvement of up to twice the resistance of the treated material. The formation of hard nitride and oxide compound phases such as titanium nitride and titanium aluminum oxide is reported as the protective layer composition, as depicted in Figure 9. Furthermore, the presence of H2 in the processing gas was beneficial due to generating a reducing atmosphere. In addition, temperatures below the β-formation temperature, e.g., 1173 K, for 5 h were found to be the best nitriding conditions. As well, the nitriding conditions, specifically the temperature, can vary the resulting compound and diffusion layers (normally found in this structure) and the core material microstructure, which influences the cracking process and subsequently the erosion performance.

Figure 9.

(a) Optical microscope image and (b) SEM cross-sectional micrographs of Ti6Al4V nitrided at 1323 K for 5h (reproduced from Reference [245] with permission (Copyright Elsevier 2016)).

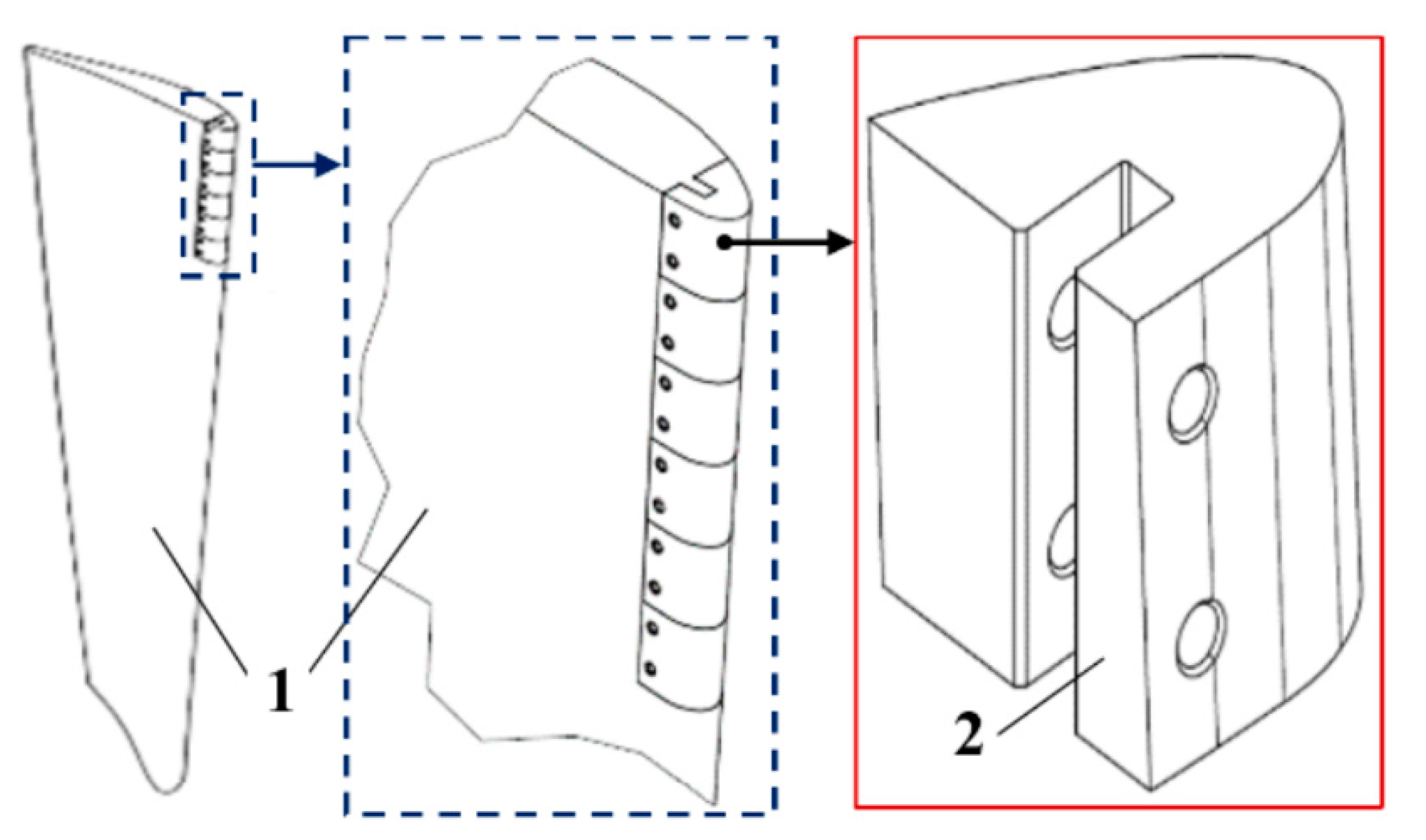

5.2.3. Laser-Assisted Nitriding

Laser-assisted nitriding is another useful technique utilized to protect turbine blades made of Ti6Al4V against water droplet erosion [246]. The efficiency of the technique is compared with some other techniques including laser deposition of metallic powders and sintered and soldered plates. The results show the superiority of the technique, and a great improvement in WDE resistance was observed. A thickness of the nitrided surface layer of a minimum of 300 µm is formed of β-phase (which is known to be harder and of higher strength than the α-phase). The laser-heat-affected zone diminishes in β-phase content by depth, until reaching the substrate phase composition of α-β titanium alloy. This hardened layer is thought to improve the wear resistance of Ti-based alloys and hence allow their application in more demanding service conditions. The introduction of nitrogen to the titanium alloy Ti6A14V along with laser irradiation under atmospheric pressure results in the generation of thin layers of TiN, Ti2N, and nitrogen-rich α-phase to the depths of tenths of a millimeter. The use of a laser involves some surface melting due to the laser energy absorption, which in turn facilitates and accelerates the gas diffusion in the base metal. In the presence of nitrogen, nitrides are produced and easily distributed throughout the melted area. The laser-assisted nitriding depth is therefore deeper than in the ion-diffusion method, which occurs at lower temperatures and in a solid state.

5.3. Surface Coatings (Welding/Cladding, Thermal Spray Coatings, Vapor-Based Coatings)

The erosion resistance is determined by the duration of the incubation period, cumulative weight or volume loss, and erosion rate, and can be improved by prolonging the incubation period, controlling volume loss, and reducing the erosion rate. Coating has been one of the most successful remedies against many industrial problems including erosion by controlling the volume loss as well as reducing the erosion rate. It benefits the mechanical, physical, thermal, and other design requirements possessed by the substrate while improving the chemical, tribological, rheological, and other surface-related shortcomings. Some of the traditional methods for coating the surfaces for the application are welding processes such as the tungsten inert gas (TIG) process and electron beam (EB) and laser cladding, among which laser cladding has been the preferred technique [247]. A variety of deposition techniques may be used for applying a single material that may affect the eventual resistance of the same material due to different techniques. For example, the cobalt-based alloy Stellite-(6 or 21) is often considered as one of the materials for WDE coating of turbine blades due to its good corrosion, wear, and high-temperature resistance. It has been deposited using various coating technologies such as thermal spraying [248], brazing [249], and laser cladding such as supersonic laser deposition (SLD) [250].

5.3.1. Laser Surface Cladding

Laser surface cladding applicable to erosion applications is presently being used and well-investigated in the turbine and power industries [251]. It provides a controlled overlay welding of literally any powders of either polymer, alloy, ceramic, composite, or cermet on the blade surface. Several important players in the industry have seriously investigated the laser cladding techniques for water droplet erosion protection, such as Rolls-Royce, Toyota, Pratt and Whitney, GEC Alstom, etc. [247].

Li et al. [252] used coaxial powder-feeding laser cladding of the Ni60A-B4C-TiN-CeO2 mixed powders on a TA15-2 titanium alloy surface (an aviation material) to develop a hard and wear-resistant composite coating. Large amounts of nanocrystalline and/or amorphous phases were produced, the interfaces of which have a high bonding energy that retards the growth of the nanocrystals to a certain extent. In turn, the nanocrystalline structure leads to the enhancement of free energy on the crystal boundaries, which increases the density of point defects, resulting in better wear resistance.

Another recent work on laser cladding for WDE protection by Chen et al. [253] is adding CeO2 to the Ni60A coating applied on Ti6Al4V alloys. During the fabrication, heterogeneous nucleation of the TiB2 + TiC eutectic structure and the formation of Ce2O3 phases were reported. These particles inhibited the growth of the hard phase formed of TiC and TiB2, resulting in a significantly lower crack sensitivity and smaller grain sizes of the TiB2 phase. In addition, the eutectic TiC + TiB2 structure helped the coating to effectively resist the shear effect caused by high-speed water droplets by playing the role of a skeleton for the coating. In this way, adding the oxide of a rare earth element such as CeO2 powder into Ni60A coatings could help improve the WDE resistance of steam turbine blades.

5.3.2. Thermal Spray Coating

Thermal spray technology embraces multitude processes and their respective techniques. Some major ones include plasma spray (air/conventional, suspension, solution precursor, vacuum, low-pressure, induction, etc.), high-velocity oxy-fuel or air-fuel (HVOF, HVAF) spray, wire arc spray, flame spray, and cold spray. They have been reported to partly or totally eliminate the incubation region of the WDE curve, mainly due to the relatively high roughness of such coatings [254] resulting in an immediate mass loss under the droplet impact process.

Plasma spray coating has been used to apply three types of coatings including Cr3C2-NiCr75-25, WC-10Co-4Cr, and Stellite 6 on 1Cr12Ni2W1Mo1V steel as a turbine material [255]. According to this work, the three kinds of coatings have certain particle erosion and water erosion resistance, among which the WC-10Co-4Cr coating has the best performance due to the highest micro-hardness caused by the dispersion of a large number of WC hard phases in the coating and the synergistic effect of other related properties.

It should be noted in using the plasma-spray process that due to the high-temperature exposure of the powder particles during the deposition of carbides, the formation of brittle phases such as W2C is an important issue affecting the quality and durability of the resulting coatings. Therefore, other processes with lower heat input to the particles such as HVOF and, even better, HVAF with still-lower temperatures can be recommended for materials containing carbides and/or nitride hard phases.

HVOF coating for WDE mitigation has been investigated by several researchers [248,255,256,257,258]. Mahdipoor et al. [257] used the HVOF process to deposit the WC-Co powders on Ti6Al4V and compared the coatings with the substrate quality. The experience showed an up to seven times improvement in the HVOF-coated material, conditioned by the quality of the coating. If the coating suffers from many defects and low integrity, the outcome can be even worse than the substrate material. In addition, a characteristic of thermal spray coating is that the incubation period in the WDE curve is almost eliminated, and the coating starts with accelerated erosion but at a much slower rate than the substrate material. Zhang et al. [255] deposited Ni60 and WC-17Co using both atmospheric plasma spray and HVOF on 17-4PH stainless steel. Among the four combinations of materials and processes, the HVOF WC-17Co cermet coating showed the best results. An important advantage of cermets containing WC-Co as the coating is that while they have high hardness and erosion resistance, their corrosion products under salt water can form a barrier against cavitation erosion, giving them a high cavitation resistance under this combined environment [248].

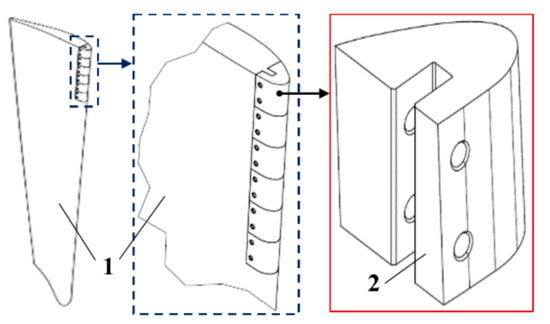

HVAF sprayed coatings using cermets is the strategy laid out by Tarasi et al. [254] to protect the blade’s leading edge. The capability of the HVAF technique (especially when the process parameters are optimized) to produce WDE-resistant coatings from WC-Co cermets was proven. The higher in-flight particle velocity in this process compared with that obtained with HVOF resulted in an increased coating density and improved performance of the coating. On the other hand, the lower temperatures that the in-flight particles experience during HVAF deposition reduce the chances of brittle W2C phases in the resulting coating. This experiment tested the coatings under a velocity of 300 m/s for 400 µm diameter for the impinging droplets. As well, Gujba et al. [258] reported the outperformance of the HVAF coatings at lower velocities and under similar droplet conditions, but similar resistance for the HVAF and HVOF coatings of the WC-10Co-4Cr tested at higher velocities of up to 350 m/s.