Optical Characterization of Inhomogeneous Thin Films Deposited onto Non-Absorbing Substrates

Abstract

1. Introduction

2. Experiment

2.1. Sample Preparation

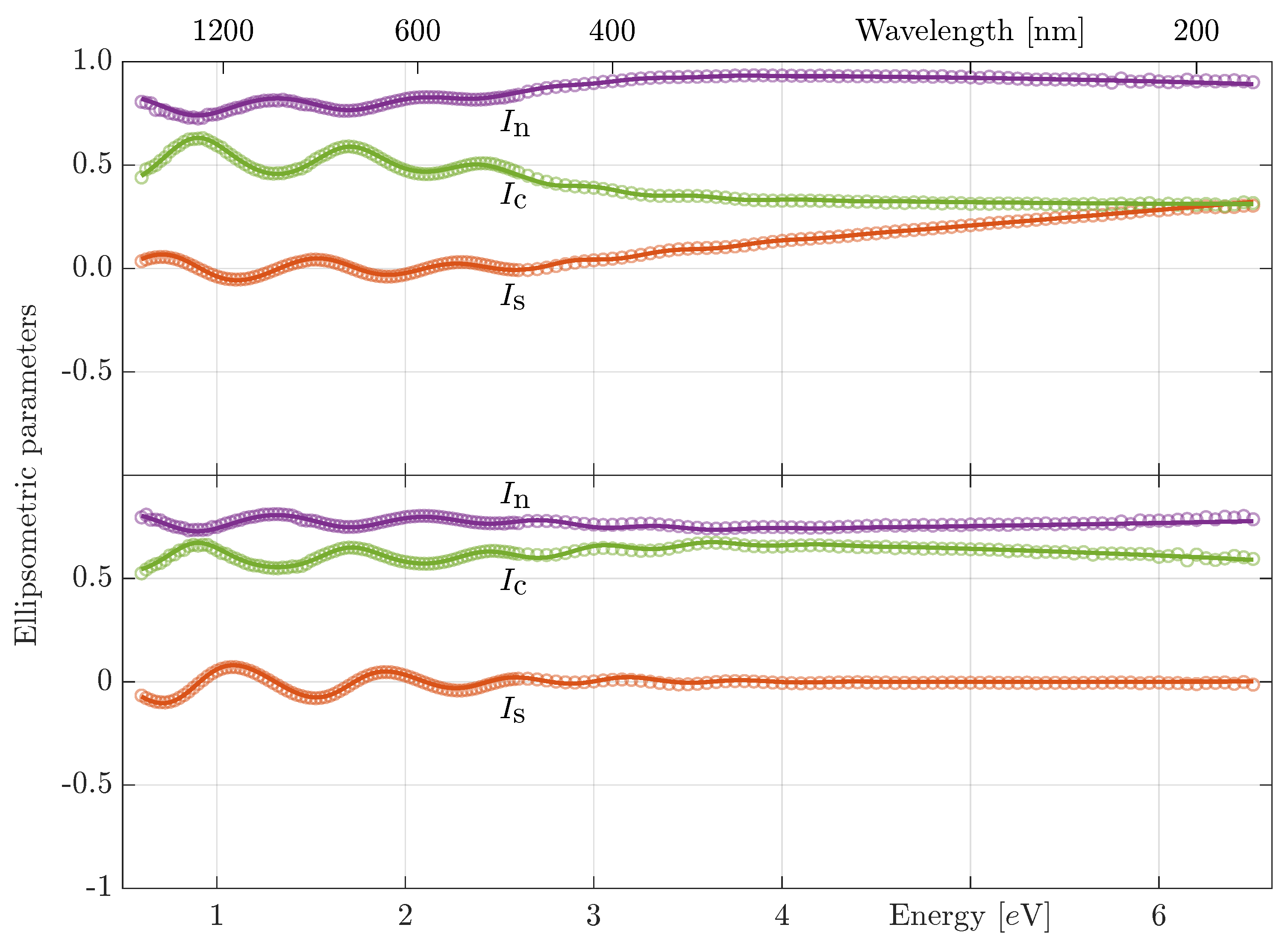

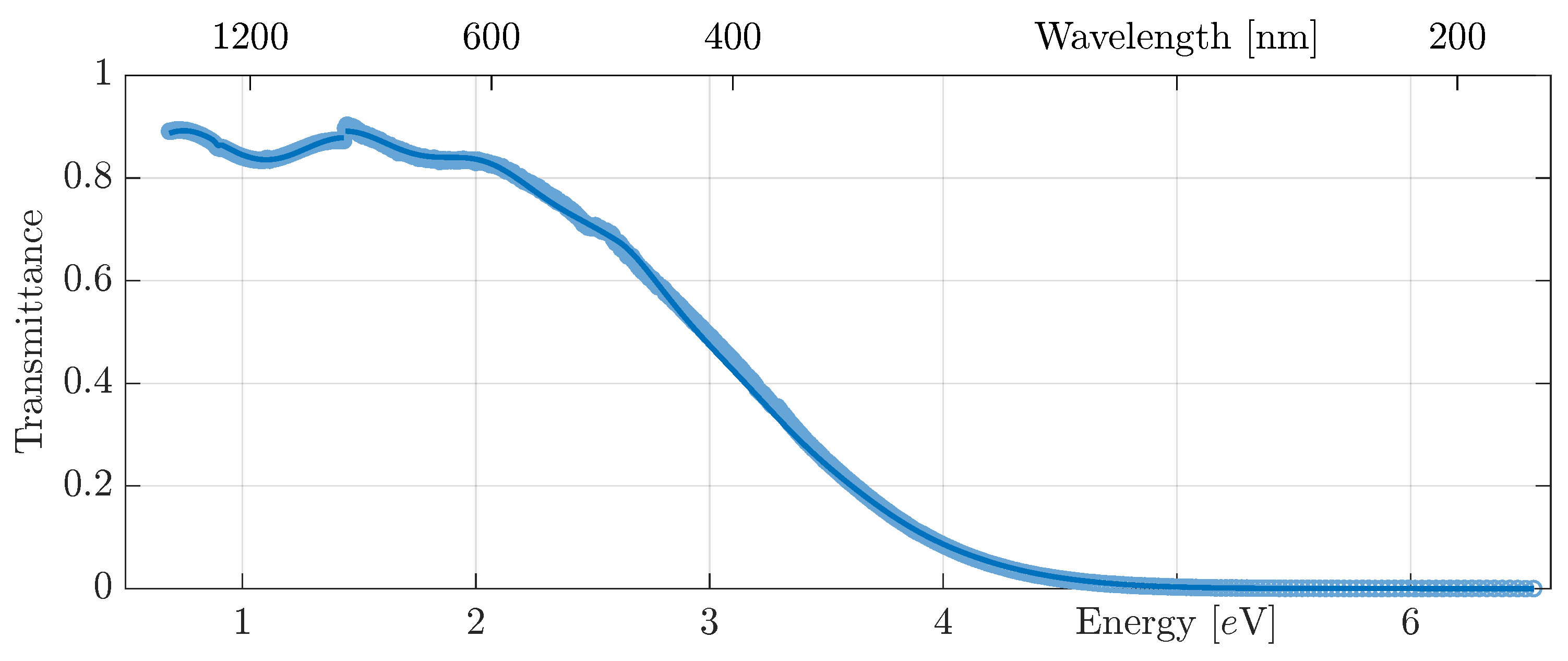

2.2. Experimental Arrangement

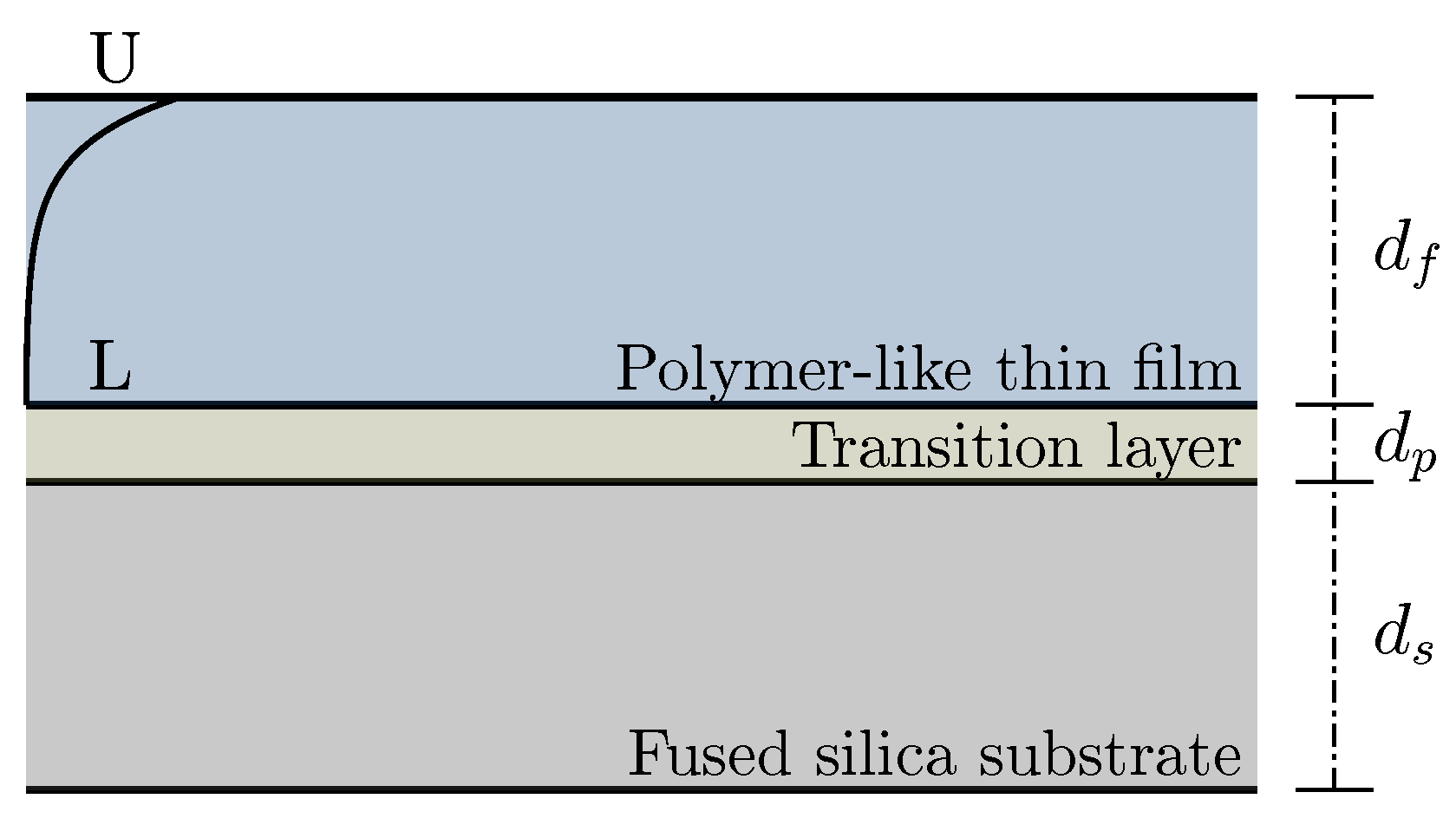

3. Structural Model

- ◦

- The surrounding medium is assumed to be air.

- ◦

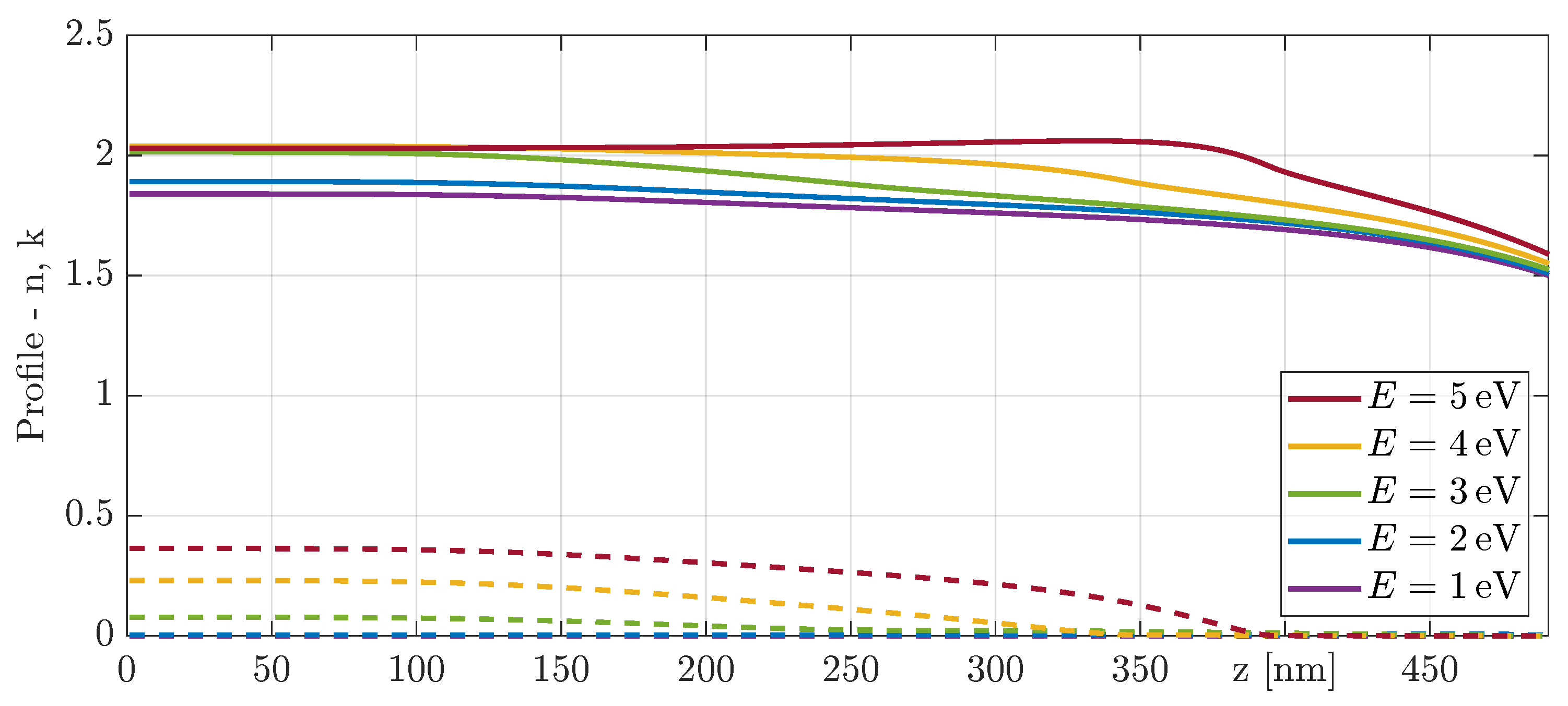

- Studied film is optically isotropic and inhomogeneous with the profile of optical constants perpendicular to the film boundary.

- ◦

- The transition layer is modeled by an isotropic homogeneous thin layer.

- ◦

- The substrate is also isotropic, homogeneous, and of sufficient thickness to disregard light interference within the substrate.

- ◦

- All boundaries are assumed to be smooth and parallel.

4. Dispersion Model of the Inhomogeneous Film

5. Dispersion Model of the Transition Layer

6. Data Processing

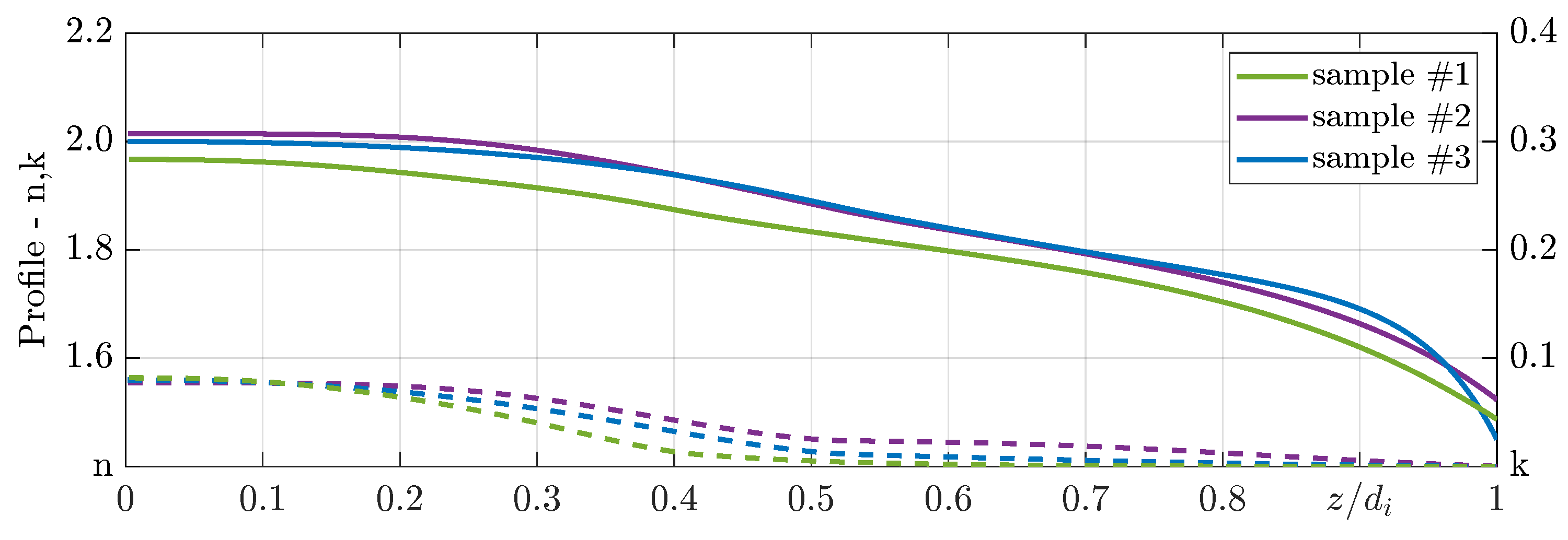

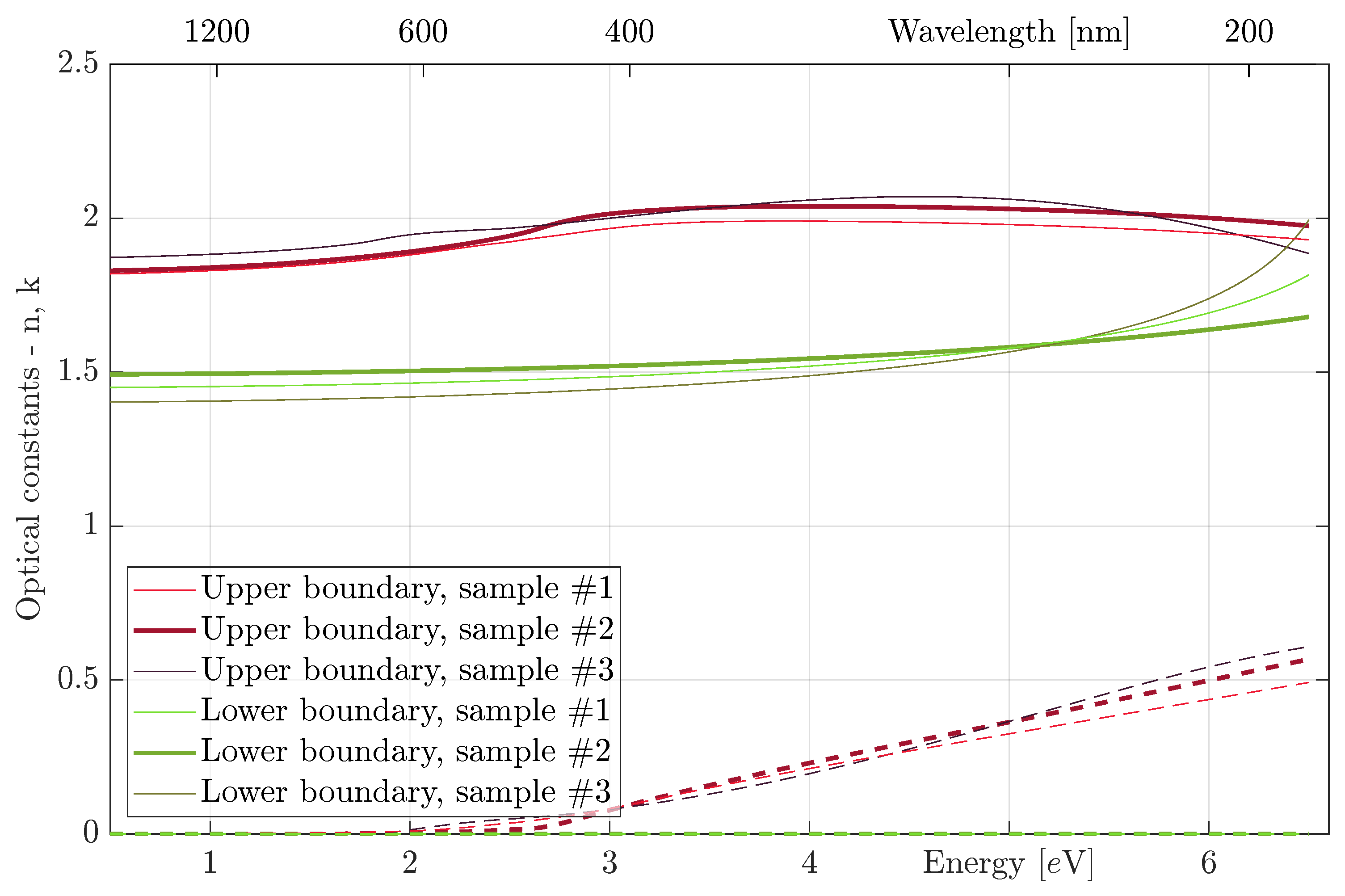

7. Results and Discussion

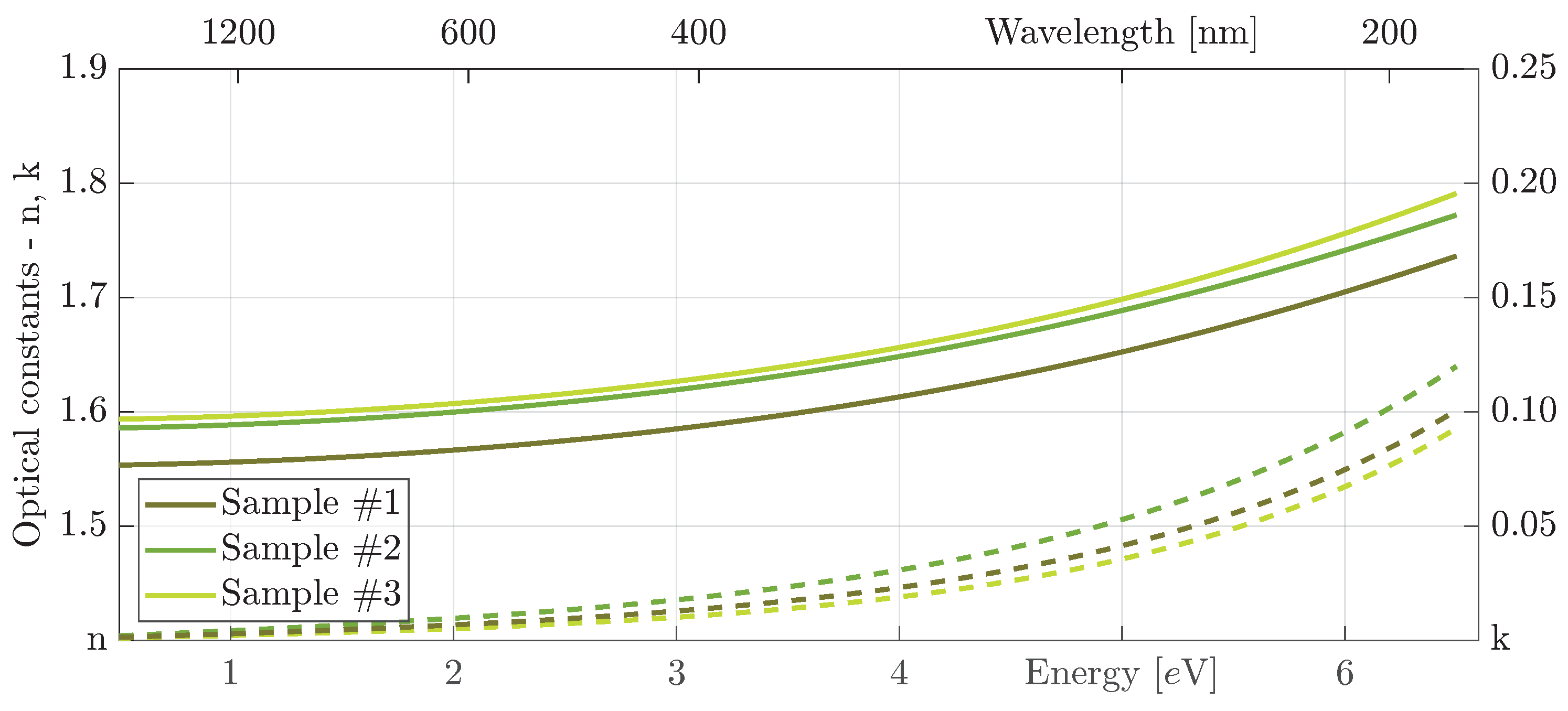

Transition Layer

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vašíček, A. Polarimetric Methods for the Determination of the Refractive Index and the Thickness of Thin Films on Glass. J. Opt. Soc. Am. 1947, 37, 145–153. [Google Scholar] [CrossRef] [PubMed]

- Ohlídal, I.; Navrátil, K.; Schmidt, E. Simple method for the complete optical analysis of very thick and weakly absorbing films: Application to magnetic garnet-films. Appl. Phys. A 1982, 29, 157–162. [Google Scholar] [CrossRef]

- Lohner, T.; Kumar, K.J.; Petrik, P.; Subrahmanyam, A.; Bársony, I. Optical analysis of room temperature magnetron sputtered ITO films by reflectometry and spectroscopic ellipsometry. J. Mater. Res. 2014, 29, 1528–1536. [Google Scholar] [CrossRef]

- Pei, L.; Jiaqi, Z.; Yuankun, Z.; Jiecai, H. Preparation and optical properties of sputtered-deposition yttrium fluoride film. Nucl. Instrum. Methods Phys. Res. B 2013, 307, 429–433. [Google Scholar] [CrossRef]

- Jin, J.; Jin, C.; Li, C.; Deng, W.; Yao, S. Influence of substrate temperatures on the properties of GdF 3 thin films with quarter-wave thickness in the ultraviolet region. Appl. Opt. 2015, 54, 5117–5122. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Maier, R.; Dewa, P.G.; Schreiber, H.; Bellman, R.A.; Elli, D.D. Nanoporous structure of a GdF 3 thin film evaluated by variable angle spectroscopic ellipsometry. Appl. Opt. 2007, 46, 3221–3226. [Google Scholar] [CrossRef] [PubMed]

- Franta, D.; Ohlídal, I.; Nečas, D.; Vižďa, F.; Caha, O.; Hasoň, M.; Pokorný, P. Optical characterization of HfO2 thin films. Thin Solid Films 2011, 519, 6085–6091. [Google Scholar]

- Franta, D.; Ohlídal, I.; Frumar, M.; Jedelský, J. Optical Characterization of Chalcogenide Thin Films. Appl. Surf. Sci. 2001, 175–176, 555–561. [Google Scholar] [CrossRef]

- Franta, D.; Ohlídal, I.; Frumar, M.; Jedelský, J. Expression of the Optical Constants of Chalcogenide Thin Films Using the New Parameterization Dispersion Model. Appl. Surf. Sci. 2003, 212–213, 116–121. [Google Scholar] [CrossRef]

- Kildemo, M.; Brenot, R.; Drévillon, B. Spectroellipsometric method for process monitoring semiconductor thin films and interfaces. Appl. Opt. 1998, 37, 5145–5149. [Google Scholar] [CrossRef]

- Kildemo, M. Real-Time Monitoring and Growth Control of Si-Gradient-Index Structures by Multiwavelength Ellipsometry. Appl. Opt. 1998, 37, 113–124. [Google Scholar] [CrossRef] [PubMed]

- Carniglia, C.K. Ellipsometric calculations for nonabsorbing thin films with linear refractive-index gradients. J. Opt. Soc. Am. A 1990, 7, 848–856. [Google Scholar] [CrossRef]

- Vedam, K.; McMarr, P.J.; Narayan, J. Nondestructive depth profiling by spectroscopic ellipsometry. Appl. Phys. Lett. 1985, 47, 339–341. [Google Scholar] [CrossRef]

- Franta, D.; Ohlídal, I. Optical characterization of inhomogeneous thin films of ZrO2 by spectroscopic ellipsometry and spectroscopic reflectometry. Surf. Interface Anal. 2000, 30, 574–579. [Google Scholar] [CrossRef]

- Jacobsson, R. Matching a Multilayer Stack to a High-Refractive Index Substrate by Means of an Inhomogeneous Layer. J. Opt. Soc. Am. 1964, 54, 422–423. [Google Scholar] [CrossRef]

- Jacobsson, R. Light Reflection from Films of Continuously Varying Refractive Index. In Progress in Optics; Wolf, E., Ed.; Elsevier: Amsterdam, The Netherlands, 1966; Volume 5, pp. 247–286. [Google Scholar]

- Chindaudom, P.; Vedam, K. Characterization of inhomogeneous transparent thin films on transparent substrates by spectroscopic ellipsometry: Refractive indices n (λ) of some fluoride coating materials. Appl. Opt. 1994, 33, 2664–2671. [Google Scholar] [CrossRef]

- Vohánka, J.; Ohlídal, I.; Ženíšek, J.; Vašina, P.; Čermák, M.; Franta, D. Use of the Richardson extrapolation in optics of inhomogeneous layers: Application to optical characterization. Surf. Interface Anal. 2018, 50, 757–765. [Google Scholar] [CrossRef]

- Nečas, D.; Franta, D.; Ohlídal, I.; Poruba, A.; Wostrý, P. Ellipsometric characterization of inhomogeneous non-stoichiometric silicon nitride films. Surf. Interface Anal. 2013, 45, 1188–1192. [Google Scholar] [CrossRef]

- Vohánka, J.; Ohlídal, I.; Ohlídal, M.; Šustek, v.; Čermák, M.; Šulc, V.; Vašina, P.; Ženíšek, J.; Franta, D. Optical Characterization of Non-Stoichiometric Silicon Nitride Films Exhibiting Combined Defects. Coatings 2019, 9, 416. [Google Scholar] [CrossRef]

- Franta, D.; Vohánka, J.; Dvořák, J.; Franta, P.; Ohlídal, I.; Klapetek, P.; Březina, J.; Škoda, D. Optical Characterization of Gadolinium Fluoride Films Using Universal Dispersion Model. Coatings 2023, 13, 218. [Google Scholar] [CrossRef]

- Fainman, Y.; Yang, M.; Gao, C.; Lin, H.; Friedman, A.; Belogolovskii, D. Nonlinear optical properties of inhomogeneous thin films. In Proceedings of the Ultrafast Nonlinear Imaging and Spectroscopy X, San Diego, CA, USA, 21–26 August 2022; p. PC122280I. [Google Scholar]

- Qiao, J. Simulation of Optical Properties of Inhomogeneous Molecular Contamination Thin Film Outgassed from Non-Metallic Materials. Teh. Vjesn. 2021, 28, 1539–1545. [Google Scholar]

- Todorov, R.; Tasseva, J.; Lozanova, V.; Lalova, A.; Iliev, T.; Paneva, A. Ellipsometric characterization of thin films from multicomponent chalcogenide glasses for application in modern optical devices. Adv. Cond. Matter Phys. 2013, 2013, 308258. [Google Scholar] [CrossRef]

- Bovard, B.G. Rugate filter design: The modified Fourier transform technique. Appl. Opt. 1990, 29, 24–30. [Google Scholar] [CrossRef]

- Vohánka, J.; Šustek, Š.; Buršíková, V.; Šklíbová, V.; Šulc, V.; Homola, V.; Franta, D.; Čermák, M.; Ohlídal, M.; Ohlídal, I. Determining shape of thickness non-uniformity using variable-angle spectroscopic ellipsometry. Appl. Surf. Sci. 2020, 534, 147625. [Google Scholar] [CrossRef]

- Nečas, D.; Ohlídal, I.; Franta, D. Variable-angle spectroscopic ellipsometry of considerably non-uniform thin films. J. Opt. 2011, 13, 085705. [Google Scholar] [CrossRef]

- Nečas, D.; Ohlídal, I.; Franta, D. The reflectance of non-uniform thin films. J. Opt. A Pure Appl. Opt. 2009, 11, 045202. [Google Scholar] [CrossRef]

- Ohlídal, M.; Ohlídal, I.; Klapetek, P.; Nečas, D.; Majumdar, A. Measurement of the thickness distribution and optical constants of non-uniform thin films. Meas. Sci. Technol. 2011, 22, 085104. [Google Scholar] [CrossRef]

- Ohlídal, I.; Vohánka, J.; Buršíková, V.; Franta, D.; Čermák, M. Spectroscopic ellipsometry of inhomogeneous thin films exhibiting thickness non-uniformity and transition layers. Opt. Express 2020, 28, 160–174. [Google Scholar] [CrossRef] [PubMed]

- Ohlídal, I.; Vohánka, J.; Buršíková, V.; Šulc, V.; Šustek, Š.; Ohlídal, M. Ellipsometric characterization of inhomogeneous thin films with complicated thickness non-uniformity: Application to inhomogeneous polymer-like thin films. Opt. Eng. 2020, 28, 36796–36811. [Google Scholar] [CrossRef] [PubMed]

- Ohlídal, I.; Navrátil, K.; Lukeš, F. Reflection of Light on a System of Non-absorbing Isotropic Film–Non-absorbing Isotropic Substrate with Rough Boundaries. Opt. Commun. 1971, 3, 40–44. [Google Scholar] [CrossRef]

- Ohlídal, I.; Lukeš, F. Ellipsometric Parameters of Rough Surfaces and of a System Substrate-Thin Film with Rough Boundaries. Opt. Acta 1972, 19, 817–843. [Google Scholar] [CrossRef]

- Bauer, J. Optical properties, band gap, and surface roughness of Si3N4. Phys. Status Solidi A 1977, 39, 411–418. [Google Scholar] [CrossRef]

- Ohlídal, I.; Vohánka, J.; Buršíková, V.; Dvořák, J.; Klapetek, P.; Kaur, N.J. Optical characterization of inhomogeneous thin films with randomly rough boundaries exhibiting wide intervals of spatial frequencies. Opt. Eng. 2022, 30, 39068–39085. [Google Scholar] [CrossRef]

- Vohánka, J.; Ohlídal, I.; Buršíková, V.; Klapetek, P.; Kaur, N.J. Optical characterization of inhomogeneous thin films with randomly rough boundaries. Opt. Express 2022, 30, 2033–2047. [Google Scholar] [CrossRef]

- Ohlídal, I.; Franta, D.; Nečas, D. Ellipsometric and reflectometric characterization of thin films exhibiting thickness non-uniformity and boundary roughness. Appl. Surf. Sci. 2017, 421, 687–696. [Google Scholar] [CrossRef]

- Ohlídal, I.; Vohánka, J.; Čermák, M.; Franta, D. Optical characterization of randomly microrough surfaces covered with very thin overlayers using effective medium approximation and Rayleigh–Rice theory. Appl. Surf. Sci. 2017, 419, 942–956. [Google Scholar] [CrossRef]

- Ohlídal, M.; Ohlídal, I.; Lukeš, F. Ellipsometric studies of polished silicon surfaces. Surf. Sci. 1976, 55, 467–476. [Google Scholar] [CrossRef]

- Franta, D.; Ohlídal, I.; Klapetek, P.; Pokorný, P.; Ohlídal, M. Analysis of Inhomogeneous Thin Films of ZrO2 by the Combined Optical Method and Atomic Force Microscopy. Surf. Interface Anal. 2001, 32, 91–94. [Google Scholar] [CrossRef]

- Taft, E.; Cordes, L. Optical Evidence for a Silicon-Silicon Oxide Interlayer. J. Electrochem. Soc. 1979, 126, 131–134. [Google Scholar] [CrossRef]

- Aspnes, D.E.; Theeten, J.B. Dielectric function of Si-SiO2 and Si-Si3N4 mixtures. J. Appl. Phys. 1979, 50, 4928–4935. [Google Scholar] [CrossRef]

- Ohlídal, I.; Vohánka, J.; Buršíková, V.; Ženíšek, J.; Vašina, P.; Čermák, M.; Franta, D. Optical characterization of inhomogeneous thin films containing transition layers using the combined method of spectroscopic ellipsometry and spectroscopic reflectometry based on multiple-beam interference model. J. Vac. Sci. Technol. B 2019, 37, 062921. [Google Scholar] [CrossRef]

- Jellison Jr, G.; Aytug, T.; Lupini, A.; Paranthaman, M.; Joshi, P.C. Optical properties of a nanostructured glass-based film using spectroscopic ellipsometry. Thin Solid Films 2016, 617, 38–43. [Google Scholar] [CrossRef]

- Kostruba, A.; Stetsyshyn, Y.; Vlokh, R. Method for determination of the parameters of transparent ultrathin films deposited on transparent substrates under conditions of low optical contrast. Appl. Opt. 2015, 54, 6208–6216. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, S.; Hijikata, Y.; Yaguchi, H. Investigation of SiC/Oxide interface structures by spectroscopic ellipsometry. In Advanced Silicon Carbide Devices and Processing; IntechOpen: Rijeka, Croatia, 2015; pp. 97–140. [Google Scholar]

- Nisol, B.; Reniers, F. Challenges in the characterization of plasma polymers using XPS. J. Electron. Spectrosc. 2015, 200, 311–331. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Ohtake, N.; Hiratsuka, M.; Kanda, K.; Akasaka, H.; Tsujioka, M.; Hirakuri, K.; Hirata, A.; Ohana, T.; Inaba, H.; Kano, M.; et al. Properties and classification of diamond-like carbon films. Materials 2021, 14, 315. [Google Scholar] [CrossRef] [PubMed]

- Jacob, W.; Möller, W. On the structure of thin hydrocarbon films. Appl. Phys. Lett. 1993, 63, 1771–1773. [Google Scholar] [CrossRef]

- Gosar, Ž.; Kovač, J.; Mozetič, M.; Primc, G.; Vesel, A.; Zaplotnik, R. Deposition of SiOxCyHz protective coatings on polymer substrates in an industrial-scale PECVD reactor. Coatings 2019, 9, 234. [Google Scholar] [CrossRef]

- Aumaille, K.; Vallée, C.; Granier, A.; Goullet, A.; Gaboriau, F.; Turban, G. A comparative study of oxygen/organosilicon plasmas and thin SiOxCyHz films deposited in a helicon reactor. Thin Solid Films 2000, 359, 188–196. [Google Scholar] [CrossRef]

- Čermák, M.; Kelarová, Š.; Jurmanová, J.; Kührová, P.; Buršíková, V. The wide range optical spectrum characterization of the silicon and oxygen doped diamond like carbon inhomogeneous thin films. Diam. Relat. Mater. 2022, 128, 109245. [Google Scholar] [CrossRef]

- Zajíčková, L.; Buršíková, V.; Kučerová, Z.; Franta, D.; Dvořák, P.; Šmíd, R.; Peřina, V.; Macková, A. Deposition of protective coatings in rf organosilicon discharges. Plasma Sources Sci. Technol. 2007, 16, S123. [Google Scholar] [CrossRef]

- Fujiwara, H. Spectroscopic Ellipsometry: Principles and Applications; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Germer, T.; Zwinkels, J.C.; Tsai, B.K. Spectrophotometry: Accurate Measurement of Optical Properties of Materials; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Franta, D.; Nečas, D.; Ohlídal, I. Universal dispersion model for characterization of optical thin films over wide spectral range: Application to hafnia. Appl. Opt. 2015, 54, 9108–9119. [Google Scholar] [CrossRef]

- Franta, D.; Vohánka, J.; Čermák, M. Universal Dispersion Model for Characterisation of Thin Films Over Wide Spectral Range. In Optical Characterization of Thin Solid Films; Stenzel, O., Ohlídal, M., Eds.; Springer International Publishing: Cham, Swizterland, 2018; pp. 31–82. [Google Scholar]

- Campi, D.; Coriasso, C. Prediction of Optical Properties of Amorphous Tetrahedrally Bounded Materials. J. Appl. Phys. 1988, 64, 4128–4134. [Google Scholar] [CrossRef]

- Tauc, J.; Menth, A. States in the gap. J. Non-Cryst. Solids 1972, 8, 569–585. [Google Scholar] [CrossRef]

- Zanatta, A.R. Revisiting the optical bandgap of semiconductors and the proposal of a unified methodology to its determination. Sci. Rep. 2019, 9, 11225. [Google Scholar] [CrossRef]

- Dolgonos, A.; Mason, T.O.; Poeppelmeier, K.R. Direct optical band gap measurement in polycrystalline semiconductors: A critical look at the Tauc method. J. Solid State Chem. 2016, 240, 43–48. [Google Scholar] [CrossRef]

- Franta, D.; Mureșan, M.G. Wide spectral range optical characterization of yttrium aluminum garnet (YAG) single crystal by the universal dispersion model. Opt. Mater. Express 2021, 11, 3930–3945. [Google Scholar] [CrossRef]

- Ohlídal, I.; Vohánka, J.; Čermák, M.; Franta, D. Ellipsometry of Layered Systems. In Optical Characterization of Thin Solid Films; Stenzel, O., Ohlídal, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 233–267. [Google Scholar]

- Franta, D.; Nečas, D.; Vohánka, J. Software for Optical Characterization newAD2. Available online: http://newad.physics.muni.cz/ (accessed on 28 March 2023).

| Step | Conditions | |

|---|---|---|

| 1. | Argon plasma treatment of the substrate | Applied power: 50 W; Argon flow rate: 5 sccm; Self-bias voltage on the substrate holder electrode: −240 V; Pressure: 17 Pa; Deposition time: 5 min |

| 2. | Deposition input parameters | Applied power: 50 W; HMDSO flow rate: 1 sccm; CH flow rate: 5 sccm; Self bias voltage on the substrate holder electrode: −110 V; Pressure: 33 Pa |

| 3. | Gradual change of methane flow rate | Applied power: 50 W; HMDSO flow rate: maintained at 1 sccm; CH flow rate: decrease from 5 to 0 sccm; Self-bias voltage: decrease from −110 to −190 V; Deposition pressure: decrease from 33 to 15 Pa; |

| 4. | Process conditions before the end of the deposition | Applied power 50 W; HMDSO flow rate: 1 sccm; CH flow rate: 0 sccm; Self-bias voltage: −190 V; Deposition pressure: 15 Pa |

| Instrument | Quantity | Mode | Spectral Range | AOI |

|---|---|---|---|---|

| Horiba Jobin Yvon UVISEL | , , | front | 0.6–6.5 eV | 55–75°, step 5° |

| Horiba Jobin Yvon UVISEL | , , | back | 0.6–6.5 eV | 55–75°, step 5° |

| Perkin Elmer Lambda 1050 | front | 190–1800 nm | 6° | |

| Perkin Elmer Lambda 1050 | back | 190–1800 nm | 6° | |

| Perkin Elmer Lambda 1050 | relative | 190–1800 nm | 6° | |

| Perkin Elmer Lambda 1050 | T | 190–1800 nm | 0° |

| Sample | #1 | #2 | #3 | ||

|---|---|---|---|---|---|

| Thickness (ellipsometry) | [nm] | ||||

| Thickness (spectrophotometry) | [nm] | ||||

| Transition layer thickness | [nm] | ||||

| Profile parameter | k |

| Parameter | Upper Boundary | Lower Boundary | Transition Layer | ||

|---|---|---|---|---|---|

| Transition strength of electrons—ibt term | [] | ||||

| Band gap energy of electrons | [] | ||||

| Transition strength of electrons—CC term | [] | ||||

| Peak position of electrons | [] | ||||

| Peak broadening of electrons | [] | ||||

| Transition strength of electrons | [] | 0 | |||

| Band gap energy of electrons | [] | ||||

| Peak position of electrons | [] | ||||

| Peak broadening of electrons | [] | ||||

| Transition strength of exponential tail | [] | ||||

| Decay rate of exponential tail | [] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dvořák, J.; Vohánka, J.; Buršíková, V.; Franta, D.; Ohlídal, I. Optical Characterization of Inhomogeneous Thin Films Deposited onto Non-Absorbing Substrates. Coatings 2023, 13, 873. https://doi.org/10.3390/coatings13050873

Dvořák J, Vohánka J, Buršíková V, Franta D, Ohlídal I. Optical Characterization of Inhomogeneous Thin Films Deposited onto Non-Absorbing Substrates. Coatings. 2023; 13(5):873. https://doi.org/10.3390/coatings13050873

Chicago/Turabian StyleDvořák, Jan, Jiří Vohánka, Vilma Buršíková, Daniel Franta, and Ivan Ohlídal. 2023. "Optical Characterization of Inhomogeneous Thin Films Deposited onto Non-Absorbing Substrates" Coatings 13, no. 5: 873. https://doi.org/10.3390/coatings13050873

APA StyleDvořák, J., Vohánka, J., Buršíková, V., Franta, D., & Ohlídal, I. (2023). Optical Characterization of Inhomogeneous Thin Films Deposited onto Non-Absorbing Substrates. Coatings, 13(5), 873. https://doi.org/10.3390/coatings13050873