Research on IR and Heat Transfer Characteristics of Molybdenum-Sputtered Polyamide Materials

Abstract

1. Introduction

2. Experiment

2.1. Materials

2.2. Characterization

- Huntreated: Value H of untreated specimens;

- Htreated: Value H of sputtered specimens;

- Suntreated: Value S of the untreated specimens;

- Streated: Value S of the sputtered specimens;

- Vuntreated: Value V of the untreated specimens;

- Vtreated: Value V of the sputtered specimens.

- Yuntreated: Value Y of the untreated specimen;

- Ytreated: Value Y of the sputtered specimen;

- Cbuntreated: Value Cb of the untreated specimen;

- Cbtreated: Value Cb of the sputtered specimen;

- Cruntreated: Value Cr of the untreated specimen;

- Crtreated: Value Cr of the sputtered specimen.

- Tw: temperature (K) of the solid surface

- T∞: liquid temperature (K) of free flow

- h: convective heat transfer coefficient

- A: surface area (m2)

- Q: heat transfer rate (W)

- T: temperature (K)

- ΔT: temperature difference (K)

- Q: heat transfer rate

- k: thermal conductivity

- A: surface area (m2)

- x: thickness (m)

- Tw: surface temperature according to the material (K)

- T∞: atmospheric temperature (K)

- Q: heat transfer rate (W)

- A: surface area (m2)

- ε: the radiation rate

- σ: Stefan-Boltzmann constant

- h: heat transfer coefficient.

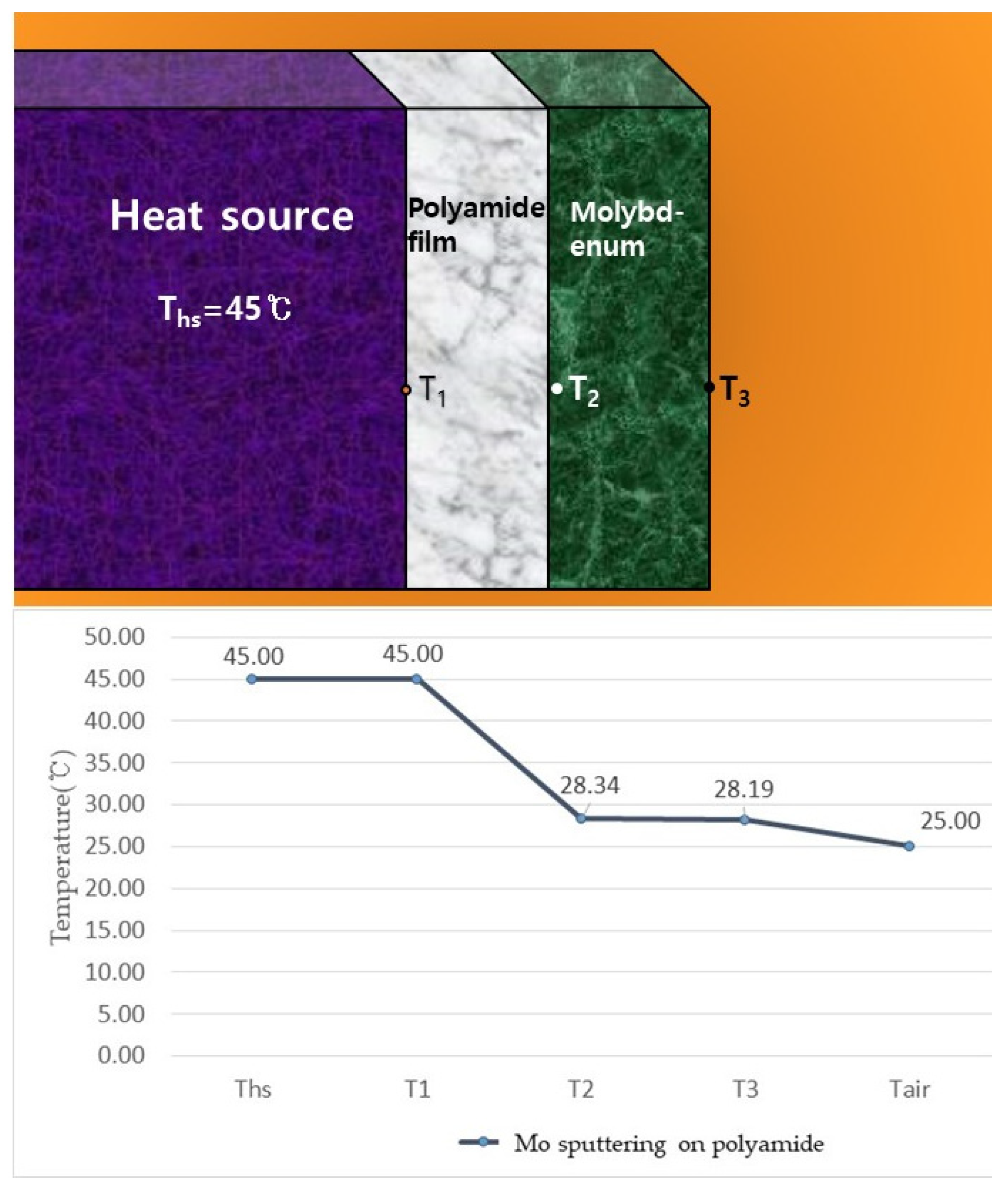

- x1: thickness of Material 1

- x2: thickness of Material 2

- T1~3: coss-section temperature

- T4: atmosphere temperature

3. Results and Discussions

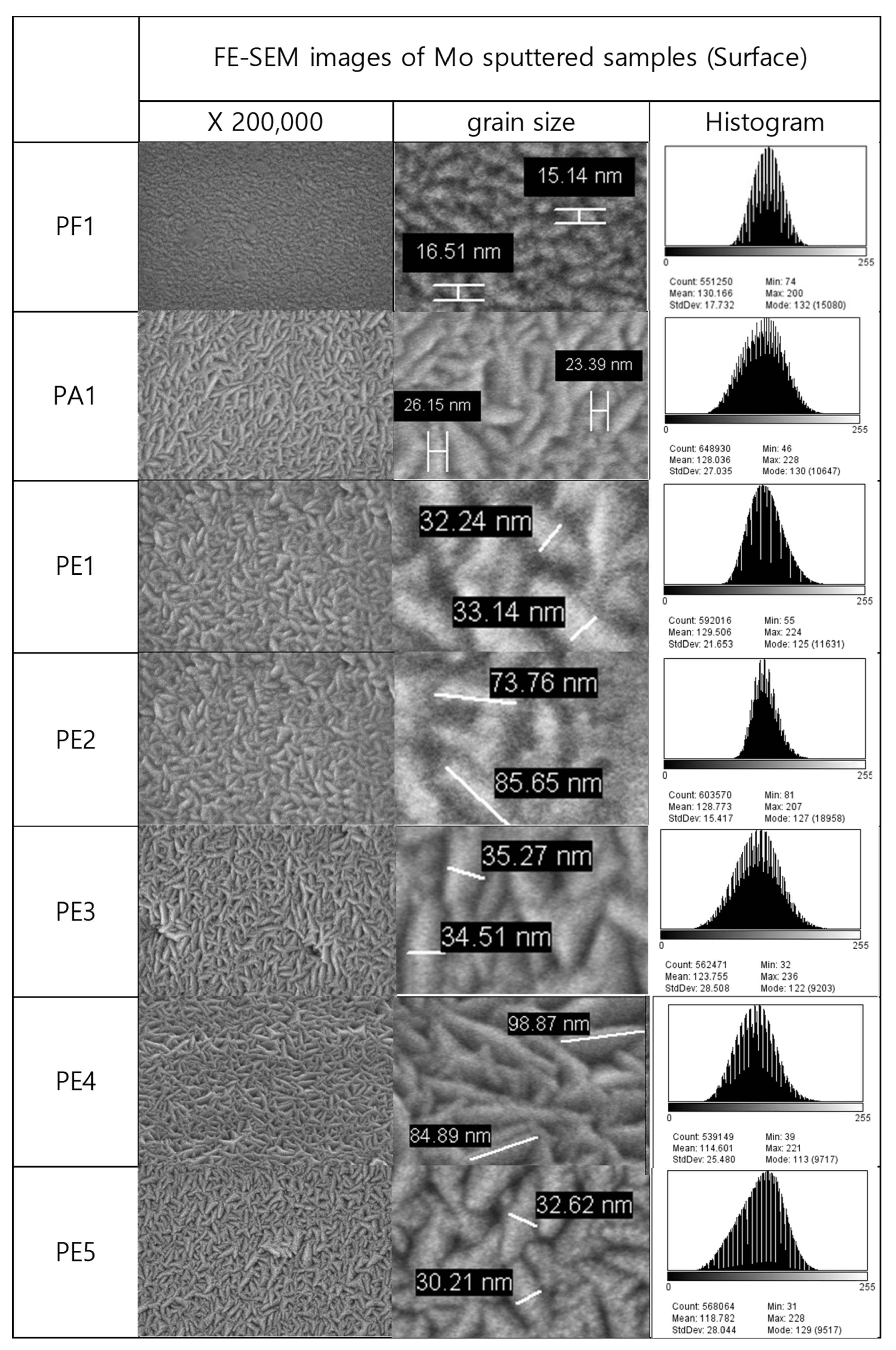

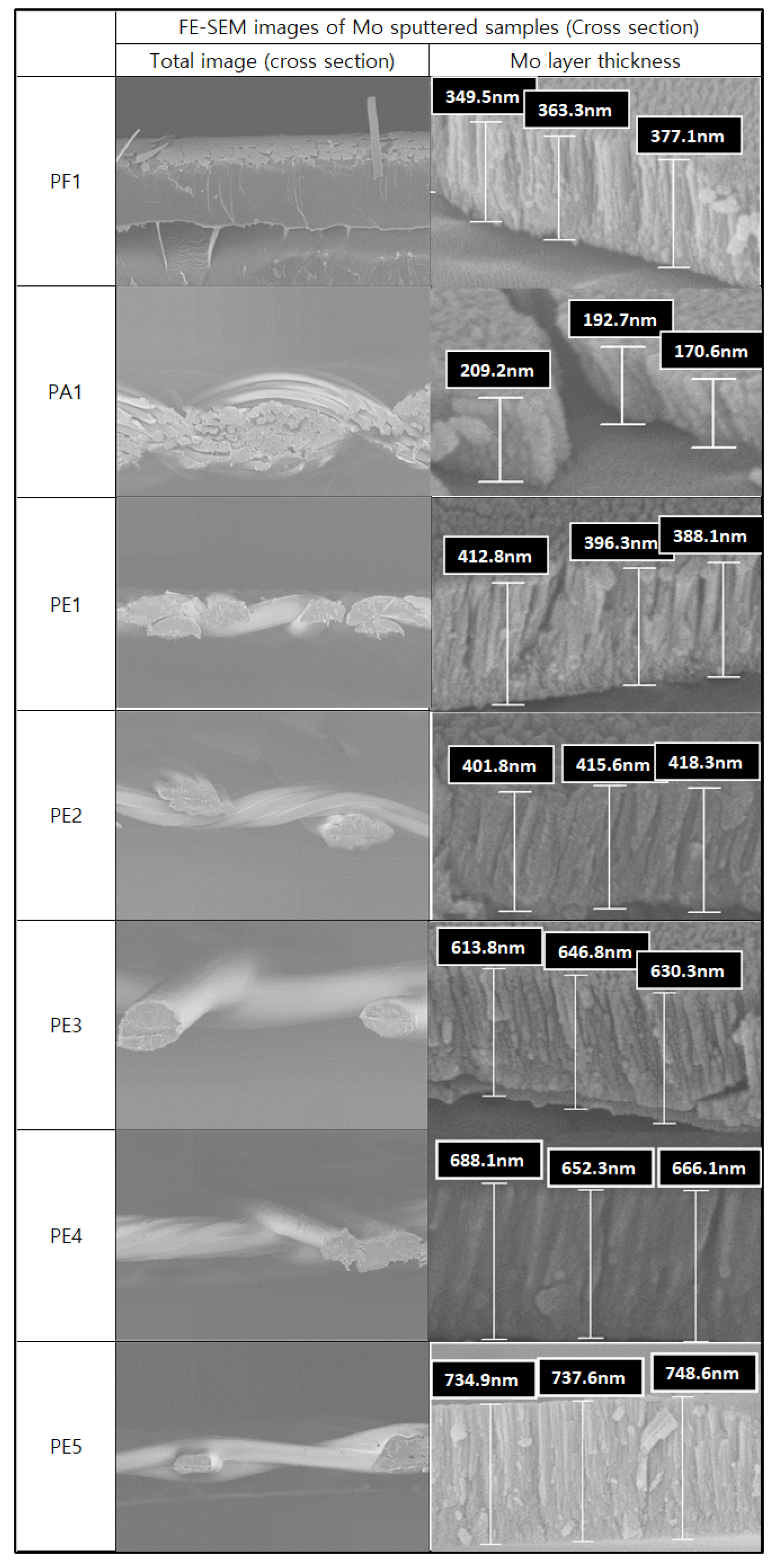

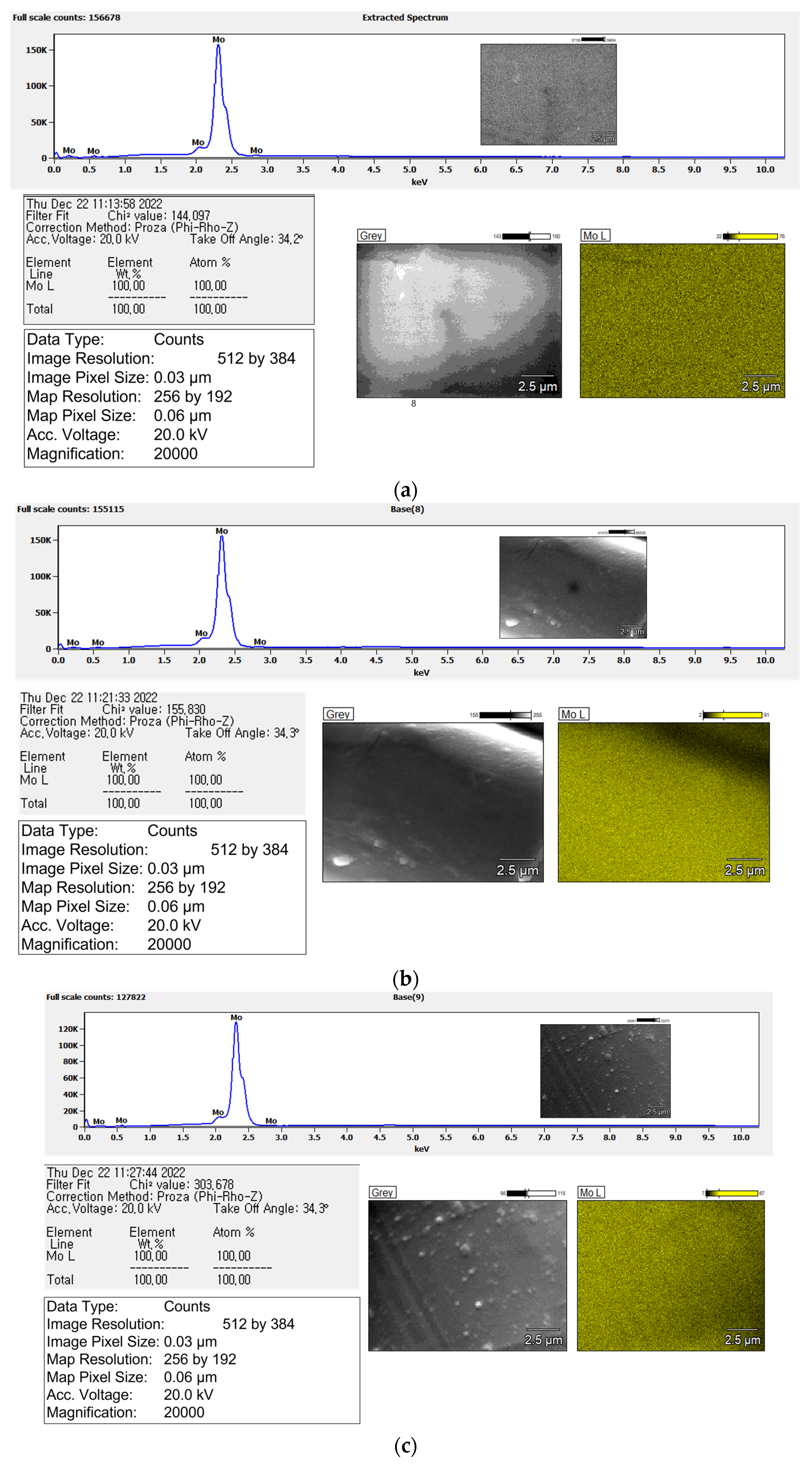

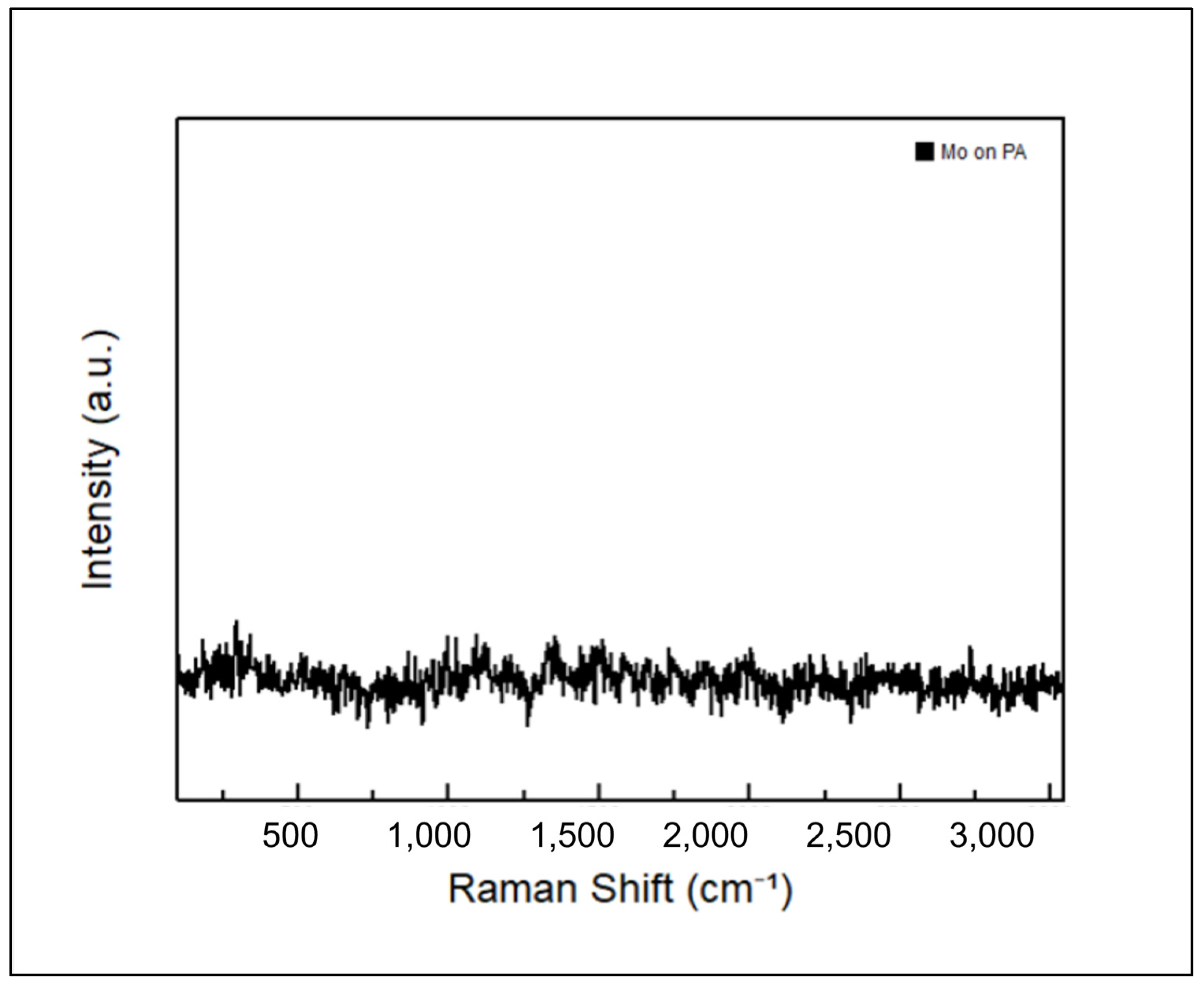

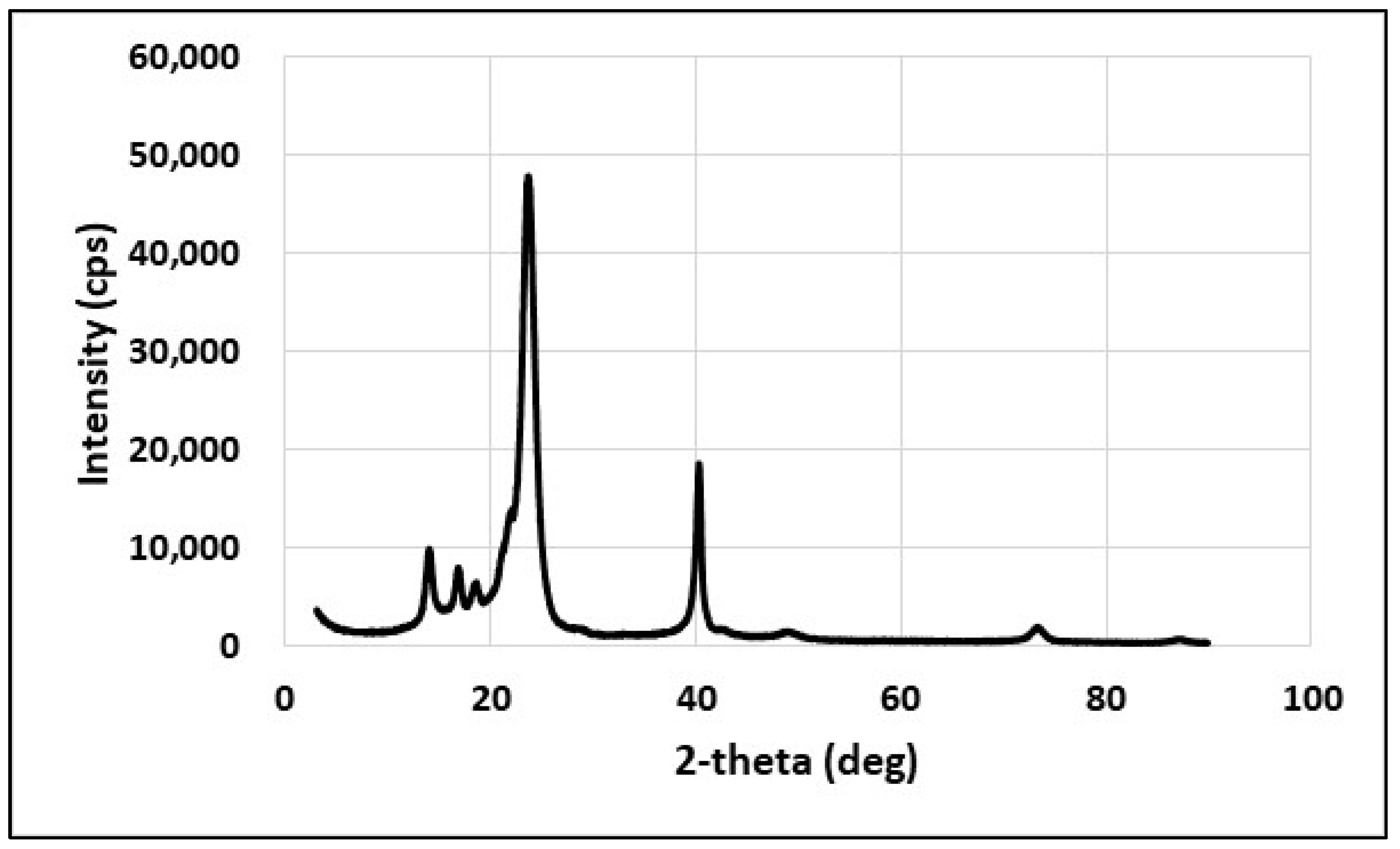

3.1. Surface Properties

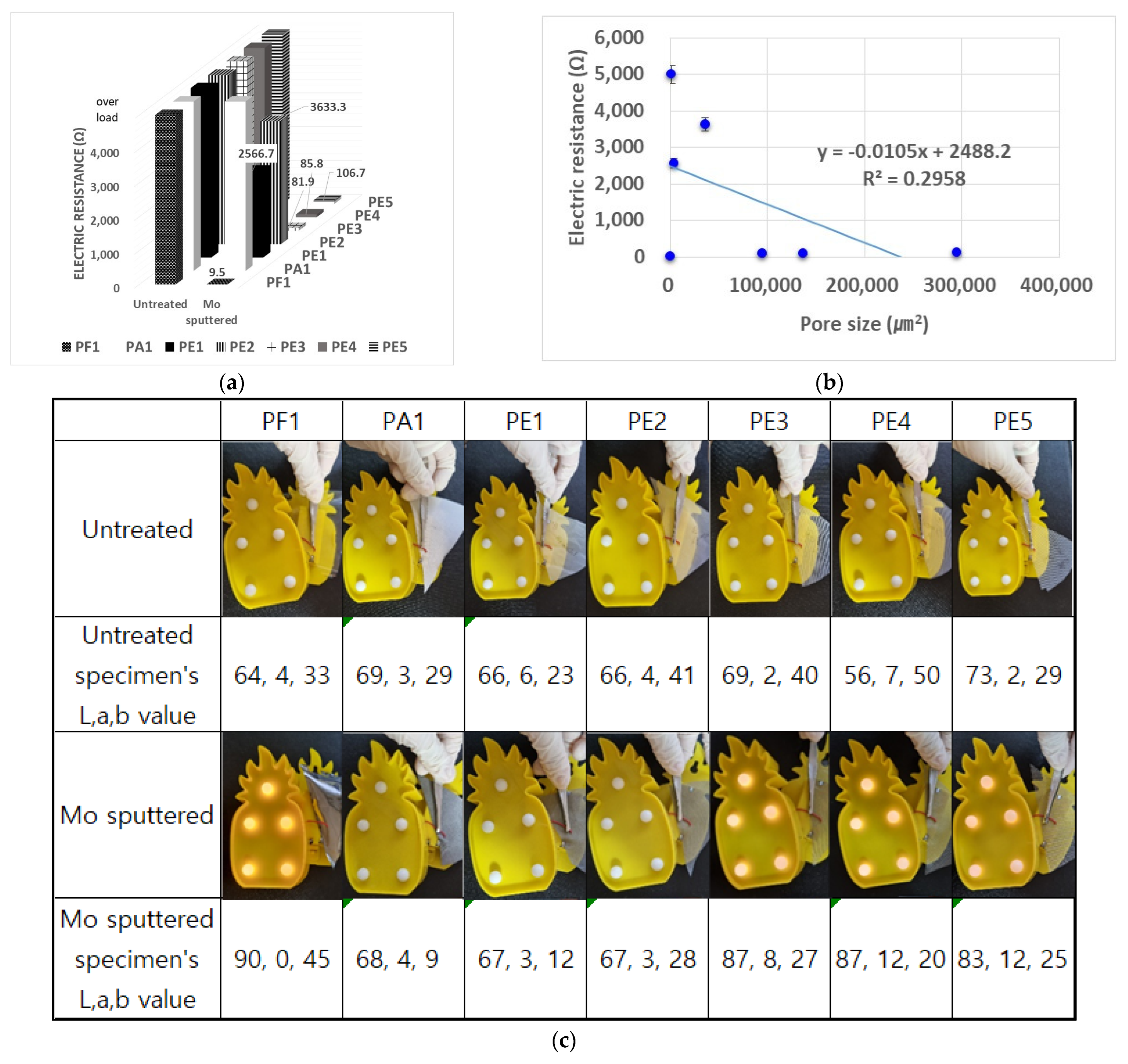

3.2. Electrical Resistance Properties

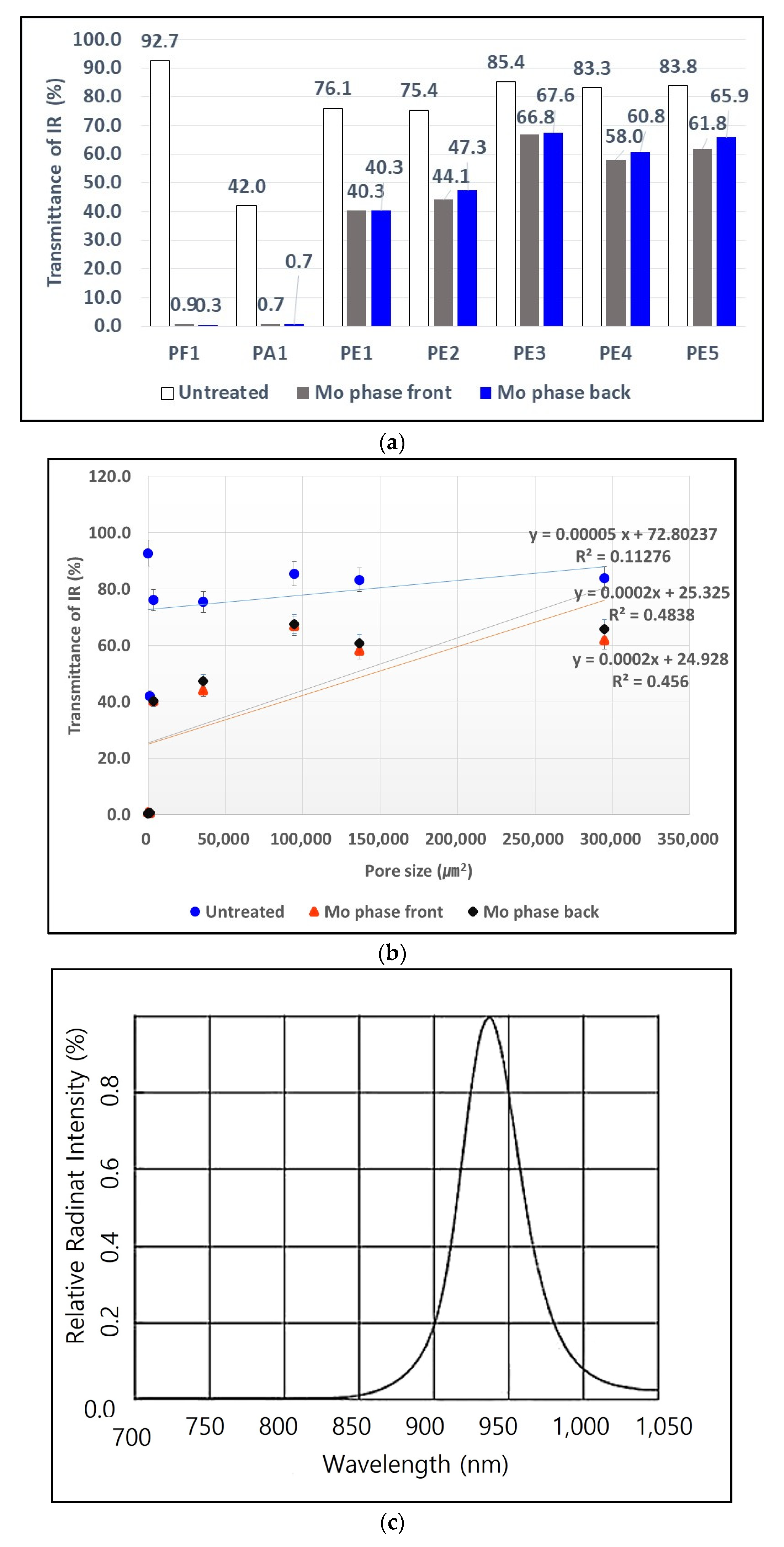

3.3. Characteristics of IR Transmittance

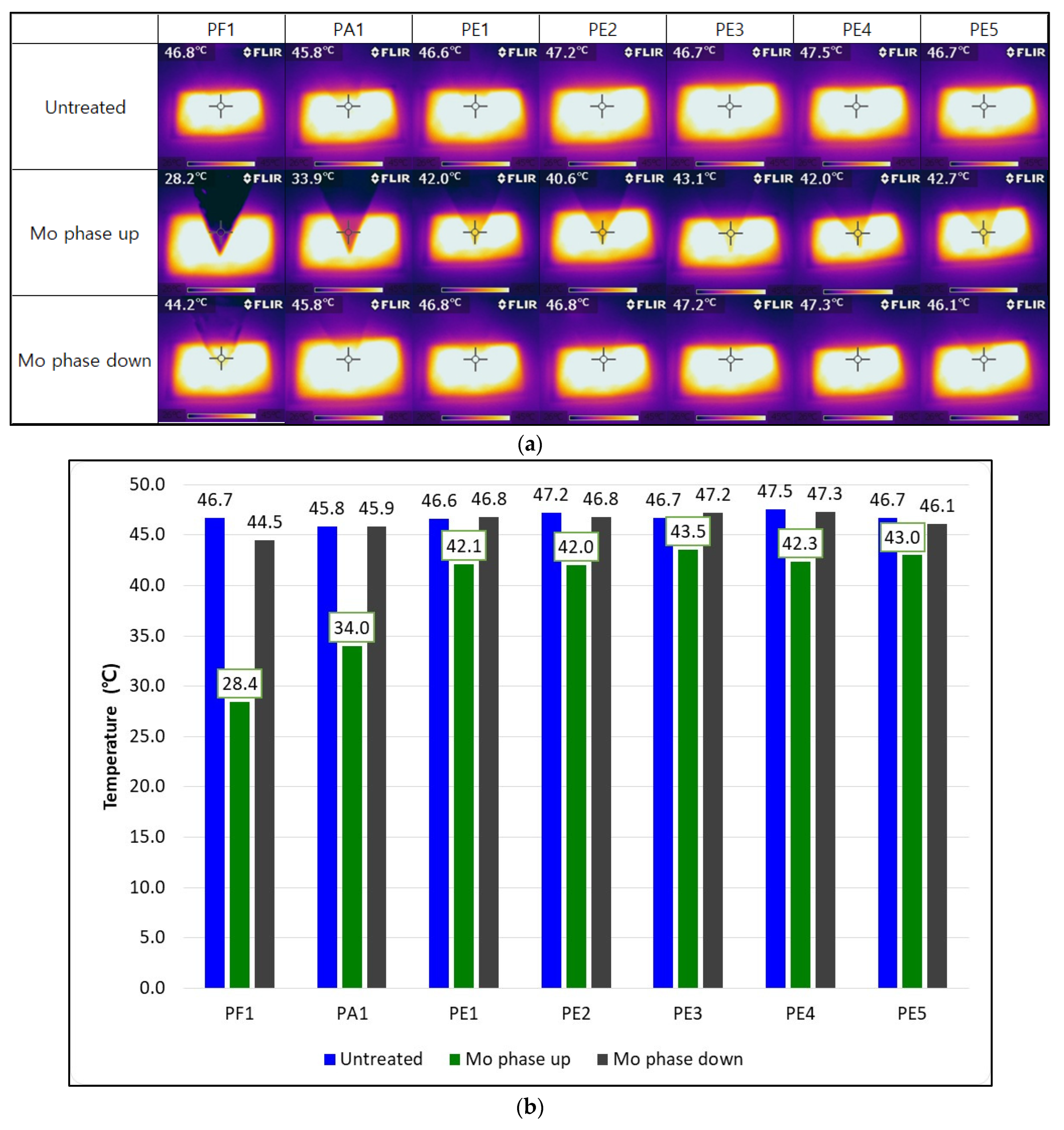

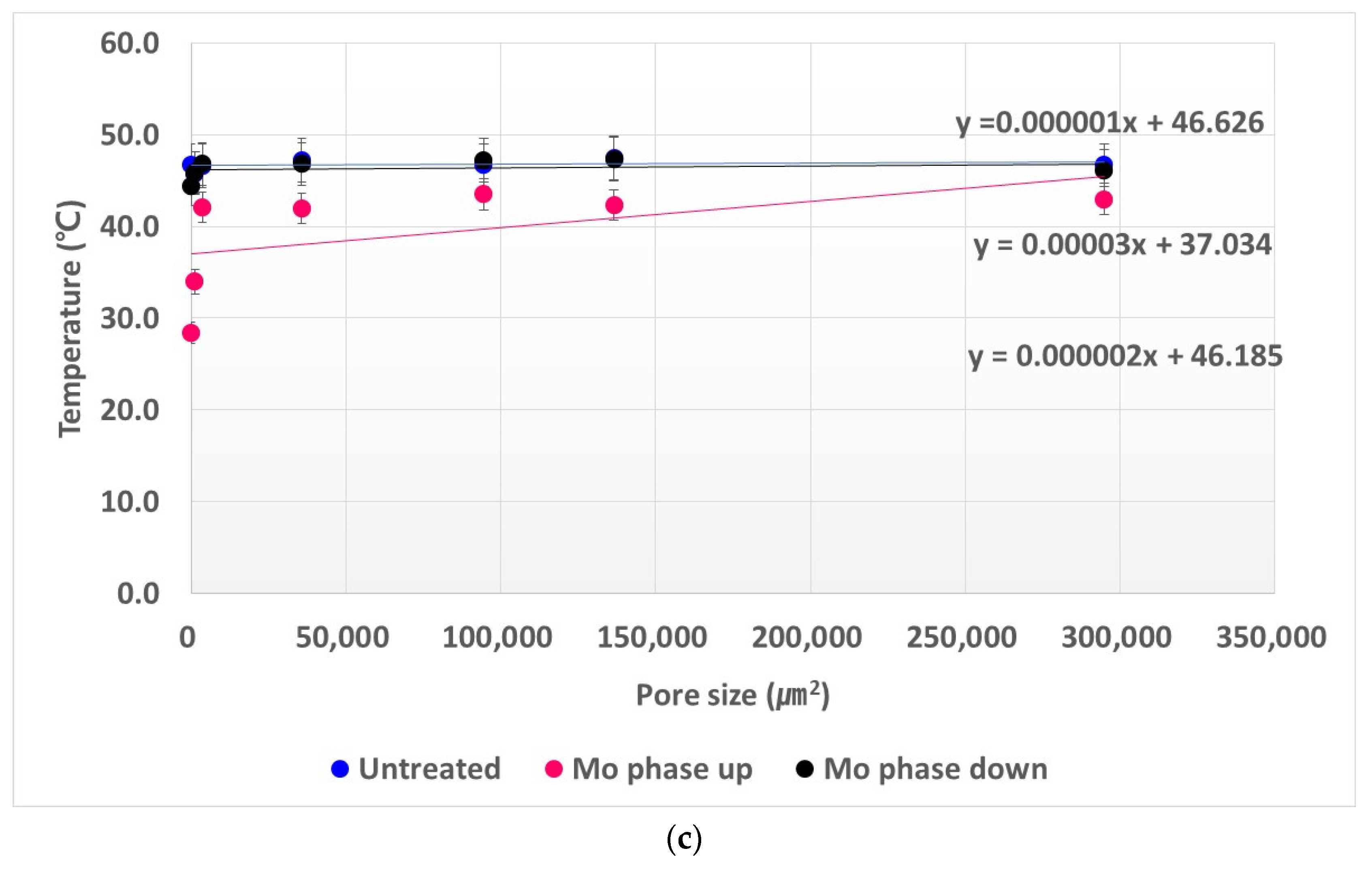

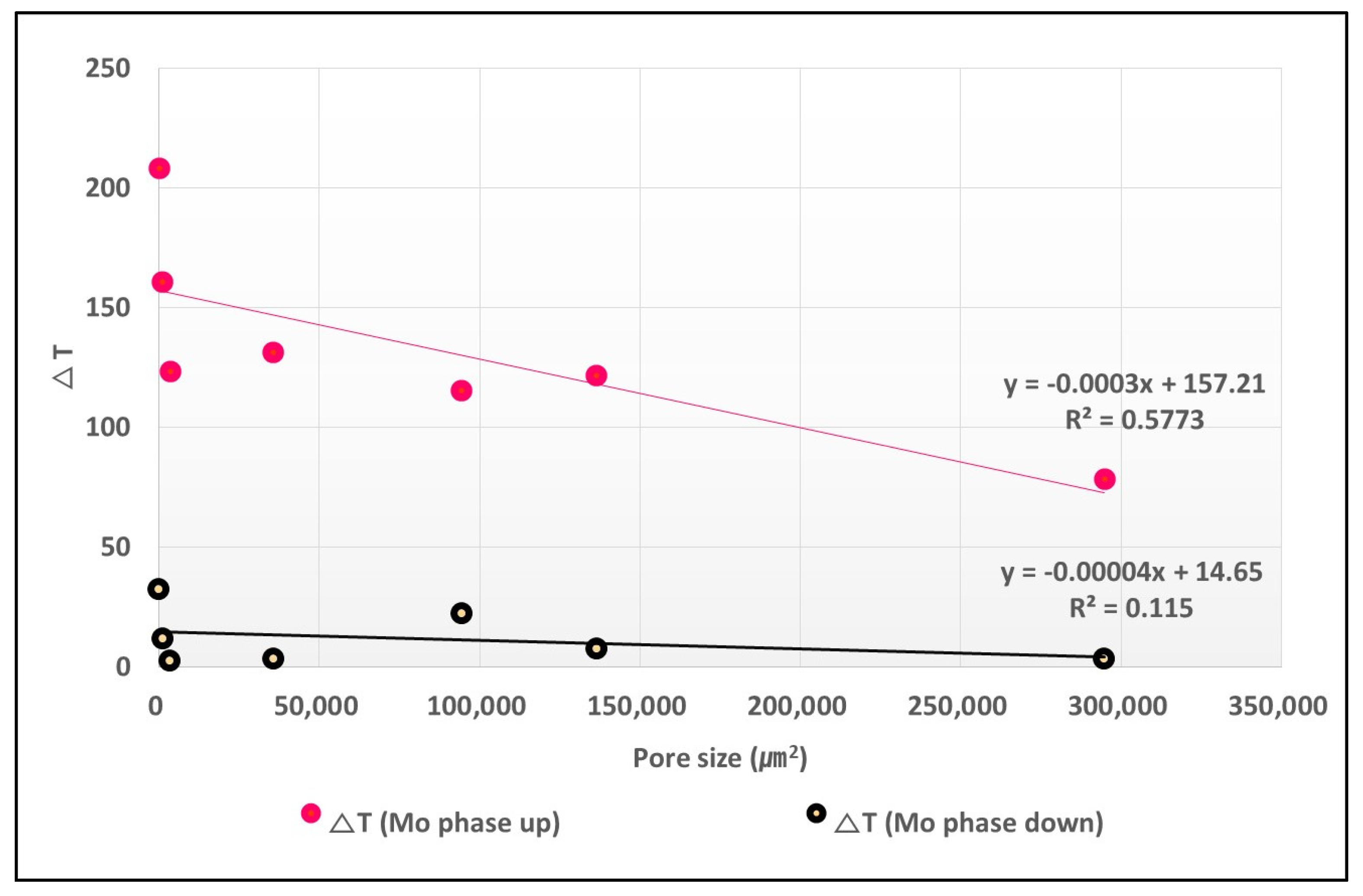

3.4. IR Camera Stealth Function Based on Heat Transfer

3.5. Theoretical Analysis with Heat Transfer

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Badding, E.D.; Srisantitham, S.; Lukoyanov, D.A.; Hoffman, B.; Suess, D. Connecting the geometric and electronic structures of the nitrogenase iron–molybdenum cofactor through site-selective 57Fe labeling. Nat. Chem. 2023, 15, 658–665. [Google Scholar] [CrossRef] [PubMed]

- Kuo, K.; Hagg, G.A. New Molybdenum Carbide. Nature 1952, 170, 245–246. [Google Scholar] [CrossRef]

- Spackman, J. Electron Spin Resonance of Charge Carriers in Impure Molybdenum Disulphide. Nature 1963, 198, 1266–1267. [Google Scholar] [CrossRef]

- Ashida, Y.; Mizushima, T.; Arashiba, K.; Egi, A.; Tanaka, H.; Yoshizawa, K.; Nishibayashi, Y. Catalytic production of ammonia from dinitrogen employing molybdenum complexes bearing N-heterocyclic carbene-based PCP-type pincer ligands. Nat. Synth. 2023. Available online: https://doi.org/10.1038/s44160-023-00292-9 (accessed on 11 May 2023). [CrossRef]

- Li, Z.; Sami, I.; Yang, J.; Li, J.; Kumar, R.V.; Chhowalla, M. Lithiated metallic molybdenum disulfide nanosheets for high-performance lithium–sulfur batteries. Nat. Energy 2023, 8, 84–93. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, C.; Chan, W.; Tiwari, S.; Rana, F. Ultrafast response of monolayer molybdenum disulfide photodetectors. Nat. Commun. 2015, 6, 8831. [Google Scholar] [CrossRef]

- Wei, H.; Huan, S.; Fei, X.; Jian, W. A review and perspective on molybdenum-based electrocatalysts for hydrogen evolution reaction. Rare Metals 2020, 39, 335–351. [Google Scholar]

- Okotrub, A.V.; Sedelnikova, O.V.; Gorodetskiy, D.V.; Fedorenko, A.D.; Asanov, I.P.; Palyanov, Y.N.; Lapega, A.V.; Gurova, O.A.; Bulusheva, L.G. Effect of Titanium and Molybdenum Cover on the Surface Restructuration of Diamond Single Crystal during Annealing. Materials 2023, 16, 1650. [Google Scholar] [CrossRef]

- Ali, A.; Piatkowski, P.; Nawaz, T.; Ahmad, S.; Ibrahim, T.; Khamis, M.; Alnaser, A.S. A Two-Step Femtosecond Laser-Based Deposition of Robust Corrosion-Resistant Molybdenum Oxide Coating. Materials 2023, 16, 909. [Google Scholar] [CrossRef]

- Candela, V.; Cavallini, C.; Gasparrini, C.; Armelao, L.; Candeloro, V.; Dalla, P.M.; Fadone, M.; Marcuzzi, D.; Pavei, M.; Pepato, A.; et al. Investigations on Caesium Dispersion and Molybdenum Coating on SPIDER Components. Materials 2023, 16, 206. [Google Scholar] [CrossRef]

- Santagata, A.; Pace, M.L.; Bellucci, A.; Mastellone, M.; Bolli, E.; Valentini, V.; Orlando, S.; Sani, E.; Failla, S.; Sciti, D.; et al. Enhanced and Selective Absorption of Molybdenum Nanostructured Surfaces for Concentrated Solar Energy Applications. Materials 2022, 15, 8333. [Google Scholar] [CrossRef] [PubMed]

- Thompson, M. Mechanisms of sputtering. Nature 1979, 277, 326–327. [Google Scholar] [CrossRef]

- Strachan, J.; Harris, N. X-ray Hazard in Sputtering Apparatus. Nature 1956, 178, 588–589. [Google Scholar] [CrossRef] [PubMed]

- Pollitt, K.; Robb, J.; Thomas, D. Mechanism of sputtering of solid surfaces by ion-impact. Nature 1978, 272, 436–437. [Google Scholar] [CrossRef]

- Haff, P.; Seiberling, L. Anomalous sputtering at high energy. Nature 1981, 290, 544–545. [Google Scholar] [CrossRef]

- Han, H.R. Hybrid Fiber Materials according to the Manufacturing Technology Methods and IOT Materials: A Systematic Review. Materials 2023, 16, 1351. [Google Scholar] [CrossRef]

- Grenadyorov, A.; Oskirko, V.; Zakharov, A.; Oskomov, K.; Rabotkin, S.; Semenov, V.; Solovyev, A.; Shmakov, A. Properties of TiAlN Coatings Obtained by Dual-HiPIMS with Short Pulses. Materials 2023, 16, 1348. [Google Scholar] [CrossRef]

- Za’abar, F.I.; Mahmood, Z.A.W.; Doroody, C.; Chelvanathan, P.; Yusoff, Y.; Abdullah, S.F.; Bahrudin, M.S.; Wan, A.W.S.; Ahmad, I.; Wan, A.W.S.; et al. Probing the Interplay between Mo Back Contact Layer Deposition Condition and MoSe2 Layer Formation at the CIGSe/Mo Hetero-Interface. Materials 2023, 16, 2497. [Google Scholar] [CrossRef]

- Andrulevičius, M.; Artiukh, E.; Suchaneck, G.; Wang, S.; Sobolev, N.A.; Gerlach, G.; Tamulevičienė, A.; Abakevičienė, B.; Tamulevičius, S. Multitarget Reactive Magnetron Sputtering towards the Production of Strontium Molybdate Thin Films. Materials 2023, 16, 2175. [Google Scholar] [CrossRef]

- Lan, N.; Pham, G.F.; Tabor, A.P.; Jacob, L.B.; Aman, T.H.; Jake, J.A. Dexterous magnetic manipulation of conductive non-magnetic objects. Nature 2021, 598, 439–443. [Google Scholar]

- Zhao, Y.; Ohm, Y.; Liao, J.; Luo, Y.; Cheng, H.; Phillip, W.; Peter, R.; Manuel, R.C.; Mohammad, F.I.; Jung, H.A.; et al. A self-healing electrically conductive organogel composite. Nat. Electron. 2023, 6, 206–215. Available online: https://www.nature.com/articles/s41928-023-00932-0 (accessed on 11 May 2023).

- Bartlett, M.D.; Dickey, M.D.; Majidi, C. Self-healing materials for soft-matter machines and electronics. NPG Asia Mater. 2019, 11, 21. Available online: https://www.nature.com/articles/s41427-019-0122-1 (accessed on 11 May 2023). [CrossRef]

- Yu, X.; Zhang, H.; Wang, Y.; Fan, X.; Li, Z.; Zhang, X.; Liu, T. Highly stretchable, ultra-soft and fast self-healable conductive hydrogels based on polyaniline nanoparticles for sensitive flexible sensors. Adv. Funct. Mater. 2022, 32, 2204366. [Google Scholar] [CrossRef]

- Polachan, K.; Chatterjee, B.; Weigand, S.; Sen, S. Human body-electrode interfaces for wide-frequency sensing and communication: A review. Nanomaterials 2021, 11, 2152. [Google Scholar] [CrossRef] [PubMed]

- Zeissler, K. Electrical control of qubits speeds up. Nat. Electron. 2023, 6, 103. [Google Scholar] [CrossRef]

- Ahmad, M.; Ha, J.H.; Mayse, L.A.; Presti, M.F.; Wolfe, A.J.; Moody, K.J.; Loh, S.N.; Movileanu, L. A generalizable nanopore sensor for highly specific protein detection at single-molecule precision. Nat. Commun. 2023, 14, 1374. [Google Scholar] [CrossRef]

- Chen, A.; Brand, H.; Helbig, T.; Hofmann, T.; Imhof, S.; Fritzsche, A.; Kießling, T.; Stegmaier, A.; Upreti, L.K.; Neupert, T.; et al. Hyperbolic matter in electrical circuits with tunable complex phases. Nat. Commun. 2023, 14, 622. [Google Scholar] [CrossRef]

- Meloni, M.; Large, M.J.; González, D.J.M.; Victor-Román, S.; Fratta, G.; Istif, E.; Tomes, O.; Salvage, J.P.; Ewels, C.P.; Pelaez-Fernandez, M.; et al. Explosive percolation yields highly-conductive polymer nanocomposites. Nat. Commun. 2022, 13, 6872. [Google Scholar] [CrossRef]

- Han, H.R. A study on the thermal and electrical conductivity properties of titanium sputtered materials. J. Korean Soc. Cloth. Text. 2022, 46, 530–544. [Google Scholar] [CrossRef]

- Han, H.R. Stealth, electromagnetic interception, and electrical properties of aluminum sputtered clothing materials—Focusing on the density change. Res. J. Costume Cult. 2022, 30, 579–593. [Google Scholar] [CrossRef]

- Chelvanathan, P.; Zakaria, Z.; Yusoff, Y.; Akhtaruzzaman, M.; Alam, M.M.; Alghoul, M.A.; Sopian, K.N. Amin Annealing effect in structural and electrical properties of sputtered Mo thin film. Appl. Surf. Sci. 2015, 334, 129–137. [Google Scholar] [CrossRef]

- Han, H.R.; Kim, J.J. A study on the thermal and physical properties of nylon fabric treated by metal sputtering (Al, Cu, Ni). Text. Res. J. 2018, 88, 2397–2414. [Google Scholar] [CrossRef]

- Han, H.R. A study on thermal and electrical properties of molybdenum sputtered clothing materials. Res. J. Costume Cult. 2022, 30, 2383–6334. [Google Scholar] [CrossRef]

- Wang, L.; Dong, J.; Zhang, W.; Zheng, C.; Liu, L. Deep Learning Assisted Optimization of Metasurface for Multi-Band Compatible Infrared Stealth and Radiative Thermal Management. Nanomaterials 2023, 13, 1030. [Google Scholar] [CrossRef] [PubMed]

- Jia, J.; Han, Z.; Liu, L.; Xie, H.; Lv, M. Design Principle of RF Stealth Anti-Sorting Signal Based on Multi-Dimensional Compound Modulation with Pseudo-Center Width Agility. Electronics 2022, 11, 4027. [Google Scholar] [CrossRef]

- Zhou, X.; Xin, B.; Chen, Z.; Peng, X.; Zhuo, T.; Yu, J. Preparation of PANI-coated hollow glass microsphere and its application in dual-band stealth coated fabric. Polym. Bull. 2021, 79, 7555–7570. [Google Scholar] [CrossRef]

- Hu, J.; Hu, Y.; Ye, Y.; Shen, R. Unique applications of carbon materials in infrared stealth: A review. Chem. Eng. J. 2023, 452, 139147. [Google Scholar] [CrossRef]

- Zhou, X.; Xin, B.; Liu, Y. Research progress on infrared stealth fabric. J. Phys. Conf. Ser. 2021, 1790, 012058. [Google Scholar] [CrossRef]

- Salah, M.S.; Ahmed, F.G.; Hanaa, A.S. Thermal Radiations Mitigation and Stealth using Egyptians Cotton Fabrics Treated with ZnO Nanoparticles and Chlorophyll. Int. J. Adv. Sci. Eng. Inf. Technol. 2022, 8, 2314–2322. [Google Scholar] [CrossRef]

| Polyamide Film | Polyamide Plain Weave (Textile) | Polyamide Net1 | Polyamide Net2 | Polyamide Net3 | Polyamide Net4 | Polyamide Net5 | |

|---|---|---|---|---|---|---|---|

| Sample code | PF1 | PA1 | PE1 | PE2 | PE3 | PE4 | PE5 |

| Sample thickness (mm) | 0.09 | 0.15 | 0.08 | 0.10 | 0.15 | 0.11 | 0.19 |

| Structure type | Flat | Plain weave | Net | Net | Net | Net | Net |

| Pore size (µm2) | 0 | 1200 | 3564 | 35,696.3 | 94,440.4 | 136,476.2 | 294,825.5 |

| Microscope image of pore |  |  |  |  |  |  |  |

| Process | Time | Process Pressure (Torr) | Gas (sccm) | Power (W) | Machine |

|---|---|---|---|---|---|

| 50 (nm/min) | 1200 s (20 min) | 6 m Torr | Ar 40 sccm | DC 500 W | SRN-120 |

| Untreated | Mo Phase Up | Mo Phase Down | |||||||

|---|---|---|---|---|---|---|---|---|---|

| H | S | V | H | S | V | H | S | V | |

| PF1 | 147 | 8 | 95 | 249 | 32 | 41 | 131 | 6 | 94 |

| PA1 | 147 | 7 | 95 | 321 | 54 | 72 | 168 | 6 | 99 |

| PE1 | 168 | 6 | 94 | 43 | 70 | 90 | 160 | 5 | 95 |

| PE2 | 161 | 7 | 95 | 31 | 89 | 98 | 180 | 4 | 100 |

| PE3 | 158 | 6 | 95 | 45 | 83 | 93 | 168 | 6 | 92 |

| PE4 | 167 | 7 | 95 | 35 | 90 | 99 | 168 | 5 | 96 |

| PE5 | 160 | 5 | 92 | 50 | 75 | 94 | 168 | 6 | 93 |

| Mo Phase Up | Mo Phase Down | |||||||

|---|---|---|---|---|---|---|---|---|

| ∆H | ∆S | ∆V | ∆E | ∆H | ∆S | ∆V | ∆E | |

| PF1 | 102 | 24 | −54 | 117.9 | −16 | −2 | −1 | 16.2 |

| PA1 | 174 | 47 | −23 | 181.7 | 21 | −1 | 4 | 21.4 |

| PE1 | −125 | 64 | −4 | 140.5 | −8 | −1 | 1 | 8.1 |

| PE2 | −130 | 82 | 3 | 153.7 | 19 | −3 | 5 | 19.9 |

| PE3 | −113 | 77 | −2 | 136.8 | 10 | 0 | −3 | 10.4 |

| PE4 | −132 | 83 | 4 | 156.0 | 1 | −2 | 1 | 2.4 |

| PE5 | −110 | 70 | 2 | 130.4 | 8 | 1 | 1 | 8.1 |

| Untreated | Mo Phase Up | Mo Phase Down | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Y | Cb | Cr | Y | Cb | Cr | Y | Cb | Cr | |

| PF1 | 234 | −2 | −9 | 26 | 4 | −17 | 206 | −16 | −1 |

| PA1 | 237 | −3 | −7 | 95 | 26 | 62 | 248 | 1 | −7 |

| PE1 | 235 | −1 | −9 | 159 | −75 | 54 | 237 | 0 | −8 |

| PE2 | 236 | 0 | −8 | 173 | −95 | 57 | 239 | 1 | −7 |

| PE3 | 240 | 0 | −8 | 184 | −89 | 39 | 218 | 1 | −7 |

| PE4 | 240 | 1 | −9 | 186 | −96 | 40 | 233 | 1 | −7 |

| PE5 | 241 | 0 | −7 | 210 | −67 | 19 | 238 | 1 | −7 |

| Mo Phase Up | Mo Phase Down | |||||||

|---|---|---|---|---|---|---|---|---|

| ∆Y | ∆Cb | ∆Cr | ∆T | ∆Y | ∆Cb | ∆Cr | ∆T | |

| PF1 | −208 | 6 | −8 | 208.2 | −28 | −14 | 8 | 32.3 |

| PA1 | −142 | 29 | 69 | 160.5 | 11 | 4 | 0 | 11.7 |

| PE1 | −76 | −74 | 63 | 123.4 | 2 | 1 | 1 | 2.4 |

| PE2 | −63 | −95 | 65 | 131.2 | 3 | 1 | 1 | 3.3 |

| PE3 | −56 | −89 | 47 | 115.2 | −22 | 1 | 1 | 22.0 |

| PE4 | −54 | −97 | 49 | 121.4 | −7 | 0 | 2 | 7.3 |

| PE5 | −31 | −67 | 26 | 78.3 | −3 | 1 | 0 | 3.2 |

| Thickness (nm) | Thermal Conductivity (W/mk) | Emissivity (%) | |

|---|---|---|---|

| Molybdenum | 363.3 | 138 | 0.74 |

| Polyamide film | 90 × 10−6 | 3.08 × 10−2 | 0.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, H.-R. Research on IR and Heat Transfer Characteristics of Molybdenum-Sputtered Polyamide Materials. Coatings 2023, 13, 1072. https://doi.org/10.3390/coatings13061072

Han H-R. Research on IR and Heat Transfer Characteristics of Molybdenum-Sputtered Polyamide Materials. Coatings. 2023; 13(6):1072. https://doi.org/10.3390/coatings13061072

Chicago/Turabian StyleHan, Hye-Ree. 2023. "Research on IR and Heat Transfer Characteristics of Molybdenum-Sputtered Polyamide Materials" Coatings 13, no. 6: 1072. https://doi.org/10.3390/coatings13061072

APA StyleHan, H.-R. (2023). Research on IR and Heat Transfer Characteristics of Molybdenum-Sputtered Polyamide Materials. Coatings, 13(6), 1072. https://doi.org/10.3390/coatings13061072