Spectral Imaging of UV-Blocking Carbon Dot-Based Coatings for Food Packaging Applications

Abstract

:1. Introduction

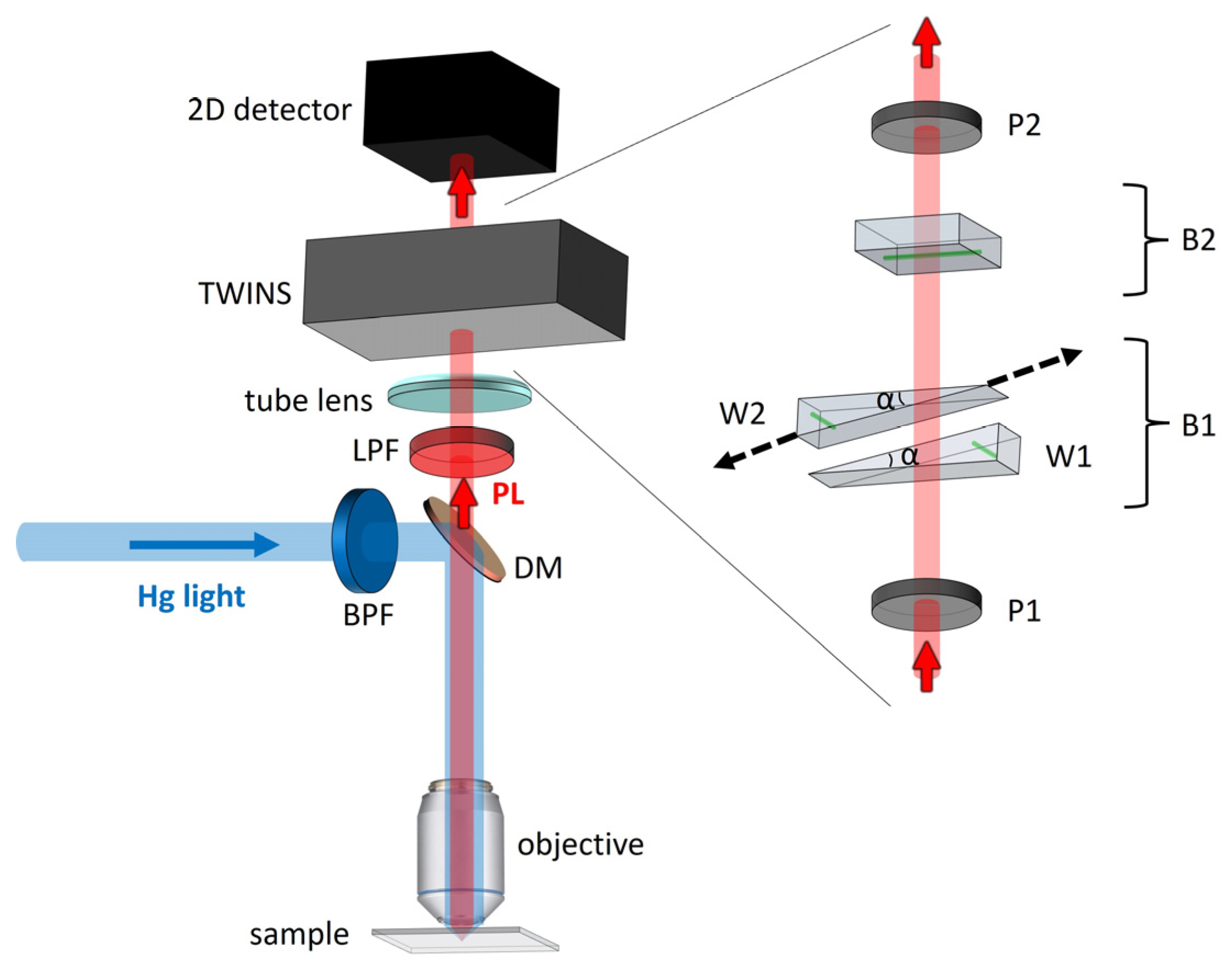

2. Spectral Microscopy Technique Applied to Coated Flexible Films

3. Materials and Methods

3.1. Samples Preparation

3.2. Sample Characterization

4. Results and Discussion

4.1. Morphological Studies by AFM and SEM

4.2. Transmission and Photoluminescence Results

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luyt, A.S. Editorial corner—A personal view: Are we closer to a solution for the plastics waste disaster which faces the earth. Express Polym. Lett. 2019, 13, 937. [Google Scholar] [CrossRef]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M. Poly-lactic acid: Production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef] [PubMed]

- Atta, O.M.; Manan, S.; Shahzad, A.; Ul-Islam, M.; Ullah, M.W.; Yang, G. Biobased materials for active food packaging: A review. Food Hydrocoll. 2022, 125, 107419. [Google Scholar]

- Iglesias Montes, M.L.; Cyras, V.P.; Manfredi, L.B.; Pettarín, V.; Fasce, A.L. Fracture evaluation of plasticized polylactic acid/poly (3-HYDROXYBUTYRATE) blends for commodities replacement in packaging applications. Polym. Test. 2020, 84, 106375. [Google Scholar] [CrossRef]

- Patanè, C.; Malvuccio, A.; Saita, A.; Rizzarelli, P.; Siracusa, L.; Rizzo, V.; Muratore, G. Nutritional changes during storage in fresh-cut long storage tomato as affected by biocompostable polylactide and cellulose based packaging. LWT 2019, 101, 618–624. [Google Scholar] [CrossRef]

- Wang, J.; Euring, M.; Ostendorf, K.; Zhang, K. Biobased materials for food packaging. J. Bioresour. Bioprod. 2022, 7, 1–13. [Google Scholar] [CrossRef]

- Oyeoka, H.C.; Ewulonu, C.M.; Nwuzor, I.C.; Obele, C.M.; Nwabanne, J.T. Packaging and degradability properties of polyvinyl alcohol/gelatin nanocomposite films filled water hyacinth cellulose nanocrystals. J. Bioresour. Bioprod. 2021, 6, 168–185. [Google Scholar] [CrossRef]

- Zhao, L.; Duan, G.; Zhang, G.; Yang, H.; He, S.; Jiang, S. Electrospun functional materials toward food packaging applications: A review. Nanomaterials 2020, 10, 150. [Google Scholar] [CrossRef]

- Rajeswari, A.; Jackcina Stobel Christy, E.; Swathi, E.; Pius, A. Fabrication of improved cellulose acetate-based biodegradable films for food packaging applications. Environ. Chem. Ecotoxicol. 2020, 2, 107–114. [Google Scholar] [CrossRef]

- Virgili, T.; Pasini, M.; Guizzardi, M.; Tizro, N.; Bollani, M. Natural dyes used as organic coatings UV protecting for food packages. Coatings 2022, 12, 417. [Google Scholar] [CrossRef]

- Pedroni, M.; Vassallo, E.; Aloisio, M.; Brasca, M.; Chen, H.; Firpo, G.; Ghezzi, F.; Morandi, S.; Pietralunga, S.M.; Silvetti, T.; et al. Plasma sputtered tungsten oxide thin film on poly (lactic acid) for food packaging applications. Coatings 2021, 11, 1281. [Google Scholar] [CrossRef]

- Alzate Marin, J.C.; Rivero, S.; Pinotti, A.; Caravelli, A.; Zaritzky, N.E. Microstructural behaviors of matrices based on polylactic acid and polyhydroxyalkanoates. J. Agric. Food Chem. 2018, 66, 10033–10040. [Google Scholar] [CrossRef]

- Sun, Y.-P.; Zhou, B.; Lin, Y.; Wang, W.; Shiral Fernando, K.A.; Pathak, P.; Meziani, M.J.; Harruff, B.A.; Wang, X.; Wang, H.; et al. Quantum-sized carbon dots for bright and colorful photoluminescence. J. Am. Chem. Soc. 2006, 128, 7756–7757. [Google Scholar] [CrossRef]

- Liu, M.L.; Chen, B.B.; Li, C.M.; Huang, C.Z. Carbon dots: Synthesis, formation mechanism, fluorescence origin and sensing applications. Green Chem. 2019, 21, 449–471. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, A. Carbon quantum dots: Synthesis, properties and applications. J. Mater. Chem. C 2014, 2, 6921–6939. [Google Scholar] [CrossRef]

- Pal, A.; Palashuddin Sk, M.; Chattopadhyay, A. Recent advances in crystalline carbon dots for superior application potential. Mater. Adv. 2020, 1, 525–553. [Google Scholar] [CrossRef]

- Xiao, L.; Sun, H. Novel properties and applications of carbon nanodots. Nanoscale Horiz. 2018, 3, 565–597. [Google Scholar] [CrossRef] [PubMed]

- Gayen, B.; Palchoudhury, S.; Chowdhury, J. Carbon dots: A mystic star in the world of nanoscience. J. Nanomater. 2019, 2019, 3451307. [Google Scholar] [CrossRef]

- Wang, L.; Li, W.; Yin, L.; Liu, Y.; Guo, H.; Lai, J.; Han, Y.; Li, G.; Li, M.; Zhang, J. Full-color fluorescent carbon quantum dots. Sci. Adv. 2020, 6, eabb6772. [Google Scholar] [CrossRef]

- Park, Y.; Kim, Y.; Chang, H.; Won, S.; Kim, H.; Kwon, W. Correction: Biocompatible nitrogen-doped carbon dots: Synthesis, characterization, and application. J. Mater. Chem. B 2020, 8, 9812. [Google Scholar] [CrossRef]

- Zuo, J.; Jiang, T.; Zhao, X.; Xiong, X.; Xiao, S.; Zhu, Z. Preparation and application of fluorescent carbon dots. J. Nanomater. 2015, 2015, 787862. [Google Scholar] [CrossRef]

- Strek, W.; Cichy, B.; Radosinski, L.; Gluchowski, P.; Marciniak, L.; Lukaszewicz, M.; Hreniak, D. Laser-induced white-light emission from graphene ceramics–opening a band gap in graphene. Light Sci. Appl. 2015, 4, e237. [Google Scholar] [CrossRef]

- Li, X.; Rui, M.; Song, J.; Shen, Z.; Zeng, H. Carbon and graphene quantum dots for optoelectronic and energy devices: A review. Adv. Funct. Mater. 2015, 25, 4929–4947. [Google Scholar] [CrossRef]

- Semeniuk, M.; Yi, Z.; Poursorkhabi, V.; Tjong, J.; Jaffer, S.; Lu, Z.-H.; Sain, M. Future perspectives and review on organic carbon dots in electronic applications. ACS Nano 2019, 13, 6224–6255. [Google Scholar] [CrossRef]

- Lagonegro, P.; Giovanella, U.; Pasini, M. Carbon Dots as a Sustainable New Platform for Organic Light Emitting Diode. Coatings 2021, 11, 5. [Google Scholar] [CrossRef]

- Li, D.; Han, D.; Qu, S.-N.; Liu, L.; Jing, P.-T.; Zhou, D.; Ji, W.-Y.; Wang, X.-y.; Zhang, T.-F.; Shen, D.-Z. Supra-(carbon nanodots) with a strong visible to near-infrared absorption band and efficient photothermal conversion. Light Sci. Appl. 2016, 5, e16120. [Google Scholar] [CrossRef]

- Qu, D.; Zheng, M.; Li, J.; Xie, Z.; Sun, Z. Tailoring color emissions from N-doped graphene quantum dots for bioimaging applications. Light Sci. Appl. 2015, 4, e364. [Google Scholar] [CrossRef]

- Campuzano, S.; Yáñez-Sedeño, P.; Pingarrón, J.M. Carbon dots and graphene quantum dots in electrochemical biosensing. Nanomaterials 2019, 9, 634. [Google Scholar] [CrossRef]

- Chan, K.K.; Hui Kit Yap, S.; Yong, K.-T. Biogreen synthesis of carbon dots for biotechnology and nanomedicine applications. Nano-Micro Lett. 2018, 10, 72. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, M.; Mujumdar, A.S.; Wang, H. Application of carbon dots in food preservation: A critical review for packaging enhancers and food preservatives. Crit. Rev. Food Sci. Nutr. 2022 17, 1–19. [CrossRef]

- Moradi, M.; Molaei, R.; Kousheh, S.A.; Guimarães, J.T.; McClements, D.L. Carbon dots synthesized from microorganisms and food by-products: Active and smart food packaging applications. Crit. Rev. Food Sci. Nutr. 2021, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Deepika, G.; Kumar, L.; Gaikwad, K.K. Carbon dots for food packaging applications. Food. Technol. 2023, 1, 185–199. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, M.; Bhandari, B.; Yang, C. Recent Development of Carbon Quantum Dots: Biological Toxicity, Antibacterial Properties and Application in Foods. Food Rev. Int. 2022, 38, 1513–1532. [Google Scholar] [CrossRef]

- Neumann, W. Fundamentals of Dispersive Optical Spectroscopy Systems, 1st ed.; SPIE, the International Society for Optics and Photonics: San Diego, CA, USA, 2014. [Google Scholar]

- Bell, R. Introductory Fourier Transform Spectroscopy, 1st ed.; Academic Press: New York, NY, USA; London, UK, 1972. [Google Scholar]

- Candeo, A.; Nogueira de Faria, B.E.; Erreni, M.; Valentini, G.; Bassi, A.; de Paula, A.M.; Cerullo, G.; Manzoni, C. A hyperspectral microscope based on an ultrastable common-path interferometer. APL Photonics 2019, 4, 120802. [Google Scholar] [CrossRef]

- Brida, D.; Manzoni, C.; Cerullo, G. Phase-Locked Pulse Pair for Two-Dimensional Spectroscopy by a Birefringent Delay Line; CLEO: Rockford, IL, USA, 2013. [Google Scholar]

- Hess, S.C.; Permatasari, F.A.; Fukazawa, H.; Schneider, E.M.; Balgis, R.; Ogi, T.; Okuyama, K.; Stark, W.J. Direct synthesis of carbon quantum dots in aqueous polymer solution: One-pot reaction and preparation of transparent UV-blocking films. J. Mater. Chem. A 2017, 5, 5187–5194. [Google Scholar] [CrossRef]

- Kumar, S.; Eaton, S.M.; Bollani, M.; Sotillo, B.; Chiappini, A.; Ferrari, M.; Ramponi, R.; Di Trapani, P.; Jedrkiewicz, O. Laser surface structuring of diamond with ultrashort Bessel beams. Sci. Rep. 2018, 8, 14021. [Google Scholar] [CrossRef] [PubMed]

- Bollani, M.; Salvalaglio, M.; Benali, A.; Bouabdellaoui, M.; Naffouti, M.; Lodari, M.; Di Corato, S.; Fedorov, A.; Voigt, A.; Fraj, I. Templated dewetting of single-crystal sub-millimeter-long nanowires and on-chip silicon circuits. Nat. Commun. 2019, 10, 5632. [Google Scholar] [CrossRef]

- Simpkins, P.G.; Kuck, V.J. On air entrainment in coatings. J. Colloid Interface Sci. 2003, 263, 562–571. [Google Scholar] [CrossRef]

- Pelagotti, A.; Del Mastio, A.; De Rosa, A.; Piva, A. Multispectral imaging of paintings. IEEE Signal Process. Mag. 2008, 25, 27–36. [Google Scholar] [CrossRef]

- Wang, P.; Ebeling, C.G.; Gerton, J.; Menon, R. Hyper-spectral imaging in scanning-confocal-fluorescence microscopy using a novel broadband diffractive optic. Opt. Commun. 2014, 324, 73–80. [Google Scholar] [CrossRef]

- Cucci, C.; Delaney, J.K.; Picollo, M. Reflectance hyperspectral imaging for investigation of works of art: Old master paintings and illuminated manuscripts. Acc. Chem. Res. 2016, 49, 2070–2079. [Google Scholar] [CrossRef] [PubMed]

| Substrate | Coating | Integration Time (s) |

|---|---|---|

| Cellulose | spin | 3 |

| Cellulose | spray | 1.2 |

| PLA | spin | 0.5 |

| PLA | spray | 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ardini, B.; Manzoni, C.; Squeo, B.; Villafiorita-Monteleone, F.; Grassi, P.; Pasini, M.; Bollani, M.; Virgili, T. Spectral Imaging of UV-Blocking Carbon Dot-Based Coatings for Food Packaging Applications. Coatings 2023, 13, 785. https://doi.org/10.3390/coatings13040785

Ardini B, Manzoni C, Squeo B, Villafiorita-Monteleone F, Grassi P, Pasini M, Bollani M, Virgili T. Spectral Imaging of UV-Blocking Carbon Dot-Based Coatings for Food Packaging Applications. Coatings. 2023; 13(4):785. https://doi.org/10.3390/coatings13040785

Chicago/Turabian StyleArdini, Benedetto, Cristian Manzoni, Benedetta Squeo, Francesca Villafiorita-Monteleone, Paolo Grassi, Mariacecilia Pasini, Monica Bollani, and Tersilla Virgili. 2023. "Spectral Imaging of UV-Blocking Carbon Dot-Based Coatings for Food Packaging Applications" Coatings 13, no. 4: 785. https://doi.org/10.3390/coatings13040785

APA StyleArdini, B., Manzoni, C., Squeo, B., Villafiorita-Monteleone, F., Grassi, P., Pasini, M., Bollani, M., & Virgili, T. (2023). Spectral Imaging of UV-Blocking Carbon Dot-Based Coatings for Food Packaging Applications. Coatings, 13(4), 785. https://doi.org/10.3390/coatings13040785