Cleaning Effect of Atmospheric-Plasma-Sprayed Y2O3 Coating Using Piranha Solution Based on Contamination Particle Measurement

Abstract

1. Introduction

2. Experimental

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Coburn, J.W.; Winters, H.F. Plasma etching—A discussion of mechanisms. J. Vac. Sci. Technol. 1979, 16, 391–403. [Google Scholar] [CrossRef]

- Donnelly, V.M.; Kornblit, A. Plasma etching: Yesterday, today, and tomorrow. J. Vac. Sci. Technol. A 2013, 31, 050825. [Google Scholar] [CrossRef]

- Ito, N.; Moriya, T.; Uesugi, F.; Matsumoto, M.; Liu, S.; Kitayama, Y. Reduction of particle contamination in plasma-etching equipment by dehydration of chamber wall. Jpn. J. Appl. Phys. 2008, 47, 3630–3634. [Google Scholar] [CrossRef]

- Kasashima, Y.; Nabeoka, N.; Motomura, T.; Uesugi, F. Many flaked particles caused by impulsive force of electric field stress and effect of electrostriction stress in mass-production plasma etching equipment. Jpn. J. Appl. Phys. 2014, 53. [Google Scholar] [CrossRef]

- Mun, S.Y.; Shin, K.C.; Lee, S.S.; Kwak, J.S.; Jeong, J.Y.; Jeong, Y.H. Etch defect reduction using SF6/O2 plasma cleaning and optimizing etching recipe in photo resist masked gate poly silicon etch process. Jpn. J. Appl. Phys. 2005, 44. [Google Scholar] [CrossRef]

- So, J.; Choi, E.; Kim, J.-T.; Shin, J.-S.; Song, J.-B.; Kim, M.; Chung, C.-W.; Yun, J.-Y. Improvement of plasma resistance of anodic aluminum-oxide film in sulfuric acid containing Cerium(IV) ion. Coatings 2020, 10, 103. [Google Scholar] [CrossRef]

- Kim, M.; Choi, E.; So, J.; Shin, J.-S.; Chung, C.-W.; Maeng, S.-J.; Yun, J.-Y. Improvement of corrosion properties of plasma in an aluminum alloy 6061-T6 by phytic acid anodization temperature. J. Mater. Res. Technol. 2020, 11, 219–226. [Google Scholar] [CrossRef]

- Song, J.-B.; Kim, J.-T.; Oh, S.-G.; Yun, J.-Y. Contamination particles and plasma etching behavior of atmospheric plasma sprayed Y2O3 and YF3 coatings under NF3 plasma. Coatings 2019, 9, 102. [Google Scholar] [CrossRef]

- Deposited, Y.O.; Coatings, Y.F. Contamination particle behavior of aerosol. Coatings 2019, 9, 310. [Google Scholar]

- Kim, M.; Choi, E.; Lee, D.; Seo, J.; Back, T.-S.; So, J.; Yun, J.-Y.; Suh, S.-M. The effect of powder particle size on the corrosion behavior of atmospheric plasma spray-Y2O3 coating: Unraveling the corrosion mechanism by fluorine-based plasma. Appl. Surf. Sci. 2022, 606, 154958. [Google Scholar] [CrossRef]

- Ahmed, R.; Faisal, N.; Reuben, R.L.; Paradowska, A.M.; Fitzpatrick, M.; Kitamura, J.; Osawa, S. Neutron diffraction residual strain measurements in alumina coatings deposited via APS and HVOF techniques. J. Phys. Conf. Ser. 2010, 251, 012051. [Google Scholar] [CrossRef]

- Lee, J.-K.; Park, S.-J.; Oh, Y.-S.; Kim, S.; Kim, H.; Lee, S.-M. Fragmentation behavior of Y2O3 suspension in axially fed suspension plasma spray. Surf. Coat. Technol. 2017, 309, 456–461. [Google Scholar] [CrossRef]

- Barve, S.; Jagannath; Mithal, N.; Deo, M.; Chand, N.; Bhanage, B.; Gantayet, L.; Patil, D. Microwave ECR plasma CVD of cubic Y2O3 coatings and their characterization. Surf. Coat. Technol. 2010, 204, 3167–3172. [Google Scholar] [CrossRef]

- Shin, J.-S.; Kim, M.; Song, J.-B.; Jeong, N.-G.; Kim, J.-T.; Yun, J.-Y. Fluorine Plasma Corrosion Resistance of Anodic Oxide Film Depending on Electrolyte Temperature. Appl. Sci. Converg. Technol. 2018, 27, 9–13. [Google Scholar] [CrossRef]

- Shin, J.-S.; Song, J.-B.; Choi, S.-H.; Kim, J.-T.; Oh, S.-G.; Yun, J.-Y. Plasma Corrosion in Oxalic Acid Anodized Coatings Depending on Tartaric Acid Content. Appl. Sci. Converg. Technol. 2016, 25, 15–18. [Google Scholar] [CrossRef]

- Amin, S.; Panchal, H. A review on thermal spray coating processes. Int. J. Curr. Trends Eng. Technol. 2016, 2, 556–563. [Google Scholar]

- Hwang, Y.-J.; Kim, K.-W.; Lee, H.-Y.; Kwon, S.-C.; Lee, K.A. Effect of spray angle the on microstructure and mechanical properties of Y2O3 coating layer manufactured by atmospheric plasma spray process. J. Korean Powder Met. Inst. 2021, 28, 310–316. [Google Scholar] [CrossRef]

- Ma, T.; List, T.; Donnelly, V.M. Comparisons of NF3 plasma-cleaned Y2O3, YOF, and YF3 chamber coatings during silicon etching in Cl2 plasmas. J. Vac. Sci. Technol. A 2018, 36, 031305. [Google Scholar] [CrossRef]

- Lee, H.-K.; Lee, S.; Kim, B.-R.; Park, T.-E.; Yun, Y.-H. Microstructure and plasma resistance of Y2O3 ceramics. J. Korean Cryst. Growth Cryst. Technol. 2014, 24, 268–273. [Google Scholar] [CrossRef]

- Kwon, H.; Kim, M.; So, J.; Shin, J. A study on plasma corrosion resistance and cleaning process of yttrium-based materials using atmospheric plasma spray coating. J. Semicond. Disp. Technol. 2022, 21, 74–79. [Google Scholar]

- Chen, S.; Sheng, B.; Xu, X.; Fu, S. Wet-cleaning of contaminants on the surface of multilayer dielectric pulse compressor gratings by the piranha solution. In 5th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Advanced Optical Manufacturing Technologies; SPIE: Dalian, China, 2010; Volume 7655, pp. 489–495. [Google Scholar]

- Sirghi, L.; Kylián, O.; Gilliland, D.; Ceccone, G.; Rossi, F. Cleaning and hydrophilization of atomic force microscopy silicon probes. J. Phys. Chem. B 2006, 110, 25975–25981. [Google Scholar] [CrossRef] [PubMed]

- Joyce, R.; Singh, K.; Varghese, S.; Akhtar, J. Effective cleaning process and its influence on surface roughness in anodic bonding for semiconductor device packaging. Mater. Sci. Semicond. Process. 2015, 31, 84–93. [Google Scholar] [CrossRef]

- Lo, Y.-S.; Huefner, N.D.; Chan, W.S.; Dryden, P.; Hagenhoff, B.; Beebe, T.P. Organic and inorganic contamination on commercial afm cantilevers. Langmuir 1999, 15, 6522–6526. [Google Scholar] [CrossRef]

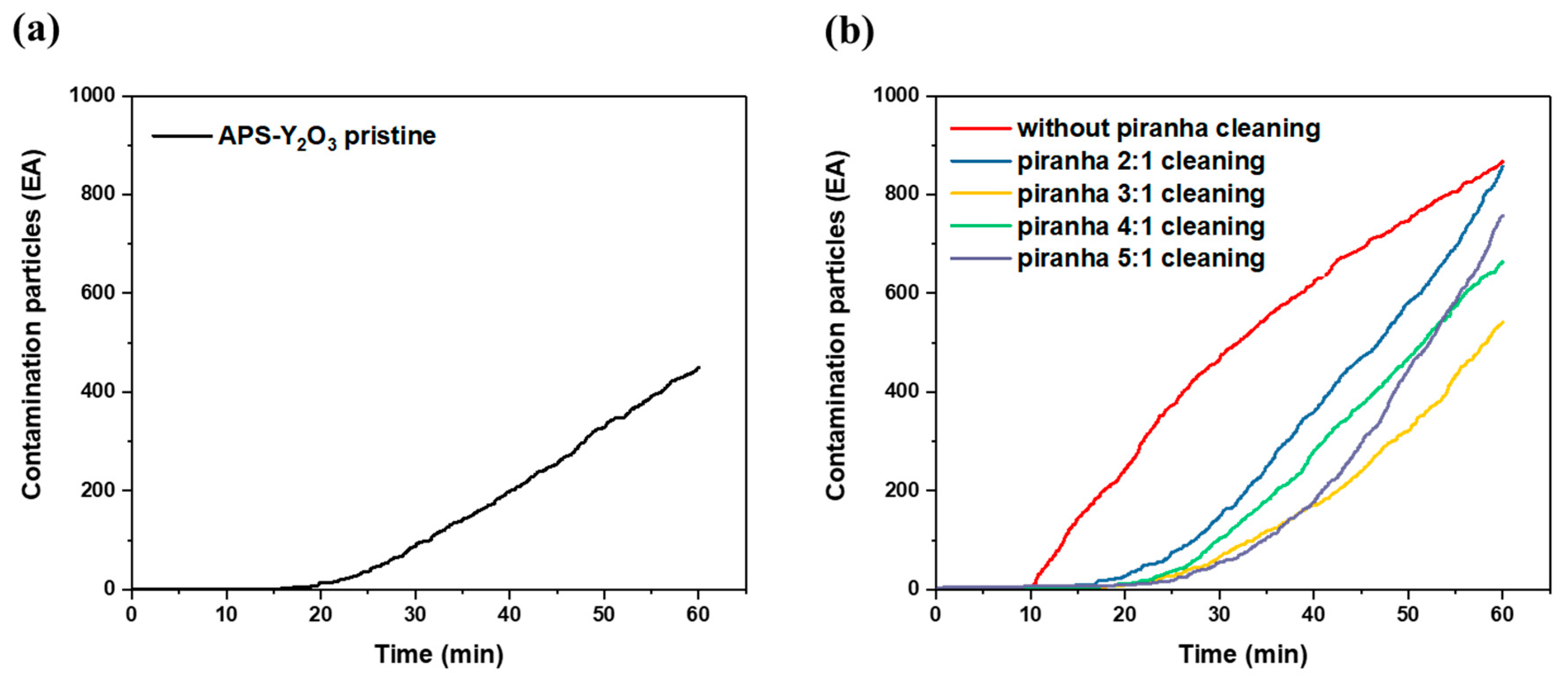

| Plasma Etching Parameters | |

|---|---|

| Gas | CF4/O2/Ar 20, 5, 15 sccm |

| Working pressure | 250–262 mTorr |

| Power | 200 W |

| Etch time | 60 min |

| Piranha Solution Ratio | ||

|---|---|---|

| H2SO4 + H2O2 | 2:1 | 40 mL, 20 mL |

| 3:1 | 45 mL, 15 mL | |

| 4:1 | 48 mL, 12 mL | |

| 5:1 | 50 mL, 10 mL | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwon, H.; Kim, M.; So, J.; Maeng, S.; Shin, J.-S.; Yun, J.-Y. Cleaning Effect of Atmospheric-Plasma-Sprayed Y2O3 Coating Using Piranha Solution Based on Contamination Particle Measurement. Coatings 2023, 13, 653. https://doi.org/10.3390/coatings13030653

Kwon H, Kim M, So J, Maeng S, Shin J-S, Yun J-Y. Cleaning Effect of Atmospheric-Plasma-Sprayed Y2O3 Coating Using Piranha Solution Based on Contamination Particle Measurement. Coatings. 2023; 13(3):653. https://doi.org/10.3390/coatings13030653

Chicago/Turabian StyleKwon, Hyuksung, Minjoong Kim, Jongho So, Seonjeong Maeng, Jae-Soo Shin, and Ju-Young Yun. 2023. "Cleaning Effect of Atmospheric-Plasma-Sprayed Y2O3 Coating Using Piranha Solution Based on Contamination Particle Measurement" Coatings 13, no. 3: 653. https://doi.org/10.3390/coatings13030653

APA StyleKwon, H., Kim, M., So, J., Maeng, S., Shin, J.-S., & Yun, J.-Y. (2023). Cleaning Effect of Atmospheric-Plasma-Sprayed Y2O3 Coating Using Piranha Solution Based on Contamination Particle Measurement. Coatings, 13(3), 653. https://doi.org/10.3390/coatings13030653