Effect of Energy Density on the Microstructure and Wear Resistance of Nickel-Based WC Coatings by Laser Cladding of Preset Zr702 Alloy Plates

Abstract

1. Introduction

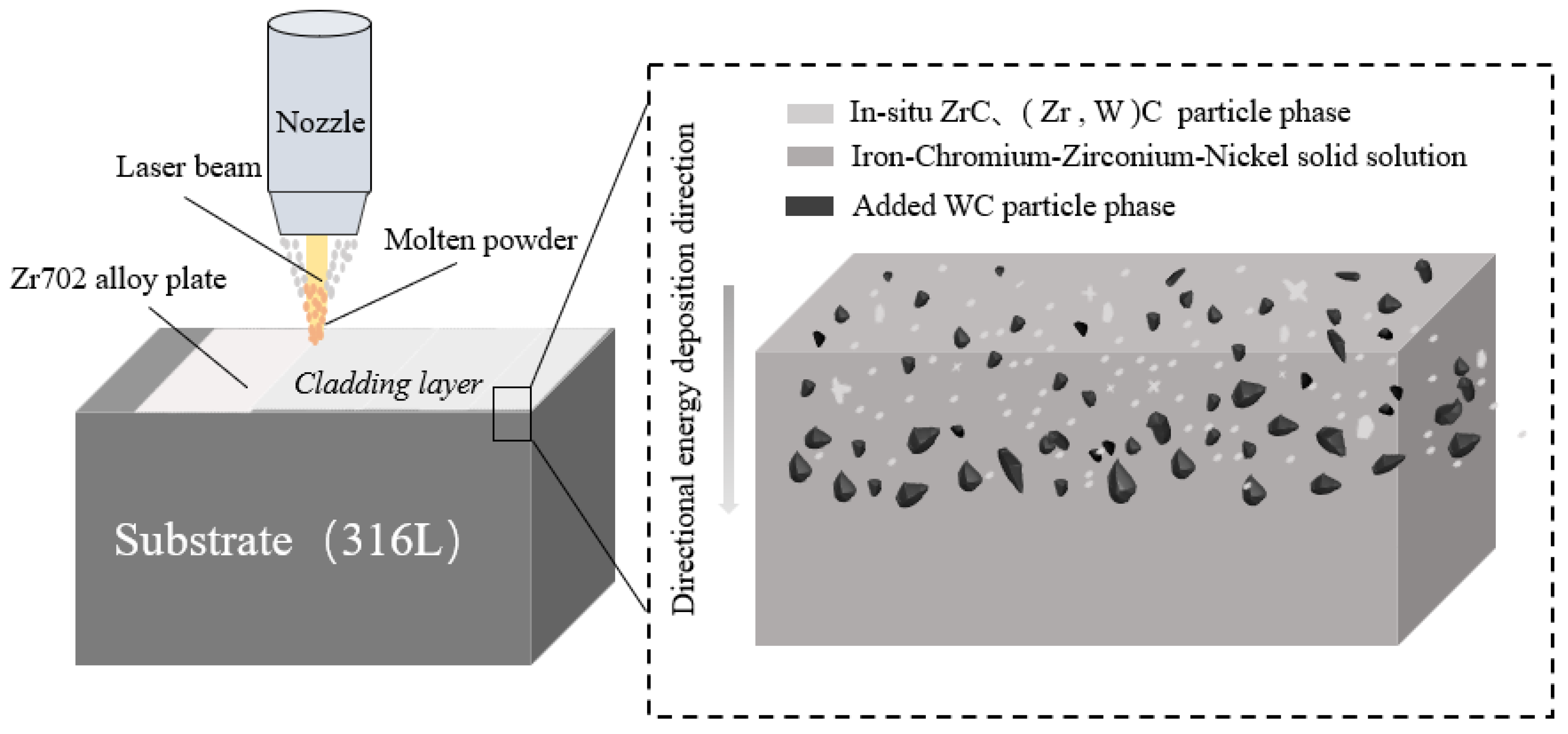

2. Materials and Methods

3. Results and Discussion

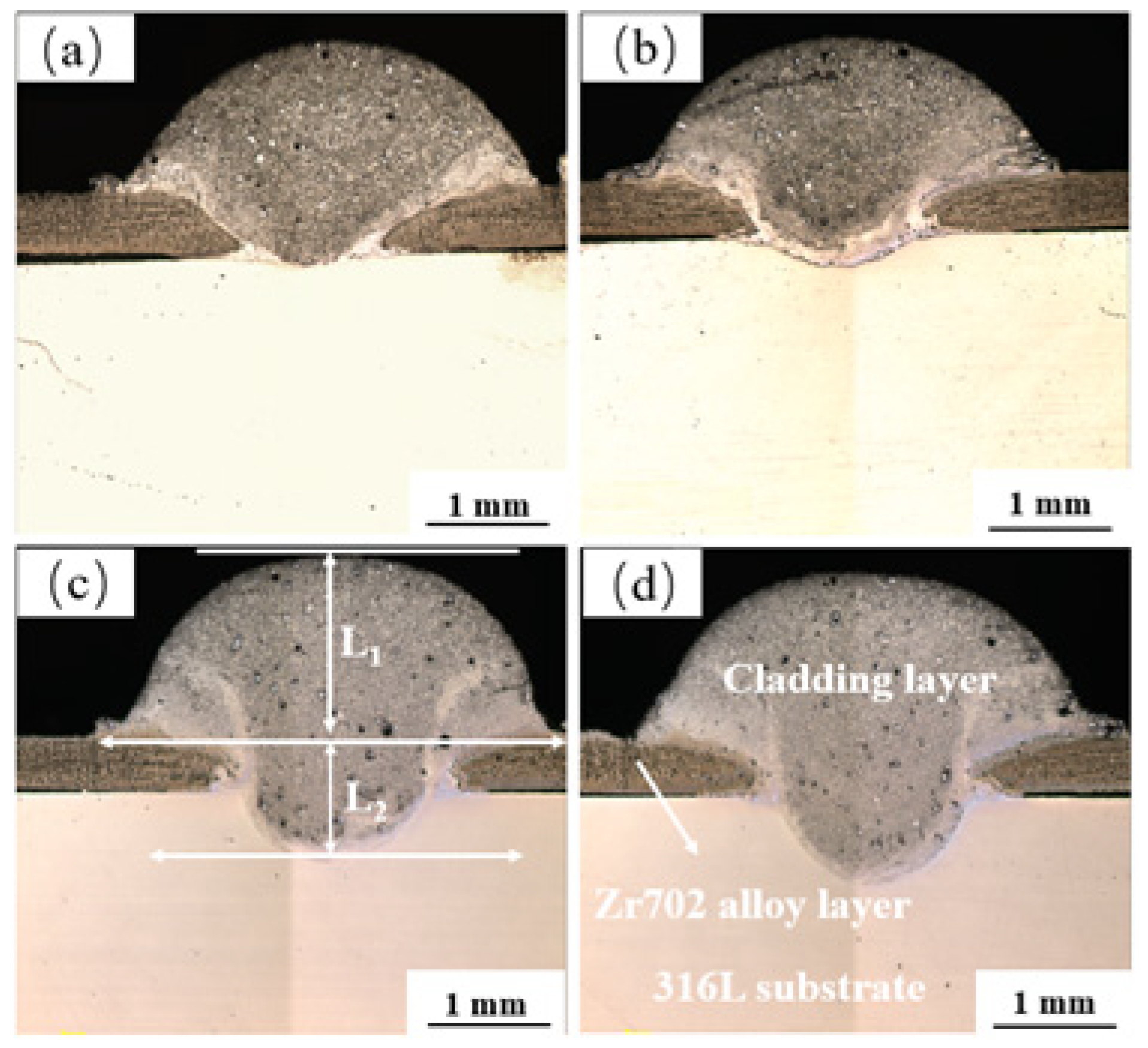

3.1. Section Morphology and Microhardness

3.2. Microstructure Analysis

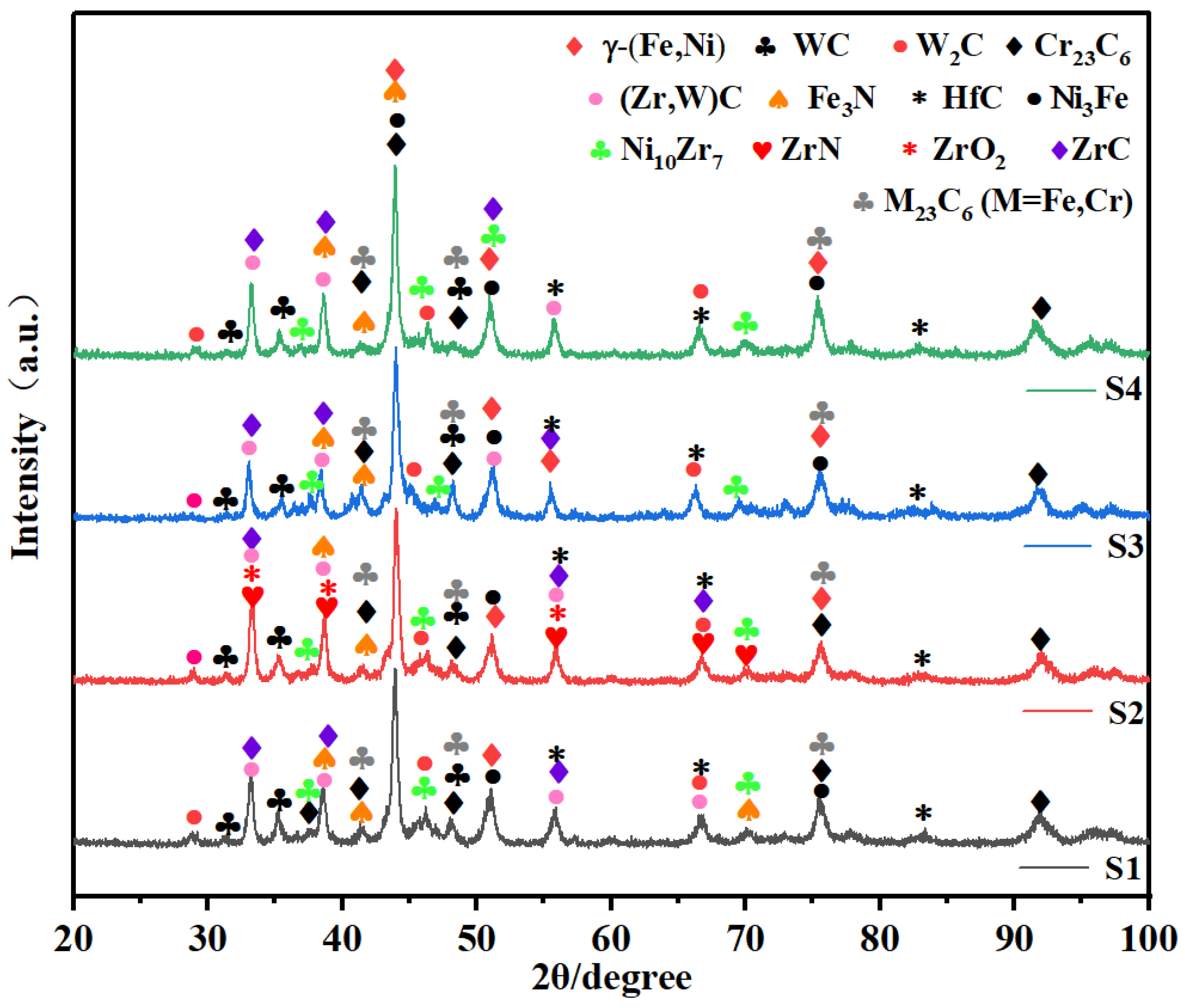

3.2.1. Composition of the Material Phase

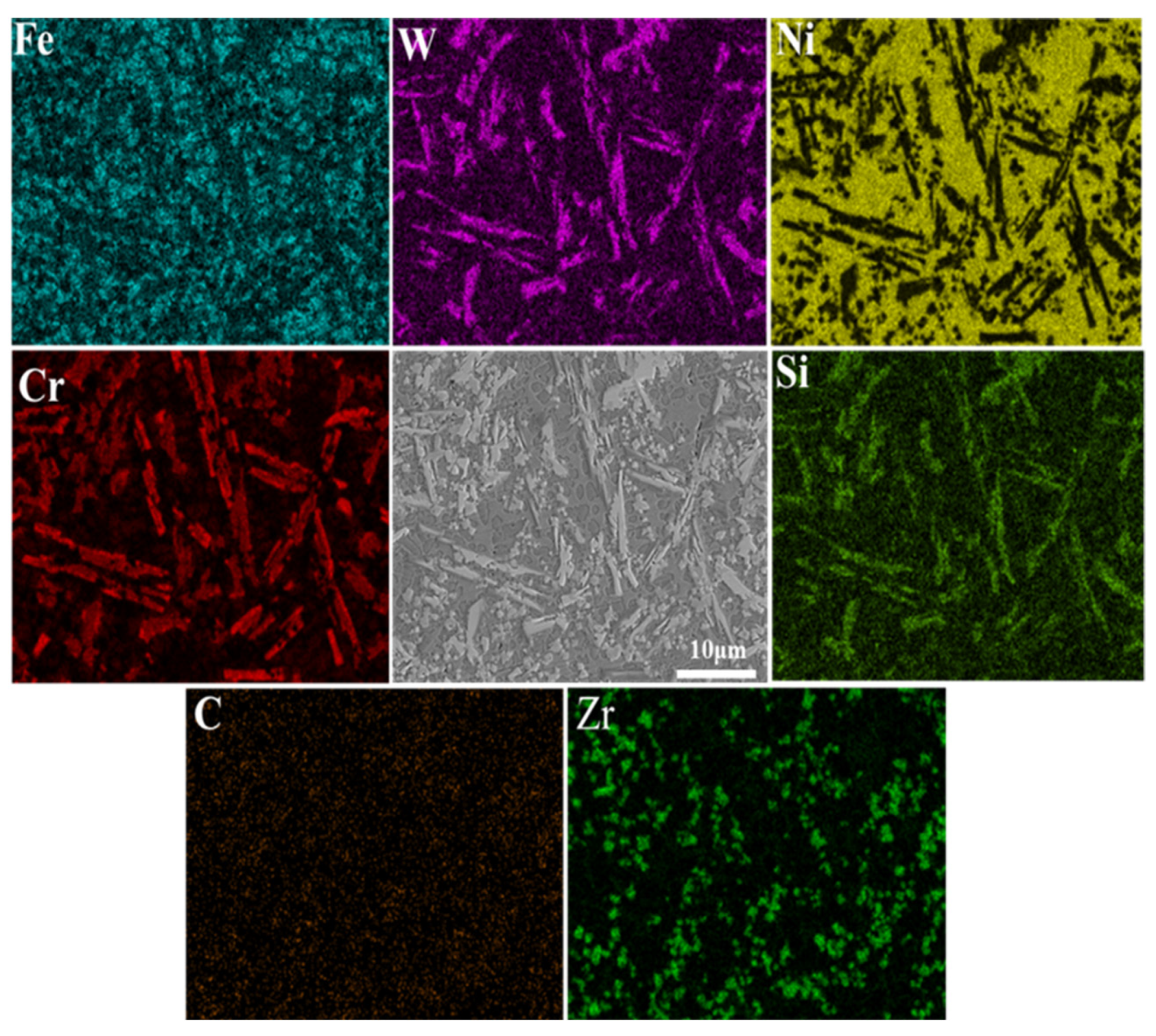

3.2.2. Microstructure and (Zr,W)C Phase Evolution Pattern

3.3. Wear Properties and Wear Mechanisms

4. Conclusions

- (1)

- When the energy density was 28.3 J/mm2, the coating microhardness was the highest among the specimens of four groups, reaching 936.4 HV0.2. With the increase in energy density, the microhardness of the coating showed a trend of increasing and then decreasing.

- (2)

- After presetting the Zr702 alloy, the coatings with different energy densities were mainly the γ-(Fe,Ni), M23C6, Cr23C6, Ni3Fe, undecomposed WC, Fe3N, ZrC, (W,Zr)C, HfC, and Ni10Zr7 phases. The fence-like tissue found in the microstructure was determined to be Ni10Zr7 after EDS point scanning with the XRD results. The Zr element ended up in the form of ZrC, (Zr,W)C hard particles as the reinforcing phase of the coating.

- (3)

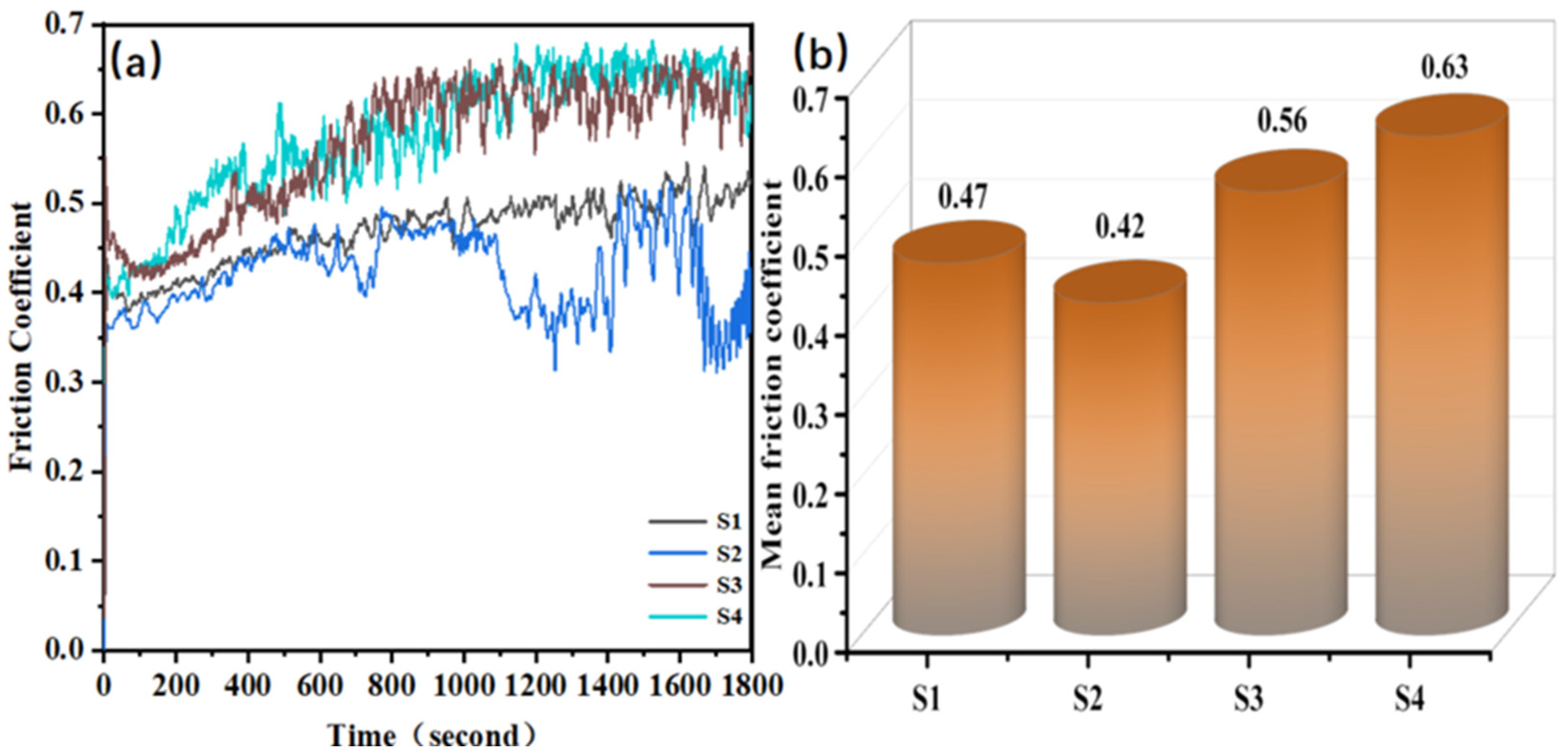

- With the increase in the energy density, the wear rate and coefficient of friction showed a trend of decreasing and then increasing. When the energy density was 28.3 J/mm2, the wear rate of the coating was the lowest at 90.8 μm3/(m·N). The wear was characterized by hard particle spalling and abrasive wear. The enhancement mechanism was mainly attributed to the low dilution of 316 L into the melt pool, the refinement of the grain, and the formation of a large number of ZrC, (Zr,W)C, which were hard particles with high wear resistance and distributed at the grain boundaries to have second-phase-strengthening effects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, P.; Dong, L.; Hu, Z.; Ren, S.; Tan, Y.; Jiang, D.; You, X. Recycling of silicon scraps by electron beam melting coupled with directional solidification and its mechanism of impurity removal. J. Clean. Prod. 2022, 355, 131716. [Google Scholar] [CrossRef]

- Vähänissi, V.; Laine, H.S.; Liu, Z.; Yli-Koski, M.; Haarahiltunen, A.; Savin, H. Full recovery of red zone in p-type high-performance multicrystalline silicon. Sol. Energy Mater. Sol. Cells 2017, 173, 120–127. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Bai, Q.; Chen, C.; Zhao, C.; Liu, Y. Effect of power spinning combined with heat treatment on the organization and wear resistance of high-speed laser cladding coatings. Mater. Lett. 2023, 333, 133594. [Google Scholar] [CrossRef]

- Lian, G.; Liu, Z.; Zhang, Y.; Que, L.; Chen, C.; Yue, K. Grey relational analysis–based composite coating property optimization fabricated by laser cladding. Int. J. Adv. Manuf. Technol. 2022, 120, 7985–7996. [Google Scholar] [CrossRef]

- Shi, C.; Lei, J.; Zhou, S.; Dai, X.; Zhang, L.-C. Microstructure and mechanical properties of carbon fibers strengthened Ni-based coatings by laser cladding: The effect of carbon fiber contents. J. Alloys Compd. 2018, 744, 146–155. [Google Scholar] [CrossRef]

- Sun, S.T.; Fu, H.G.; Ping, X.L.; Guo, X.Y.; Lin, J.; Lei, Y.P.; Wu, W.B.; Zhou, J.X. Formation mechanism and mechanical properties of titanium-doped NbC reinforced Ni-based composite coatings. Appl. Surf. Sci. 2019, 476, 914–927. [Google Scholar] [CrossRef]

- Tan, C.; Zou, J.; Wang, D.; Ma, W.; Zhou, K. Duplex strengthening via SiC addition and in-situ precipitation in additively manufactured composite materials. Compos. Part B Eng. 2022, 236, 109820. [Google Scholar] [CrossRef]

- Li, W.; Yang, X.; Xiao, J.; Hou, Q. Effect of WC mass fraction on the microstructure and friction properties of WC/Ni60 laser cladding layer of brake discs. Ceram. Int. 2021, 47, 28754–28763. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, K.; Yao, C.W.; Li, Z.G. Effect of MoO3 on the microstructure and tribological properties of laser-clad Ni60/nanoCu/h-BN/MoO3 composite coatings over wide temperature range. Surf. Coat. Technol. 2020, 387, 125477. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, J.; Peng, Y.; Shen, G. In-situ synthesized novel eyeball-like Al2O3/TiC composite ceramics reinforced Fe-based alloy coating produced by laser cladding. Surf. Coat. Technol. 2020, 391, 125671. [Google Scholar] [CrossRef]

- Yang, C.; Cheng, X.; Tang, H.; Tian, X.; Liu, D. Influence of microstructures and wear behaviors of the microalloyed coatings on TC11 alloy surface using laser cladding technique. Surf. Coat. Technol. 2018, 337, 97–103. [Google Scholar] [CrossRef]

- Li, X.; Liu, S.; Wang, J.; Yu, M.; Tang, H. Effect of Different ZrN Addition on Microstructure and Wear Properties of Titanium Based Coatings by Laser Cladding Technique. Coatings 2019, 9, 261. [Google Scholar] [CrossRef]

- Yong, Y.-W.; Fu, W.; Deng, Q.-L.; Yang, J.-G. Mechanism of Zr in in situ-synthesized particle reinforced composite coatings by laser cladding. Rare Met. 2017, 36, 934–941. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, J.; Zhao, J.; Chen, J. Effect of ZrB2 on the Microstructure and Wear Resistance of Ni-Based Composite Coating Produced on Pure Ti by Laser Cladding. Tribol. Trans. 2010, 54, 80–86. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Wang, J.; Ma, Q. In-situ synthesized Ni–Zr intermetallic/ceramic reinforced composite coatings on zirconium substrate by high power diode laser. J. Alloys Compd. 2015, 624, 234–240. [Google Scholar] [CrossRef]

- Zhu, S.; Chen, W.; Zhan, X.; Ding, L.; Wang, E. Optimization of dilution rate of laser cladding repair based on deep learning. Int. J. Adv. Manuf. Technol. 2020, 110, 1471–1484. [Google Scholar] [CrossRef]

- Rui, H.; Meiping, W.; Chen, C.; Dadong, J.; Yuling, G.; Xiaojin, M. Microstructure evolution, mechanical properties of FeCrNiMnAl high entropy alloy coatings fabricated by laser cladding. Surf. Coat. Technol. 2022, 447, 128851. [Google Scholar] [CrossRef]

- Cui, C.; Wu, M.; Miao, X.; Gong, Y.; Zhao, Z. The effect of laser energy density on the geometric characteristics, microstructure and corrosion resistance of Co-based coatings by laser cladding. J. Mater. Res. Technol. 2021, 15, 2405–2418. [Google Scholar] [CrossRef]

- Ghasempour-Mouziraji, M.; Limouei, M.B.; Najafizadeh, M.; Hosseinzadeh, M.; Cavaliere, P. The effect of simple shear extrusion on the mechanical properties and microstructure of copper. Mater. Lett. 2023, 335, 133815. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Wang, J.; Ma, Q. Effect of high dilution on the in situ synthesis of Ni–Zr/Zr–Si(B, C) reinforced composite coating on zirconium alloy substrate by laser cladding. Mater. Des. 2015, 87, 66–74. [Google Scholar] [CrossRef]

- Berretta, S.; Wang, Y.; Davies, R.; Ghita, O.R. Polymer viscosity, particle coalescence and mechanical performance in high-temperature laser sintering. J. Mater. Sci. 2016, 51, 4778–4794. [Google Scholar] [CrossRef]

- Song, G.-M.; Wang, Y.-J.; Zhou, Y. The mechanical and thermophysical properties of ZrC/W composites at elevated temperature. Mater. Sci. Eng. A 2002, 334, 223–232. [Google Scholar] [CrossRef]

- Yu, T.; Deng, Q.; Dong, G.; Yang, J. Effects of Ta on microstructure and microhardness of Ni based laser clad coating. Appl. Surf. Sci. 2011, 257, 5098–5103. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, Y.; Zhou, Y.; Song, G. Effect of temperature gradient in the disk during sintering on microstructure and mechanical properties of ZrC.sub.p/W composite. Int. J. Refract. Met. Hard Mater. 2009, 27, 126. [Google Scholar] [CrossRef]

- Kim, J.-H.; Park, C.; Ha, D.; Kang, S. WC-toughened (Zr,W)C solid solution carbides. J. Alloys Compd. 2015, 637, 183–187. [Google Scholar] [CrossRef]

- Yang, L.; Yu, T.; Li, M.; Zhao, Y.; Sun, J. Microstructure and wear resistance of in-situ synthesized Ti(C, N) ceramic reinforced Fe-based coating by laser cladding. Ceram. Int. 2018, 44, 22538–22548. [Google Scholar] [CrossRef]

- Kharanzhevskiy, E.V.; Ipatov, A.G.; Makarov, A.V.; Gil’mutdinov, F.Z.; Soboleva, N.N.; Krivilyov, M.D. Effect of oxygen in surface layers formed during sliding wear of Ni–ZrO2 coatings. Surf. Coat. Technol. 2022, 434, 128174. [Google Scholar] [CrossRef]

- Deng, X.; Huang, L.; Wang, Q.; Fu, T.; Wang, Z. Three-body abrasion wear resistance of TiC-reinforced low-alloy abrasion-resistant martensitic steel under dry and wet sand conditions. Wear 2020, 452–453, 203310. [Google Scholar] [CrossRef]

- Yazdani, S.; Vitry, V. Using Molecular Dynamic Simulation to Understand the Deformation Mechanism in Cu, Ni, and Equimolar Cu-Ni Polycrystalline Alloys. Alloys 2023, 2, 77–88. [Google Scholar] [CrossRef]

| Element | Zr + Hf | Hf | Si | Cr | Fe | Ni | C | B | N | H | O |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Zr702 alloy plates | ≥99.2 | ≤4.5 | 0.2 | 0.05 | 0.025 | 0.005 | 0.16 | ||||

| Ni60A power | 4.3 | 13.7 | 4.43 | Bal. | 0.6 | 3.18 |

| Sample | Off-Focus Volume (mm) | Laser Power (W) | Scanning Speed (mm/s) | Feed Rate (r/min) | Beam Diameter (mm) | Energy Density (J/mm2) |

|---|---|---|---|---|---|---|

| S1 | 2.5 | 800 | 6 | 16 | 3 | 22.6 |

| S2 | 2.5 | 1000 | 6 | 16 | 3 | 28.3 |

| S3 | 2.5 | 1300 | 6 | 16 | 3 | 36.8 |

| S4 | 2.5 | 1500 | 6 | 16 | 3 | 42.5 |

| Element | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| C | 6.30 | 5.75 | 6.61 | 8.23 | 0.71 | 1.07 |

| O | 0.52 | 0.48 | ||||

| Si | 1.13 | 1.82 | ||||

| Cr | 2.25 | 1.73 | 18.43 | 17.80 | 11.31 | 3.48 |

| Fe | 1.48 | 1.32 | 1.61 | 2.65 | 7.46 | 3.07 |

| Ni | 17.93 | 14.45 | 5.55 | 7.29 | 76.88 | 86.58 |

| Zr | 40.82 | 42.64 | 0.57 | 3.98 | ||

| Hf | 2.54 | 2.40 | ||||

| W | 28.17 | 31.24 | 67.8 | 66.49 | 1.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Feng, A.; Zhao, P.; Pan, X.; Feng, H. Effect of Energy Density on the Microstructure and Wear Resistance of Nickel-Based WC Coatings by Laser Cladding of Preset Zr702 Alloy Plates. Coatings 2023, 13, 826. https://doi.org/10.3390/coatings13050826

Zhang G, Feng A, Zhao P, Pan X, Feng H. Effect of Energy Density on the Microstructure and Wear Resistance of Nickel-Based WC Coatings by Laser Cladding of Preset Zr702 Alloy Plates. Coatings. 2023; 13(5):826. https://doi.org/10.3390/coatings13050826

Chicago/Turabian StyleZhang, Guangsheng, Aixin Feng, Pu Zhao, Xiaoming Pan, and Huibin Feng. 2023. "Effect of Energy Density on the Microstructure and Wear Resistance of Nickel-Based WC Coatings by Laser Cladding of Preset Zr702 Alloy Plates" Coatings 13, no. 5: 826. https://doi.org/10.3390/coatings13050826

APA StyleZhang, G., Feng, A., Zhao, P., Pan, X., & Feng, H. (2023). Effect of Energy Density on the Microstructure and Wear Resistance of Nickel-Based WC Coatings by Laser Cladding of Preset Zr702 Alloy Plates. Coatings, 13(5), 826. https://doi.org/10.3390/coatings13050826

.jpg)