Multi-Objective Process Optimization of Laser Cladding Co-Based Alloy by Process Window and Grey Relational Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials and Equipment

2.2. Experimental Design

3. Results and Discussion

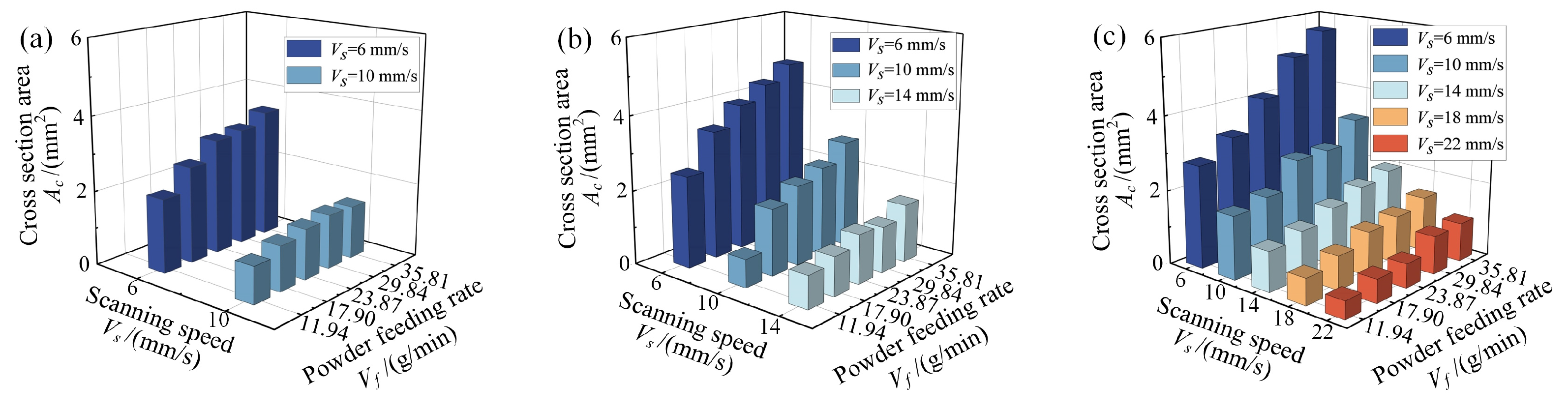

3.1. Optimal Process Window

3.2. Multi-Objective Process Optimization

3.2.1. Subsubsection

3.2.2. The Grey Relational Analysis for Multi-Objective

3.3. Experimental Verification

4. Conclusions

- (1)

- Considering the cross-section area of the cladding track, cladding efficiency, and powder utilization rate, the optimal process window of the Co-based alloy cladding layer was constructed. The optimal process parameter interval was determined as: P = 1300–2100 W, Vs = 6–14 mm/s and Vf = 17.90–29.84 g/min. The ANOVA results showed that the cross-section area and cladding efficiency were correlated with laser power, scanning speed, and powder feeding rate. The powder feeding rate had an inconspicuous effect on the fluctuation ratio, powder utilization rate, and heat-affected zone area. The scanning speed and powder feeding rate had a significant influence on the ratio of cladding track width to height.

- (2)

- The optimal process parameters were determined by grey correlation analysis as follows: P = 2100 W, Vs = 6 mm/s and Vf = 17.90 g/min. It was concluded that the influence order of laser process parameters on the forming characteristics of the cladding track is: P > Vs > Vf. The GRG value of the optimal process parameter combination P5Vs1Vf1 was 0.681, and the prediction accuracy was 96%, which was 0.260 higher than that of the initial parameter combination P1Vs5Vf5.

- (3)

- The cross-section area, the ratio of cladding track width to height, cladding efficiency, and powder utilization rate of the optimal cladding track increased by 4.065 mm2, 1.031, 19.032, and 70.3%, respectively, and the fluctuation ratio decreased by 60.9%. The forming characteristics of the optimized cladding track were favorable, and the metallurgical bonding was formed with the substrate. The elements were evenly distributed without segregation, and the reinforcing phases of Cr7C3, CoCX, and WC were precipitated from the cladding layer. The forming quality, processing efficiency, and cost economy of the optimized cladding track have been expected to improve effectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, W.; Wang, S.C.; Hu, K.K.; Jiang, X.Z.; Yu, H.Y.; Sun, D.B. Effect of laser cladding speed on microstructure and properties of titanium alloy coating on low carbon steel. Surf. Coat. Technol. 2022, 451, 129029. [Google Scholar] [CrossRef]

- Li, Y.T.; Wang, K.M.; Fu, H.G.; Guo, X.Y.; Lin, J.N. Microstructure and wear resistance of in-situ TiC reinforced AlCoCrFeNi-based coatings by laser cladding. Appl. Surf. Sci. 2022, 585, 152703. [Google Scholar] [CrossRef]

- Bax, B.; Rajput, R.; Kellet, R.; Reisacher, M. Systematic evaluation of process parameter maps for laser cladding and directed energy deposition. Addit. Manuf. 2018, 21, 487–494. [Google Scholar] [CrossRef]

- Yue, H.T.; Lv, N.; Guo, C.G.; Zhao, L.J.; Li, Q.; Zhang, J.Z.; Zhang, Y. Microstructure and mechanical properties of TiC/FeCrSiB coating by laser additive remanufacturing on shearer spiral blade. Surf. Coat. Technol. 2022, 431, 128043. [Google Scholar] [CrossRef]

- Souza, N.D.; Ravichandran, S.; Donovan, S.; Daum, P.; Morrell, R.; Nye, Z.; Lancaster, R.J. On the design optimisation of direct energy deposited support structures to repair aero-engine turbine segments. Addit. Manuf. 2022, 56, 102905. [Google Scholar]

- Thakare, J.G.; Pandey, C.; Mahapatra, M.M.; Mulik, R.S. Thermal Barrier Coatings—A State of the Art Review. Met. Mater. Int. 2021, 27, 1947–1968. [Google Scholar] [CrossRef]

- Xiao, Q.; Li, S.Y.; Yang, W.B.; Yang, C.H.; Chen, D.Y.; Ding, H.H.; Wang, W.J. High-temperature tribological properties of coatings repaired by laser additive manufacturing on railway wheel tread damage. Wear 2023, 520–521, 204674. [Google Scholar] [CrossRef]

- Ding, H.H.; Mu, X.P.; Zhu, Y.; Yang, W.B.; Xiao, Q.; Wang, W.J.; Liu, Q.Y.; Guo, J.; Zhou, Z.R. Effect of laser claddings of Fe-based alloy powder with different concentrations of WS2 on the mechanical and tribological properties of railway wheel. Wear 2022, 488–489, 204174. [Google Scholar] [CrossRef]

- Sun, F.Z.; Cai, K.Q.; Li, X.X.; Pang, M. Research on Laser Cladding Co-Based Alloy on the Surface of Vermicular Graphite Cast Iron. Coatings 2021, 11, 1241. [Google Scholar] [CrossRef]

- Gao, Q.; Liu, H.; Chen, P.J.; Liu, X.H.; Yang, H.F.; Hao, J.B. Multi-objective optimization for laser cladding refractory MoNbTiZr high-entropy alloy coating on Ti6Al4V. Opt. Laser Technol. 2023, 161, 109220. [Google Scholar] [CrossRef]

- Meng, G.R.; Zhu, L.D.; Zhang, J.D.; Yang, Z.C.; Xue, P.S. Statistical analysis and multi-objective process optimization of laser cladding TiC-Inconel718 composite coating. Optik 2021, 240, 166828. [Google Scholar] [CrossRef]

- Wu, S.; Liu, Z.H.; Huang, X.F.; Wu, Y.F.; Gong, Y. Process parameter optimization and EBSD analysis of Ni60A-25% WC laser cladding. Int. J. Refract. Met. Hard Mater. 2021, 101, 105675. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Yuan, J.F.; Wu, M.Y.; Arif, A.F.M.; Li, D.Y. Effect of laser cladding parameters on Inconel 718 coating performance and multi-parameter optimization. Opt. Laser Technol. 2023, 158, 108850. [Google Scholar] [CrossRef]

- Deng, D.W.; Li, T.S.; Huang, Z.Y.; Jiang, H.; Yang, S.H.; Zhang, Y. Multi-response optimization of laser cladding for TiC particle reinforced Fe matrix composite based on Taguchi method and grey relational analysis. Opt. Laser Technol. 2022, 153, 108259. [Google Scholar] [CrossRef]

- Guo, C.G.; Lv, N.; Yue, H.T.; Li, Q.; Zhang, J.Z. Laser additive remanufacturing parameters optimization and experimental study of heavy-duty sprocket. Int. J. Adv. Manuf. Technol. 2022, 118, 3789–3800. [Google Scholar] [CrossRef]

- Ilanlou, M.; Razavi, S.R.; Nourollahi, A.; Hosseini, S.; Haghighat, S. Prediction of the geometric characteristics of the laser cladding of Inconel 718 on the Inconel 738 substrate via genetic algorithm and linear regression. Opt. Laser Technol. 2022, 156, 108507. [Google Scholar] [CrossRef]

- Nabhani, M.; Razavi, S.R.; Barekat, M. An empirical-statistical model for laser cladding of Ti-6Al-4V powder on Ti-6Al-4V substrate. Opt. Laser Technol. 2018, 100, 265–271. [Google Scholar] [CrossRef]

- Barekat, M.; Razavi, S.R.; Ghasemi, A. Nd:YAG laser cladding of Co–Cr–Mo alloy on γ-TiAl substrate. Opt. Laser Technol. 2016, 80, 145–152. [Google Scholar] [CrossRef]

- Cui, C.; Wu, M.P.; Miao, X.J.; Gong, Z.S.; Zhao, Y.L. The effect of laser energy density on the geometric characteristics, microstructure and corrosion resistance of Co-based coatings by laser cladding. J. Mater. Res. Technol. 2021, 15, 2405–2418. [Google Scholar]

- Zhou, J.L.; Kong, D.J. Friction–wear performances and oxidation behaviors of Ti3AlC2 reinforced Co–based alloy coatings by laser cladding. Surf. Coat. Technol. 2021, 408, 126816. [Google Scholar] [CrossRef]

- Cui, C.; Wu, M.; He, R.; Gong, Y.L.; Miao, X.J. Investigation on the columnar-to-equiaxed transition and corrosion behavior in multi-track Stellite-6 coating fabricated by laser cladding. Mater. Chem. Phys. 2022, 291, 126681. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Jian, Y.X.; Chen, Z.H.; Qi, H.J.; Huang, Z.F.; Huang, G.S.; Xing, J.D. Microstructure, hardness and slurry erosion-wear behaviors of high-speed laser cladding Stellite 6 coatings prepared by the inside-beam powder feeding method. J. Mater. Res. Technol. 2022, 19, 2596–2610. [Google Scholar] [CrossRef]

- Shao, J.Y.; Yu, G.; He, X.L.; Li, S.X.; Li, Z.X.; Wang, X. Process maps and optimal processing windows based on three-dimensional morphological characteristics in laser directed energy deposition of Ni-based alloy. Opt. Laser Technol. 2021, 142, 107162. [Google Scholar] [CrossRef]

- Lian, G.F.; Zhang, H.; Zhang, Y.; Tanaka, M.L.; Chen, C.R.; Jiang, J.B. Optimizing Processing Parameters for Multi-Track Laser Cladding Utilizing Multi-Response Grey Relational Analysis. Coatings 2019, 9, 356. [Google Scholar] [CrossRef] [Green Version]

- Yang, B.; Lai, Y.B.; Yue, X.; Wang, D.Y.; Zhao, Y.H. Parametric Optimization of Laser Additive Manufacturing of Inconel 625 Using Taguchi Method and Grey Relational Analysis. Scanning 2020, 2020, 9176509. [Google Scholar] [CrossRef]

- Songur, F.; Arslan, E.; Dikici, B. Taguchi optimization of PEO process parameters for corrosion protection of AA7075 alloy. Surf. Coat. Technol. 2022, 434, 128202. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.; Liu, W.S.; Ma, Y.Z.; Tang, S.W.; Liang, C.P.; Cai, Q.S.; Zhang, C. Optimization of parameters in laser powder deposition AlSi10Mg alloy using Taguchi method. Opt. Laser Technol. 2019, 111, 470–480. [Google Scholar] [CrossRef]

- Yadav, R.; Pandey, C.; Mahapatra, M.M.; Mulik, R.S. Study on Effect of Process Variables on Distributed Compositional Characteristics in Metallurgically and Mechanically Bonded Claddings. Trans. Indian Inst. Met. 2017, 70, 1805–1815. [Google Scholar] [CrossRef]

- Guo, C.G.; He, S.Z.; Yue, H.T.; Li, Q.; Hao, G.B. Prediction modelling and process optimization for forming multi-layer cladding structures with laser directed energy deposition. Opt. Laser Technol. 2021, 134, 106607. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Qiu, J.R.; Hwang, S.J. Multi-objective optimization of directed energy deposition process by using Taguchi-Grey relational analysis. Int. J. Adv. Manuf. Technol. 2022, 120, 7547–7563. [Google Scholar] [CrossRef] [PubMed]

- Lian, G.F.; Xiao, S.H.; Zhang, Y.; Jiang, J.B.; Zhan, Y.J. Multi-objective optimization of coating properties and cladding efficiency in 316L/WC composite laser cladding based on grey relational analysis. Int. J. Adv. Manuf. Technol. 2021, 112, 1449–1459. [Google Scholar] [CrossRef]

- Yu, T.B.; Yang, L.; Zhao, Y.; Sun, J.Y.; Li, B.C. Experimental research and multi-response multi-parameter optimization of laser cladding Fe313. Opt. Laser Technol. 2018, 108, 321–332. [Google Scholar] [CrossRef]

- Yue, H.T.; Lv, N.; Guo, C.G.; Zhao, L.J.; Li, Q.; Zhang, J.Z.; Zhang, Y. Microstructure evolution and defect characteristics of multilayer Fe-Cr alloy coatings fabricated by laser melting deposition. Opt. Laser Technol. 2023, 158, 108802. [Google Scholar] [CrossRef]

- Guimaraes, B.; Guedes, A.; Fernandes, C.M.; Figueiredo, D.; Bartolomeu, F.; Miranda, G.; Silva, F.S. WC-Co/316L stainless steel joining by laser powder bed fusion for multi-material cutting tools manufacturing. Int. J. Refract. Met. Hard Mater. 2023, 112, 106140. [Google Scholar] [CrossRef]

- Wang, L.; Mao, J.Z.; Xue, C.G.; Ge, H.H.; Dong, G.; Zhang, Q.L.; Yao, J.H. Cavitation-Erosion behavior of laser cladded Low-Carbon Cobalt-Based alloys on 17-4PH stainless steel. Opt. Laser Technol. 2023, 158, 108761. [Google Scholar] [CrossRef]

- Chang, W.; Xiao, G.C.; Zhang, H.; Chen, H.; Yi, M.D.; Zhang, J.J.; Chen, Z.Q.; Xu, C.H. Microstructure and properties of graphene reinforced co-based composite coating by laser cladding. Surf. Coat. Technol. 2023, 453, 129139. [Google Scholar] [CrossRef]

| Level | Laser Power P (W) | Scanning Speed Vs (mm/s) | Powder Feeding Rate Vf (r/min) |

|---|---|---|---|

| 1 | 500 | 6 | 11.94 |

| 2 | 900 | 10 | 17.90 |

| 3 | 1300 | 14 | 23.87 |

| 4 | 1700 | 18 | 29.84 |

| 5 | 2100 | 22 | 35.81 |

| Level | Laser Power P (W) | Scanning Speed Vs (mm/s) | Powder Feeding Rate Vf (r/min) |

|---|---|---|---|

| 1 | 1300 | 6 | 17.90 |

| 2 | 1500 | 8 | 20.88 |

| 3 | 1700 | 10 | 23.87 |

| 4 | 1900 | 12 | 26.85 |

| 5 | 2100 | 14 | 29.84 |

| No. | P (W) | Vs (mm/s) | Vf (g/min) | No. | P (W) | Vs (mm/s) | Vf (g/min) |

|---|---|---|---|---|---|---|---|

| 1# | 1300 | 6 | 17.90 | 14# | 1700 | 12 | 17.90 |

| 2# | 1300 | 8 | 20.88 | 15# | 1700 | 14 | 20.88 |

| 3# | 1300 | 10 | 23.87 | 16# | 1900 | 6 | 26.85 |

| 4# | 1300 | 12 | 26.85 | 17# | 1900 | 8 | 29.84 |

| 5# | 1300 | 14 | 29.84 | 18# | 1900 | 10 | 17.90 |

| 6# | 1500 | 6 | 20.88 | 19# | 1900 | 12 | 20.88 |

| 7# | 1500 | 8 | 23.87 | 20# | 1900 | 14 | 23.87 |

| 8# | 1500 | 10 | 26.85 | 21# | 2100 | 6 | 29.84 |

| 9# | 1500 | 12 | 29.84 | 22# | 2100 | 8 | 17.90 |

| 10# | 1500 | 14 | 17.90 | 23# | 2100 | 10 | 20.88 |

| 11# | 1700 | 6 | 23.87 | 24# | 2100 | 12 | 23.87 |

| 12# | 1700 | 8 | 26.85 | 25# | 2100 | 14 | 26.85 |

| 13# | 1700 | 10 | 29.84 |

| No. | Ac (mm2) | AHAZ (mm2) | λW/H | λf (%) | ηc (mm3/s) | ηp (%) |

|---|---|---|---|---|---|---|

| 1# | 2.64 | 4.60 | 3.37 | 27.03 | 15.84 | 47.89 |

| 2# | 1.11 | 3.76 | 4.17 | 40.27 | 8.88 | 22.61 |

| 3# | 0.89 | 3.26 | 4.76 | 49.30 | 8.90 | 19.71 |

| 4# | 0.65 | 2.37 | 3.34 | 55.20 | 7.80 | 15.23 |

| 5# | 0.67 | 1.90 | 3.54 | 80.47 | 9.38 | 16.47 |

| 6# | 3.56 | 5.30 | 3.31 | 16.29 | 21.36 | 55.87 |

| 7# | 2.55 | 4.46 | 3.55 | 24.91 | 20.40 | 46.23 |

| 8# | 1.77 | 3.72 | 4.48 | 35.20 | 17.70 | 35.57 |

| 9# | 1.42 | 3.08 | 4.28 | 40.34 | 17.04 | 30.40 |

| 10# | 0.62 | 3.10 | 5.35 | 54.97 | 8.68 | 25.54 |

| 11# | 4.4 | 5.72 | 3.05 | 12.27 | 26.40 | 60.03 |

| 12# | 3.09 | 4.87 | 3.39 | 21.36 | 24.72 | 49.70 |

| 13# | 2.33 | 4.14 | 4.03 | 27.61 | 23.30 | 42.31 |

| 14# | 1.21 | 3.88 | 5.21 | 39.22 | 14.52 | 43.44 |

| 15# | 1.02 | 4.09 | 4.59 | 41.41 | 14.28 | 36.17 |

| 16# | 5.29 | 6.25 | 3.08 | 8.05 | 31.74 | 64.93 |

| 17# | 3.79 | 5.34 | 3.54 | 18.21 | 30.32 | 55.46 |

| 18# | 2.08 | 4.93 | 4.74 | 28.07 | 20.80 | 62.64 |

| 19# | 1.67 | 4.52 | 4.88 | 31.43 | 20.04 | 51.40 |

| 20# | 1.31 | 4.00 | 5.22 | 40.85 | 18.34 | 41.09 |

| 21# | 6.34 | 7.23 | 2.89 | 13.81 | 38.04 | 70.46 |

| 22# | 3.13 | 6.55 | 4.39 | 18.75 | 25.04 | 76.18 |

| 23# | 2.6 | 5.76 | 4.86 | 21.05 | 26.00 | 67.54 |

| 24# | 1.93 | 4.89 | 4.84 | 31.25 | 23.16 | 52.09 |

| 25# | 1.23 | 4.27 | 5.25 | 38.22 | 17.22 | 34.10 |

| No. | SNR | |||||

|---|---|---|---|---|---|---|

| Ac | AHAZ | λW/H | λf | ηc | ηp | |

| 1# | 8.432 | −13.255 | 10.542 | 11.361 | 23.995 | −6.395 |

| 2# | 0.906 | −11.504 | 12.396 | 7.900 | 18.968 | −12.913 |

| 3# | −1.012 | −10.264 | 13.551 | 6.144 | 18.988 | −14.104 |

| 4# | −3.742 | −7.495 | 10.473 | 5.161 | 17.842 | −16.344 |

| 5# | −3.479 | −5.5751 | 10.973 | 1.887 | 19.444 | −15.668 |

| 6# | 11.029 | −14.486 | 10.384 | 15.759 | 26.592 | −5.056 |

| 7# | 8.131 | −12.987 | 11.008 | 12.072 | 26.193 | −6.701 |

| 8# | 4.959 | −11.411 | 13.028 | 9.069 | 24.959 | −8.977 |

| 9# | 3.046 | −9.771 | 12.632 | 7.886 | 24.629 | −10.343 |

| 10# | −4.152 | −9.8272 | 14.565 | 5.197 | 18.770 | −11.855 |

| 11# | 12.869 | −15.148 | 9.683 | 18.223 | 28.432 | −4.432 |

| 12# | 9.799 | −13.751 | 10.599 | 13.410 | 27.861 | −6.072 |

| 13# | 7.347 | −12.34 | 12.108 | 11.178 | 27.347 | −7.470 |

| 14# | 1.656 | −11.777 | 14.336 | 8.131 | 23.239 | −7.242 |

| 15# | 0.172 | −12.234 | 13.229 | 7.657 | 23.095 | −8.832 |

| 16# | 14.469 | −15.918 | 9.757 | 21.888 | 30.032 | −3.752 |

| 17# | 11.573 | −14.551 | 10.978 | 14.793 | 29.635 | −5.120 |

| 18# | 6.361 | −13.857 | 13.523 | 11.035 | 26.361 | −4.063 |

| 19# | 4.454 | −13.103 | 13.759 | 10.054 | 26.038 | −5.781 |

| 20# | 2.345 | −12.041 | 14.357 | 7.777 | 25.268 | −7.725 |

| 21# | 16.042 | −17.183 | 9.216 | 17.196 | 31.605 | −3.041 |

| 22# | 9.911 | −16.325 | 12.858 | 14.540 | 27.973 | −2.363 |

| 23# | 8.299 | −15.208 | 13.725 | 13.534 | 28.299 | −3.409 |

| 24# | 5.711 | −13.786 | 13.704 | 10.103 | 27.295 | −5.665 |

| 25# | 1.798 | −12.609 | 14.410 | 8.354 | 24.721 | −9.345 |

| Source | Ac | AHAZ | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| P | Vs | Vf | Error | Total | P | Vs | Vf | Error | Total | |

| DF | 4 | 4 | 4 | 12 | 24 | 4 | 4 | 4 | 12 | 24 |

| Seq SS | 10.873 | 37.750 | 3.087 | 1.545 | 53.255 | 19.328 | 18.138 | 0.570 | 0.531 | 38.567 |

| Adj SS | 10.873 | 37.750 | 3.087 | 1.545 | 19.328 | 18.138 | 0.570 | 0.531 | ||

| Adj MS | 2.718 | 9.438 | 0.772 | 0.129 | 4.832 | 4.535 | 0.143 | 0.044 | ||

| F-value | 21.12 | 73.31 | 6.00 | 109.25 | 102.53 | 3.22 | ||||

| p-value | 0.000 | 0.000 | 0.007 | 0.000 | 0.000 | 0.052 | ||||

| Source | Ac | AHAZ | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| P | Vs | Vf | Error | Total | P | Vs | Vf | Error | Total | |

| DF | 4 | 4 | 4 | 12 | 24 | 4 | 4 | 4 | 12 | 24 |

| Seq SS | 1.095 | 9.306 | 2.888 | 1.887 | 15.176 | 0.228 | 0.374 | 0.011 | 0.023 | 0.636 |

| Adj SS | 1.095 | 9.306 | 2.888 | 1.887 | 0.228 | 0.374 | 0.011 | 0.023 | ||

| Adj MS | 0.274 | 2.326 | 0.722 | 0.157 | 0.057 | 0.094 | 0.003 | 0.002 | ||

| F-value | 1.74 | 14.79 | 4.59 | 29.51 | 48.37 | 1.37 | ||||

| p-value | 0.206 | 0.000 | 0.018 | 0.000 | 0.000 | 0.300 | ||||

| Source | Ac | AHAZ | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| P | Vs | Vf | Error | Total | P | Vs | Vf | Error | Total | |

| DF | 4 | 4 | 4 | 12 | 24 | 4 | 4 | 4 | 12 | 24 |

| Seq SS | 789.85 | 505.38 | 126.54 | 33.30 | 1455.07 | 0.398 | 0.247 | 0.036 | 0.035 | 0.716 |

| Adj SS | 789.85 | 505.38 | 126.54 | 33.30 | 0.398 | 0.247 | 0.036 | 0.035 | ||

| Adj MS | 197.46 | 126.34 | 31.636 | 2.775 | 0.099 | 0.062 | 0.009 | 0.003 | ||

| F-value | 71.15 | 45.52 | 11.40 | 33.66 | 20.87 | 3.04 | ||||

| p-value | 0.000 | 0.000 | 0.018 | 0.000 | 0.000 | 0.060 | ||||

| Ac | AHAZ | λW/H | |||||||

|---|---|---|---|---|---|---|---|---|---|

| P | Vs | Vf | P | Vs | Vf | P | Vs | Vf | |

| 1 | 0.221 | 12.568 | 4.442 | −9.619 | −15.198 | −13.008 | 11.587 | 9.917 | 13.165 |

| 2 | 4.603 | 8.064 | 4.972 | −11.696 | −13.823 | −13.307 | 12.324 | 11.568 | 12.699 |

| 3 | 6.369 | 5.191 | 5.609 | −13.050 | −12.616 | −12.845 | 11.991 | 13.187 | 12.451 |

| 4 | 7.841 | 2.225 | 5.457 | −13.894 | −11.186 | −12.237 | 12.475 | 12.981 | 11.653 |

| 5 | 8.352 | −0.663 | 6.906 | −15.022 | −10.457 | −11.884 | 12.783 | 13.307 | 11.181 |

| Delta | 8.131 | 13.231 | 2.464 | 5.403 | 4.740 | 1.43 | 1.196 | 3.590 | 1.983 |

| Rank | 2 | 1 | 3 | 1 | 2 | 3 | 3 | 1 | 2 |

| λf | ηc | ηp | |||||||

| P | Vs | Vf | P | Vs | Vf | P | Vs | Vf | |

| 1 | 6.491 | 16.886 | 10.053 | 19.851 | 28.130 | 24.071 | −13.085 | −4.535 | −6.384 |

| 2 | 9.997 | 12.543 | 10.981 | 24.230 | 26.132 | 24.602 | −8.586 | −6.634 | −7.198 |

| 3 | 11.720 | 10.192 | 10.864 | 25.992 | 25.191 | 25.244 | −6.810 | −7.605 | −7.726 |

| 4 | 13.110 | 8.267 | 11.577 | 27.470 | 23.813 | 25.086 | −5.288 | −9.075 | −8.898 |

| 5 | 12.745 | 6.175 | 10.588 | 27.981 | 22.263 | 26.535 | −4.765 | −10.685 | −8.329 |

| Delta | 6.619 | 10.711 | 1.524 | 8.130 | 5.867 | 2.464 | 8.320 | 6.150 | 2.515 |

| Rank | 2 | 1 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| No. | xi (k) | |||||

|---|---|---|---|---|---|---|

| Ac | AHAZ | λW/H | λf | ηc | ηp | |

| 1# | 0.623 | 0.338 | 0.248 | 0.474 | 0.447 | 0.712 |

| 2# | 0.251 | 0.489 | 0.594 | 0.301 | 0.082 | 0.245 |

| 3# | 0.155 | 0.596 | 0.810 | 0.213 | 0.083 | 0.160 |

| 4# | 0.020 | 0.835 | 0.235 | 0.164 | 0.000 | 0.000 |

| 5# | 0.033 | 1.000 | 0.328 | 0.000 | 0.116 | 0.048 |

| 6# | 0.752 | 0.232 | 0.218 | 0.694 | 0.636 | 0.807 |

| 7# | 0.608 | 0.361 | 0.335 | 0.509 | 0.607 | 0.690 |

| 8# | 0.451 | 0.497 | 0.713 | 0.359 | 0.517 | 0.527 |

| 9# | 0.356 | 0.639 | 0.639 | 0.300 | 0.493 | 0.429 |

| 10# | 0.000 | 0.634 | 1.000 | 0.165 | 0.067 | 0.321 |

| 11# | 0.843 | 0.175 | 0.087 | 0.817 | 0.769 | 0.852 |

| 12# | 0.691 | 0.296 | 0.258 | 0.576 | 0.728 | 0.735 |

| 13# | 0.569 | 0.417 | 0.541 | 0.465 | 0.691 | 0.635 |

| 14# | 0.288 | 0.466 | 0.957 | 0.312 | 0.392 | 0.651 |

| 15# | 0.214 | 0.426 | 0.750 | 0.288 | 0.382 | 0.537 |

| 16# | 0.922 | 0.109 | 0.101 | 1.000 | 0.886 | 0.901 |

| 17# | 0.779 | 0.227 | 0.329 | 0.645 | 0.857 | 0.803 |

| 18# | 0.521 | 0.287 | 0.805 | 0.457 | 0.619 | 0.878 |

| 19# | 0.426 | 0.351 | 0.849 | 0.408 | 0.596 | 0.756 |

| 20# | 0.322 | 0.443 | 0.961 | 0.294 | 0.540 | 0.616 |

| 21# | 1.000 | 0.000 | 0.000 | 0.765 | 1.000 | 0.952 |

| 22# | 0.696 | 0.074 | 0.681 | 0.633 | 0.736 | 1.000 |

| 23# | 0.617 | 0.170 | 0.843 | 0.582 | 0.760 | 0.925 |

| 24# | 0.488 | 0.293 | 0.839 | 0.411 | 0.687 | 0.764 |

| 25# | 0.295 | 0.394 | 0.971 | 0.323 | 0.500 | 0.501 |

| No. | GRC | GRG | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Ac | AHAZ | λW/H | λf | ηc | ηp | Values | SNR | Rank | |

| 1# | 0.570 | 0.430 | 0.613 | 0.487 | 0.475 | 0.634 | 0.535 | −5.434 | 15 |

| 2# | 0.400 | 0.495 | 0.552 | 0.417 | 0.353 | 0.399 | 0.436 | −7.214 | 24 |

| 3# | 0.372 | 0.553 | 0.725 | 0.388 | 0.353 | 0.373 | 0.461 | −6.731 | 23 |

| 4# | 0.338 | 0.751 | 0.395 | 0.374 | 0.333 | 0.333 | 0.421 | −7.516 | 25 |

| 5# | 0.341 | 1.000 | 0.427 | 0.333 | 0.361 | 0.344 | 0.468 | −6.599 | 22 |

| 6# | 0.668 | 0.394 | 0.390 | 0.620 | 0.579 | 0.722 | 0.562 | −5.002 | 9 |

| 7# | 0.561 | 0.439 | 0.429 | 0.505 | 0.560 | 0.617 | 0.518 | −5.706 | 17 |

| 8# | 0.477 | 0.499 | 0.635 | 0.438 | 0.509 | 0.514 | 0.512 | −5.817 | 18 |

| 9# | 0.437 | 0.580 | 0.580 | 0.417 | 0.497 | 0.467 | 0.496 | −6.084 | 20 |

| 10# | 0.333 | 0.577 | 1.000 | 0.375 | 0.349 | 0.424 | 0.510 | −5.853 | 19 |

| 11# | 0.761 | 0.377 | 0.354 | 0.732 | 0.684 | 0.772 | 0.613 | −4.246 | 5 |

| 12# | 0.618 | 0.415 | 0.403 | 0.541 | 0.648 | 0.653 | 0.546 | −5.251 | 13 |

| 13# | 0.537 | 0.462 | 0.521 | 0.483 | 0.618 | 0.578 | 0.533 | −5.463 | 16 |

| 14# | 0.412 | 0.483 | 0.921 | 0.421 | 0.451 | 0.589 | 0.546 | −5.250 | 12 |

| 15# | 0.389 | 0.466 | 0.667 | 0.413 | 0.447 | 0.519 | 0.483 | −6.314 | 21 |

| 16# | 0.865 | 0.359 | 0.357 | 1.000 | 0.814 | 0.834 | 0.705 | −3.035 | 2 |

| 17# | 0.693 | 0.393 | 0.427 | 0.585 | 0.777 | 0.717 | 0.599 | −4.455 | 6 |

| 18# | 0.511 | 0.412 | 0.720 | 0.480 | 0.568 | 0.804 | 0.582 | −4.697 | 7 |

| 19# | 0.466 | 0.435 | 0.768 | 0.458 | 0.553 | 0.672 | 0.559 | −5.057 | 10 |

| 20# | 0.424 | 0.473 | 0.928 | 0.415 | 0.521 | 0.566 | 0.554 | −5.123 | 11 |

| 21# | 1.000 | 0.333 | 0.333 | 0.681 | 1.000 | 0.912 | 0.710 | −2.977 | 1 |

| 22# | 0.622 | 0.351 | 0.610 | 0.576 | 0.655 | 1.000 | 0.636 | −3.935 | 3 |

| 23# | 0.566 | 0.376 | 0.761 | 0.545 | 0.676 | 0.870 | 0.632 | −3.983 | 4 |

| 24# | 0.494 | 0.414 | 0.756 | 0.459 | 0.615 | 0.679 | 0.570 | −4.888 | 8 |

| 25# | 0.415 | 0.452 | 0.945 | 0.425 | 0.500 | 0.500 | 0.540 | −5.359 | 14 |

| Source | GRG | ||||

|---|---|---|---|---|---|

| P | Vs | Vf | Error | Total | |

| DF | 4 | 4 | 4 | 12 | 24 |

| Seq SS | 0.077 | 0.041 | 0.003 | 0.008 | 0.128 |

| Adj SS | 0.077 | 0.041 | 0.003 | 0.008 | |

| Adj MS | 0.019 | 0.010 | 0.001 | 0.001 | |

| F-value | 30.53 | 16.30 | 1.14 | ||

| p-value | 0.000 | 0.000 | 0.384 | ||

| Level | P | Vs | Vf |

|---|---|---|---|

| 1 | −6.699 | −4.139 | −5.034 |

| 2 | −5.692 | −5.312 | −5.514 |

| 3 | −5.305 | −5.338 | −5.339 |

| 4 | −4.437 | −5.759 | −5.396 |

| 5 | −4.228 | −5.850 | −5.116 |

| Delta | 2.470 | 1.711 | 0.480 |

| Rank | 1 | 2 | 3 |

| Evaluation Items | Initial Parameters | Optimal Parameters | |

|---|---|---|---|

| Experiment | Prediction | ||

| P1Vs5Vf5 (5#) | P5Vs1Vf1 | P5Vs1Vf1 | |

| Ac (mm2) | 0.65 | 4.735 | - |

| AHAZ (mm2) | 2.37 | 7.282 | - |

| λW/H | 3.34 | 4.568 | - |

| λf (%) | 0.552 | 0.196 | - |

| ηc (mm3/s) | 7.80 | 28.41 | - |

| ηp (%) | 0.152 | 0.868 | - |

| GRG | 0.421 | 0.681 | 0.706 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, H.; Lv, N.; Guo, C.; Zhai, J.; Dai, W.; Zhang, J.; Zhao, G. Multi-Objective Process Optimization of Laser Cladding Co-Based Alloy by Process Window and Grey Relational Analysis. Coatings 2023, 13, 1090. https://doi.org/10.3390/coatings13061090

Yue H, Lv N, Guo C, Zhai J, Dai W, Zhang J, Zhao G. Multi-Objective Process Optimization of Laser Cladding Co-Based Alloy by Process Window and Grey Relational Analysis. Coatings. 2023; 13(6):1090. https://doi.org/10.3390/coatings13061090

Chicago/Turabian StyleYue, Haitao, Ning Lv, Chenguang Guo, Jianhua Zhai, Weibing Dai, Jianzhuo Zhang, and Guochao Zhao. 2023. "Multi-Objective Process Optimization of Laser Cladding Co-Based Alloy by Process Window and Grey Relational Analysis" Coatings 13, no. 6: 1090. https://doi.org/10.3390/coatings13061090

APA StyleYue, H., Lv, N., Guo, C., Zhai, J., Dai, W., Zhang, J., & Zhao, G. (2023). Multi-Objective Process Optimization of Laser Cladding Co-Based Alloy by Process Window and Grey Relational Analysis. Coatings, 13(6), 1090. https://doi.org/10.3390/coatings13061090