Experimental Study on the Effect of Shot Peening and Re-Shot Peening on the Residual Stress Distribution and Fatigue Life of 20CrMnTi

Abstract

:1. Introduction

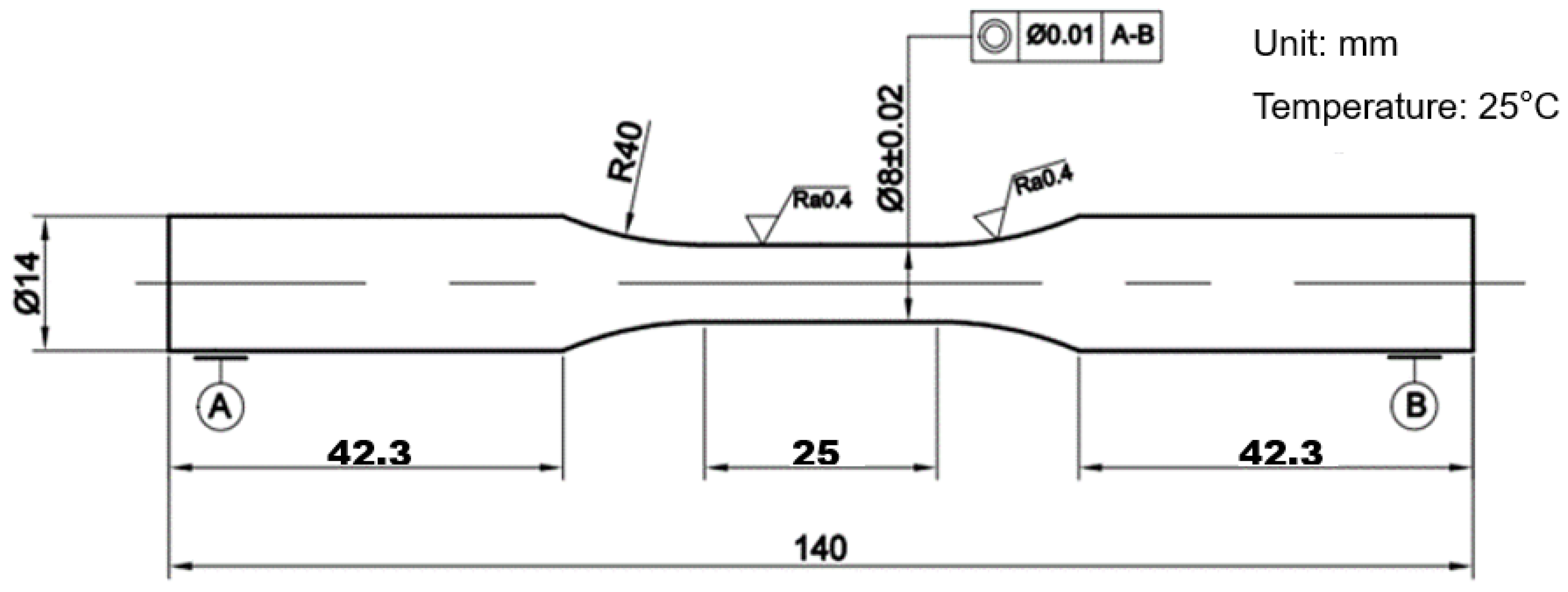

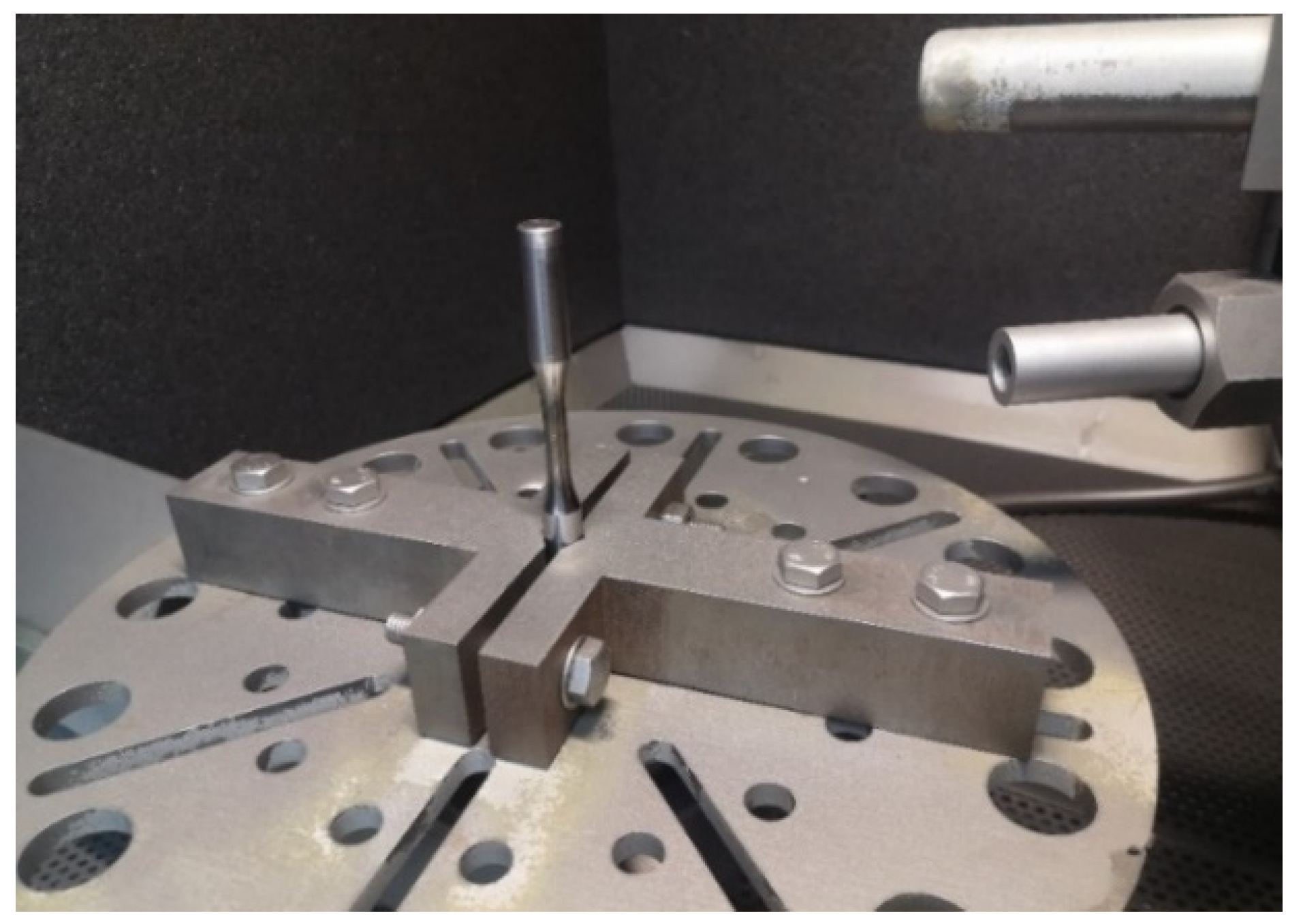

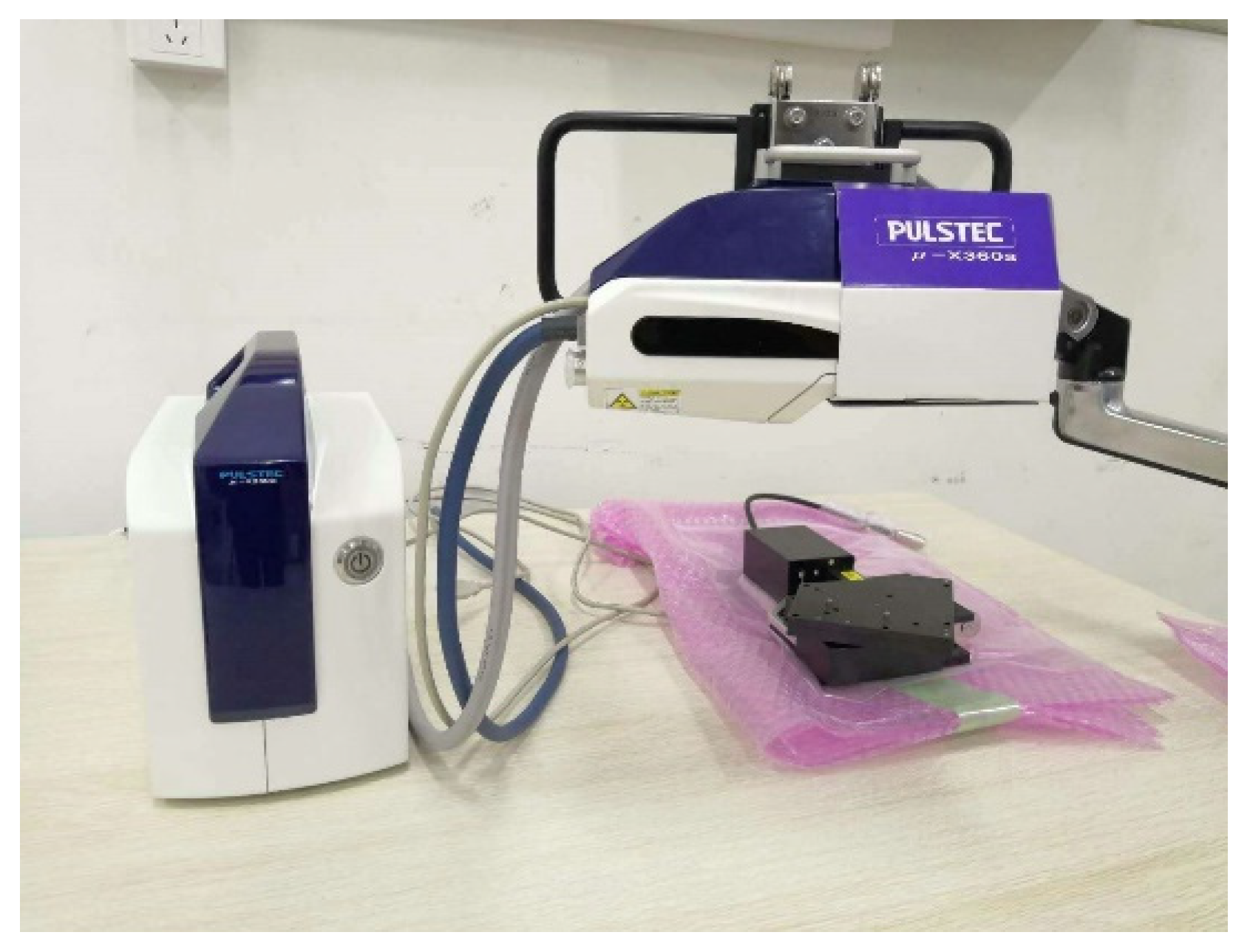

2. Experimental Procedure

3. Results and Discussion

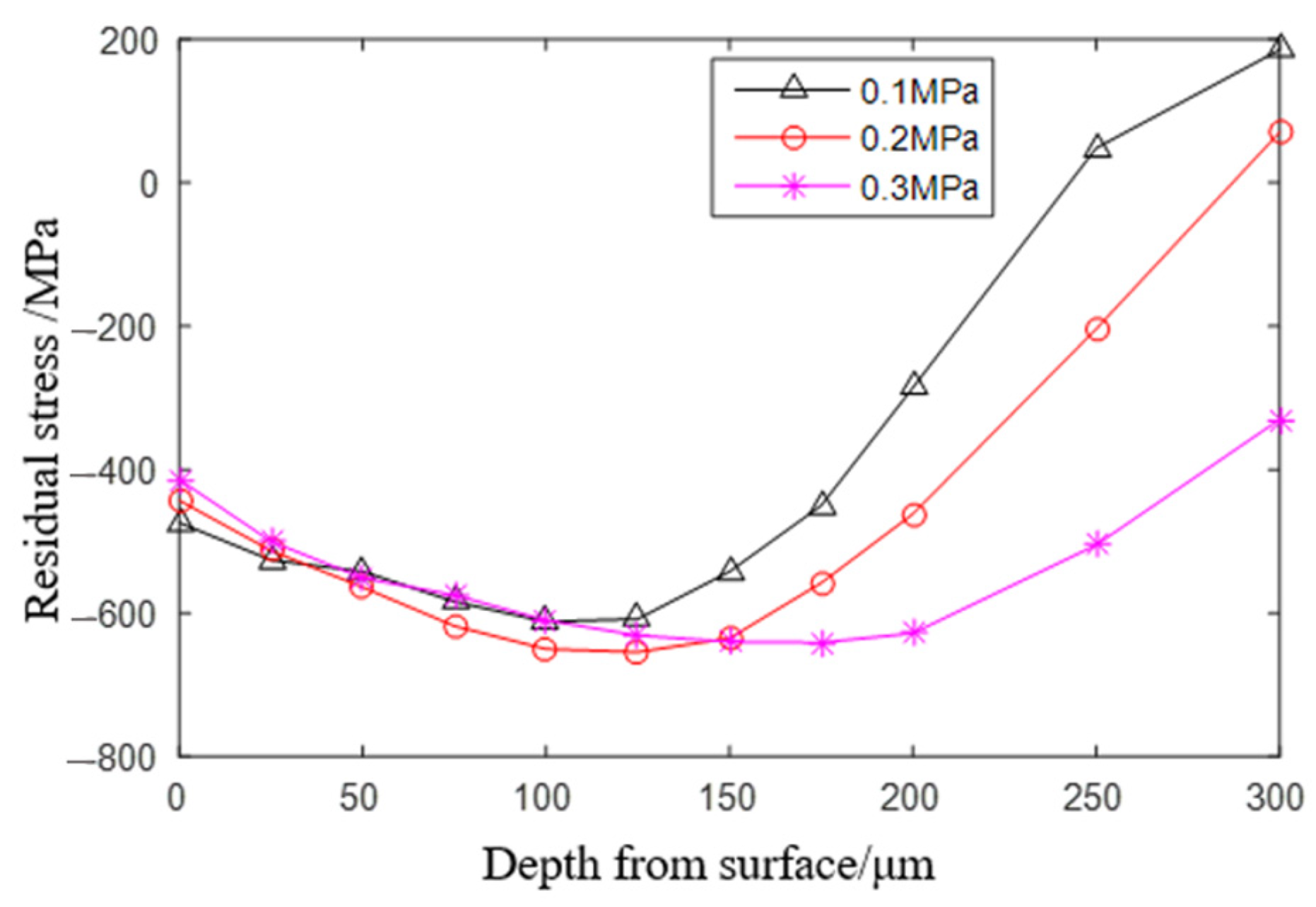

3.1. Residual Compressive Stress Distribution on the Material Surface after Shot Peening

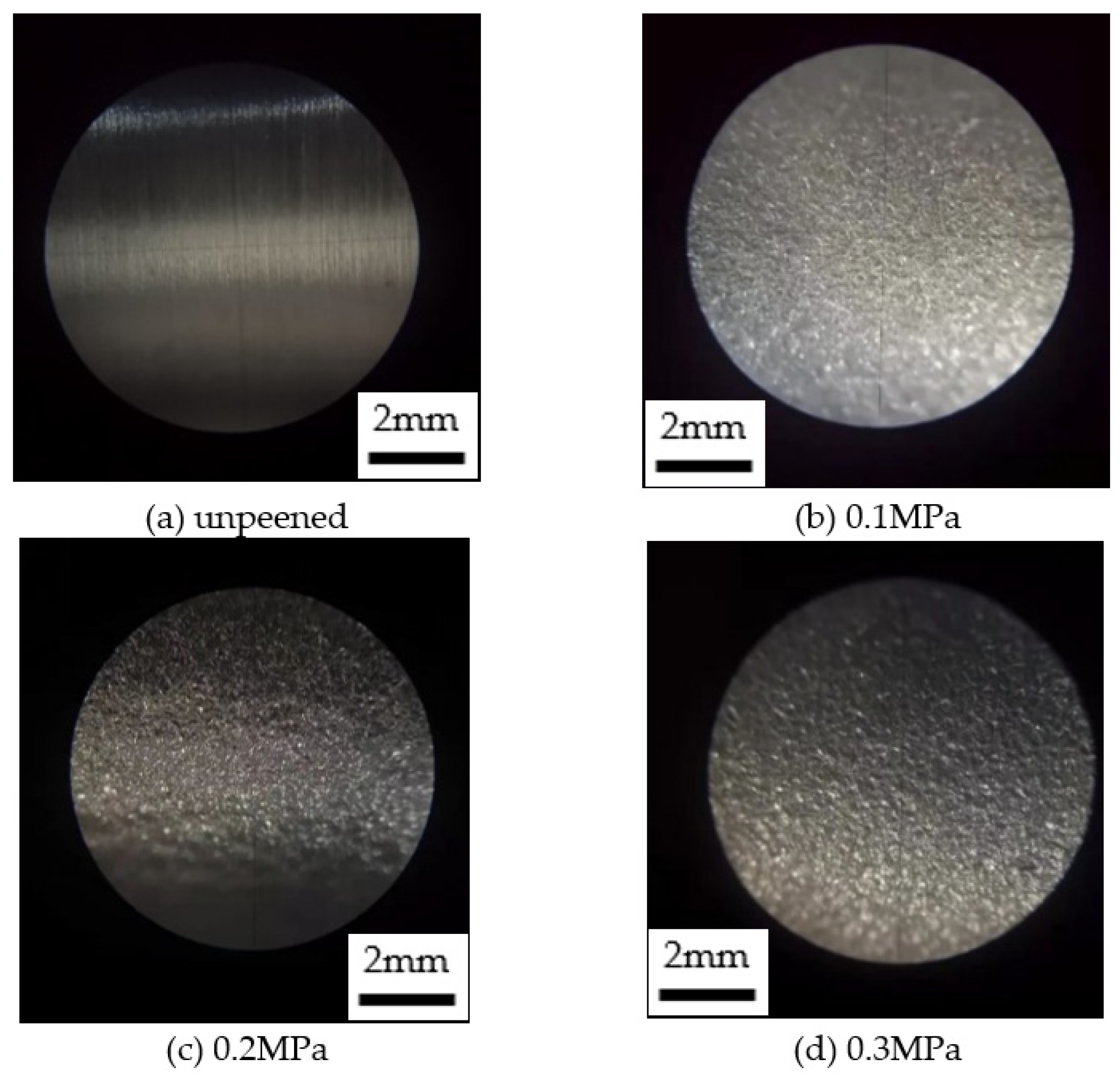

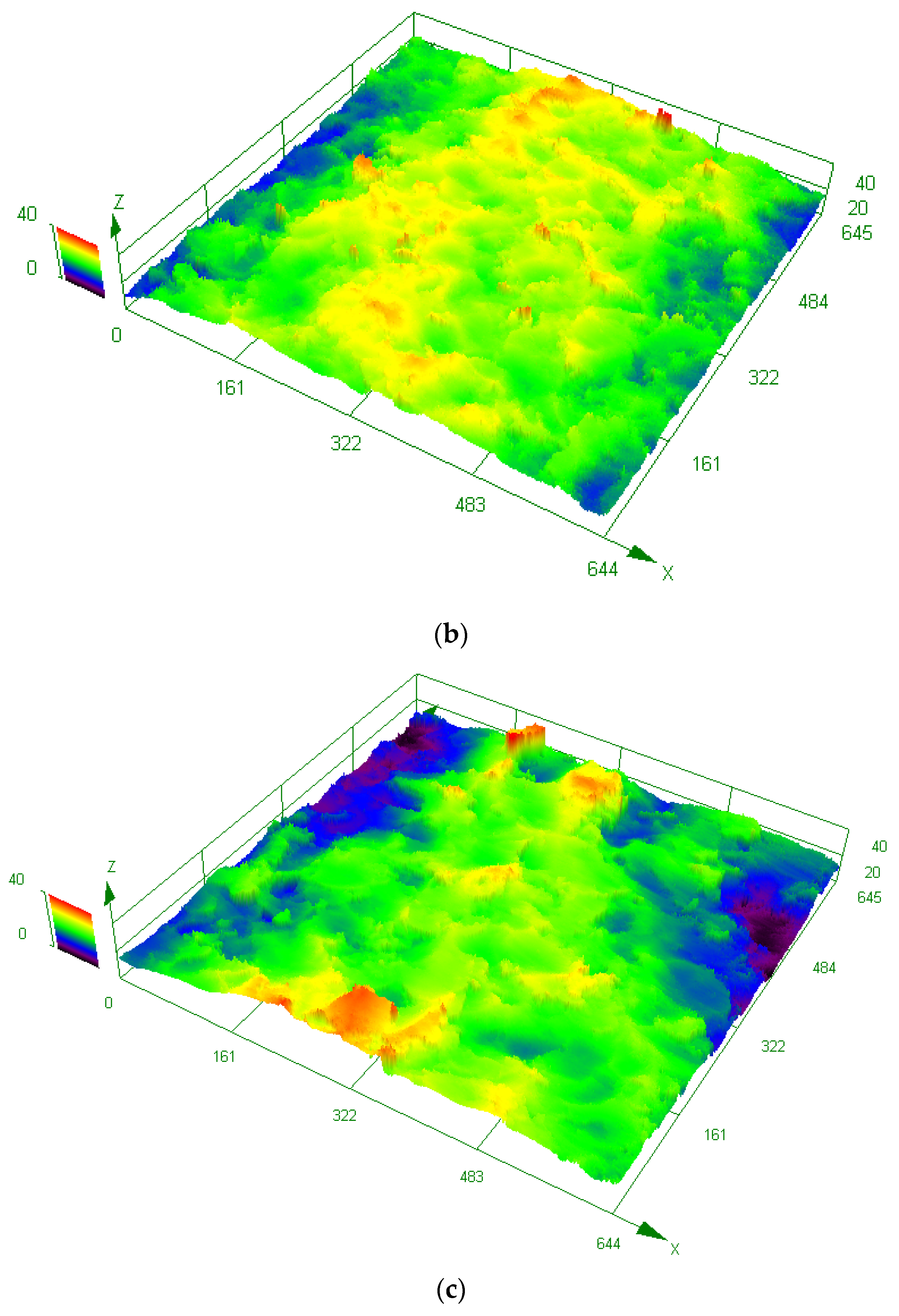

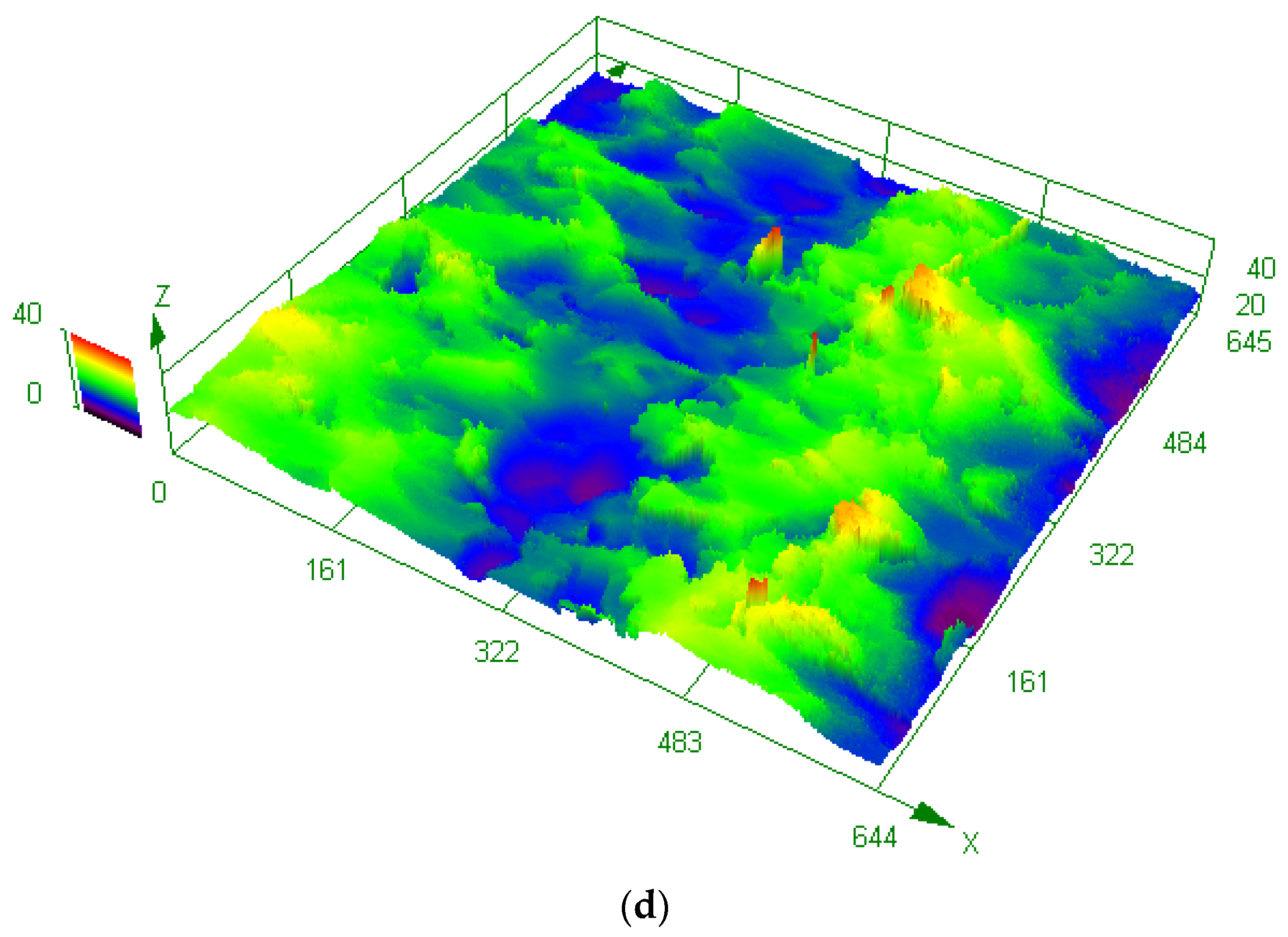

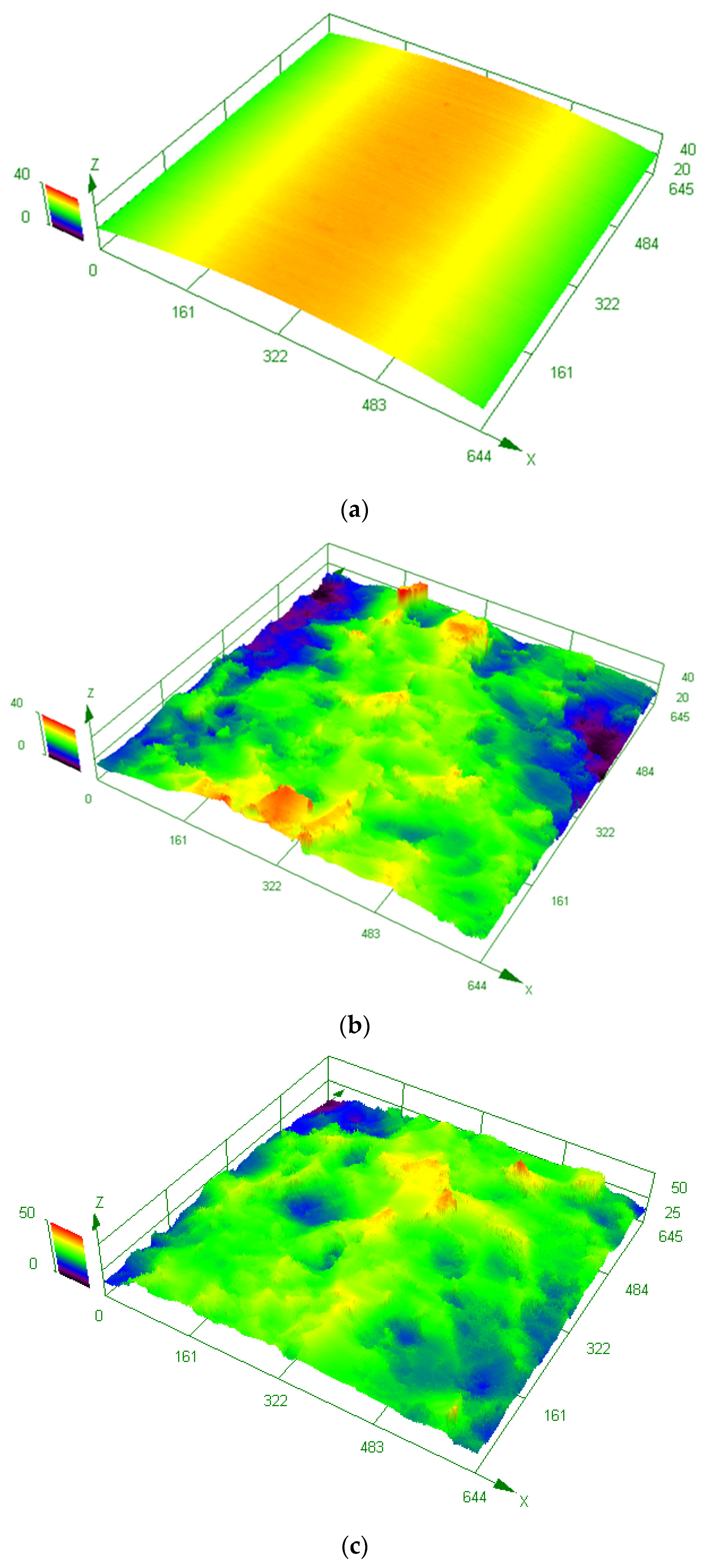

3.2. The Effect of Shot Peening on Surface Morphology and Organization

3.3. The Effect of Shot Peening Pressure on Fatigue Life

3.4. The Effect of Shot Peening Coverage on Fatigue Life

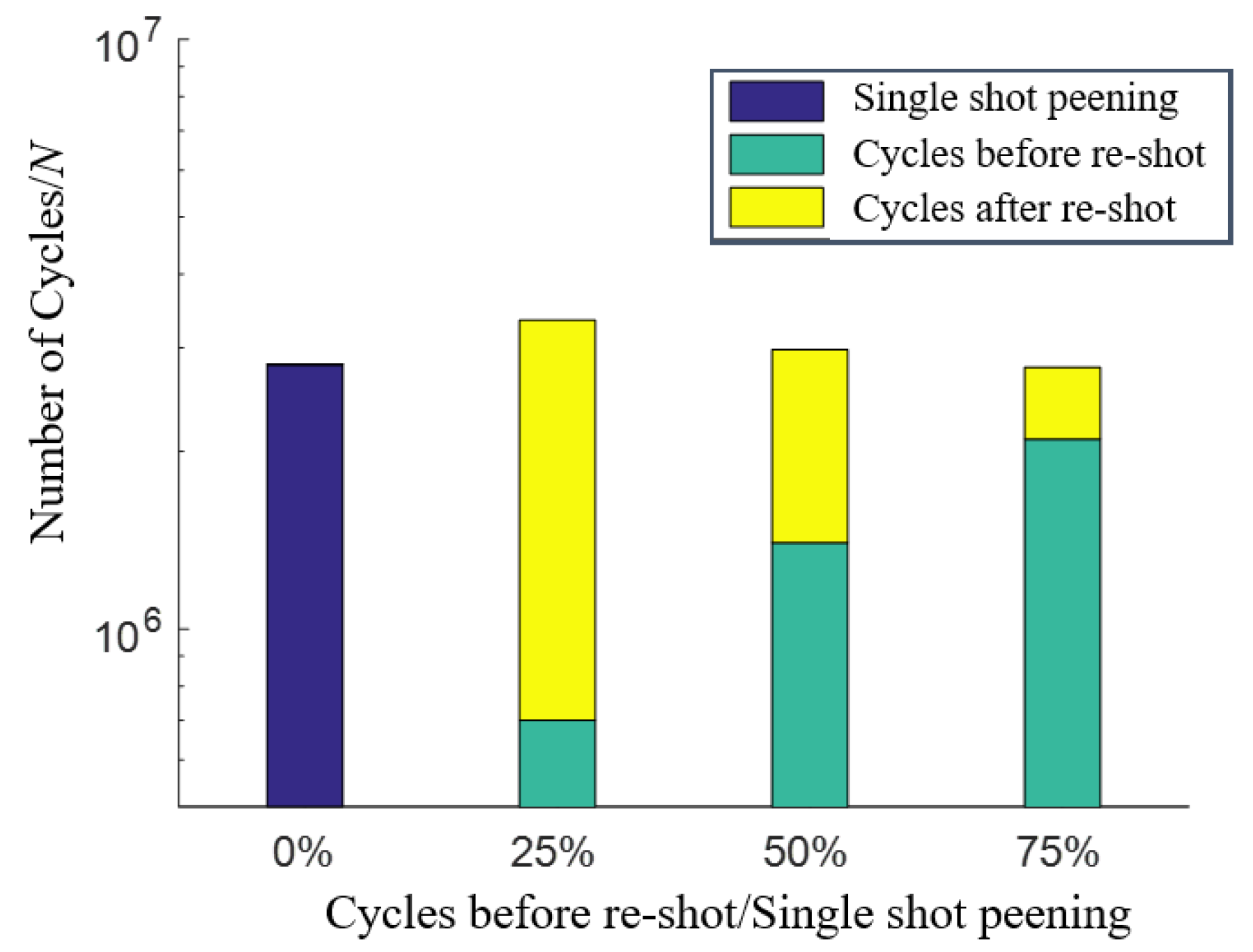

3.5. The Effect of Re-Shot Peening on Fatigue Life

4. Conclusions

- (1)

- The test results show that by shot peening, residual compressive stresses can be introduced on the surface of the part, thus effectively increasing the fatigue life of the material. An increase in shot peening pressure has an effect on causing an increase in the surface roughness of the material, while the effect on the surface residual stress field is not a continuous increase but only an increase in the depth of the residual stress field. Thus, when the shot peening pressure is too large, the negative effect of surface roughness is greater than the positive effect of the residual stress field, but will reduce the effect of shot peening so that the fatigue life of the material is reduced. Therefore, it is necessary to reasonably choose the shot peening pressure;

- (2)

- In the initial stage of shot peening, the coverage of the projectile gradually increases. At the same time, the surface roughness and residual stress of the material also gradually increase. When the coverage reaches 100%, the fatigue life of the material will be significantly increased. When the coverage rate increases again, the surface roughness of the material starts to become stable or even decreases slightly, and when the coverage rate reaches 200%, increasing the coverage rate again will not significantly improve the fatigue life of the material;

- (3)

- The shot-peened material will undergo stress relaxation during service due to alternating loads, resulting in the weakening or even disappearance of the residual compressive stress field on the surface of the material. Secondary shot peening can effectively restore the residual compressive stress on the surface of the shot-peened material, eliminating the stress relaxation of the material in the process of service. The research in this paper shows that the maximum value of the residual compressive stress on the surface of the test material after shot peening is 443 MPa, and after 106 cycles of fatigue loads, the residual compressive stress on the surface is reduced to 203 MPa, which is subjected to secondary shot peening, restoring the residual compressive stress to 415 MPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Soyama, H. Comparison between the improvements made to the fatigue strength of stainless steel by cavitation peening, water jet peening, shot peening and laser peening. J. Mater. Process. Technol. 2019, 269, 65–78. [Google Scholar] [CrossRef]

- Sheng, X.; Xia, Q.; Cheng, X.; Lin, L. Residual stress field induced by shot peening based on random-shots for 7075 aluminum alloy. Trans. Nonferrous Met. Soc. China 2012, 22, s261–s267. [Google Scholar] [CrossRef]

- Wang, P.; Cao, Q.; Liu, S.; Peng, Q. Surface strengthening of stainless steels by nondestructive laser peening. Mater. Des. 2021, 205, 109754. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, K.; Hu, Z.; Chen, T.; Susmel, L.; Wei, B. The synergetic effects of shot peening and laser-shot peening on the microstructural evo-lution and fatigue performance of a medium carbon steel. Int. J. Fatigue 2023, 166, 107246. [Google Scholar] [CrossRef]

- Wang, T.; Yu, J.; Dong, B. Surface nanocrystallization induced by shot peening and its effect on corrosion resistance of 1Cr18Ni9Ti stainless steel. Surf. Coat. Technol. 2006, 200, 4777–4781. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Wu, G.; Gan, J.; Yang, Y.; Huang, H.; He, J.; Zhong, H. Combining the finite element method and response surface methodolo-gy for optimization of shot peening parameters. Int. J. Fatigue 2019, 129, 105231. [Google Scholar] [CrossRef]

- Benedetti, M. Bending fatigue behaviour of differently shot peened Al 6082 T5 alloy. Int. J. Fatigue 2004, 26, 889–897. [Google Scholar] [CrossRef]

- Liu, G.; Shen, Z.; Huang, G.; He, L.; Mu, R. Microstructure evolution and thermal cyclic failure behavior of thermal barrier coatings with interface modification. Vacuum 2022, 206, 111567. [Google Scholar] [CrossRef]

- AI-Obaid, Y.F. Shot peening mechanics: Experimental and theoretical analysis. Mech. Mater. 1995, 19, 10. [Google Scholar]

- Leguinagoicoa, N.; Albizuri, J.; Larrañaga, A. Fatigue improvement and residual stress relaxation of shot-peened alloy steel DIN 34CrNiMo6 under axial loading. Int. J. Fatigue 2022, 162, 107006. [Google Scholar] [CrossRef]

- Wang, J.; Qu, S.; Shao, H.; Hu, X.; Guo, B.; Li, X. Ultra-high fatigue property and fracture mechanism of modified 20CrMoH steel by gas carburizing technology combined with shot peening treatment. Int. J. Fatigue 2022, 165, 107221. [Google Scholar] [CrossRef]

- Nobre, J.P.; Batista, A.C.; Coelho, L.; Dias, A.M. Two experimental methods to determining stress–strain behavior of work-hardened surface layers of metallic components. J. Mater. Process. Technol. 2010, 210, 2285–2291. [Google Scholar] [CrossRef]

- Gao, Z.; Liao, K.; Chen, J. Surface Characteristic Function of Al Alloy after Shot Peening. Coatings 2021, 11, 160. [Google Scholar] [CrossRef]

- Heydari Astaraee, A.; Bagherifard, S.; Bradanini, A.; Duó, P.; Henze, S.; Taylor, B.; Guagliano, M. Application of shot peening to case-hardened steel gears: The effect of gradient material properties and component geometry. Surf. Coat. Technol. 2020, 398, 126084. [Google Scholar] [CrossRef]

- Zhang, X.; Wei, P.; Parker, R.G.; Liu, G.; Liu, H.; Wu, S. Study on the relation between surface integrity and contact fatigue of carburized gears. Int. J. Fatigue 2022, 165, 107203. [Google Scholar] [CrossRef]

- Coelho, L.; Batista, A.; Nobre, J.; Marques, M. Evaluation of stress-strain behavior of surface treated steels by X-ray diffraction. Open Eng. 2012, 2, 91–95. [Google Scholar] [CrossRef] [Green Version]

- Gundgire, T.; Jokiaho, T.; Santa-aho, S.; Rautio, T.; Järvenpää, A.; Vippola, M. Comparative study of additively manufactured and reference 316 L stainless steel samples—Effect of severe shot peening on microstructure and residual stresses. Mater. Charact. 2022, 191, 112162. [Google Scholar] [CrossRef]

- Gao, Y. Residual compressive stress field in tc18 ultra-high strength titanium alloy by shot peening. Rare Met. Mater. Eng. 2004, 33, 4. [Google Scholar]

- Zhang, S.; Fan, D.; Yu, S. The Effect of Shot Peening on the Fatigue Strength of Pure Titanium. Trans. Mater. Heat Treat. 2004, 25, 4. [Google Scholar]

- Nakagawara, Y.; Sato, H.; Moritani, T.; Watanabe, Y. Effects of strain-induced cyclic transformation on the microstructure of the peened sur-face of sus 304 austenitic stainless steel. Phys. Status Solidi (b) 2022, 259, 2100603. [Google Scholar] [CrossRef]

- Huang, H.; Niu, J.; Xing, X.; Lin, Q.; Chen, H.; Qiao, Y. Effects of the Shot Peening Process on Corrosion Resistance of Aluminum Alloy: A Review. Coatings 2022, 12, 629. [Google Scholar] [CrossRef]

- Xia, B.; Wang, B.; Zhang, P.; Ren, C.; Duan, Q.; Li, X.; Zhang, Z. Improving the high-cycle fatigue life of a high-strength spring steel for automobiles by suitable shot peening and heat treatment. Int. J. Fatigue 2022, 161, 106891. [Google Scholar] [CrossRef]

- Majzoobi, G.H.; Azizi, R.; Alavi Nia, A. A three-dimensional simulation of shot peening process using multiple shot impacts. J. Mater. Process. Technol. 2005, 164–165, 1226–1234. [Google Scholar] [CrossRef]

- Zhou, J.; Cui, K.; Xu, Z.; Sun, Z.; Guelorget, B.; Retraint, D. Modelling residual stress and residual work hardening induced by surface mechanical attrition treatment. Int. J. Mech. Sci. 2022, 233, 107688. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.; Wu, Q. Numerical simulations of shot--peening process and impact effect: Numerical simula-tions of shot–peening process and impact effect. Acta Metall. Sin. 2010, 2010, 111–117. [Google Scholar] [CrossRef]

- Li, Z.-M.; Zhu, Y.-L.; Huang, Y.-L.; Liu, K.-L.; Xie, J.-F. Influence of surface integrity on fatigue resistance of the 30crmnsini2a steel after shot peening. Zhongguo Biao Mian Gong Cheng 2012, 25, 85–89. [Google Scholar]

- Chen, M.; Liu, H.; Wang, L.; Wang, C.; Zhu, K.; Xu, Z.; Jiang, C.; Ji, V. Evaluation of the residual stress and microstructure character in SAF 2507 duplex stainless steel after multiple shot peening process. Surf. Coat. Technol. 2018, 344, 132–140. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Huang, H.; Gan, J.; Yang, Y.; He, J.; Shi, M. Effect of high-energy shot peening on surface nanocrystallization and integrity of AISI 4140 Steel: A Numerical and Experimental Investigation. J. Mater. Eng. Perform. 2021, 30, 5579–5592. [Google Scholar] [CrossRef]

- Lee, H.; Mall, S.; Sathish, S. Investigation into effects of re-shot-peening on fretting fatigue behavior of Ti–6Al–4V. Mater. Sci. Eng. A 2005, 390, 227–232. [Google Scholar] [CrossRef]

- Unal, O.; Maleki, E.; Karademir, I.; Husem, F.; Efe, Y.; Das, T. Effects of conventional shot peening, severe shot peening, re-shot peening and pre-cised grinding operations on fatigue performance of AISI 1050 railway axle steel. Int. J. Fatigue 2022, 155, 106613. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, H.; Xiong, X.; Li, M.; Chen, M.; Liu, H.; Jiang, C. Changes in surface integrity of cemented tungsten carbide with shot peening treatment. Surf. Coat. Technol. 2021, 425, 127710. [Google Scholar] [CrossRef]

- Wang, X.; Gao, Y.-K.; Wang, Q.; Song, Y.-G.; Lu, F. Effect of re-shot-peening on the fatigue life of tc18 titanium alloy. J. Mater. Eng. Perform. 2012, 2, 5. [Google Scholar]

- Zhao, H.; Chen, G.; Gai, P.; Li, Z.; Zhou, W.; Fu, X. Residual stress relaxation and re-shot-peening process of wet shot-peened titanium alloy during tensile fatigue load. J. Mater. Eng. Perform. 2020, 48, 8. [Google Scholar]

- Ongtrakulkij, G.; Khantachawana, A.; Kajornchaiyakul, J.; Kondoh, K. Effects of the secondary shot in the double shot peening process on the residual compressive stress distribution of Ti–6Al–4V. Heliyon 2022, 8, e08758. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.; Cheng, J.-H.; Guan, H.-J.; Tan, W.-J.; Zhang, Y.-H. Investigation of wet shot peening on microstructural evolution and tensile-tensile fatigue properties of Ti-6Al-4V alloy. Mater. Chem. Phys. 2022, 291, 126635. [Google Scholar] [CrossRef]

- Qian, W.; Huang, S.; Yin, X.; Xie, L. Simulation Analysis with Randomly Distributed Multiple Projectiles and Experimental Study of Shot Peening. Coatings 2022, 12, 1783. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, B.; Yang, J.; Liang, S. Modeling and optimization of alloy steel 20CrMnTi grinding process parameters based on experiment investigation. Int. J. Adv. Manuf. Technol. 2018, 95, 1859–1873. [Google Scholar] [CrossRef]

- Branco, R.; Costa, J.D.; Borrego, L.P.; Wu, S.C.; Long, X.Y.; Zhang, F.C. Effect of strain ratio on cyclic deformation behaviour of 7050-T6 aluminium alloy. Int. J. Fatigue 2019, 129, 105234. [Google Scholar] [CrossRef]

- Sarangi, C.K.; Sahu, B.P.; Mishra, B.K.; Mitra, R. Pulse electrodeposition and characterization of graphene oxide particle-reinforced Ni–W alloy matrix nanocomposite coatings. J. Appl. Electrochem. 2020, 50, 265–279. [Google Scholar] [CrossRef]

- Macek, W. Post-failure fracture surface analysis of notched steel specimens after bending-torsion fatigue. Eng. Fail. Anal. 2019, 105, 1154–1171. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Ni | Cu | Ti |

|---|---|---|---|---|---|---|---|---|

| 0.18 | 0.24 | 0.96 | 0.013 | 0.005 | 1.12 | 0.01 | 0.04 | 0.06 |

| /MPa | /MPa | /% | /% | /J |

|---|---|---|---|---|

| 835 | 1080 | 13 | 60 | 99 |

| Group Number | Shot Peening Pressure/MPa | Fatigue Life (Mean) (700 MPa) | Fatigue Life (STD) (700 MPa) | Difference (%) | Fatigue Life (Mean) (630 MPa) | Fatigue Life (STD) (630 MPa) | Difference (%) |

|---|---|---|---|---|---|---|---|

| A | unpeened | 7.78 × 104 | 8558 | - | 1.69 × 106 | 219,700 | - |

| B | 0.1 | 1.02 × 105 | 12,240 | 31.1 | 2.43 × 106 | 376,650 | 43.8 |

| C | 0.2 | 1.25 × 105 | 16,350 | 60.7 | 2.81 × 106 | 519,850 | 66.3 |

| D | 0.3 | 4.09 × 104 | 3681 | −47.4 | 6.94 × 105 | 76,340 | −58.9 |

| Group Number | Coverage (%) | Fatigue Life (Mean) (700 MPa) | Fatigue Life (STD) (700 MPa) | Difference (%) | Fatigue Life (Mean) (630 MPa) | Fatigue Life (STD) (630 MPa) | Difference (%) |

|---|---|---|---|---|---|---|---|

| A | unpeened | 7.78 × 104 | 8558 | - | 1.69 × 106 | 219,700 | - |

| C | 100 | 1.25 × 105 | 16,350 | 60.7 | 2.81 × 106 | 519,850 | 66.3 |

| E | 200 | 1.43 × 105 | 20,023 | 83.8 | 3.63 × 106 | 907,500 | 114.8 |

| Pressure/MPa | Coverage/% | Stress Level/MPa | Cycles | Surface Residual Compressive Stress/MPa |

|---|---|---|---|---|

| 0.2 | 200 | 630 | 0 | 443 |

| 0.2 | 200 | 630 | 3 × 105 | 314 |

| 0.2 | 200 | 630 | 1 × 106 | 203 |

| 0.2 | 200 | 630 | 1 × 106 | 415 (Re-shot peening) |

| Number | Coverage/% | Stress Level/MPa | Cycles before Re-Shot Peening | Total Cycles |

|---|---|---|---|---|

| 0 | 200 | 630 | 0 | 3.63 × 106 |

| 1 | 200 + 100 | 630 | 0.9 × 106 | 3.87 × 106 |

| 2 | 200 + 100 | 630 | 1.8 × 106 | 3.71 × 106 |

| 3 | 200 + 100 | 630 | 2.7 × 106 | 3.56 × 106 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, W.; Wang, Y.; Liu, K.; Yin, X.; He, X.; Xie, L. Experimental Study on the Effect of Shot Peening and Re-Shot Peening on the Residual Stress Distribution and Fatigue Life of 20CrMnTi. Coatings 2023, 13, 1210. https://doi.org/10.3390/coatings13071210

Qian W, Wang Y, Liu K, Yin X, He X, Xie L. Experimental Study on the Effect of Shot Peening and Re-Shot Peening on the Residual Stress Distribution and Fatigue Life of 20CrMnTi. Coatings. 2023; 13(7):1210. https://doi.org/10.3390/coatings13071210

Chicago/Turabian StyleQian, Wenxue, Yi Wang, Kexin Liu, Xiaowei Yin, Xuehong He, and Liyang Xie. 2023. "Experimental Study on the Effect of Shot Peening and Re-Shot Peening on the Residual Stress Distribution and Fatigue Life of 20CrMnTi" Coatings 13, no. 7: 1210. https://doi.org/10.3390/coatings13071210

APA StyleQian, W., Wang, Y., Liu, K., Yin, X., He, X., & Xie, L. (2023). Experimental Study on the Effect of Shot Peening and Re-Shot Peening on the Residual Stress Distribution and Fatigue Life of 20CrMnTi. Coatings, 13(7), 1210. https://doi.org/10.3390/coatings13071210