The Role of Friction Stir Processing Parameters and Hybrid ZrC/WC Reinforcement Particles in Improving the Surface Composite Dissimilar Matrix’s Dynamic Behavior and Microstructure Refinement

Abstract

:1. Introduction

2. Experimental Work and Materials

2.1. Materials Preparation

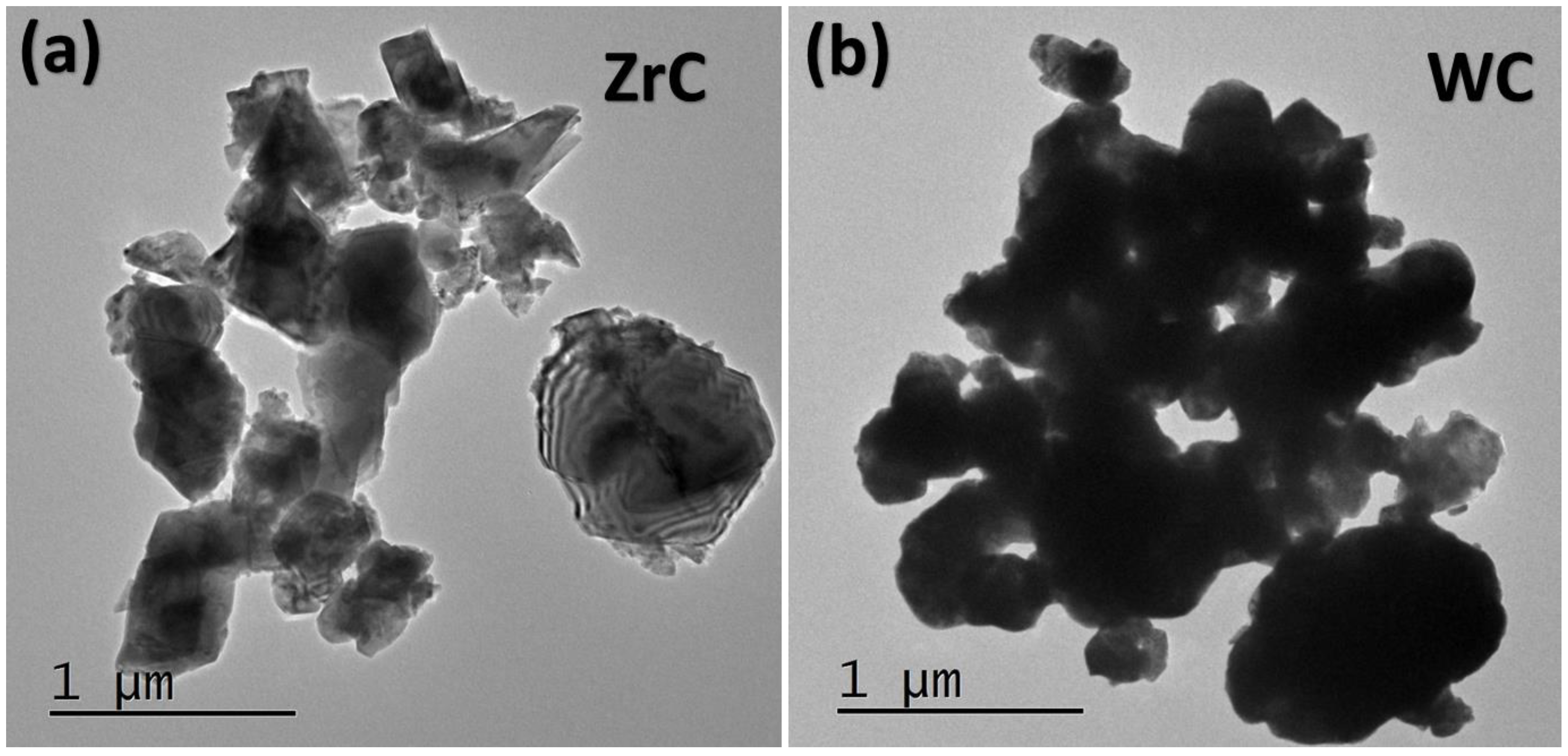

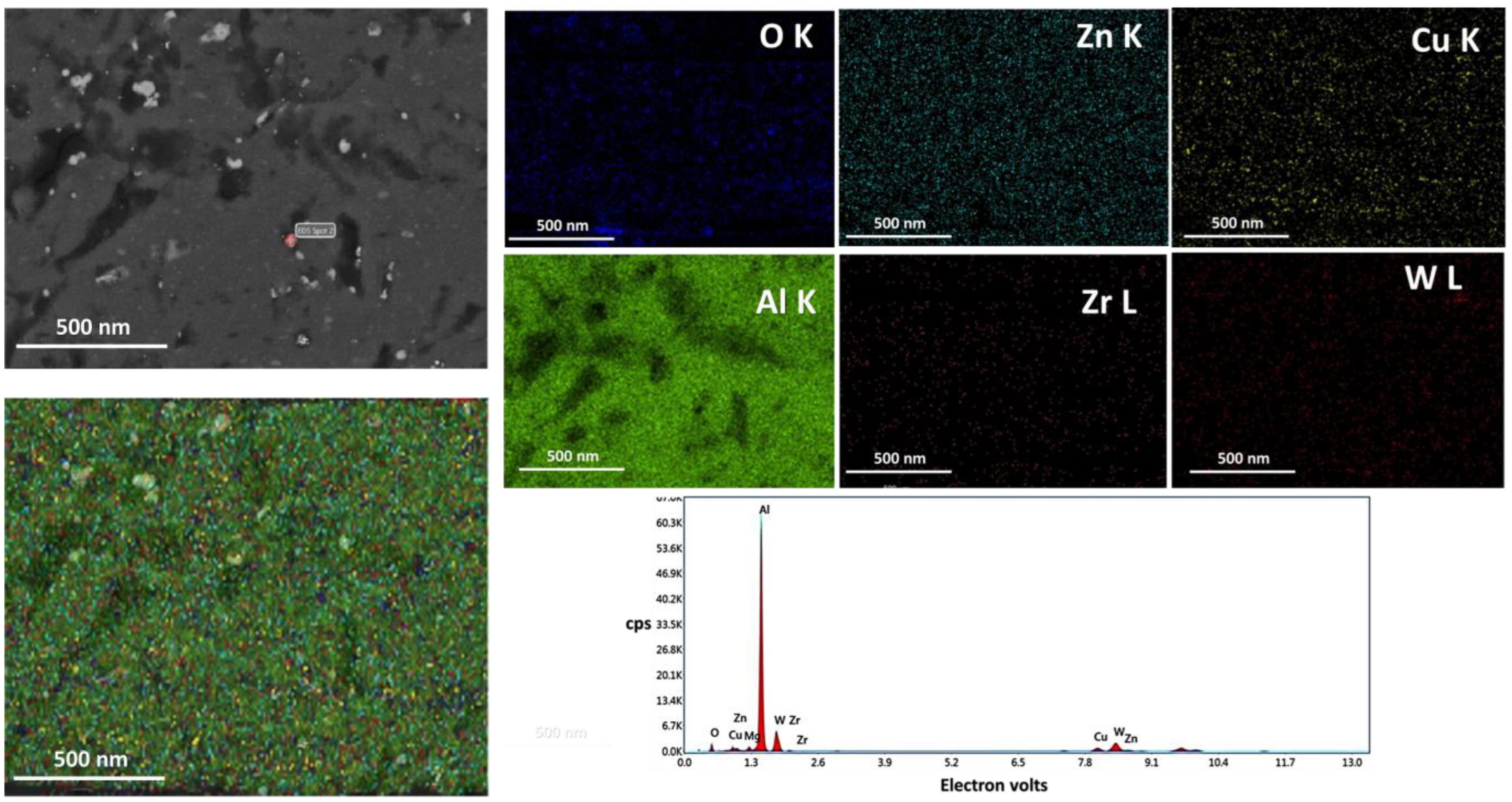

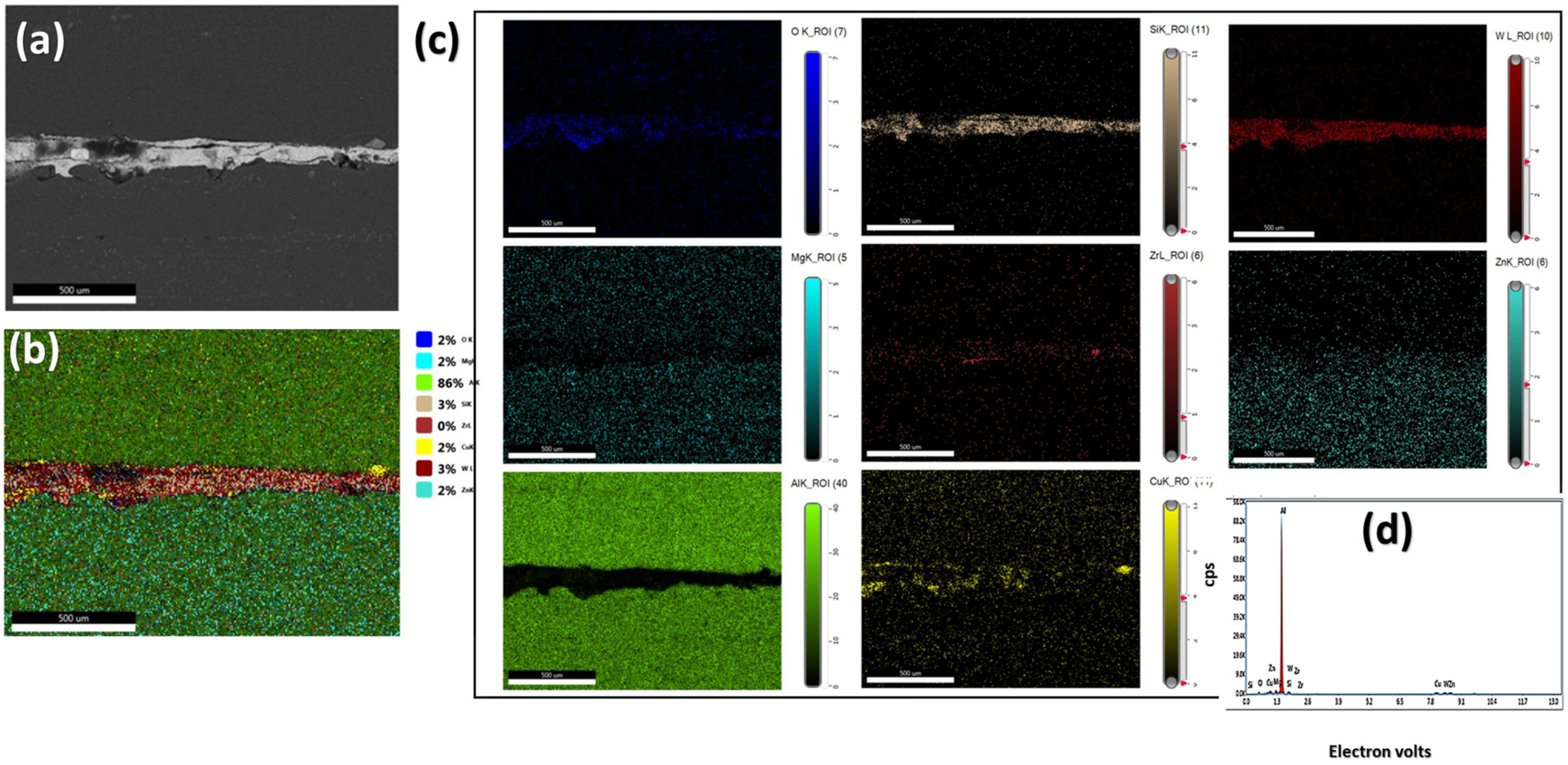

2.2. Microstructure

2.3. Mechanical Properties

2.4. Free Impact Vibration Test

3. Results and Discussions

3.1. Microstructure Observation

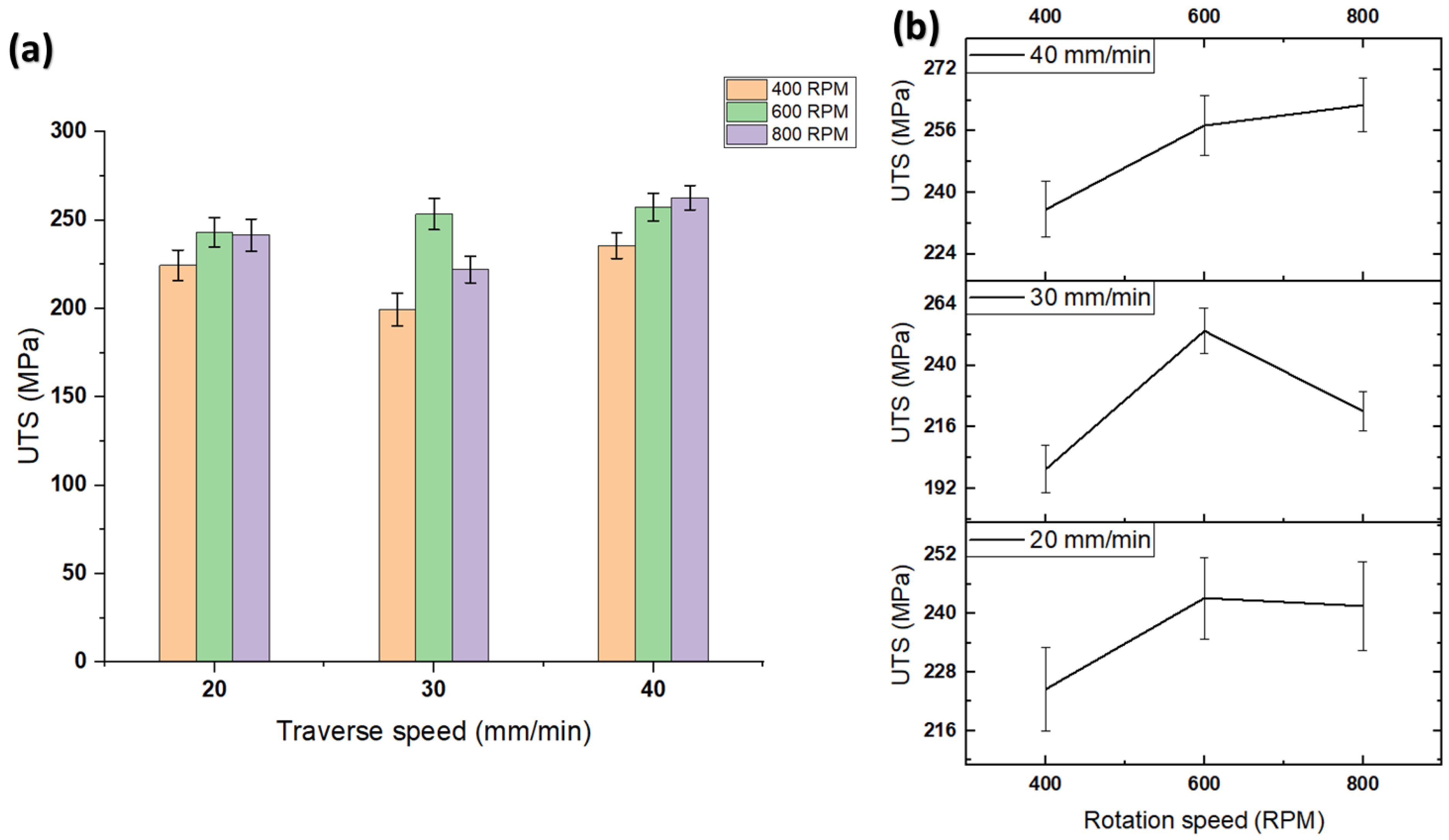

3.2. Mechanical Properties

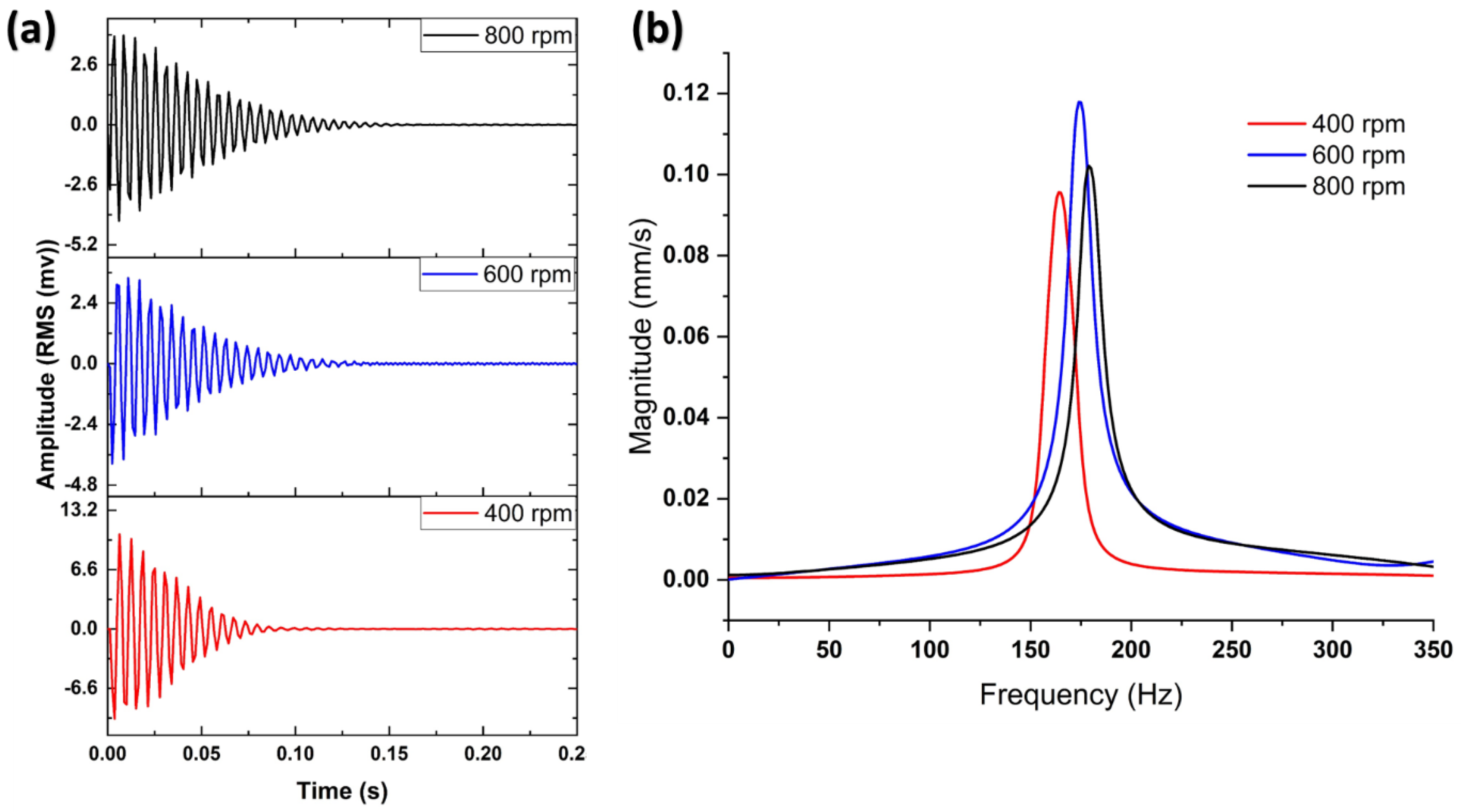

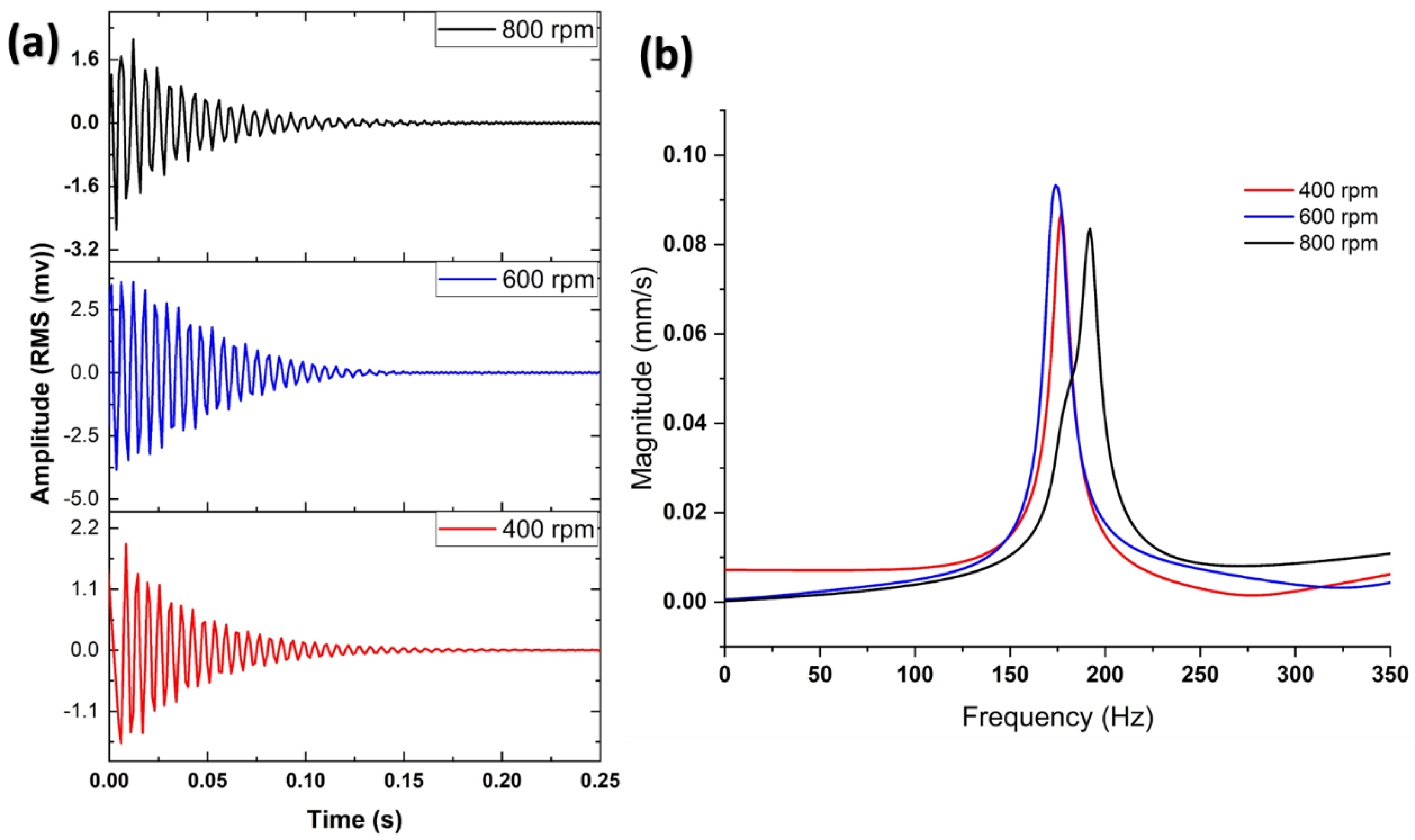

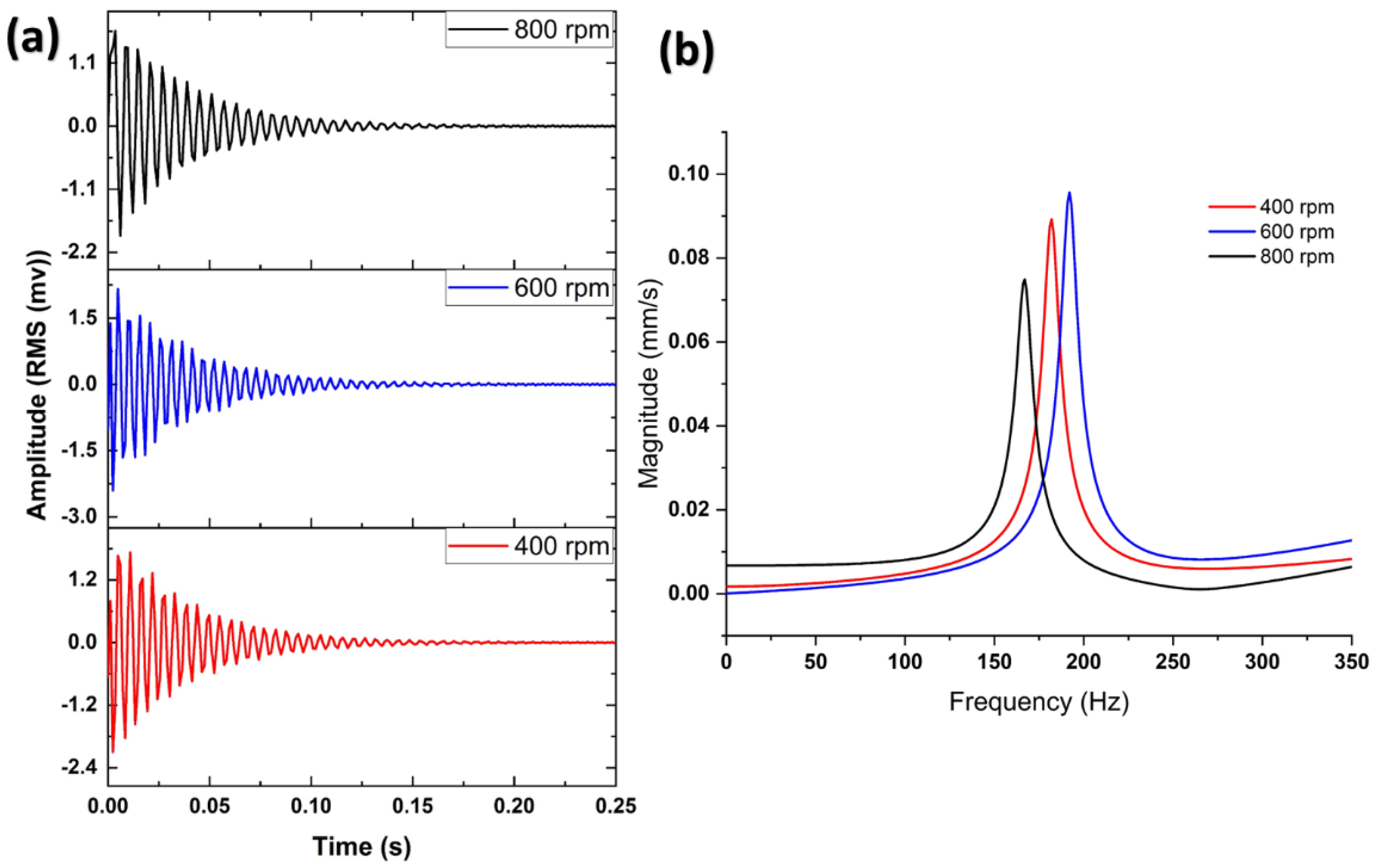

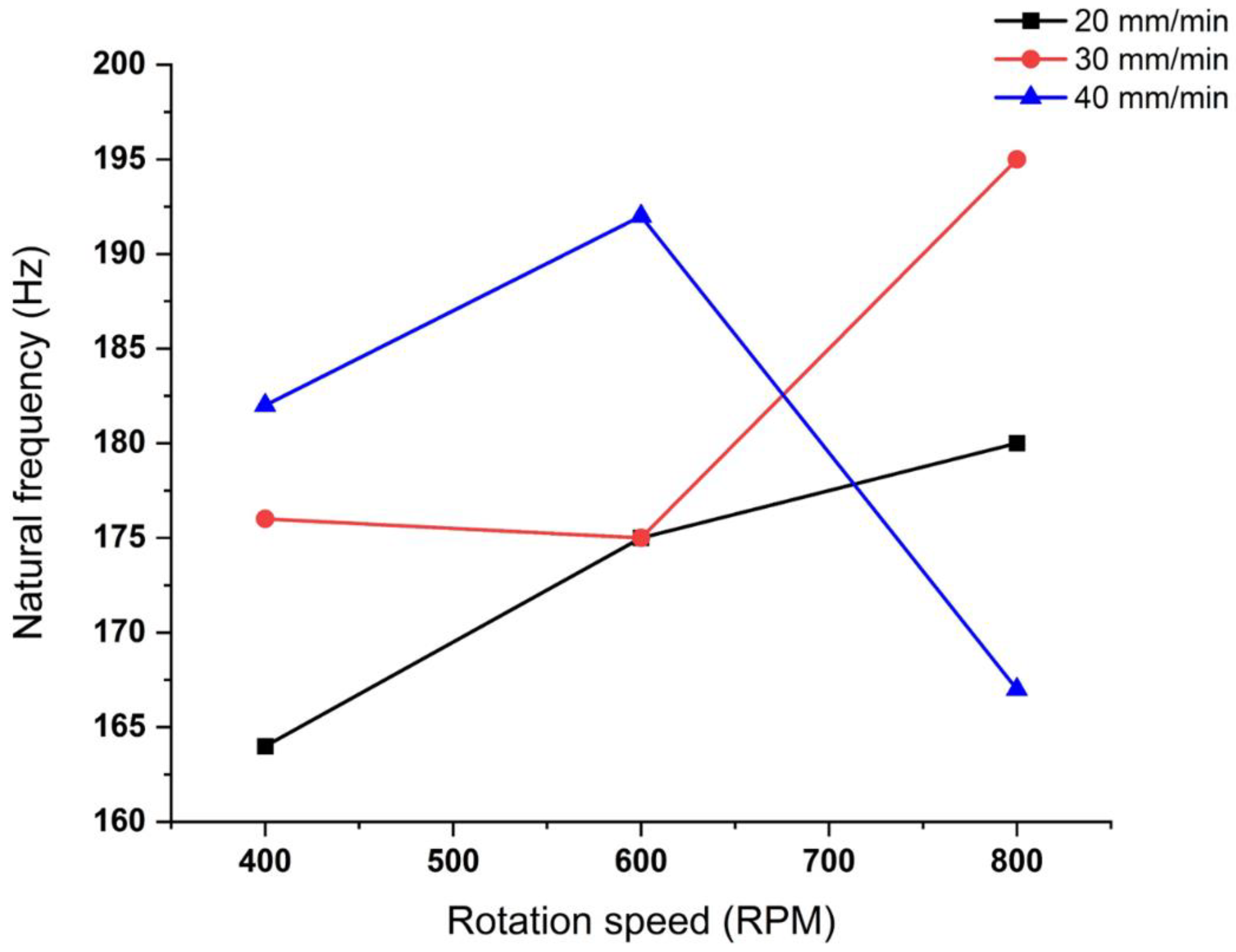

3.3. Dynamic Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shah, L.H.; Ishak, M. Review of Research Progress on Aluminum–Steel Dissimilar Welding. Mater. Manuf. Process. 2014, 29, 928–933. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Wang, G.; Wang, F.; Vairis, A.; Niu, P. Friction Stir Welding of Dissimilar Aluminum Alloy Combinations: State-of-the-Art. Metals 2019, 9, 270. [Google Scholar] [CrossRef] [Green Version]

- Pouraliakbar, H.; Beygi, R.; Fallah, V.; Hosseini Monazzah, A.; Reza Jandaghi, M.; Khalaj, G.; da Silva, L.F.M.; Pavese, M. Processing of Al-Cu-Mg alloy by FSSP: Parametric analysis and the effect of cooling environment on microstructure evolution. Mater. Lett. 2022, 308, 131157. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Zidan, Z.A.; Ramadan, R.M.; Ataya, S.; Alsaleh, N.A. Microstructure and Mechanical Properties of Dissimilar Friction Stir Welded AA2024-T4/AA7075-T6 T-Butt Joints. Metals 2021, 11, 128. [Google Scholar] [CrossRef]

- Eskandari, H.; Taheri, R. A Novel Technique for Development of Aluminum Alloy Matrix/TiB2/Al2O3 Hybrid Surface Nanocomposite by Friction Stir Processing. Procedia Mater. Sci. 2015, 11, 503–508. [Google Scholar] [CrossRef] [Green Version]

- Riccardis, M.F.D.; Virginia, M. Hybrid Conducting Nanocomposites Coatings for Corrosion Protection. In Developments in Corrosion Protection; Aliofkhazraei, M., Ed.; IntechOpen: Rijeka, Croatia, 2014; Chapter 13. [Google Scholar]

- Khan, S.A.; Sezer, N.; Koç, M. Design, synthesis, and characterization of hybrid micro-nano surface coatings for enhanced heat transfer applications. Int. J. Energy Res. 2020, 44, 12525–12534. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.P.; Robson, J.D.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752. [Google Scholar] [CrossRef]

- Gibson, B.T.; Lammlein, D.H.; Prater, T.J.; Longhurst, W.R.; Cox, C.D.; Ballun, M.C.; Dharmaraj, K.J.; Cook, G.E.; Strauss, A.M. Friction stir welding: Process, automation, and control. J. Manuf. Process. 2014, 16, 56–73. [Google Scholar] [CrossRef]

- Mirjavadi, S.S.; Alipour, M.; Emamian, S.; Kord, S.; Hamouda, A.M.S.; Koppad, P.G.; Keshavamurthy, R. Influence of TiO2 nanoparticles incorporation to friction stir welded 5083 aluminum alloy on the microstructure, mechanical properties and wear resistance. J. Alloys Compd. 2017, 712, 795–803. [Google Scholar] [CrossRef]

- Moustafa, E. Effect of Multi-Pass Friction Stir Processing on Mechanical Properties for AA2024/Al2O3 Nanocomposites. Materials 2017, 10, 1053. [Google Scholar] [CrossRef] [Green Version]

- Cioffi, F.; Fernández, R.; Gesto, D.; Rey, P.; Verdera, D.; González-Doncel, G. Friction stir welding of thick plates of aluminum alloy matrix composite with a high volume fraction of ceramic reinforcement. Compos. Part A Appl. Sci. Manuf. 2013, 54, 117–123. [Google Scholar] [CrossRef] [Green Version]

- Abnar, B.; Gashtiazar, S.; Javidani, M. Friction Stir Welding of Non-Heat Treatable Al Alloys: Challenges and Improvements Opportunities. Crystals 2023, 13, 576. [Google Scholar] [CrossRef]

- Kundu, A.K.; Gupta, M.K.; Rajput, N.S.; Rathore, R. Adhesive assisted TiB2 coating effects on friction stir welded joints. Sci. Rep. 2022, 12, 17894. [Google Scholar] [CrossRef]

- Hassanifard, S.; Ghiasvand, A.; Hashemi, S.M.; Varvani-Farahani, A. The effect of the friction stir welding tool shape on tensile properties of welded Al 6061-T6 joints. Mater. Today Commun. 2022, 31, 103457. [Google Scholar] [CrossRef]

- Rudrapati, R. Effects of welding process conditions on friction stir welding of polymer composites: A review. Compos. Part C Open Access 2022, 8, 100269. [Google Scholar] [CrossRef]

- Abdel Aziz, S.S.; Abulkhair, H.; Moustafa, E.B. Role of hybrid nanoparticles on thermal, electrical conductivity, microstructure, and hardness behavior of nanocomposite matrix. J. Mater. Res. Technol. 2021, 13, 1275–1284. [Google Scholar] [CrossRef]

- Ramprasad, A. Mechanical Properties of Al 6061-SiCp Metal Matrix Composite Weld Joints Made using Friction Stir Welding. Int. J. Recent Innov. Trends Comput. Commun. 2015, 3, 4573–4576. [Google Scholar]

- Abd Elnabi, M.M.; Elshalakany, A.B.; Abdel-Mottaleb, M.M.; Osman, T.A.; El Mokadem, A. Influence of friction stir welding parameters on metallurgical and mechanical properties of dissimilar AA5454–AA7075 aluminum alloys. J. Mater. Res. Technol. 2019, 8, 1684–1693. [Google Scholar] [CrossRef]

- Devaiah, D.K.K.; Laxminarayana, P. Parametric Optimization of Friction Stir Welding Parameters Using Taguchi Technique for Dissimilar Aluminum Alloys (AA5083 and AA6061). IOSR J. Eng. 2017, 7, 44–49. [Google Scholar]

- Song, S.-W.; Kim, B.-C.; Yoon, T.-J.; Kim, N.-K.; Kim, I.-B.; Kang, C.-Y. Effect of Welding Parameters on Weld Formation and Mechanical Properties in Dissimilar Al Alloy Joints by FSW. Mater. Trans. 2010, 51, 1319–1325. [Google Scholar] [CrossRef] [Green Version]

- Kasman, S.; Kahraman, F.; Emiralioğlu, A.; Kahraman, H. A Case Study for the Welding of Dissimilar EN AW 6082 and EN AW 5083 Aluminum Alloys by Friction Stir Welding. Metals 2017, 7, 6. [Google Scholar] [CrossRef] [Green Version]

- Donatus, U.; Thompson, G.E.; Zhou, X.; Wang, J.; Cassell, A.; Beamish, K. Corrosion susceptibility of dissimilar friction stir welds of AA5083 and AA6082 alloys. Mater. Charact. 2015, 107, 85–97. [Google Scholar] [CrossRef]

- Md, S.; Birru, A.K. Mechanical and metallurgical properties of friction stir welded dissimilar joints of AZ91 magnesium alloy and AA 6082-T6 aluminium alloy. J. Magnes. Alloys 2019, 7, 264–271. [Google Scholar] [CrossRef]

- Bayazid, S.M.; Farhangi, H.; Ghahramani, A. Investigation of Friction Stir Welding Parameters of 6063-7075 Aluminum Alloys by Taguchi Method. Procedia Mater. Sci. 2015, 11, 6–11. [Google Scholar] [CrossRef] [Green Version]

- Kalemba-Rec, I.; Wróbel, M.; Kopyściański, M. Investigations of Friction Stir Welds between 5083 and 7075 Aluminum Alloys Using EBSD and X-Ray Techniques. Acta Phys. Pol. A 2016, 130, 996–999. [Google Scholar] [CrossRef]

- Laska, A.; Szkodo, M.; Cavaliere, P.; Perrone, A. Influence of the Tool Rotational Speed on Physical and Chemical Properties of Dissimilar Friction-Stir-Welded AA5083/AA6060 Joints. Metals 2022, 12, 1658. [Google Scholar] [CrossRef]

- Ahmed, S.; Rahman, R.A.; Awan, A.; Ahmad, S.; Akram, W.; Amjad, M.; Yahya, M.Y.; Rahimian Koloor, S.S. Optimization of Process Parameters in Friction Stir Welding of Aluminum 5451 in Marine Applications. J. Mar. Sci. Eng. 2022, 10, 1539. [Google Scholar] [CrossRef]

- Khalafe, W.H.; Sheng, E.L.; Bin Isa, M.R.; Omran, A.B.; Shamsudin, S.B. The Effect of Friction Stir Welding Parameters on the Weldability of Aluminum Alloys with Similar and Dissimilar Metals: Review. Metals 2022, 12, 2099. [Google Scholar] [CrossRef]

- Rabe, P.; Reisgen, U.; Schiebahn, A. Non-destructive evaluation of the friction stir welding process, generalizing a deep neural defect detection network to identify internal weld defects across different aluminum alloys. Weld. World 2023, 67, 549–560. [Google Scholar] [CrossRef]

- Muhammad, N.A.; Wu, C. Evaluation of capabilities of ultrasonic vibration on the surface, electrical and mechanical behaviours of aluminium to copper dissimilar friction stir welds. Int. J. Mech. Sci. 2020, 183, 105784. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Melaibari, A.; Basha, M. Wear and microhardness behaviors of AA7075/SiC-BN hybrid nanocomposite surfaces fabricated by friction stir processing. Ceram. Int. 2020, 46, 16938–16943. [Google Scholar] [CrossRef]

- Moustafa, E.B. Dynamic Characteristics Study for Surface Composite of AMMNCs Matrix Fabricated by Friction Stir Process. Materials 2018, 11, 1240. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ralston, K.D.; Birbilis, N.; Weyland, M.; Hutchinson, C.R. The effect of precipitate size on the yield strength-pitting corrosion correlation in Al–Cu–Mg alloys. Acta Mater. 2010, 58, 5941–5948. [Google Scholar] [CrossRef]

- Sauvage, X.; Dédé, A.; Muñoz, A.C.; Huneau, B. Precipitate stability and recrystallisation in the weld nuggets of friction stir welded Al–Mg–Si and Al–Mg–Sc alloys. Mater. Sci. Eng. A 2008, 491, 364–371. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Triveni, M.K.; Katiyar, J.K.; Tiwari, T.N.; Roy, B.S. Prediction of heat generation effect on force torque and mechanical properties at varying tool rotational speed in friction stir welding using Artificial Neural Network. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 1. [Google Scholar] [CrossRef]

- Ghosh, B.; Das, H.; Samanta, A.; Majumdar, J.D.; Ghosh, M. Influence of tool rotational speed on the evolution of microstructure and mechanical properties of precipitation-hardened Aluminium 6061 butt joint during friction stir welding. Eng. Res. Express 2022, 4, 015009. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M.B.; Wu, C.S. Thermal analysis of friction stir processing (FSP) using arbitrary Lagrangian-Eulerian (ALE) and smoothed particle hydrodynamics (SPH) meshing techniques. Mater. Werkst. 2020, 51, 550–557. [Google Scholar] [CrossRef]

| Alloy | Cu | Zn | Si | Fe | Mg | Others | Al |

|---|---|---|---|---|---|---|---|

| AA2024 | 4.62 | 0.21 | 0.44 | 0.51 | 1.7 | 1.4 | 91.12 |

| AA7075 | 1.54 | 5.28 | 0.29 | 0.11 | 2.97 | 0.3 | 89.51 |

| Tool Rotation Speed (rpm) | Traverse Speed (mm/min) | Average Grain Size (µm) |

|---|---|---|

| 400 | 20 | 29 ± 2.5 |

| 400 | 30 | 31 ± 1.8 |

| 400 | 40 | 28 ± 3.1 |

| 600 | 20 | 23 ± 2.6 |

| 600 | 30 | 19 ± 2.1 |

| 600 | 40 | 21 ± 1.7 |

| 800 | 20 | 23 ± 2.3 |

| 800 | 30 | 20 ± 1.5 |

| 800 | 40 | 24 ± 2.8 |

| Tool Rotation Speed (rpm) | Traverse Speed (mm/min) | Average UTS (MPa) | Natural Frequency (Hz) | Improvement Percentage in the Damping Ratio (ζ) % |

|---|---|---|---|---|

| 400 | 20 | 224.52 ± 8.63 | 164 ± 1.05 | 6.8 |

| 400 | 30 | 199.57 ± 9.35 | 176 ± 0.87 | 9.15 |

| 400 | 40 | 235.59 ± 7.23 | 182 ± 0.88 | 24.51 |

| 600 | 20 | 243.13 ± 8.14 | 175 ± 1.87 | 11.43 |

| 600 | 30 | 253.49 ± 8.95 | 177 ± 1.1 | 11.43 |

| 600 | 40 | 257.41 ± 7.68 | 192 ± 1.45 | 29.73 |

| 800 | 20 | 241.52 ± 9.11 | 180 ± 0.89 | 20.261 |

| 800 | 30 | 222.14 ± 7.53 | 195 ± 1.04 | 29.41 |

| 800 | 40 | 262.73 ± 6.92 | 167 ± 1.76 | 8.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Djouider, F.; Alhawsawi, A.; Elmoujarkach, E.; Banoqitah, E.; Alharazi, M.; Moustafa, E.B. The Role of Friction Stir Processing Parameters and Hybrid ZrC/WC Reinforcement Particles in Improving the Surface Composite Dissimilar Matrix’s Dynamic Behavior and Microstructure Refinement. Coatings 2023, 13, 1393. https://doi.org/10.3390/coatings13081393

Djouider F, Alhawsawi A, Elmoujarkach E, Banoqitah E, Alharazi M, Moustafa EB. The Role of Friction Stir Processing Parameters and Hybrid ZrC/WC Reinforcement Particles in Improving the Surface Composite Dissimilar Matrix’s Dynamic Behavior and Microstructure Refinement. Coatings. 2023; 13(8):1393. https://doi.org/10.3390/coatings13081393

Chicago/Turabian StyleDjouider, Fathi, Abdulsalam Alhawsawi, Ezzat Elmoujarkach, Essam Banoqitah, Mazen Alharazi, and Essam B. Moustafa. 2023. "The Role of Friction Stir Processing Parameters and Hybrid ZrC/WC Reinforcement Particles in Improving the Surface Composite Dissimilar Matrix’s Dynamic Behavior and Microstructure Refinement" Coatings 13, no. 8: 1393. https://doi.org/10.3390/coatings13081393

APA StyleDjouider, F., Alhawsawi, A., Elmoujarkach, E., Banoqitah, E., Alharazi, M., & Moustafa, E. B. (2023). The Role of Friction Stir Processing Parameters and Hybrid ZrC/WC Reinforcement Particles in Improving the Surface Composite Dissimilar Matrix’s Dynamic Behavior and Microstructure Refinement. Coatings, 13(8), 1393. https://doi.org/10.3390/coatings13081393