Non-Destructive Elemental Analysis of Raster Roller Damage Using X-ray Fluorescence Spectroscopy

Abstract

:1. Introduction

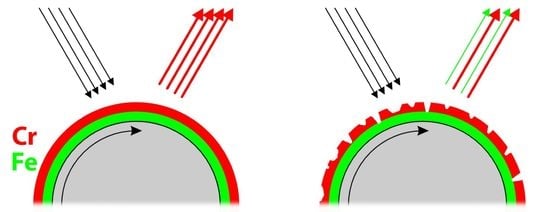

2. Materials and Methods

2.1. Material for Research

2.2. Research Methods

3. Results and Discussion

3.1. Influence of the Scanning Settings on the Elemental Composition Results for an Anilox Coating

3.2. Verification of the Suitability of the XRF Technique for Aniloxes with Different Screen Rulings

3.3. Analysis of Anilox Damage with Various Scanning Modes (Stationary and Rotating Cylinder)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Savickas, A.; Stonkus, R.; Jurkonis, E.; Iljin, I. Assessment of the condition of anilox rollers. Coatings 2021, 11, 1301. [Google Scholar] [CrossRef]

- Bohan, M.F.J.; Townsend, P.; Hamblyn, S.M.; Claypole, T.C.; Gethin, D.T. Evaluation of Pressures in Flexographic Printing. In Proceedings of the TAGA Conference, Montreal, QC, Canada, 14–17 April 2003; pp. 311–320. [Google Scholar]

- Valdec, D.; Hajdek, K.; Vragović, L.; Geček, R. Determining the print quality due to deformation of the halftone dots in flexography. Appl. Sci. 2021, 11, 10601. [Google Scholar] [CrossRef]

- Bould, D.C.; Hamblyn, S.M.; Gethin, D.T.; Claypole, T.C. Effect of impression pressure and anilox specification on solid and halftone density. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 699–709. [Google Scholar] [CrossRef]

- Kim, C.H.; Jo, J.; Lee, S.H. Design of roll-to-roll printing equipment with multiple printing methods for multi-layer printing. Rev. Sci. Instrum. 2012, 83, 065001. [Google Scholar] [CrossRef] [PubMed]

- Wirojrungson, W. An Investigation into the Effect of Plate Hardness, and Surface Speed Differential on Flexographic Gear Marking. Master’s Thesis, School of Printing Management and Sciences, Rochester Institute of Technology, Rochester, MN, USA, 2000. [Google Scholar]

- Trautenbach, U.; Abu-Mahfouz, I. Using sound and vibration signals to monitor cell wear on anilox rolls. Nondestruct. Test. Eva. 2007, 19, 187–198. [Google Scholar] [CrossRef]

- Warner, B. Uniform Doctor Blade Metering. How to Achieve Desired Results. Available online: https://allisonblades.com/wp-content/uploads/2017/05/FLEXO_June2012.pdf (accessed on 10 July 2023).

- Monteleone, D. Reducing Ink and Solvent Use in Enclosed Flexographic Inking Systems. Available online: https://www.ideals.illinois.edu/items/111732 (accessed on 10 July 2023).

- Kattumenu, R.C. Flexography Printing of Silver Based Conductive Inks on Packaging Substrates. ProQuest. Available online: https://www.proquest.com/openview/ff95facc33f2a072a9b08392fc23e267/1?pq-origsite=gscholar&cbl=18750 (accessed on 8 July 2023).

- Vademecum Wałków Rastrowych. Available online: https://barmey.eu/public/ck/userfiles/files/Vademecum%20wa%C5%82k%C3%B3w%20rastrowych.pdf (accessed on 8 June 2023).

- Hansuebsai, A.; Nawakitwong, S. Printability analysis of compostable films by flexographic water based ink. Key Eng. Mater. 2020, 843, 26–32. [Google Scholar]

- Yusof, M.S.; Gethin, D.T. Investigation of carbon black ink on fine solid line printing in flexography. Mater. Sci. 2011, 138–142. [Google Scholar]

- Specifying the Right Anilox. Available online: https://www.harperimage.com/AniloxRolls/Anilox-Guides/Specifying-the-Right-Anilox (accessed on 5 July 2023).

- Savickas, A.; Stonkus, R.; Jurkonis, E. Investigation of anilox roller cell clogging. J. Graph. Eng. Des. 2020, 11, 61–67. [Google Scholar] [CrossRef]

- Pawlowski, L. Technology of thermally sprayed anilox rolls: State of art, problems, and perspectives. J. Therm. Spray Technol. 1996, 5, 317–334. [Google Scholar] [CrossRef]

- Joshi, A.V. Optimization of flexo process parameters to reduce the overall manufacturing cost. Int. J. Optim. Control Theor. Appl. 2022, 12, 66–78. [Google Scholar] [CrossRef]

- Lipiak, J. Methodology for assessing the factors affecting the quality and efficiency of flexographic printing process. Procedia Eng. 2017, 182, 403–411. [Google Scholar] [CrossRef]

- Bould, D.; Claypole, T.C.; Galton, D. Process parameters in flexography: Effect on UV ink transfer and image quality characteristics. JPMTR 2012, 1, 41–49. [Google Scholar]

- Watson, D. Standardizing Anilox Rolls. ProQuest. Available online: https://www.proquest.com/openview/057ac1e54406f263943c744b15704cbf/1?pq-origsite=gscholar&cbl=48979 (accessed on 11 June 2023).

- Anilox Roll Inspection: So Simple, So Important. ProQuest. Available online: https://www.proquest.com/openview/91cd36ad6688e7ff92718df8722801f1/1?pq-origsite=gscholar&cbl=48979 (accessed on 11 June 2023).

- The Anilox Roll Audit: Do You Know What You Have? ProQuest. Available online: https://www.proquest.com/openview/5f7c4ec091d2898ce9e86a6971edfe2b/1?pq-origsite=gscholar&cbl=48979 (accessed on 11 June 2023).

- How to Make Anilox Roll Improvements Work for You. ProQuest. Available online: https://www.proquest.com/openview/899354013a4562b69b27f5d6d035dd79/1?pq-origsite=gscholar&cbl=48979 (accessed on 11 June 2023).

- Anilox Roll Are Key When Printing Corrugated Board. ProQuest. Available online: https://www.proquest.com/openview/0346dc3bdd040626ef0cd27476c76b35/1?pq-origsite=gscholar&cbl=48979 (accessed on 11 June 2023).

- Winkler, R.; Bültmann, F.; Hartmann, S.; Burkard, H. 316L—An alternative to NiCr bondcoats for Cr2O3-coatings on anilox rolls. Therm. Spray Proc. 2003, 83638, 149–152. [Google Scholar] [CrossRef]

- Roll Cleaning Technology Keeps Pace with Roll Advances. ProQuest. Available online: https://www.proquest.com/openview/642b4a52c3b5b7b1b0830a6d89042fb4/1?pq-origsite=gscholar&cbl=48979 (accessed on 11 June 2023).

- Valdec, D.; Miljković, P.; Auguštin, B. The influence of printing substrate properties on color characterization in flexography according to the ISO specifications. Teh. Glas. 2017, 11, 73–77. [Google Scholar]

- Valdec, D.; Hajdek, K.; Majnarić, I.; Čerepinko, D. Influence of printing substrate on quality of line and text reproduction in flexography. Appl. Sci. 2021, 11, 7827. [Google Scholar] [CrossRef]

- Shapiro, F. Cleaning Anilox Rollers. PNEAC Fact Sheet. Available online: https://www.ideals.illinois.edu/items/111722 (accessed on 8 June 2023).

- Lanska, D.J. A Clean Look at Anilox Cleaning Systems. PNEAC Fact Sheet. Available online: https://www.ideals.illinois.edu/items/111720 (accessed on 9 June 2023).

- Using of Cavitation Effects in the Ultrasonic Cleaning of Anilox Rolls. Available online: https://elibrary.ru/item.asp?id=36303321 (accessed on 9 June 2023).

- What’s Really Going on with You Anilox Rolls? ProQuest. Available online: https://www.proquest.com/openview/1b55678bba344c0f2ff4ddc8747bd4b1/1?pq-origsite=gscholar&cbl=48979 (accessed on 10 June 2023).

- Kohli, R. Applications of dry vapor steam cleaning technique for removal of surface contaminants. Dev. Surf. Contam. Clean. Appl. Clean. Tech. 2019, 11, 681–702. [Google Scholar] [CrossRef]

- Sharma, A. Printing industry applications. Therm. Spray Technol. 2013, 5A, 332–333. [Google Scholar] [CrossRef]

- Wasserman, C.; Boecking, R.; Gustafsson, S. Replacement for Hard Chrome Plating in Printing Machinery. In Proceedings of the International Thermal Spray, Singapore, 28–30 May 2001; pp. 69–74. [Google Scholar]

- Znamirowski, Z.; Pawlowski, L.; Cichy, T.; Czarczynski, W. Low macroscopic field electron emission from surface of plasma sprayed and laser engraved TiO2, Al2O3+13TiO2 and Al2O3+40TiO2 coatings. Surf. Coat. Technol. 2004, 187, 37–46. [Google Scholar] [CrossRef]

- Bould, D.C.; Claypole, T.C.; Bohan, M.F.J. An investigation into plate deformation in flexographic printing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 1499–1511. [Google Scholar] [CrossRef]

- Measuring Anilox Volume: FQC’s Gauge R&R Study—Flexographic Technical Association. Available online: https://www.flexography.org/industry-news/measuring-anilox-volume-fqc-gauge-rr-study/ (accessed on 10 June 2023).

- Di, Z.W.; Chen, S.; Hong, Y.P.; Jacobsen, C.; Leyffer, S.; Wild, S.M. Joint reconstruction of x-ray fluorescence and transmission tomography. Opt. Express 2017, 25, 13107–13124. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Davis, J.M.; Newbury, D.E.; Fahey, A.; Ritchie, N.W.; Vicenzi, E.; Bentz, D. Bridging the Micro-to-Macro Gap: A New Application for Micro X-Ray Fluorescence. Microsc. Microanal. 2011, 17, 410–417. [Google Scholar] [CrossRef] [PubMed]

- Modica, A.; Alberghina, M.; Brai, M.; Bruno, M.; Di Bella, M.; Fontana, D.; Tranchina, L. XRF analysis to identify historical photographic processes: The case of some Interguglielmi Jr.’s images from the Palermo Municipal Archive. Radiat. Phys. Chem. 2017, 135, 76–80. [Google Scholar] [CrossRef]

- Trojek, T.; Musílek, L. X-ray fluorescence—A non-destructive tool in investigation of Czech fine and applied art objects. Radiat. Phys. Chem. 2017, 137, 230–233. [Google Scholar] [CrossRef]

- Stanley, T. Black and blue printing ink analysis by XRF, DRIFTS and Raman spectroscopy of recently discovered Gutenbergian Ars minor fragments. J. Am. Inst. Conserv. 2018, 57, 203–220. [Google Scholar] [CrossRef]

- Melendez-Perez, J.J.; Correa, D.N.; Hernandes, V.V.; de Morais, D.R.; de Oliveira, R.B.; de Souza, W.; Santos, J.M.; Eberlin, M.N. Forensic Application of X-ray Fluorescence Spectroscopy for the Discrimination of Authentic and Counterfeit Revenue Stamps. Appl. Spectrosc. 2016, 70, 1910–1915. [Google Scholar] [CrossRef] [PubMed]

- Enyeart, J.L.; Anderson, A.B.; Perron, S.J.; Rollins, D.K.; Fernando, Q. Non-destructive elemental analysis of photographic paper and emulsions by X-ray fluorescence spectroscopy. Hist. Photogr. 2013, 7, 99–113. [Google Scholar] [CrossRef]

- Čechák, T.; Kopecká, I.; Trojek, T.; Štanzel, T.; Bártová, H. Application of X-ray fluorescence in an investigation of photographic heritage. Radiat. Phys. Chem. 2015, 116, 8–13. [Google Scholar] [CrossRef]

| Screen Ruling, L/cm | Inkwell Capacity, mL/m2 |

|---|---|

| 80 | 24 |

| 90 | 20 |

| 90 | 16 |

| 120 | 12 |

| 140 | 8 |

| 180 | 4 |

| Fe Content, % | |

|---|---|

| Stationary Cylinder | Rotating Cylinder |

| 8.34 (9.37) * | 0.88 (0.97) |

| 6.80 (7.18) | 0.82 (0.86) |

| 6.48 (5.06) | 0.52 (0.40) |

| 3.50 (4.63) | 0.35 (0.46) |

| 9.29 (3.54) | 1.45 (0.58) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Małachowska, E.; Lipkiewicz, A.; Dubowik, M.; Drozd, R.; Przybysz, P. Non-Destructive Elemental Analysis of Raster Roller Damage Using X-ray Fluorescence Spectroscopy. Coatings 2023, 13, 1398. https://doi.org/10.3390/coatings13081398

Małachowska E, Lipkiewicz A, Dubowik M, Drozd R, Przybysz P. Non-Destructive Elemental Analysis of Raster Roller Damage Using X-ray Fluorescence Spectroscopy. Coatings. 2023; 13(8):1398. https://doi.org/10.3390/coatings13081398

Chicago/Turabian StyleMałachowska, Edyta, Aneta Lipkiewicz, Marcin Dubowik, Robert Drozd, and Piotr Przybysz. 2023. "Non-Destructive Elemental Analysis of Raster Roller Damage Using X-ray Fluorescence Spectroscopy" Coatings 13, no. 8: 1398. https://doi.org/10.3390/coatings13081398

APA StyleMałachowska, E., Lipkiewicz, A., Dubowik, M., Drozd, R., & Przybysz, P. (2023). Non-Destructive Elemental Analysis of Raster Roller Damage Using X-ray Fluorescence Spectroscopy. Coatings, 13(8), 1398. https://doi.org/10.3390/coatings13081398