The Influence of the Gravure Printing Quality on the Layer Functionality: The Study Case of LFP Cathode for Li-Ion Batteries

Abstract

1. Introduction

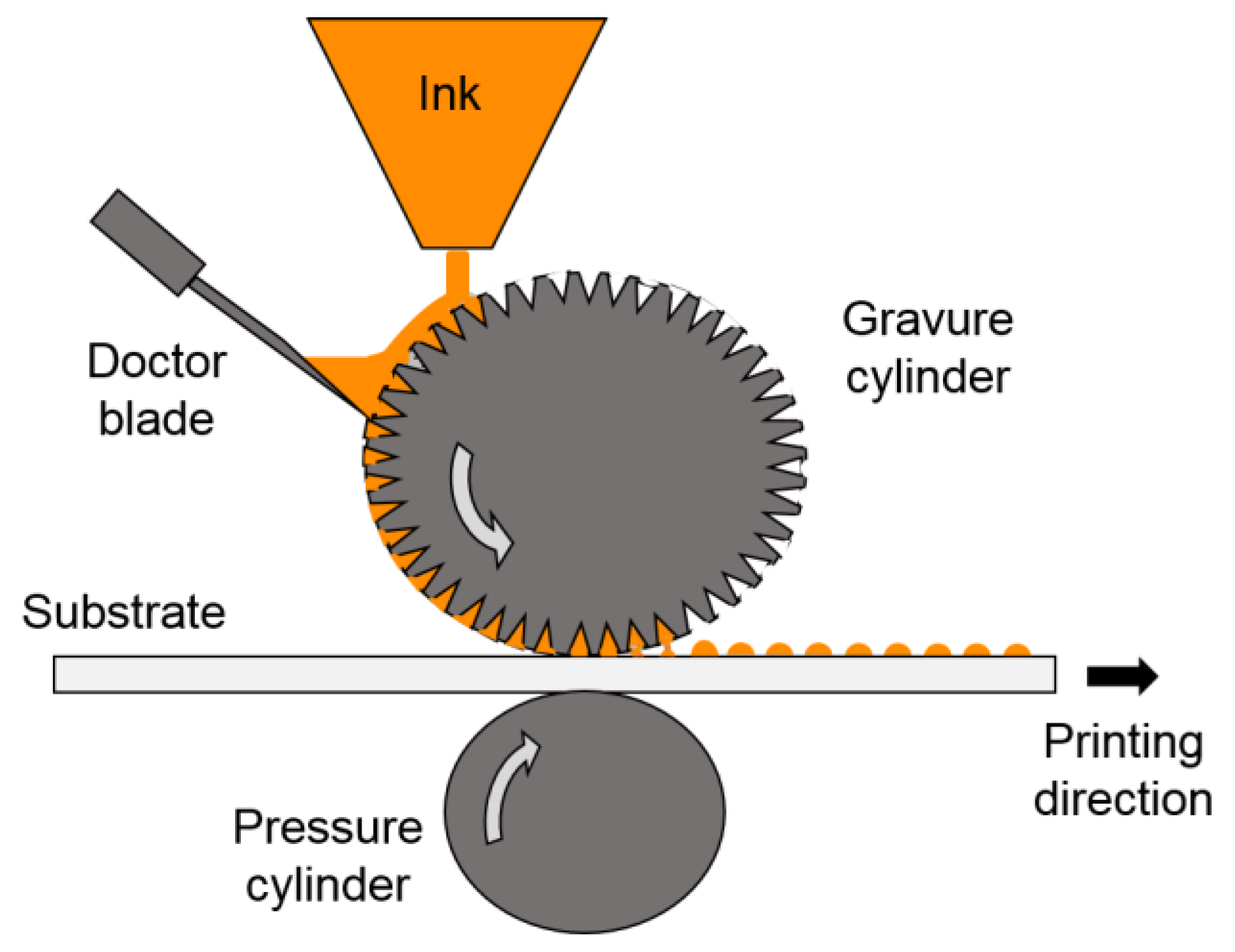

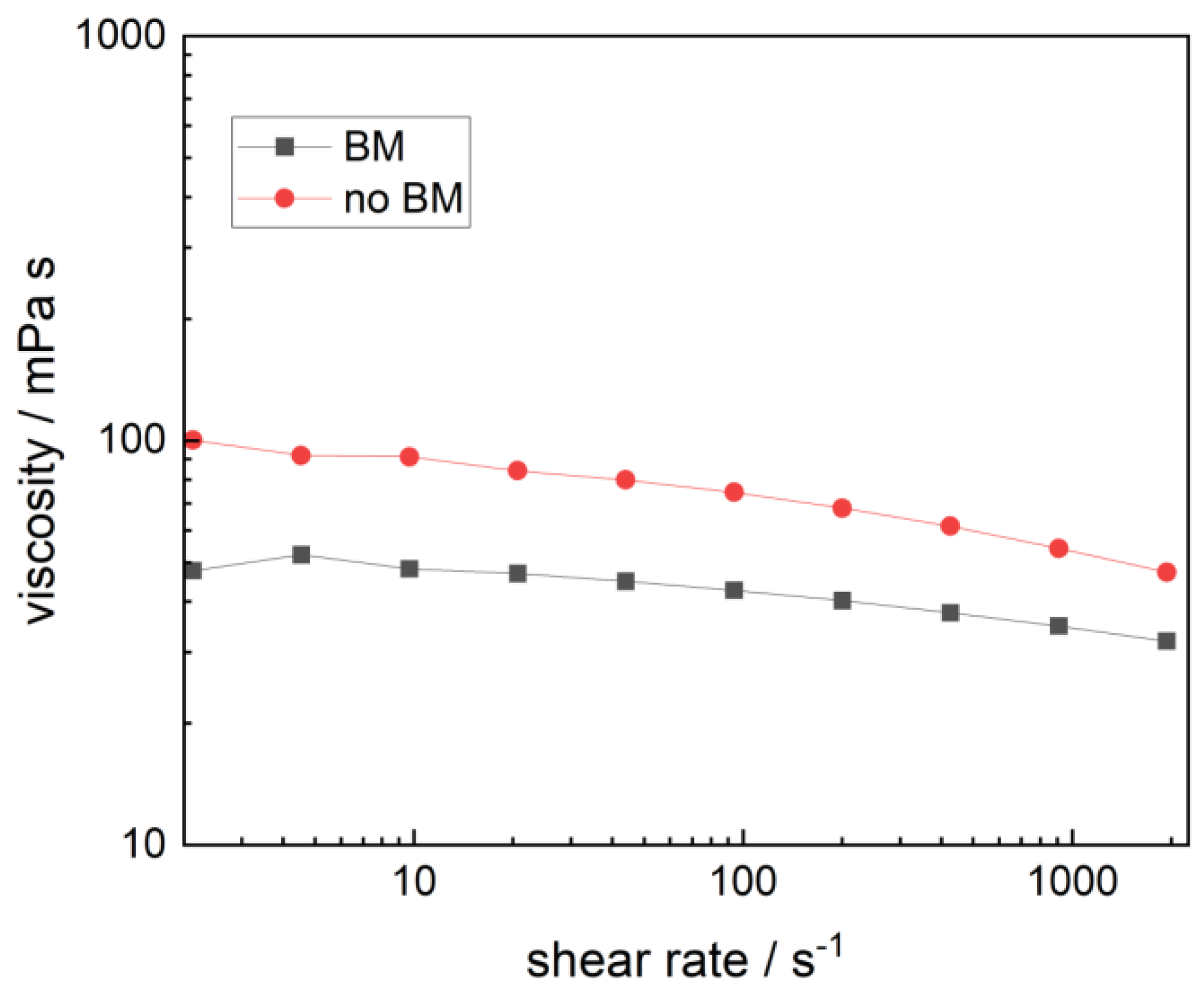

2. Materials and Methods

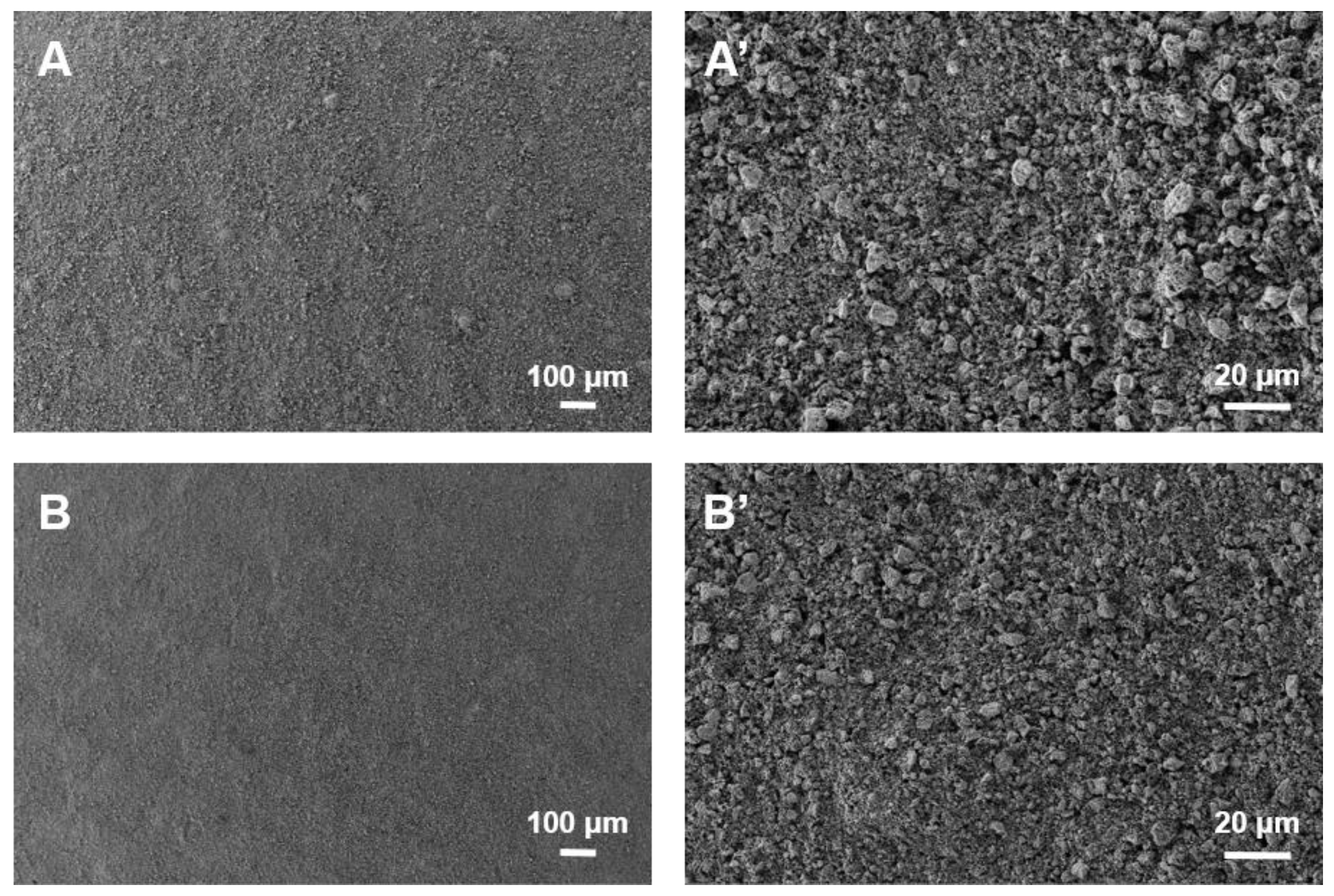

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oliveira, J.; Costa, C.M.; Lanceros-Méndez, S. Printed Batteries Materials, Technologies and Applications; John Wiley & Sons Ltd.: Chichester, UK, 2018. [Google Scholar]

- Costa, C.M.; Gonçalves, R.; Lanceros-Méndez, S. Recent advances and future challenges in printed batteries. Energy Storage Mater. 2020, 28, 216–234. [Google Scholar] [CrossRef]

- Zhu, M.; Shmidt, O.G. Tiny robots and sensors need tiny batteries—Here’s how to do it. Nature 2021, 589, 195. [Google Scholar] [CrossRef] [PubMed]

- You, C.-Y.; Hu, B.-F.; Xu, B.-R.; Zhang, Z.-Y.; Wu, B.-M.; Huang, G.-S.; Song, E.-M.; Mei, Y.-F. Foldable-circuit-enabled miniaturized multifunctional sensor for smart digital dust. Chip 2022, 1, 100034. [Google Scholar] [CrossRef]

- Grau, G.; Kitsomboonloha, R.; Subramanian, V. Fabrication of a high-resolution roll for gravure printing of 2μm features. In Proceedings of the SPIE Organic Photonics + Electronics, San Diego, CA, USA, 9–13 August 2015. [Google Scholar]

- Grau, G.; Subramanian, V. Fully High-Speed Gravure Printed, Low-Variability, High-Performance Organic Polymer Transistors with Sub-5 V Operation. Adv. Electron. Mater. 2016, 2, 1500328. [Google Scholar] [CrossRef]

- Huang, Q.; Zhu, Y. Printed Electronics: Printing Conductive Nanomaterials for Flexible and Stretchable Electronics: A Review of Materials, Processes, and Applications. Adv. Mater. Technol. 2019, 4, 1800546. [Google Scholar] [CrossRef]

- Hwang, S.S.; Cho, C.G.; Park, K.-S. Stabilizing LiCoO2 electrode with an overlayer of LiNi0.5Mn1.5O4 by using a Gravure printing method. Electrochem. Commun. 2011, 13, 279–283. [Google Scholar] [CrossRef]

- Montanino, M.; Sico, G.; De Girolamo Del Mauro, A.; Moreno, M. LFP-Based Gravure Printed Cathodes for Lithium-Ion Printed Batteries. Membranes 2019, 9, 71. [Google Scholar] [CrossRef] [PubMed]

- Montanino, M.; Sico, G.; De Girolamo Del Mauro, A.; Asenbauer, J.; Binder, J.R.; Bresser, D.; Passerini, S. Gravure-Printed Conversion/Alloying Anodes for Lithium-Ion Batteries. Energy Technol. 2021, 9, 2100315. [Google Scholar] [CrossRef]

- Montanino, M.; De Girolamo Del Mauro, A.; Paoletti, C.; Sico, G. Gravure Printing of Graphite-Based Anodes for Lithium-Ion Printed Batteries. Membranes 2022, 12, 999. [Google Scholar] [CrossRef] [PubMed]

- Montanino, M.; Paoletti, C.; De Girolamo Del Mauro, A.; Sico, G. Gravure printed composites based on Lithium Manganese Oxide: A study case for Li-ion batteries manufacturing. Macromolecular Symposia, submitted.

- Sico, G.; Montanino, M.; Prontera, C.T.; De Girolamo Del Mauro, A.; Minarini, C. Gravure printing for thin film ceramics manufacturing from nanoparticles. Ceram. Int. 2018, 44, 19526–19534. [Google Scholar] [CrossRef]

- Garcia, A.J.L.; Sico, G.; Montanino, M.; Defoor, V.; Pusty, M.; Mescot, X.; Loffredo, F.; Villani, F.; Nenna, G.; Ardila, G. Low-Temperature Growth of ZnO Nanowires from Gravure-Printed ZnO Nanoparticle Seed Layers for Flexible Piezoelectric Devices. Nanomaterials 2021, 11, 1430. [Google Scholar] [CrossRef]

- Khan, S.; Lorenzelli, L.; Dahiya, R.S. Technologies for printing sensors and electronics over large flexible substrates: A review. IEEE Sens. J. 2014, 15, 3164–3185. [Google Scholar] [CrossRef]

- Khandavalli, S.; Rothstein, J.P. Ink transfer of non-Newtonian fluids from an idealized gravure cell: The effect of shear and extensional deformation. J. Non-Newton. Fluid Mech. 2017, 243, 16–26. [Google Scholar] [CrossRef]

- Pingulkar, H.; Peixinho, J.; Crumeyrolle, O. Liquid transfer for viscoelastic solutions. Langmuir 2021, 37, 10348–10353. [Google Scholar] [CrossRef]

- Choi, Y.; Kim, G.H.; Jeong, W.H.; Kim, H.J.; Chin, B.D.; Yu, J.-W. Characteristics of gravure printed InGaZnO thin films as an active channel layer in thin film transistors. Thin Solid Film 2010, 518, 6249–6252. [Google Scholar] [CrossRef]

- Sankaran, A.K.; Rothstein, J.P. Effect of viscoelasticity on liquid transfer during gravure printing. J. Non-Newton. Fluid Mech. 2012, 175, 64–75. [Google Scholar] [CrossRef]

- Liang, J.; Jiang, C.; Wu, W. Printed flexible supercapacitor: Ink formulation, printable electrode materials and applications. Appl. Phys. Rev. 2021, 8, 021319. [Google Scholar] [CrossRef]

- Sico, G.; Montanino, M.; Loffredo, F.; Borriello, C.; Miscioscia, R. Gravure Printing for PVDF Thin-Film Pyroelectric Device Manufacture. Coatings 2022, 12, 1020. [Google Scholar] [CrossRef]

- Glasser, A.; Cloutet, E.; Hadziioannou, G.; Kellay, H. Tuning the rheology of conductiong polymer inks for various deposition processes. Chem. Mater. 2019, 31, 6936–6944. [Google Scholar] [CrossRef]

- Chang, Q.; Cao, C.; Qiao, H.; Hu, Y.; Xiao, G.; Shi, W. Ink transfer for printed flexible microsupercapacitors. Carbon 2021, 178, 285–293. [Google Scholar] [CrossRef]

- Vázquez, G.; Alvarez, E.; Navaza, J.M. Surface Tension of Alcohol + Water from 20 to 50 °C. J. Chem. Eng. Data 1995, 40, 611–614. [Google Scholar] [CrossRef]

| Dry Solid Content [wt%] | Ball Milling | Viscosity [mPa s] |

|---|---|---|

| 23 | No | 245 |

| 18 | No | 196 |

| 15 | No | 74 |

| 15 | Yes | 43 |

| 8 | No | 17 |

| Dry Solid Content [wt%] | Ball Milling | Printing Speed [m/min] | Printing Force [N] | Ca | Mass Loading [mg/cm2] | Layer Thickness [µm] | Apparent Layer Density [g/cm3] |

|---|---|---|---|---|---|---|---|

| 15 | No | 12 | 700 | 0.5 | |||

| 15 | Yes | 12 | 700 | 0.3 | |||

| 15 | No | 36 | 700 | 1.5 | 1.8 ± 0.2 | 20 ± 1 | 0.90 |

| 15 | Yes | 36 | 700 | 0.8 | 1.4 ± 0.2 | 15 ± 1 | 0.93 |

| 15 | No | 60 | 700 | 2.4 | |||

| 15 | Yes | 60 | 700 | 1.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montanino, M.; Paoletti, C.; De Girolamo Del Mauro, A.; Sico, G. The Influence of the Gravure Printing Quality on the Layer Functionality: The Study Case of LFP Cathode for Li-Ion Batteries. Coatings 2023, 13, 1214. https://doi.org/10.3390/coatings13071214

Montanino M, Paoletti C, De Girolamo Del Mauro A, Sico G. The Influence of the Gravure Printing Quality on the Layer Functionality: The Study Case of LFP Cathode for Li-Ion Batteries. Coatings. 2023; 13(7):1214. https://doi.org/10.3390/coatings13071214

Chicago/Turabian StyleMontanino, Maria, Claudia Paoletti, Anna De Girolamo Del Mauro, and Giuliano Sico. 2023. "The Influence of the Gravure Printing Quality on the Layer Functionality: The Study Case of LFP Cathode for Li-Ion Batteries" Coatings 13, no. 7: 1214. https://doi.org/10.3390/coatings13071214

APA StyleMontanino, M., Paoletti, C., De Girolamo Del Mauro, A., & Sico, G. (2023). The Influence of the Gravure Printing Quality on the Layer Functionality: The Study Case of LFP Cathode for Li-Ion Batteries. Coatings, 13(7), 1214. https://doi.org/10.3390/coatings13071214