Influence of Surface Roughness on Nanocrystalline Diamond Films Deposited by Distributed Antenna Array Microwave System on TA6V Substrates

Abstract

:1. Introduction

2. Experimental Methods

2.1. NCD Film Synthesis

2.2. Surface Analysis Techniques

3. Results and Discussion

- Str: Spatial parameter (ISO 25178): Texture-aspect ratio;

- Sa (µm): Amplitude parameter (ISO 25178): Arithmetic mean height;

- Sku: Amplitude parameter (ISO 25178): Kurtosis;

- Vvv (mm3/mm2): Volume functional parameters: Pit void volume.

4. Conclusions

- The transformation of the peaks into sinusoids (Sku) leads to a homogenization of the surface (stochastic surface) (Str);

- The presence of these sinusoids forms valleys (Vvv) of smaller characteristic size and reinforces the homogenization of the surface (Str);

- All this leads to an increase in the average roughness (Sa) and a harmonization of the surface regardless of the polishing protocol used (1200 vs. 2400 vs. 4000 abrasive paper).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Black, J. Biological Performance of Materials: Fundamentals of Biocompatibility, 4th ed.; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Lampin, M.; Warocquier-Clérout, R.; Legris, C.; Degrange, M.; Sigot-Luizard, M.F. Correlation between substratum roughness and wettability, cell adhesion, and cell migration. J. Biomed. Mater.Res. Off. J. Soc. Biomater. Jpn. Soc. Biomater. 1997, 36, 99–108. [Google Scholar] [CrossRef]

- MacDonald, D.; Deo, N.; Markovic, B.; Stranick, M.; Somasundaran, P. Adsorption and dissolution behavior of human plasma fibronectin on thermally and chemically modified titanium dioxide particles. Biomaterials 2001, 23, 1269–1279. [Google Scholar] [CrossRef] [PubMed]

- Sandrini, E.; Morris, C.; Chiesa, R.; Cigada, A.; Santin, M. In vitro assessment of the osteointegrative potential of a novel multiphase anodic spark deposition coating for orthopaedic and dental implants. J. Biomed. Mater. Res. Part B Appl. Biomater. 2005, 73B, 392–399. [Google Scholar] [CrossRef] [PubMed]

- Neel, E.A.A.; Mizoguchi, T.; Ito, M.; Bitar, M.; Salih, V.; Knowles, J.C. In vitro bioactivity and gene expression by cells cultured on titanium dioxide doped phosphate-based glasses. Biomaterials 2007, 28, 2967–2977. [Google Scholar] [CrossRef]

- Skoog, S.A.; Kumar, G.; Zheng, J.; Sumant, A.V.; Goering, P.L.; Narayan, R.J. Biological evaluation of ultrananocrystalline and nanocrystalline diamond coatings. J. Mater. Sci. Mater. Med. 2016, 27, 1–13. [Google Scholar] [CrossRef]

- Dekkar, D.; Bénédic, F.; Falentin-Daudré, C.; Rangel, A.; Issaoui, R.; Migonney, V.; Achard, J. Microstructure and biological evaluation of nanocrystalline diamond films deposited on titanium substrates using distributed antenna array microwave system. Diam. Relat. Mater. 2020, 103, 107700. [Google Scholar] [CrossRef]

- Al-Azizi, A.A.; Eryilmaz, O.; Erdemir, A.; Kim, S.H. Nano-texture for a wear-resistant and near-frictionless diamond-like carbon. Carbon 2014, 73, 403–412. [Google Scholar] [CrossRef]

- Bernal, R.A.; Chen, P.; Schall, J.D.; Harrison, J.A.; Jeng, Y.-R.; Carpick, R.W. Influence of chemical bonding on the variability of diamond-like carbon nanoscale adhesion. Carbon 2018, 128, 267–276. [Google Scholar] [CrossRef]

- Ţălu, Ş.; Bramowicz, M.; Kulesza, S.; Ghaderi, A.; Dalouji, V.; Solaymani, S.; Kenari, M.F.; Ghoranneviss, M. Fractal features and surface micromorphology of diamond nanocrystals. J. Microsc. 2016, 264, 143–152. [Google Scholar] [CrossRef]

- Schade, A.; Rosiwal, S.M.; Singer, R.F. Influence of surface topography of HF-CVD diamond films on self-mated planar sliding contacts in dry environments. Surf. Coatings Technol. 2007, 201, 6197–6205. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Elam, J.; Erdemir, A.; Carlisle, J.; Auciello, O.; Libera, J.; Pellin, M.; Gruen, D.; Hryn, J. Development of ultrananocrystalline diamond (UNCD) coatings for multipurpose mechanical pump seals. Wear 2011, 270, 325–331. [Google Scholar] [CrossRef]

- Jacobs, T.D.B.; Ryan, K.E.; Keating, P.L.; Grierson, D.S.; Lefever, J.A.; Turner, K.T.; Harrison, J.A.; Carpick, R.W. The Effect of Atomic-Scale Roughness on the Adhesion of Nanoscale Asperities: A Combined Simulation and Experimental Investigation. Tribol. Lett. 2013, 50, 81–93. [Google Scholar] [CrossRef]

- Ryan, K.E.; Keating, P.L.; Jacobs, T.D.B.; Grierson, D.S.; Turner, K.T.; Carpick, R.W.; Harrison, J.A. Simulated Adhesion between Realistic Hydrocarbon Materials: Effects of Composition, Roughness, and Contact Point. Langmuir 2014, 30, 2028–2037. [Google Scholar] [CrossRef]

- Alcaide, M.; Papaioannou, S.; Taylor, A.; Fekete, L.; Gurevich, L.; Zachar, V.; Pennisi, C.P. Resistance to protein adsorption and adhesion of fibroblasts on nanocrystalline diamond films: The role of topography and boron doping. J. Mater. Sci. Mater. Med. 2016, 27, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Mehedi, H.-A.; Achard, J.; Rats, D.; Brinza, O.; Tallaire, A.; Mille, V.; Silva, F.; Provent, C.; Gicquel, A. Low temperature and large area deposition of nanocrystalline diamond films with distributed antenna array microwave-plasma reactor. Diam. Relat. Mater. 2014, 47, 58–65. [Google Scholar] [CrossRef]

- Nave, A.; Baudrillart, B.; Hamann, S.; Bénédic, F.; Lombardi, G.; Gicquel, A.; Van Helden, J.H.; Ropcke, J. Spectroscopic study of low pressure, low temperature H2–CH4–CO2 microwave plasmas used for large area deposition of nanocrystalline diamond films. Part I: On temperature determination and energetic aspects. Plasma Sources Sci. Technol. 2016, 25, 065002. [Google Scholar] [CrossRef]

- Nave, A.; Baudrillart, B.; Hamann, S.; Bénédic, F.; Lombardi, G.; Gicquel, A.; Van Helden, J.H.; Ropcke, J. Spectroscopic study of low pressure, low temperature H2–CH4–CO2 microwave plasmas used for large area deposition of nanocrystalline diamond films. Part II: On plasma chemical processes. Plasma Sources Sci. Technol. 2016, 25, 065003. [Google Scholar] [CrossRef]

- Baudrillart, B.; Bénédic, F.; Brinza, O.; Bieber, T.; Chauveau, T.; Achard, J.; Gicquel, A. Microstructure and growth kinetics of nanocrystalline diamond films deposited in large area/low temperature distributed antenna array microwave-plasma reactor. Phys. Status Solidi A 2015, 212, 2611–2615. [Google Scholar] [CrossRef]

- Monshi, A.; Foroughi, M.R.; Monshi, M.R. Modified Scherrer Equation to Estimate More Accurately Nano-Crystallite Size Using XRD. World J. Nano Sci. Eng. 2012, 02, 154–160. [Google Scholar] [CrossRef] [Green Version]

- Rietveld, H.M. Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallogr. 1967, 22, 151–152. [Google Scholar] [CrossRef]

- Deltombe, R.; Kubiak, K.J.; Bigerelle, M. How to select the most relevant 3D roughness parameters of a surface. Scanning 2013, 36, 150–160. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baudrillart, B.; Bénédic, F.; Chauveau, T.; Bartholomot, A.; Achard, J. Nanocrystalline diamond films grown at very low substrate temperature using a distributed antenna array microwave process: Towards polymeric substrate coating. Diam. Relat. Mater. 2017, 75, 44–51. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Raman spectroscopy of amorphous, nanostructured, diamond–like carbon, and nanodiamond. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2004, 362, 2477–2512. [Google Scholar] [CrossRef]

- Hu, L.; Guo, Y.; Du, S.; Tian, S.; Li, J.; Gu, C. Probing trans-polyacetylene segments in a diamond film by tip-enhanced Raman spectroscopy. Diam. Relat. Mater. 2021, 116, 108415. [Google Scholar] [CrossRef]

- Mahi, C.; Brinza, O.; Issaoui, R.; Achard, J.; Bénédic, F. Synthesis of High Quality Transparent Nanocrystalline Diamond Films on Glass Substrates Using a Distributed Antenna Array Microwave System. Coatings 2022, 12, 1375. [Google Scholar] [CrossRef]

- Al-Rubaie, K.S.; Melotti, S.; Rabelo, A.; Paiva, J.M.; Elbestawi, M.A.; Veldhuis, S.C. Machinability of SLM-produced Ti6Al4V titanium alloy parts. J. Manuf. Process. 2020, 57, 768–786. [Google Scholar] [CrossRef]

- Gambardella, A.; Marchiori, G.; Maglio, M.; Russo, A.; Rossi, C.; Visani, A.; Fini, M. Determination of the Spatial Anisotropy of the Surface MicroStructures of Different Implant Materials: An Atomic Force Microscopy Study. Materials 2021, 14, 4803. [Google Scholar] [CrossRef] [PubMed]

- Mordo, S.; Popravko, V.; Barari, A. Study of the Effect of Coating Parameters and Substrates on 3D Surface Roughness in Diamond-Like-Carbon Coating Process. IFAC Proc. Vol. 2013, 46, 1861–1866. [Google Scholar] [CrossRef]

- Zhang, H.-S.; Endrino, J.; Anders, A. Comparative surface and nano-tribological characteristics of nanocomposite diamond-like carbon thin films doped by silver. Appl. Surf. Sci. 2008, 255, 2551–2556. [Google Scholar] [CrossRef] [Green Version]

- Lerebours, A.; Vigneron, P.; Bouvier, S.; Rassineux, A.; Bigerelle, M.; Egles, C. Additive manufacturing process creates local surface roughness modifications leading to variation in cell adhesion on multifaceted TiAl6V4 samples. Bioprinting 2019, 16, e00054. [Google Scholar] [CrossRef]

- Lamolle, S.F.; Monjo, M.; Lyngstadaas, S.P.; Ellingsen, J.E.; Haugen, H.J. Titanium implant surface modification by cathodic reduction in hydrofluoric acid: Surface characterization and in vivo performance. J. Biomed. Mater. Res. Part A 2008, 88A, 581–588. [Google Scholar] [CrossRef] [PubMed]

- Catledge, S.A.; Borham, J.; Vohra, Y.K.; Lacefield, W.R.; Lemons, J.E. Nanoindentation hardness and adhesion investigations of vapor deposited nanostructured diamond films. J. Appl. Phys. 2002, 91, 5347–5352. [Google Scholar] [CrossRef]

- Pareta, R.; Yang, L.; Kothari, A.; Sirinrath, S.; Xiao, X.; Sheldon, B.W.; Webster, T.J. Tailoring nanocrystalline diamond coated on titanium for osteoblast adhesion. J. Biomed. Mater. Res. Part A 2010, 95A, 129–136. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Bigerelle, M.; Marteau, J.; Mazeran, P.-E.; Bouvier, S.; Iost, A. Effect of surface roughness in the determination of the mechanical properties of material using nanoindentation test. Scanning 2013, 36, 134–149. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aparicio, C.; Rodriguez, D.; Gil, F.J. The effect of shot blasting and heat treatment on the fatigue behavior of titanium for dental implant applications. Dent. Mater. 2007, 23, 486–491. [Google Scholar] [CrossRef]

| Sample | Str | Sa (µm) | Sku | Vvv (mm3/mm2) | ||||

|---|---|---|---|---|---|---|---|---|

| Average | Standard Deviation | Average | Standard Deviation | Average | Standard Deviation | Average | Standard Deviation | |

| TA6V1200 | 0.42 | 0.18 | 0.12 | 0.03 | 18.38 | 26.93 | 0.03 | 0.01 |

| NCD/TA6V1200 | 0.52 | 0.24 | 0.2 | 0.06 | 6.36 | 2.27 | 0.05 | 0.02 |

| TA6V2400 | 0.6 | 0.31 | 0.08 | 0.01 | 20.72 | 25.5 | 0.02 | 0.01 |

| NCD/TA6V2400 | 0.82 | 0.09 | 0.18 | 0.05 | 7.7 | 4.34 | 0.05 | 0.01 |

| TA6V4000 | 0.82 | 0.1 | 0.07 | 0.01 | 21.59 | 19.66 | 0.02 | 0.01 |

| NCD/TA6V4000 | 0.76 | 0.23 | 0.19 | 0.06 | 6.36 | 2.27 | 0.04 | 0.02 |

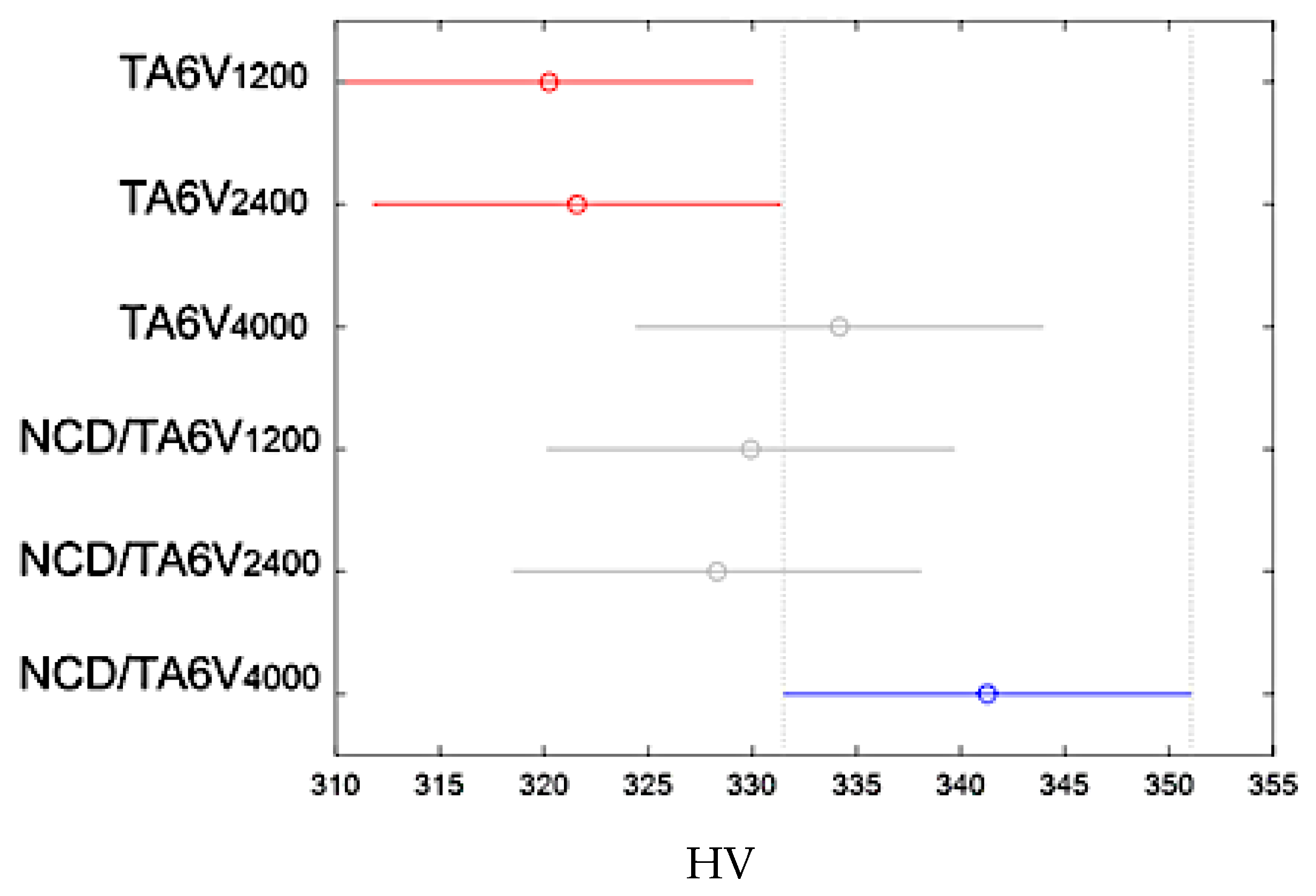

| Sample | Hardness (HV) | Statistical Tests | ||

|---|---|---|---|---|

| Average | Standard Deviation | ANOVA | Tukey Kramer | |

| TA6V1200 | 320.24 | 4.00 | p = 0.0267 | * |

| NCD/TA6V1200 | 329.92 | 12.91 | * | |

| TA6V2400 | 321.58 | 10.63 | ||

| NCD/TA6V2400 | 328.3 | 5.71 | ||

| TA6V4000 | 334.18 | 5.25 | ||

| NCD/TA6V4000 | 341.28 | 15.63 | ** | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valinattaj Omran, A.; Mahi, C.; Vayron, R.; Falentin-Daudré, C.; Bénédic, F. Influence of Surface Roughness on Nanocrystalline Diamond Films Deposited by Distributed Antenna Array Microwave System on TA6V Substrates. Coatings 2023, 13, 1300. https://doi.org/10.3390/coatings13071300

Valinattaj Omran A, Mahi C, Vayron R, Falentin-Daudré C, Bénédic F. Influence of Surface Roughness on Nanocrystalline Diamond Films Deposited by Distributed Antenna Array Microwave System on TA6V Substrates. Coatings. 2023; 13(7):1300. https://doi.org/10.3390/coatings13071300

Chicago/Turabian StyleValinattaj Omran, Azadeh, Chaimaa Mahi, Romain Vayron, Céline Falentin-Daudré, and Fabien Bénédic. 2023. "Influence of Surface Roughness on Nanocrystalline Diamond Films Deposited by Distributed Antenna Array Microwave System on TA6V Substrates" Coatings 13, no. 7: 1300. https://doi.org/10.3390/coatings13071300

APA StyleValinattaj Omran, A., Mahi, C., Vayron, R., Falentin-Daudré, C., & Bénédic, F. (2023). Influence of Surface Roughness on Nanocrystalline Diamond Films Deposited by Distributed Antenna Array Microwave System on TA6V Substrates. Coatings, 13(7), 1300. https://doi.org/10.3390/coatings13071300