Abstract

The aging of paper depends on various factors, including environmental conditions, microbiological factors and chemical composition. Chitosan-coated paper is an eco-friendly material that has potential use in various packaging applications due to its mechanical, barrier and antibacterial properties. In this study, the aging stability of chitosan-coated wood-free wrapping paper was evaluated by examining pulp and four paper samples with different quantities of chitosan. Accelerated thermal aging and dynamic thermogravimetric analysis were used to assess the aging stability, while color changes were examined to understand the impact of chitosan coating. The study found that increasing chitosan coating led to improved aging stability due to the improved crosslinking process between chitosan and paper. The coated paper samples displayed a yellowish hue after 72 h of aging, with increased strength and resistance to weight loss. TGA results indicated that the temperature of complete burning of the sample increased with increasing chitosan coating. Additionally, coated paper samples exhibited a more even surface and improved barrier properties. Overall, chitosan-coated paper is a promising material for sustainable and eco-friendly packaging, printing and wrapping applications. This study’s findings have important implications for the development of environmentally-friendly packaging materials that possess desirable mechanical and barrier properties.

1. Introduction

Due to the versatility of paper, with different properties and capabilities such as recyclability, biodegradability, light weight and good mechanical properties, it is an excellent material for various applications such as packaging, printing, hygiene and household products [1]. Its porous and fibrous network structure and its poor barrier properties, especially its low oil and grease resistance, are among its most important characteristics, which greatly affect its various packaging applications [2]. Furthermore, due to its lipophilic nature, paper absorbs fatty substances that can damage the print and the individual laminated materials [2]. Although various surface modifications of paper, such as the application of waxes and multi-layer lamination with polyethylene, polyvinyl chloride, ethylene–vinyl alcohol copolymer and aluminum films, are used in the market, they pose an environmental problem related to the recycling and recovery of materials [3,4]. In addition, imparting antibacterial properties to paper used in the medical and food packaging sectors can be critical, not only to prevent product deterioration, but also to prevent bacterial growth and thus reduce contamination during storage, transportation and usage.

Recently, the green and sustainable paper and packaging industry has been committed to using raw materials, solvents and reagents that are as environmentally friendly as possible, thereby reducing or eliminating the use and production of hazardous substances and realizing the recycling of resources and waste materials. Against the backdrop of worsening pollution and the energy crisis, the development of sustainable or renewable materials has been identified as a global imperative for the sustainable development of society. The European Green Deal is a comprehensive plan by the European Union to make the European economy more sustainable and reduce greenhouse gas emissions. It also aims to end packaging waste by 2030 and promote reuse and recycling [5].

Therefore, the development of environmentally-friendly, renewable polysaccharide-based composites is of great importance for improving packaging (e.g., food packaging), reducing the generation of hazardous by-products and recycling resources. Renewable polysaccharides, such as cellulose, nanocellulose, hemicellulose, chitosan, starch, pectin, etc., play an important role in the field of paper coatings.

Chitosan is one of the most extensively-used polysaccharides in a variety of applications [6]. It is the product of N-deacetylation of the natural polysaccharide chitin, which has a similar chemical structure to cellulose [4]. Chitosan has many physiological properties, such as biodegradability, biocompatibility, non-toxicity and many others. Therefore, it is widely-used in packaging as a coating, food additive or antibacterial agent. Chitosan has been used to coat paper surfaces to improve the mechanical, barrier and antimicrobial properties of the paper and the coated paper could be used as an alternative packaging material to replace fossil-based packaging [7]. Recent studies on chitosan as a coating have focused on the development of composite coatings or multilayer coatings on the paper surface to combine the good mechanical resistance of the paper material with the barrier properties of coating materials [7,8,9,10,11]. The improvement of the barrier and mechanical properties of the paper by the addition of chitosan was confirmed by the fact that the pores of the paper are filled with chitosan [12,13,14]. This had an impact on reducing water vapor permeability, as well as improving stiffness, strength and toughness [15,16,17,18]. In addition, due to the improved mechanical properties of chitosan, many researchers have proposed chitosan-coated paper as an antimicrobial packaging [19,20,21,22].

Chitosan also exhibits a high sensitivity to numerous types of degradation, including thermodegradation, and studies have revealed that temperatures beyond 200–220 °C present critical degrees of degradation [23,24,25,26]. Researchers have been focused on addition of different plasticizers in the production of chitosan films [25,26]. Namely, different non-volatile polyol plasticizers (glycerol, xylitol and sorbitol) were investigated.

Thermal analysis such as thermogravimetry (TGA) has been widely used for the characterization of polymeric materials, since it monitors physical modifications of chitosan polymer matrix, composites, etc. [27,28,29]. Indeed, during the processing (packaging process) of coated materials, certain processes can seriously damage the polymer matrix. Therefore, controlling the processing and working conditions of any polymer material is important to maintain the material with the desired properties and avoid unnecessary degradation.

Recent advancements in applications of chitosan-based materials in the packaging and paper field include the development of composite coatings or multilayer coatings on paper surfaces to combine the good mechanical resistance of the paper material with the barrier properties of coating materials. These coatings have been shown to improve the mechanical, barrier and antimicrobial properties of paper, which makes them a potential alternative packaging material to replace fossil-based packaging. Furthermore, recent studies have explored the potential of chitosan-based materials as active packaging, which is designed to improve the quality and safety of packaged food products by extending their shelf life and reducing spoilage [30,31,32]. These materials can be used to control the release of active compounds such as antimicrobials and antioxidants to the packaged food product. The recent advancements in the applications of chitosan-based materials in the packaging and paper field have shown great potential for improving the properties of paper and providing more environmentally-friendly packaging alternatives [33,34,35].

As the applications and future possibilities of chitosan-based coatings and composites increase in various fields, this study presents a detailed investigation of the thermal stability of paper coatings. This is unique compared to previous research and is a novelty in that it gathers important information on the aging of paper in combination with bio-based chitosan coatings as packaging materials. This study aimed to form chitosan coatings with different amount of the chitosan on paper samples.

In developing this experiment, the aim was to prepare bio-based chitosan-coated wood-free wrapping paper and to study its strength and thermal stability, giving the answer as to whether chitosan coatings stabilized the desired properties over time.

2. Materials and Methods

2.1. Materials and Preparation Procedures

First, mixtures of cellulose for paper samples were prepared from bleached kraft wood-free pulp samples. The softwood had been delivered by Svenska Cellulosa Aktiebolaget (SCA), Sundsvall, Sweden. The hardwood cellulose had been delivered by Svilosa AD, Svishtov, Bulgaria. A separate cellulose refining process had been conducted using laboratory Valley beater (a laboratory Hollander-type beater), according to ISO 5264-1:1979. Next, the cellulose mixture was prepared in ratio 80:20. The obtained pulp mixture was beaten with a degree of 30 °SR (Schopper Riegler value), in accordance with ISO 5267-1/AC:2004.

The experimental investigations were conducted with one sample of only pulp, one with base-paper and three paper samples coated with chitosan. The wet-end chemical additives used for base paper preparation were added in the following order: (1) alkylketendimer sizing agent—1% of o.d.f (Kemira® Fennosize KD 157YC, Kemira Oyj, Helsinki, Finland); (2) cationic retention additive—0.025% of o.d.f. (modified polyacrylamide with molecular weight 11.106 g/mol and charge density +1.05 from Ciba Specialty Chemicals-Ciba® Percol® Co. (Basel, Switzerland)).

For the laboratory papermaking simulation process, a Rapid-Köthen laboratory paper-sheet machine (Birkenau, Germany) was used. All samples were prepared according to ISO 5269-2:2005, with base weight of 50 g/m2. The wet paper samples were dried at 95 °C under negative pressure of −90 kPa for a duration of 7 min.

Fluka (BioChemika, Tokyo, Japan) Crayfish Chitosan 28191 (2-Amino-2-deoxy-(1->4)-β-D-glucopyranan) with medium viscosity and acetic acid—99.8% with M = 60.05 g/mol—were used for the chitosan coating preparation. Chitosan (1 g) was dissolved in 1% (v/v) aqueous acetic acid (100 mL). The solution was stirred at 300 rev/min on a magnetic stirrer for 24 h, until the complete dissolving of chitosan. In the first 2 h, the solution was heated to 50 °C. The viscosity of the obtained chitosan was 300 mPa∙s.

Laboratory obtained base paper samples (50 g/m2) were coated with 3, 5 and 7 mL chitosan and dried in a vacuum dryer with P = 0.08 MPa and t = 50 °C until the samples were completely dried. The grammages of the obtained coatings were, respectively, 0.5 g/m2, 1 g/m2 and 2 g/m2. Paper samples’ coating was performed with the laboratory coating machine K Control Coater (RK PrintCoat, Royston, UK). The coating machine with automatic control used standard wire-wound bars to produce a uniform and repeatable coating. Stainless steel wet film deposit K-bar 120 µm with wire diameter 1.52 mm was used.

2.2. Methods

2.2.1. Microscopic Analysis

Fiber and paper compositions, with regard to their size and structure, were analyzed by specific microscopic analysis. A small amount of mechanically pre-milled fibers were placed in a porcelain pounder with 10 mL of 1% NaOH for 10 min. After rinsing the sample with distilled water on a fine metal mesh, three visual fields of fibers were prepared on a glass slide and evenly distributed. A drop of Herzberg’s reagent (Cl-Zn-I), according to ISO 9184-3:1990, was dropped on each of the fiber fields and, again, very carefully distributed. Finally, the samples were dried at about 50 °C. After cooling to room temperature, each sample was covered with a thin glass slide so that the fiber samples were evenly distributed, free of accumulations and air bubbles. Stained fiber samples were observed with a VisiScope® TL254T1 (VWR, Milano, Italy) microscope at 100× magnification; objective: 10×/0.25 E-PLAN, eyepiece: WF10×/20 mm.

2.2.2. Structural Properties

Basic weight of all samples was determined in accordance with the ISO 536 standard. Density and porosity were calculated form grammage and thickness, as described in the standard method ISO 534. Smoothness was determined by Bekk method, according to standard ISO 5627:1995. A minimum of 10 probes for each sample were tested. The thickness of samples was measured with a digital micrometer (Mitutoyo Corporation, Kawasaki, Japan) to the nearest 0.001 µm at 10 random locations on each paper.

2.2.3. Strength Properties

Tensile Index, TEA Index and elongation at break of all paper samples were determined on a tensile testing machine Zwick/Roell (Zwick/Roell GmbH, Ulm, Germany), according to ISO 1924-1/2:2000. The tested speed was 20 mm/min. Samples of paper strips 18 cm in length and 1.5 cm in width were used and a minimum of 10 probes for each sample were tested. Tear resistance is the force required to tear the sample after a cut is already made. The test was performed with an Elmendorf tester and proceeded as described in standard ISO 1974:2012. For each paper sheet, four parallel samples were measured. Tear index was calculated in mNm2/g.

All paper samples were analyzed in a standard atmosphere of 23 °C and 50% relative humidity.

2.2.4. Thermogravimetric Analysis

The TGA Q5000 analyzer (TA Instruments Inc., New Castle, DE, USA) was used for thermogravimetric analysis (TGA) of the investigated pulp, uncoated and chitosan-coated paper samples. Square samples (see Table 1) of 5 × 5 mm were cut and placed into the sample dish. A dynamic TGA method was performed, meaning that the temperature continued to increase over time as mass was recorded. The temperature-measuring range was between 10 °C and 600 °C. Heating rate was 10 °C/min.

Table 1.

Mass of the samples for TGA analysis.

2.2.5. Thermal Aging of Paper Samples

The accelerated thermal aging of the investigated paper samples was conducted, according to ISO 5630-1:2014, in a closed chamber at 105 °C, with air circulated at a standard humidity of 50%, for a duration of 72 h.

2.2.6. Colorimetric Properties of Paper

The color coordinates L*, a* and b* from the CIE Lab color space were measured after each 6 h of the 72 h of accelerated thermal aging by Konica Minolta Spectrophotometer CM-3630 from Frank-PTI (Birkenau, Germany), according to ISO 5631-2:2008, at measuring geometry and illuminant D65/10°.

2.2.7. Statistical Analysis

Statistical analysis was carried out using one-way ANOVA with a confidence level of 95% (p < 0.05) in Microsoft Excel (version 2016) using data analysis ToolPak. All experiments were performed according to standards and the results were expressed as the mean ± standard deviation.

3. Results and Discussion

The multiplicity of its fiber composition, the wet-end chemical additives’ presence, the production technology and additional calandering, coating or other finishing and ennobling processes determine the paper’s anisotropicity and its multifunctional applicability [36].

Generally, as a packaging material for household application, the obtained paper samples have to have optimal barrier properties with respect to water and grease, excellent optical and surface properties and sufficient strength, all well-balanced with its lower basic weight. Thus, fiber raw materials used were primarily bleached kraft soft- and hardwood tree species’ celluloses.

3.1. Fiber and Paper Sample Analysis

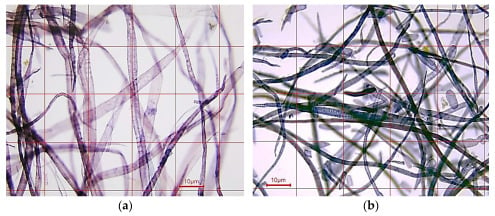

Figure 1 represents the fiber observation results from the microscopic analysis carried out in order to describe the precise type of cellulose used. The cellulose fibers from softwood trees consist of bleached kraft softwood cellulose from pine wood and bleached kraft hardwood cellulose from poplar and beech wood.

Figure 1.

Microphotograph of a fiber raw material: (a) bleached sulfate softwood from pine wood; (b) bleached sulfate hardwood from beech wood.

It is well-known that the higher the delignification, the stronger the hydrogen bonds in the paper to be obtained. The used Herzberg’s reagent stained the fiber a violet-bluish color, which determined its delignification degree and lignin content as up to 9%, while brown-yellowish designated over 9%. Based on the degree of inter-fiber connection depending on the delignification, we could infer that the strength properties of the obtained paper samples would meet the end users’ requirements. Of essential importance for the successful application of paper are the detailed characterization of its structure and the influence of chemical additives on the complex parameters of paper. As an anisotropic material, paper properties should be determined in different directions, as to provide meaningful scientific discussions, starting with basic weight determination, as well as its thickness, porosity, density and smoothness.

Paper smoothness is of substantial importance for a successful surface-coating process. It also indicates a paper surface structure amendment. From the structural-dimensional base paper and the chitosan-coated paper properties data in Table 2, it is found that the addition of hydrophobic agent and retention additive does not affect the paper surface smoothness (compare sample 0 to sample 1). The obtained coated paper samples are characterized by a dense structure, increasing respectively to the grammage of the chitosan coating.

Table 2.

Structural-dimensional properties of uncoated and coated paper samples.

Regarding the chitosan-coated paper samples (samples 2 to 4), a rise in the paper smoothness is observed. As the chitosan coating amount increases, the effect also increases. As expected, paper sample thickness has mostly the same values. From Table 2 data, it can also be seen that as the chitosan coating grammage increases from 0.5 to 2 g/m2, the density increases and the porosity decreases. The examined chitosan-coated paper samples have even structure, accordingly with the chitosan coating grammage.

3.2. Thermogravimetric Analysis of Uncoated and Coated Paper Samples

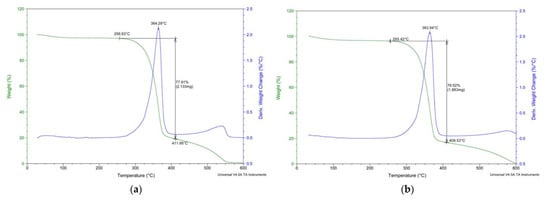

Figure 2 shows the weight loss (colored green) and derivative weight loss (colored blue) curves from a thermogravimetric analysis of each of the samples, from which both the beginning and the end of the second stage of the weight loss can be identified. The weight loss of each sample as a function of temperature is shown in Figure 2. The results show that each sample passes through three stages of weight loss. The initial stage of weight loss for samples 0 and 1 takes place between 10 °C and 100 °C, where moisture evaporation occurs. Figure 2a,b shows that the second stage occurs between 257 °C and 412 °C, with weight losses of 77.91% for sample 0 and 79.52% for sample 1, respectively. After 412 °C, the third stage occurs in both samples, where the paper becomes completely degraded.

Figure 2.

TGA curves of (a) Sample 0 (only pulp) reprinted from Ref. [36]; (b) Sample 1 (base paper) reprinted from Ref. [36]; (c) Sample 2 (base paper + 0.5 g/m2 chitosan); (d) Sample 3 (base paper + 1 g/m2 chitosan); (e) Sample 4 (base paper + 2 g/m2 chitosan); (f) All paper samples in a comparative view.

It has been reported that the TGA curve of pure chitosan has two stages of weight loss in the range from 47 °C to 450 °C. The first occurs in the range of 47–100 °C due to the loss of water molecules, with a weight loss of about 9%. The primary degradation of pure chitosan starts at 247 °C. It is totally degraded at about 450 °C, with a weight loss of approximately 34% [37,38]. Figure 2c–f presents the samples coated with chitosan solutions. Three stages are also detected. It is observed that, with the increase in the amount of chitosan coating, the second stage of weight loss decreases. At 0.5 g/m2 chitosan, the start of the second stage begins at 254.61 °C, and with 2 g/m2, the stage begins at 241.70 °C. From the analysis, when comparing sample 1 (Figure 2b) with coated samples 2, 3 and 4 (Figure 2c–e), it is seen that the weight loss of coated paper samples is slightly lower than the uncoated base paper. With increasing chitosan coating amount, the weight loss slightly increases, but the decreasing trend continues between samples 3 and 4.

The second stages of weight loss of chitosan started at 232 °C to 441 °C and the last stages, in which chitosan continued to degrade, started above 441 °C. This result might be due to the degradation of polysaccharides and decomposition of chitosan molecules. It is also seen that the maximum weigh loss temperature increases with increasing chitosan coating amount.

The thermal degradation patterns of the studied samples are identical, for the cellulose sample, the base paper and the chitosan-coated paper samples (Figure 2f). Undoubtedly, this makes an impression of the different behavior of sample 3 (base paper + 2 g/m2 chitosan), which has different behavior from the other samples’ deviation weight change. This result is probably due to the unevenly-distributed chitosan coating, as a result of larger chitosan coating amount at low base paper weight, which is only 50 g/m2 (Figure 3).

Figure 3.

Unevenly distributed chitosan coating (in the blue circle area).

3.3. Colorimetric Parameter Characterization of Uncoated and Coated Paper Samples during Accelerated Thermal Aging

Due to the specific applications investigated in this paper, the change in the color characteristics, especially lightness, of the uncoated and coated papers over time, defined by accelerated thermal aging with duration of 72 h at 105 °C, is also of an increased significance.

Natural aging of paper is too slow to allow for observing changes in an acceptable period. Thereby, laboratory techniques for accelerated paper aging under dry heat or light exposure have often been used [36]. Three major ambitions of carrying out the accelerated paper aging are stated hereafter: firstly, to provide the relative ranking of materials or physical combination of materials in a conveniently short time, with respect to their physical durability or chemical stability; secondly, to predict or to evaluate the potential long-term appropriateness of material systems under proposed conditions of use; thirdly, to elucidate the chemical reactions involved (the degradation mechanism) and the physical consequences thereof. Hydrolytic degradation has been discussed as the most important cause for the decrease in paper strength properties and the lignin content as the most important aging factor [39,40]. In the current experiment, the fiber cellulose material was bleached (lignin content is lower than 9%), so it cannot be a curtailing factor for paper color changes during accelerated thermal aging. Therefore, if changes are observed, they are a result of the applied chitosan coating.

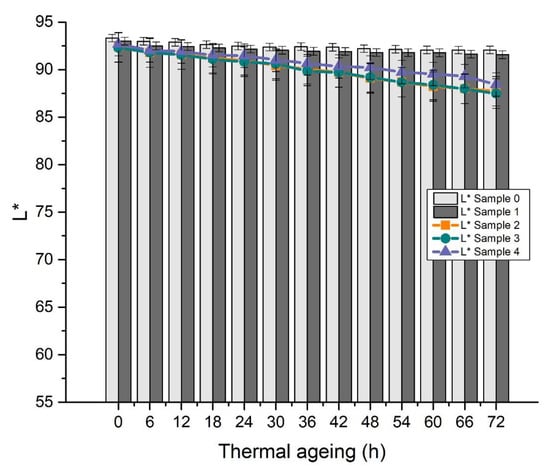

In the CIE L*a*b* color space, color coordinate L* presents the brilliance of paper—its brightness and lightness. The coordinate is vertical; from 0 at the bottom (absolute black), paper has no brightness; through 50 (grey) in the middle; to 100 at the top (absolute white), where paper has maximum brilliance. The lighter the color, the higher the value. The a* scale presents red vs. green scale, at which a positive number indicates red and a negative indicates green. The b* scale presents yellow vs. blue, at which a positive number indicates yellow and a negative number indicates blue. The change in the lightness of the investigated paper samples without and with chitosan coating, in the beginning and after 72 h of accelerated thermal aging, are presented in Figure 4.

Figure 4.

Lightness of the paper samples without and with chitosan coating during 72 h thermal aging.

As expected, the color coordinate—L*—of the examined paper samples decreases over time. Small differences (nearly to the error of the analysis) between paper samples of only cellulose (sample 0) and base paper (sample 1) have been observed. A comparatively low color parameter variation over time has been observed, being most sensitive during the first 24 h of the accelerated thermal aging. By adding the chitosan coating, paper lightness becomes slightly darker, but remains still very similar to the base paper. When increasing the chitosan coating from 0.5 g/m2 to 2 g/m2 and the duration of the thermal aging, the color of the paper samples becomes darker and the color difference becomes bigger. The location of the curves does not correspond to the amount of chitosan coating. The higher location of the curve characterizing the whiteness of paper with 2 g/m2 of chitosan coating (sample 4) is noticeable. The fact that this paper has an increased whiteness compared to the other two coated samples (sample 2 and sample 3) is probably due both to the poorer distribution of the coating, due to the inability of the paper to absorb this large amount of coating, and to additional cross-linking processes occurring in the chitosan coating at 105 °C. The lightness reversion from 0 h to 72 h of thermal aging for the three investigated coated papers is in the range of 92 to 87, which is not high when taking into account the high temperature when conducting the accelerated aging.

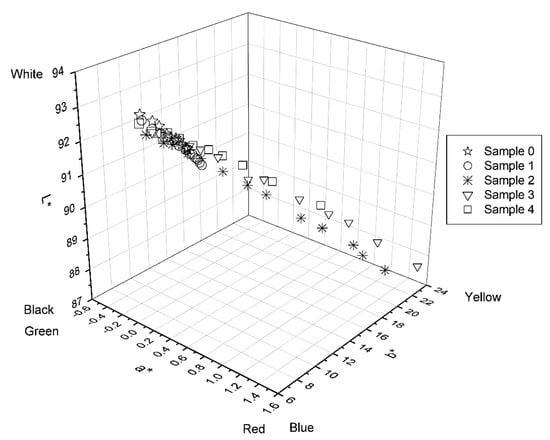

Figure 5 shows the colorimetric properties results for the examined paper samples (color characteristics L*, a* and b*) with and without chitosan coating before and after 72 h for each 6 h of accelerated thermal aging.

Figure 5.

Colorimetric characteristics L*, a* and b* of paper samples during 72 h of accelerated thermal aging.

The color coordinate measurements, presented in Figure 5, clearly show that the only cellulose sheet material (sample 0) and base paper sample (sample 1) are most stable. No drastic amending of the color has been observed. For the chitosan-coated paper samples (samples 2, 3 and 4), the color revision occurs after 36 h of thermal aging. The values of the colorimetric characteristics decrease, which means darkening of the paper, i.e., becoming yellowish. This change is significant and shows a bigger step for 0.5 g/m2 and 1 g/m2 chitosan-coated paper samples. Therefore, the smaller the coating, the higher the yellowing that is observed. When applying a bigger coating layer, the aging of the paper is slower. This is also proven by the observed increase in the tensile index test results, evidencing the additional cross-linking between the cellulose fibers in the paper and the coating and the chitosan coating itself.

The observed variations in color parameters may also occur due to the laboratory coating technique used. It should be noted that, in industrial paper production, additional processing of the paper, in most cases, occurs before the complete paper web drying and, in cases of impossibility, an abnormality should be foreseen. In an industrial papermaking process, these variations most probably could be prevented.

3.4. Strength Properties of Uncoated and Coated Paper Samples during Accelerated Thermal Aging

Strength properties of paper are a convenient indicator, defining paper’s ability to endure processing. It also determines the load resistance level of the products produced.

Investigated paper strength properties’ description starts with defining the tensile index, the tensile energy absorption index, the elongation and the tear index. The results are presented in Table 3. Most interesting from a scientific point of view are the strength changes, which are as expected after the thermal aging of chitosan-coated papers. The strength reversion of the uncoated paper is well-known [41,42,43]. How much and in which direction the chitosan-coated paper changes occur could be resultant from the coating and base paper adhesion and the level of cross-linking among chitosan molecules.

Table 3.

Strength properties of base and chitosan-coated paper samples before and after 72 h thermal aging.

From Table 3, strength properties are observed that, with respect to the strength properties, the addition of the “wet-end” chemical additives is positive, while for tensile index, the chitosan coating effect is negative. This chitosan coating effect is probably because of the decreased elasticity and plasticity of the base paper. The structure of the paper is more static and the strength decreases, while the elongation increases, based on the increased elasticity of the chitosan. Rather than an observed reduction in tensile index, an increase of about 46.75% is measured at 2 g/m2 chitosan coating compared to the base paper and 10.30% at the lowest chitosan coating (0.5 g/m2). TEA index increases from sample 0 to sample 4, because it has a mathematical dependence on two parameters—tensile and elongation—and, as is visible, the elongation of the samples rises with the coating quantity. As the chitosan coating on paper increases from 0.5 g/m2 to 2 g/m2, the values of the strength indicators increase, both at 0 h and 72 h of thermal aging. This effect is due not only to the bigger coating layer, but also to the improved base paper and chitosan layer adhesion. Undoubtedly, the chitosan crosslinking effect at the higher thermal aging temperature is also visible.

4. Conclusions

Chitosan coating of paper has been an endorsed exemplary method for improving paper properties and for enhancing the range of its application. From the experiments conducted with uncoated and chitosan-coated paper samples of bleached soft- and hardwood pulp (in ratio 80:20), it was found that coated papers had excellent strength and thermal stability during 72 h of accelerated thermal aging. The change in the weight loss of the paper samples as a function of temperature was monitored by TGA. When comparing the weight losses, it was found that, with the increase in the amount of chitosan coating, the second stage of weight loss decreased. At 0.5 g/m2 chitosan, the start of the second stage began at 254.61 °C, and at 2 g/m2, the stage began at 241.70 °C. The second stages of weight loss of chitosan started at 232 °C to 441 °C and the last stages, in which chitosan continued to degrade, were above 441 °C. The weight loss of coated paper samples was slightly lower than the uncoated base paper. The maximum weigh loss temperature increased with increasing chitosan coating amount. A comparatively low color parameter variation over time has been observed, being most sensitive during the first 24 h of the accelerated thermal aging. By adding the chitosan layer, paper lightness became slightly darker, but was still very close to the base paper. Increasing the chitosan coating from 0.5 g/m2 to 2 g/m2 and the duration of the thermal aging, the color of the paper samples became darker and the color difference grew bigger. The lightness reversion from 0 h to 72 h of thermal aging for the three investigated coated papers was in the range of 92 to 87, which was not high when taking into account the high temperature when conducting the accelerated aging. After the aging, rather than observing a reduction in tensile index, an increase of about 46.75% was measured at 2 g/m2 chitosan coating, compared to the base paper, and 10.30% at the lowest chitosan coating (0.5 g/m2).

Author Contributions

D.T., N.Y. and U.V.-B. were responsible for carrying out the analysis, investigation, validation, methodology, visualization and writing of the main manuscript text; D.T. and V.L. were responsible for carrying out the conceptualization, validation, editing and writing of the main manuscript text. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Bulgarian Science Fund, grant number 920 (KP-06-H49/1)—“Investigation of new possibilities for obtaining multifunctional properties of paper”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript or in the decision to publish the results.

References

- Jung, J.; Raghavendra, G.M.; Kim, D.; Seo, J. One-step synthesis of starch-silver nanoparticle solution and its application to antibacterial paper coating. Int. J. Biol. Macromol. 2018, 107, 2285–2290. [Google Scholar] [CrossRef]

- Wang, F.-J.; Wang, L.-Q.; Zhang, X.-C.; Ma, S.-F.; Zhao, Z.-C. Enhancement of oil resistance of cellulose packaging paper for food application by coating with materials derived from natural polymers. J. Food Eng. 2022, 332, 111039. [Google Scholar] [CrossRef]

- Chen, H.; Wang, B.; Li, J.; Ying, G.; Chen, K. High-strength and super-hydrophobic multilayered paper based on nano-silica coating and micro-fibrillated cellulose. Carbohydr. Polym. 2022, 288, 119371. [Google Scholar] [CrossRef] [PubMed]

- Deng, J.; Zhu, E.-Q.; Xu, G.-F.; Naik, N.; Murugadoss, V.; Ma, M.-G.; Guo, Z.; Shi, Z.-J. Overview of renewable polysaccharide-based composites for biodegradable food packaging applications. Green Chem. 2021, 24, 480–492. [Google Scholar] [CrossRef]

- European Commission–Press Release. European Green Deal: Putting an End to Wasteful Packaging, Boosting Reuse and Recycling, Last Revised November 2022. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_22_7155 (accessed on 28 March 2023).

- Azmana, M.; Mahmood, S.; Hilles, A.R.; Rahman, A.; Bin Arifin, M.A.; Ahmed, S. A review on chitosan and chitosan-based bionanocomposites: Promising material for combatting global issues and its applications. Int. J. Biol. Macromol. 2021, 185, 832–848. [Google Scholar] [CrossRef]

- Tanpichai, S.; Witayakran, S.; Wootthikanokkhan, J.; Srimarut, Y.; Woraprayote, W.; Malila, Y. Mechanical and antibacterial properties of the chitosan coated cellulose paper for packaging applications: Effects of molecular weight types and concentrations of chitosan. Int. J. Biol. Macromol. 2019, 155, 1510–1519. [Google Scholar] [CrossRef] [PubMed]

- Gatto, M.; Ochi, D.; Yoshida, C.M.P.; da Silva, C.F. Study of chitosan with different degrees of acetylation as cardboard paper coating. Carbohydr. Polym. 2019, 210, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Winotapun, C.; Hararak, B.; Treetong, A.; Chaloeijitkul, K.; Sane, A. Self-assembly of colloidal lignin nanosphere particles blended with chitosan composite coated bagasse paper: An eco-friendly food packaging with antimicrobial properties. Colloids Surf. A Physicochem. Eng. Asp. 2022, 655, 130207. [Google Scholar] [CrossRef]

- Hameed, A.Z.; Raj, S.A.; Kandasamy, J.; Baghdadi, M.A.; Shahzad, M.A. Chitosan: A Sustainable Material for Multifarious Applications. Polymers 2022, 14, 2335. [Google Scholar] [CrossRef]

- Adibi, A.; Valdesueiro, D.; Simon, L.; Lenges, C.P.; Mekonnen, T.H. High Barrier Sustainable Paper Coating Based on Engineered Polysaccharides and Natural Rubber. ACS Sustain. Chem. Eng. 2022, 10, 10718–10732. [Google Scholar] [CrossRef]

- Fernandes, S.C.; Freire, C.S.; Silvestre, A.J.; Neto, C.P.; Gandini, A. Novel materials based on chitosan and cellulose. Polym. Int. 2011, 60, 875–882. [Google Scholar] [CrossRef]

- Verma, A.; Singh, C.; Singh, V.; Jain, N. Fabrication and characterization of chitosan-coated sisal fiber–Phytagel modified soy protein-based green composite. J. Compos. Mater. 2019, 53, 2481–2504. [Google Scholar] [CrossRef]

- Wu, M.; Xu, R.; Liu, C.; Li, B.; Long, Z. Amelioration of Physical Properties and Printability of Paper Coated with N-methylated Chitosan. Sci. Rep. 2020, 10, 9936. [Google Scholar] [CrossRef] [PubMed]

- Khwaldia, K.; Basta, A.H.; Aloui, H.; El-Saied, H. Chitosan–caseinate bilayer coatings for paper packaging materials. Carbohydr. Polym. 2014, 99, 508–516. [Google Scholar] [CrossRef]

- Nicu, R.; Lupei, M.; Balan, T.; Bobu, E. Alkyl-Chitosan as Paper Coating Material to Improve Water Barrier Properties. Cellul. Chem. Technol. 2013, 47, 623–630. Available online: https://www.cellulosechemtechnol.ro/pdf/CCT7-8(2013)/p.623-630.pdf (accessed on 28 March 2023).

- Divsalar, E.; Tajik, H.; Moradi, M.; Forough, M.; Lotfi, M.; Kuswandi, B. Characterization of cellulosic paper coated with chitosan-zinc oxide nanocomposite containing nisin and its application in packaging of UF cheese. Int. J. Biol. Macromol. 2018, 109, 1311–1318. [Google Scholar] [CrossRef]

- Bordenave, N.; Grelier, S.; Coma, V. Hydrophobization and Antimicrobial Activity of Chitosan and Paper-Based Packaging Material. Biomacromolecules 2010, 11, 88–96. [Google Scholar] [CrossRef] [PubMed]

- Egil, A.C.; Ozdemir, B.; Gunduz, S.K.; Altıkatoglu-Yapaoz, M.; Budama-Kilinc, Y.; Mostafavi, E. Chitosan/calcium nanoparticles as advanced antimicrobial coating for paper documents. Int. J. Biol. Macromol. 2022, 215, 521–530. [Google Scholar] [CrossRef]

- Morin-Crini, N.; Lichtfouse, E.; Torri, G.; Crini, G. Applications of chitosan in food, pharmaceuticals, medicine, cosmetics, agriculture, textiles, pulp and paper, biotechnology, and environmental chemistry. Environ. Chem. Lett. 2019, 17, 1667–1692. [Google Scholar] [CrossRef]

- Cabañas-Romero, L.V.; Valls, C.; Valenzuela, S.V.; Roncero, M.B.; Pastor, F.I.J.; Diaz, P.; Martinez, J. Bacterial Cellulose–Chitosan Paper with Antimicrobial and Antioxidant Activities. Biomacromolecules 2020, 21, 1568–1577. [Google Scholar] [CrossRef]

- Brodnjak, U.V.; Tihole, K. Chitosan Solution Containing Zein and Essential Oil as Bio Based Coating on Packaging Paper. Coatings 2020, 10, 497. [Google Scholar] [CrossRef]

- Kurek, M.; Brachais, C.-H.; Nguimjeu, C.M.; Bonnotte, A.; Voilley, A.; Galić, K.; Couvercelle, J.-P.; Debeaufort, F. Structure and thermal properties of a chitosan coated polyethylene bilayer film. Polym. Degrad. Stab. 2012, 97, 1232–1240. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Aisyah, H.A.; Nordin, A.H.; Ngadi, N.; Yusoff, M.; Zuhri, M.; Rizal, M.; Asyraf, M.; Sapuan, S.M.; Zainudin, E.S.; et al. Nanocomposites for Various Advanced Applications. Polymers 2022, 14, 874. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, C.; Coelhoso, I.M.; Fernando, A.L. Chitosan Composites in Packaging Industry—Current Trends and Future Challenges. Polymers 2020, 12, 417. [Google Scholar] [CrossRef]

- Nair, M.S.; Tomar, M.; Punia, S.; Kukula-Koch, W.; Kumar, M. Enhancing the functionality of chitosan- and alginate-based active edible coatings/films for the preservation of fruits and vegetables: A review. Int. J. Biol. Macromol. 2020, 164, 304–320. [Google Scholar] [CrossRef] [PubMed]

- Xing, Y.; Li, X.; Guo, X.; Li, W.; Chen, J.; Liu, Q.; Xu, Q.; Wang, Q.; Yang, H.; Shui, Y.; et al. Effects of Different TiO2 Nanoparticles Concentrations on the Physical and Antibacterial Activities of Chitosan-Based Coating Film. Nanomaterials 2020, 10, 1365. [Google Scholar] [CrossRef] [PubMed]

- Nurazzi, N.M.; Asyraf, M.R.M.; Rayung, M.; Norrrahim, M.N.F.; Shazleen, S.S.; Rani, M.S.A.; Shafi, A.R.; Aisyah, H.A.; Radzi, M.H.M.; Sabaruddin, F.A.; et al. Thermogravimetric Analysis Properties of Cellulosic Natural Fiber Polymer Composites: A Review on Influence of Chemical Treatments. Polymers 2021, 13, 2710. [Google Scholar] [CrossRef] [PubMed]

- Nurazzi, N.M.; Abdullah, N.; Norrrahim, M.N.F.; Kamarudin, S.H.; Ahmad, S.; Shazleen, S.S.; Rayung, M.; Asyraf, M.R.M.; Ilyas, R.A.; Kuzmin, M. Thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) of PLA/cellulose composites. In Polylactic Acid-Based Nanocellulose and Cellulose Composites, 1st ed.; Parameswaranpillai, J., Siengchin, S., Salim, N.V., George, J.J., Poulose, A., Eds.; CRC Press: Boca Raton, FL, USA, 2022; pp. 145–164. [Google Scholar] [CrossRef]

- Ezati, P.; Rhim, J.-W. pH-responsive chitosan-based film incorporated with alizarin for intelligent packaging applications. Food Hydrocoll. 2020, 102, 105629. [Google Scholar] [CrossRef]

- Casalini, S.; Baschetti, M.G. The use of essential oils in chitosan or cellulose-based materials for the production of active food packaging solutions: A review. J. Sci. Food Agric. 2023, 103, 1021–1041. [Google Scholar] [CrossRef]

- Rapa, M.; Vasile, C. Chitin- and Chitosan-Based Bionanocomposites for Active Packaging. In Chitin- and Chitosan-Based Biocomposites for Food Packaging Applications, 1st ed.; Jacob, J., Loganathan, S., Thomas, S., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 59–68. [Google Scholar] [CrossRef]

- Zeng, J.; Ren, X.; Zhu, S.; Gao, Y. Fabrication and characterization of an economical active packaging film based on chitosan incorporated with pomegranate peel. Int. J. Biol. Macromol. 2021, 192, 1160–1168. [Google Scholar] [CrossRef] [PubMed]

- Flórez, M.; Guerra-Rodríguez, E.; Cazón, P.; Vázquez, M. Chitosan for food packaging: Recent advances in active and intelligent films. Food Hydrocoll. 2022, 124, 107328. [Google Scholar] [CrossRef]

- Riseh, R.S.; Vatankhah, M.; Hassanisaadi, M.; Kennedy, J.F. Chitosan-based nanocomposites as coatings and packaging materials for the postharvest improvement of agricultural product: A review. Carbohydr. Polym. 2023, 309, 120666. [Google Scholar] [CrossRef]

- Yavorov, N.; Todorova, D.; Brodnjak, U.V.; Lasheva, V. Thermal stability of packaging papers treated of silver water. In International Symposium on Graphic Engineering and Design, Novi Sad, Serbia, 3-5 November 2022; Vladić, G., Ed.; University of Novi Sad: Novi Sad, Serbia, 2022; pp. 63–72. [Google Scholar] [CrossRef]

- Kumar, S.; Dutta, P.; Koh, J. A physico-chemical and biological study of novel chitosan–chloroquinoline derivative for biomedical applications. Int. J. Biol. Macromol. 2011, 49, 356–361. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Koh, J. Physiochemical, Optical and Biological Activity of Chitosan-Chromone Derivative for Biomedical Applications. Int. J. Mol. Sci. 2012, 13, 6102–6116. [Google Scholar] [CrossRef] [PubMed]

- Małachowska, E.; Dubowik, M.; Boruszewski, P.; Łojewska, J.; Przybysz, P. Influence of lignin content in cellulose pulp on paper durability. Sci. Rep. 2020, 10, 19998. [Google Scholar] [CrossRef] [PubMed]

- Małachowska, E.; Dubowik, M.; Boruszewski, P.; Przybysz, P. Accelerated ageing of paper: Effect of lignin content and humidity on tensile properties. Heritage Sci. 2021, 9, 132. [Google Scholar] [CrossRef]

- Afsharpour, M.; Imani, S. Preventive protection of paper works by using nanocomposite coating of zinc oxide. J. Cult. Herit. 2017, 25, 142–148. [Google Scholar] [CrossRef]

- Todorova, D.; Yavorov, N.; Lasheva, V.; Damyanova, S.; Kostova, I. Lavender Essential Oil as Antibacterial Treatment for Packaging Paper. Coatings 2023, 13, 32. [Google Scholar] [CrossRef]

- Todorova, D.; Yavorov, N.; Lasheva, V. Improvement of barrier properties for packaging applications. Sustain. Chem. Pharm. 2022, 27, 100685. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).