Photocured Zwitterionic Coatings Containing POSS for Antifogging Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Glass Slide Pretreatment

2.3. Zwitterionic Coating Fabrication

2.4. Characterization

2.5. Antifogging Test

3. Results and Discussion

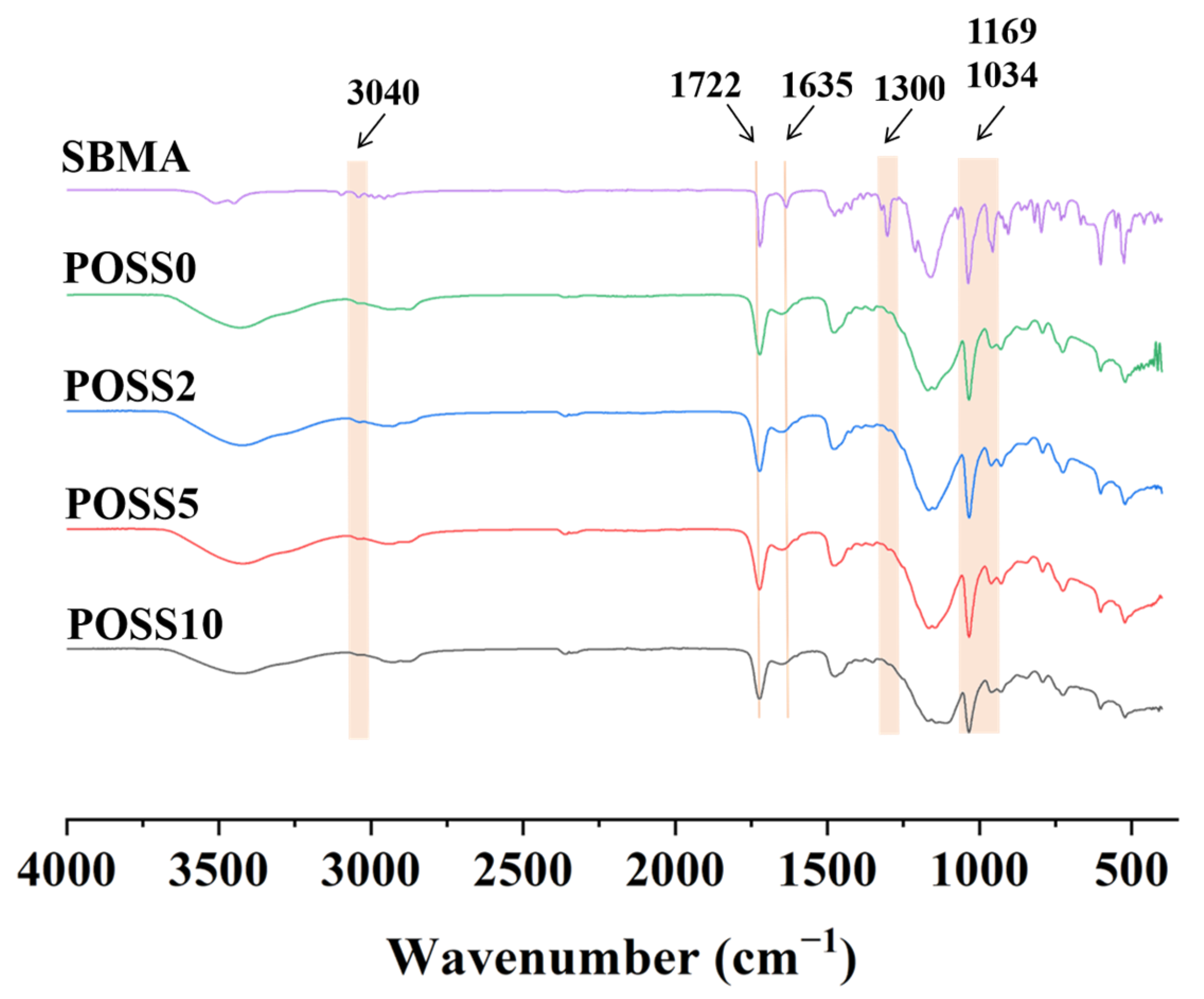

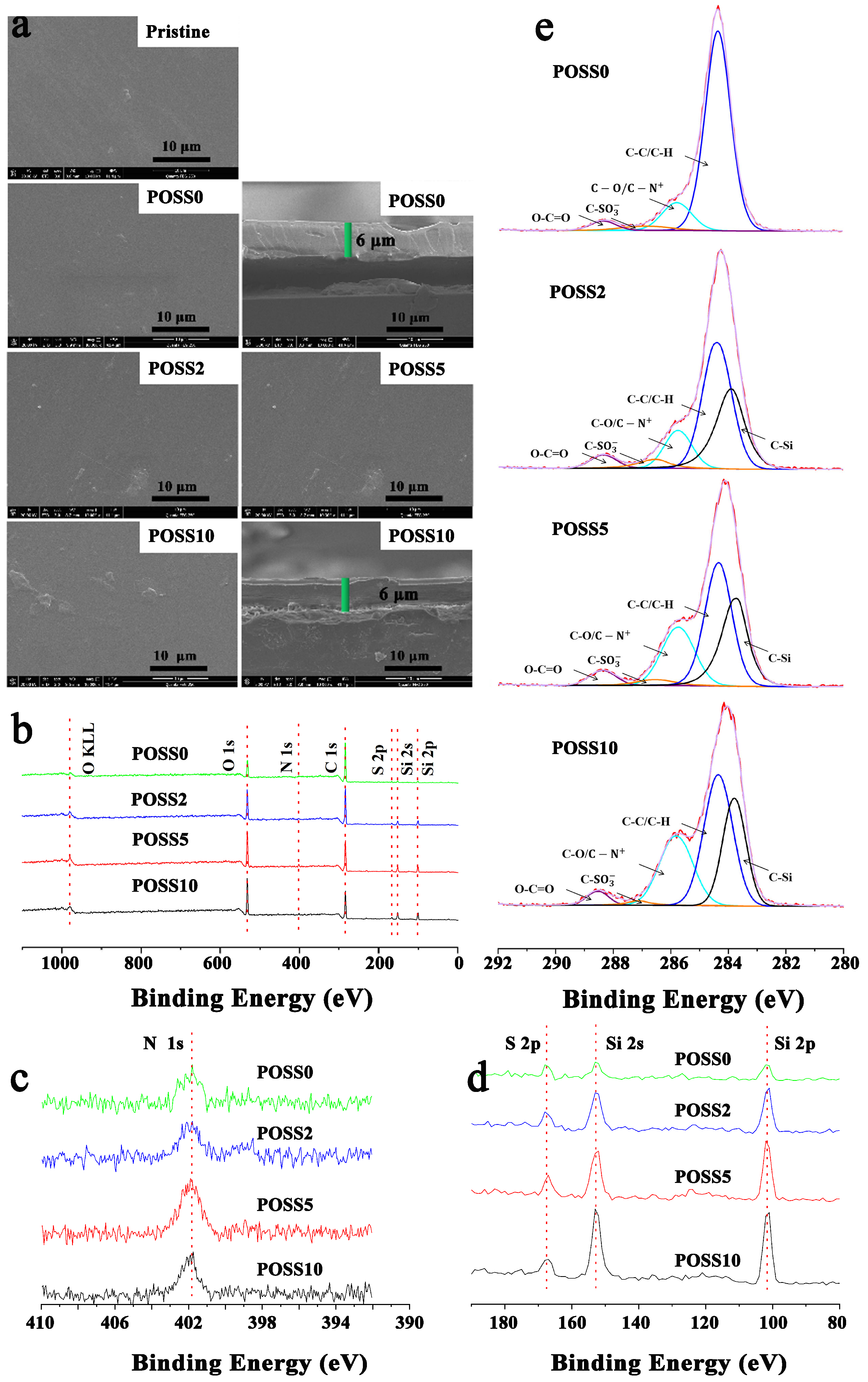

3.1. Coatings Preparation and Characterization

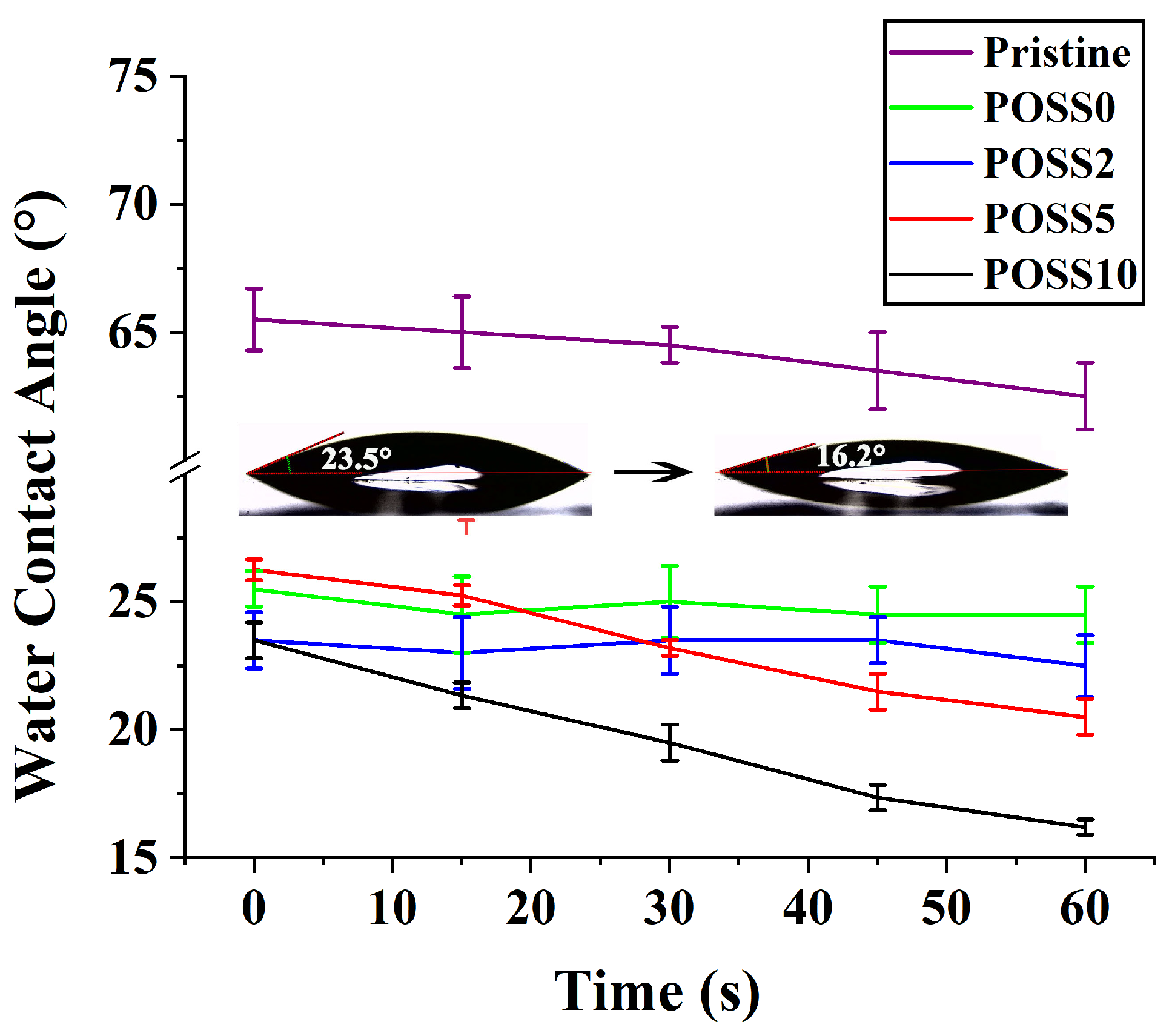

3.2. Coating Surface Wettability

3.3. Coating Transmittance and Antifogging Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Di Mundo, R.; d’Agostino, R.; Palumbo, F. Long-lasting antifog plasma modification of transparent plastics. ACS Appl. Mater. Interfaces 2014, 6, 17059–17066. [Google Scholar] [CrossRef]

- Li, Y.; Fang, X.; Wang, Y.; Ma, B.; Sun, J. Highly transparent and water-enabled healable antifogging and frost-resisting films based on poly(vinyl alcohol)–nafion complexes. Chem. Mater. 2016, 28, 6975–6984. [Google Scholar] [CrossRef]

- Duran, I.R.; Laroche, G. Water drop-surface interactions as the basis for the design of anti-fogging surfaces: Theory, practice, and applications trends. Adv. Colloid Interface Sci. 2019, 263, 68–94. [Google Scholar] [CrossRef]

- San-Juan, M.; Martín, Ó.; Mirones, B.J.; De Tiedra, P. Assessment of efficiency of windscreen demisting systems in electrical vehicles by using IR thermography. Appl. Therm. Eng. 2016, 104, 479–485. [Google Scholar] [CrossRef]

- Walker, C.; Mitridis, E.; Kreiner, T.; Eghlidi, H.; Schutzius, T.M.; Poulikakos, D. Transparent metasurfaces counteracting fogging by harnessing sunlight. Nano Lett. 2019, 19, 1595–1604. [Google Scholar] [CrossRef] [Green Version]

- Mitridis, E.; Lambley, H.; Trober, S.; Schutzius, T.M.; Poulikakos, D. Transparent photothermal metasurfaces amplifying superhydrophobicity by absorbing sunlight. ACS Nano 2020, 14, 11712–11721. [Google Scholar] [CrossRef]

- Mouterde, T.; Lehoucq, G.; Xavier, S.; Checco, A.; Black, C.T.; Rahman, A.; Midavaine, T.; Clanet, C.; Quere, D. Antifogging abilities of model nanotextures. Nat. Mater. 2017, 16, 658–663. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, L.; Feng, S.; Zheng, Y. A strategy of antifogging: Air-trapped hollow microsphere nanocomposites. Chem. Mater. 2017, 29, 2899–2905. [Google Scholar] [CrossRef]

- Wang, D.; Sun, Q.; Hokkanen, M.J.; Zhang, C.; Lin, F.Y.; Liu, Q.; Zhu, S.P.; Zhou, T.; Chang, Q.; He, B.; et al. Design of robust superhydrophobic surfaces. Nature 2020, 582, 55–59. [Google Scholar] [CrossRef]

- Han, Z.; Feng, X.; Guo, Z.; Niu, S.; Ren, L. Flourishing bioinspired antifogging materials with superwettability: Progresses and challenges. Adv. Mater. 2018, 30, e1704652. [Google Scholar] [CrossRef]

- Sun, Z.; Liao, T.; Liu, K.; Jiang, L.; Kim, J.H.; Dou, S.X. Fly-eye inspired superhydrophobic anti-fogging inorganic nanostructures. Small 2014, 10, 3001–3006. [Google Scholar] [CrossRef]

- Song, Y.; Liu, Y.; Jiang, H.; Zhang, Y.; Zhao, J.; Han, Z.; Ren, L. Mosquito eyes inspired surfaces with robust antireflectivity and superhydrophobicity. Surf. Coat. Technol. 2017, 316, 85–92. [Google Scholar] [CrossRef]

- Li, J.; Zhu, J.; Gao, X. Bio-inspired high-performance antireflection and antifogging polymer films. Small 2014, 10, 2578–2582. [Google Scholar] [CrossRef]

- Garlisi, C.; Palmisano, G. Radiation-free superhydrophilic and antifogging properties of e-beam evaporated TiO2 films on glass. Appl. Surf. Sci. 2017, 420, 83–93. [Google Scholar] [CrossRef]

- Park, C.; Kim, T.; Kim, Y.-I.; Lee, M.W.; An, S.; Yoon, S.S. Supersonically sprayed transparent flexible multifunctional composites for self-cleaning, anti-icing, anti-fogging, and anti-bacterial applications. Compos. Part B Eng. 2021, 222, 109070. [Google Scholar] [CrossRef]

- Zhang, L.; Dillert, R.; Bahnemann, D.; Vormoor, M. Photo-induced hydrophilicity and self-cleaning: Models and reality. Energ. Environ. Sci. 2012, 5, 7491. [Google Scholar] [CrossRef]

- Zhao, J.; Meyer, A.; Ma, L.; Wang, X.; Ming, W. Terpolymer-based SIPN coating with excellent antifogging and frost-resisting properties. RSC Adv. 2015, 5, 102560–102566. [Google Scholar] [CrossRef]

- Raula, M.; Kar, S.; Ansari, F.; Das, S.; Ghosh, S.K. Zwitter-wettable acrylic polymeric coating on glasses for anti-fog applications. J. Appl. Polym. Sci. 2020, 137, 49303. [Google Scholar] [CrossRef]

- Ezzat, M.; Huang, C.-J. Zwitterionic polymer brush coatings with excellent anti-fog and anti-frost properties. RSC Adv. 2016, 6, 61695–61702. [Google Scholar] [CrossRef]

- Yang, H.; Jin, K.; Wang, H.; Fan, Z.; Zhang, T.; Liu, Z.; Cai, Z. Facile preparation of a high-transparency zwitterionic anti-fogging poly(SBMA-co-IA) coating with self-healing property. Prog. Org. Coat. 2022, 165, 106764. [Google Scholar] [CrossRef]

- Zheng, Z.; Liu, Y.; Wang, L.; Yu, L.; Cen, Y.; Zhu, T.; Yu, D.; Chen, C. A novel organic-inorganic zwitterionic acrylate polymer for high-performance anti-fog coating. Prog. Org. Coat. 2020, 142, 105578. [Google Scholar] [CrossRef]

- Liu, Z.; Tu, P.; Ji, Y.; Cai, Z.; Wu, H.; Xu, B. An eco-friendly and durable anti-fogging coating based on sulfobetaines and silicones. Prog. Org. Coat. 2023, 177, 107413. [Google Scholar] [CrossRef]

- Lee, H.; Alcaraz, M.L.; Rubner, M.F.; Cohen, R.E. Zwitter-wettability and antifogging coatings with frost-resisting capabilities. ACS Nano 2013, 7, 2172–2185. [Google Scholar] [CrossRef]

- Zhao, J.; Meyer, A.; Ma, L.; Ming, W. Acrylic coatings with surprising antifogging and frost-resisting properties. Chem. Commun. 2013, 49, 11764–11766. [Google Scholar] [CrossRef]

- Li, C.; Li, X.; Tao, C.; Ren, L.; Zhao, Y.; Bai, S.; Yuan, X. Amphiphilic antifogging/anti-Icing coatings containing POSS-PDMAEMA-b-PSBMA. ACS Appl. Mater. Interfaces 2017, 9, 22959–22969. [Google Scholar] [CrossRef]

- Zhao, J.; Lu, P.; Song, L.; Tian, L.; Ming, W.; Ren, L. Highly efficient antifogging and frost-resisting acrylic coatings from one-step thermal curing. Colloids Surf. A 2020, 585, 124160. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, L.; Millians, W.; Wu, T.; Ming, W. Dual-Functional Antifogging/Antimicrobial Polymer Coating. ACS Appl. Mater. Interfaces 2016, 8, 8737–8742. [Google Scholar] [CrossRef]

- Tao, C.; Bai, S.; Li, X.; Li, C.; Ren, L.; Zhao, Y.; Yuan, X. Formation of zwitterionic coatings with an aqueous lubricating layer for antifogging/anti-icing applications. Prog. Org. Coat. 2018, 115, 56–64. [Google Scholar] [CrossRef]

- Bai, S.; Li, X.; Zhang, R.; Li, C.; Zhu, K.; Sun, P.; Zhao, Y.; Ren, L.; Yuan, X. Enhancing antifogging/frost-resisting performances of amphiphilic coatings via cationic, zwitterionic or anionic polyelectrolytes. Chem. Eng. J. 2019, 357, 667–677. [Google Scholar] [CrossRef]

- Wang, W.; Lu, P.; Fan, Y.; Tian, L.; Niu, S.; Zhao, J.; Ren, L. A facile antifogging/frost-resistant coating with self-healing ability. Chem. Eng. J. 2019, 378, 122173. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, L.; Ren, T.; He, J. Robust yet self-healing antifogging/antibacterial dual-functional composite films by a simple one-pot strategy. J. Colloid Interface Sci. 2019, 540, 107–114. [Google Scholar] [CrossRef]

- Kim, Y.; Thuy, L.T.; Kim, Y.; Seong, M.; Cho, W.K.; Choi, J.S.; Kang, S.M. Coordination-driven surface zwitteration for antibacterial and antifog applications. Langmuir 2022, 38, 1550–1559. [Google Scholar] [CrossRef]

- Haechler, I.; Ferru, N.; Schnoering, G.; Mitridis, E.; Schutzius, T.M.; Poulikakos, D. Transparent sunlight-activated antifogging metamaterials. Nat. Nanotechnol. 2023, 18, 137–144. [Google Scholar] [CrossRef] [PubMed]

- Kozuma, T.; Mihata, A.; Kaneko, Y. Preparation of soluble POSS-linking polyamide and Its application in antifogging films. Materials 2021, 14, 3178. [Google Scholar] [CrossRef] [PubMed]

- Gao, S.; Liu, B.; Peng, J.; Zhu, K.; Zhao, Y.; Li, X.; Yuan, X. Icephobic durability of branched PDMS slippage coatings co-cross-linked by functionalized POSS. ACS Appl. Mater. Interfaces 2019, 11, 4654–4666. [Google Scholar] [CrossRef]

- Bai, S.; Li, X.; Zhao, Y.; Ren, L.; Yuan, X. Antifogging/antibacterial coatings constructed by N-hydroxyethylacrylamide and quaternary ammonium-containing copolymers. ACS Appl. Mater. Inter. 2020, 12, 12305–12316. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Lin, Q.; Shen, C.; Han, Y.; Tang, J.; Chen, H. Synthesis of MA POSS–PMMA as an intraocular lens material with high light transmittance and good cytocompatibility. RSC Adv. 2014, 4, 52959–52966. [Google Scholar] [CrossRef]

| Samples | O 1s | N 1s | C 1s | S 2p | Si 2p |

|---|---|---|---|---|---|

| POSS0 | 15.9 | 2.2 | 76.3 | 3.8 | 1.8 |

| POSS2 | 21.1 | 2.8 | 65.3 | 1.9 | 8.9 |

| POSS5 | 24.3 | 2.5 | 60.8 | 2.1 | 10.3 |

| POSS10 | 26.7 | 2.3 | 54.2 | 2.4 | 14.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, L.; Li, Z.; Wu, X.; Wang, K.; Abbas, F.; Wu, Y.; Zhang, F. Photocured Zwitterionic Coatings Containing POSS for Antifogging Applications. Coatings 2023, 13, 1152. https://doi.org/10.3390/coatings13071152

Guo L, Li Z, Wu X, Wang K, Abbas F, Wu Y, Zhang F. Photocured Zwitterionic Coatings Containing POSS for Antifogging Applications. Coatings. 2023; 13(7):1152. https://doi.org/10.3390/coatings13071152

Chicago/Turabian StyleGuo, Lei, Zhuping Li, Xiubang Wu, Kai Wang, Faheem Abbas, Yundong Wu, and Fan Zhang. 2023. "Photocured Zwitterionic Coatings Containing POSS for Antifogging Applications" Coatings 13, no. 7: 1152. https://doi.org/10.3390/coatings13071152