Abstract

The paper presents the results of research on composite Ni-B coatings with embedded particles of boron produced by a chemical reduction method and their influence on the mechanical, tribological, and corrosion properties of produced materials. Boron was used in two forms: an alloy component and nanoparticles incorporated into the Ni-B matrix. The coatings were deposited from a bath at different concentrations of dispersion phase. The paper also presents the characteristics of the used boron particles. Results of morphology and surface topography (SEM) as well as the structure (XRD) of the produced coatings are presented. The mechanical properties of the produced coatings, like Knoop hardness, Martens hardness, and indentation hardness, as well as the modulus of elasticity, were determined. The tribological tests were carried out using the ball-on-disc method. Electrochemical corrosion tests were conducted by the potentiodynamic method. The adhesion of the coatings to the substrate was evaluated by the scratch test method. Consequently, this investigation yielded a novel material in the form of Ni-B/B composite coatings, exhibiting significantly improved mechanical and tribological properties compared to Ni-B coatings without embedded particles of the dispersion phase.

1. Introduction

Deposition of alloy coatings through chemical reduction gives great opportunities to modify the properties of metallic products. This method enables the coating of products with complex shapes made of various materials. Nickel alloy coatings, such as Ni-P coatings, are of great importance in the field of technology. Research on the production and properties of these materials being deposited on steel, copper, magnesium, and aluminum substrates, is found in numerous studies: [1,2,3,4,5,6]. Ni-B alloy coatings, although less explored, are equally interesting from the point of view of potential technical applications. Literature reports indicate that Ni-B coatings can enhance corrosion resistance, wear resistance, and oxidation resistance, while also serving as catalysts in the production of renewable energy [7]. Authors have described the antibacterial properties of electroless Ni-B coatings applied to stainless steel components for medical device usage [8]. Ni-B alloy coatings can also be used as a source of boron in the diffusion boronization of steel [9]. Moreover, compared to Ni-P coatings, Ni-B alloy coatings exhibit significantly higher hardness [10]. Additionally, the properties of coatings composed of such materials can be modified by incorporating dispersion phases from other materials into the coating material and through heat treatment. A study [11] investigated the influence of heat treatment on the properties, including the hardness, of coatings made from these materials. After heat treatment at 360 °C for 20 min, the Ni-B/B composite coatings had a hardness exceeding 1250 HK0.01. This value closely approximates the hardness of chrome coatings, making it possible to use them as substitutes for chrome coatings that are subject to restrictions in the European Union [12]. The choice of dispersion phase material, particle size, and concentration within the bath enables the customization of the properties of composite materials produced through chemical reduction as coatings. The embedding of dispersion phase particles into the coating matrix, whether via chemical or electrochemical reduction methods, typically leads to improvements in mechanical, tribological, and corrosion properties. Nanometric particles of the dispersion phase (<100 nm) are of great importance in shaping the properties of composite materials. Several studies have examined the influence of hard ceramic particles on the properties of Ni-B matrix composite coatings. For instance, SiC particles increased hardness and enhanced corrosion resistance [13]. Similarly, the embedding of TiO2 particles [14,15] and graphene oxide flakes resulted in increased hardness and improved corrosion resistance in Ni-B/graphene oxide coatings [16]. The mechanical and tribological properties were improved by the embedding of CeO2 particles into the Ni-B matrix, leading to a reduction in the friction coefficient, increased hardness, and improved modulus of elasticity [17]. Other dispersion phases incorporated into the Ni-B matrix included Si3N4 [18] and Al2O3 [19].

This study addressed the Ni-B/B composite coatings produced by chemical reduction on a steel substrate. These coatings can contain one of two forms of boron, which is either a constituent of the Ni-B alloy matrix or its particles of the dispersion phase embedded in composite coatings. The use of boron as dispersion phase particles embedded in the Ni-B alloy matrix represents an innovative approach. Reports on this subject can be found in our own previous works [11,20]. The first study focused on boron particles being embedded in a nickel matrix through electrochemical deposition. The second study involved the deposition of Ni-B/B coatings using the electroless method, with the main emphasis on comparing the properties of this type of material before and after heat treatment. In this work, the coatings were deposited at different concentrations of the dispersion phase (B) in the bath (0.1–1.0 g/dm3), and the resulting effect on the properties of the composite coatings produced was analyzed. The choice of boron is motivated by its desirable properties, such as high hardness and chemical and thermal resistance (melting point exceeding 2000 °C) [20].

2. Materials and Methods

2.1. Materials

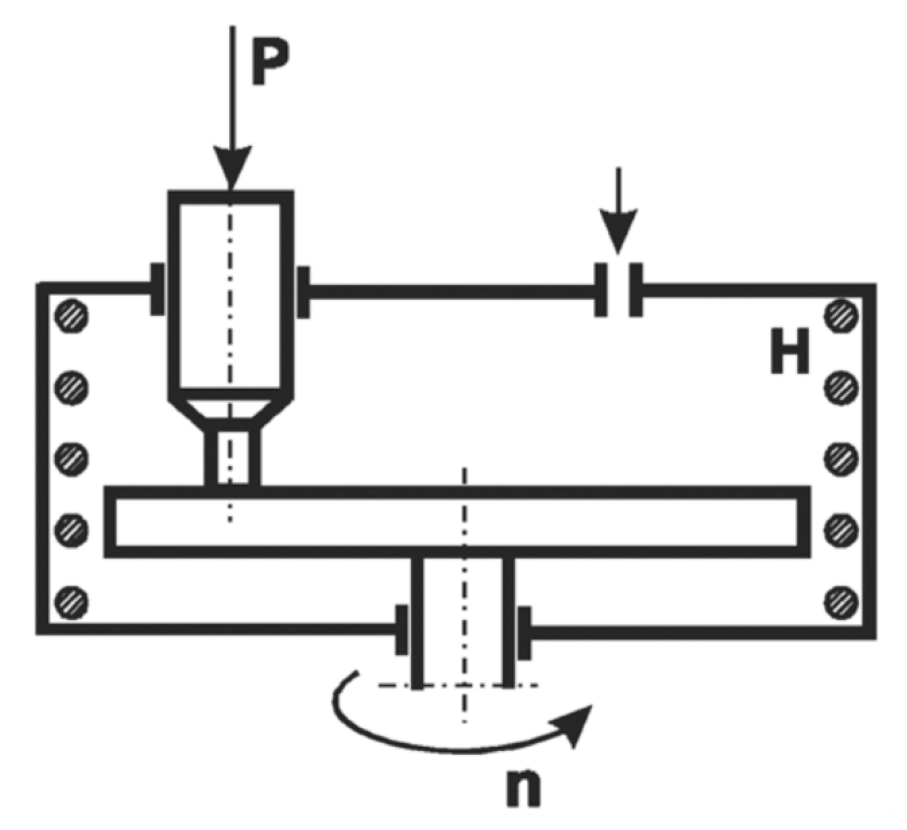

Ni-B alloy coatings and Ni-B/B composite coatings with embedded boron particles were deposited on S355 carbon steel substrates in the form of 25.4 mm diameter discs through chemical reduction. The substrate samples underwent preparatory steps, including grinding with 180–1200 grit sandpaper, degreasing in acetone, and activation in 15% H2SO4. These treatments were implemented to eliminate impurities, such as rust, dust, and oxides, which could adversely affect the coating adhesion to the steel substrate. The bath from which the coatings were deposited contained NiCl2 × 6H2O (nickel chloride), NaBH4 (sodium borohydride), C2H8N2 (ethylenediamine), NaOH (sodium hydroxide), and PbNO3 (lead nitrate). All reagents used were of high purity (PURE) and were supplied by Chempur (Poland). In the electroless coating deposition bath, nickel chloride is a source of Ni2+ ions. Sodium borohydride reduces nickel ions to their elemental form, and the course of this reaction is quite intense and rapid. Ethylenediamine (a complexing agent) is used to slow down the reaction and make the process stable. Lead nitrate acts as a stabilizer and protects the bath against decomposition. Sodium hydroxide is a pH corrector [21]. Sigma Aldrich boron powder was used as the dispersion phase for the production of composite coatings. Boron was added to the bath before the coating deposition process. All coatings were deposited using consistent process parameters: a bath temperature of 90 °C, a deposition time of 90 min, and a mixing speed of 100 rpm. The diagram of the laboratory setup is depicted in Figure 1.

Figure 1.

Schematic diagram of laboratory setup for the deposition process.

2.2. Methods

The morphology of the boron powder and the surface of the produced coatings were characterized using a scanning electron microscope JSM-IT100 LA (Jeol, Akishima, Japan). The content of boron, being the alloy component, was determined by ICP-OES in the Ni-B coating without dispersion phase particles. The content of dispersion phase particles in the composite coatings was determined gravimetrically by dissolving previously produced Ni-B/B films and weighing the remaining boron particles. The internal structure of the Ni-B and Ni-B/B coatings was investigated by performing SEM analysis on cross-sections perpendicular to the surface on metallographic specimens. The samples were prepared by cutting off a 5 mm sample and embedding it in a thermosetting resin (Struers); then, the samples were sanded with 120–1200 grit sandpaper and polished with diamond paste. The metallographic microsections were also used to test hardness using the Knoop method (HK0.025) with a load of 25 g applied via a Wilson T1202 hardness tester (Buehler, Lake Bluff, IL, USA). Mechanical properties were evaluated using the DSI (depth-sensing indentation) method [22], applying a progressive load of 0–300 mN with an indentation rate of 1000 mN/min and a pause at a maximum load for 15 s. The DSI test provided material parameters, including Martens hardness (HM), indentation hardness (HIT), Young’s modulus (EIT), and the elastic deformation index (KH). Indentation hardness (HIT) was calculated as the quotient of the maximum applied force (Fmax) and the projection area of the contact surface between indenter and test material A(hc), as follows:

Martens hardness (HM) was calculated as the quotient of the applied load (F) and the indenter surface area As(h), as follows:

The percentage of a given deformation (KH) was determined by evaluating the ratio of plastic ( to elastic (H) deformation during the testing of the fabricated materials [23], as follows:

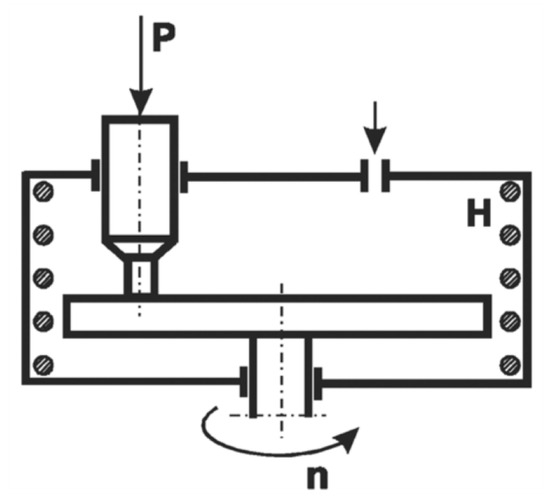

The Ra roughness parameter was measured using a Surftest SJ210 profilometer (Mitutoyo). Abrasive wear resistance was evaluated using the ball-on-disc method on the T11 device (Łukasiewicz Institute for Sustainable Technologies). The tribosystem consists of the stationary pin (ball) pressed at the required load (P) against the disk (tested sample) rotating at the defined speed (n). The friction couple is inserted in the insulated test chamber (Figure 2) [24].

Figure 2.

Scheme of the T11 tribosystem [25].

The coated samples served as the discs and the counterparts were 6.35 mm diameter alumina balls. The sliding speed and sliding distance were, respectively, 0.1 m/s and 500 m. Wear tests were carried out under loads of 10 N with sliding distances of 500 m. The wear tracks were captured using a KEYENCE VHX 5000 digital optical microscope. The adhesion of the coatings to the substrate was evaluated by the scratch test method using the CSEM Revetest device with a progressive load of 0–100 N for 60 s at a Rockwell indenter speed of 10 mm/min. Electrochemical corrosion tests were conducted in a three-electrode system consisting of a saturated calomel electrode (SCE 0.27 V vs. HE) as the reference electrode, the counter electrode in the form of a platinum mesh and the tested sample as the working electrode. Polarization curves were recorded after an hour of potential stabilization in the potential range from −0.25 V to 0.25 V relative to the open circuit potential (OCP) at a potential change rate of 1 mV/s. Electrochemical tests were performed on the test surface of 1 cm2 in an aerated solutions of 0.15 M NaCl with neutral pH and a volume of 150 cm3. The tests were carried out using the SP-200 potentiostat (Bio-Logic, Seyssinet-Pariset, France). As part of the result analysis, the corrosion current density and corrosion potential were determined by extrapolating the Tafel curves.

3. Results and Discussion

3.1. Characteristics of Boron Powder

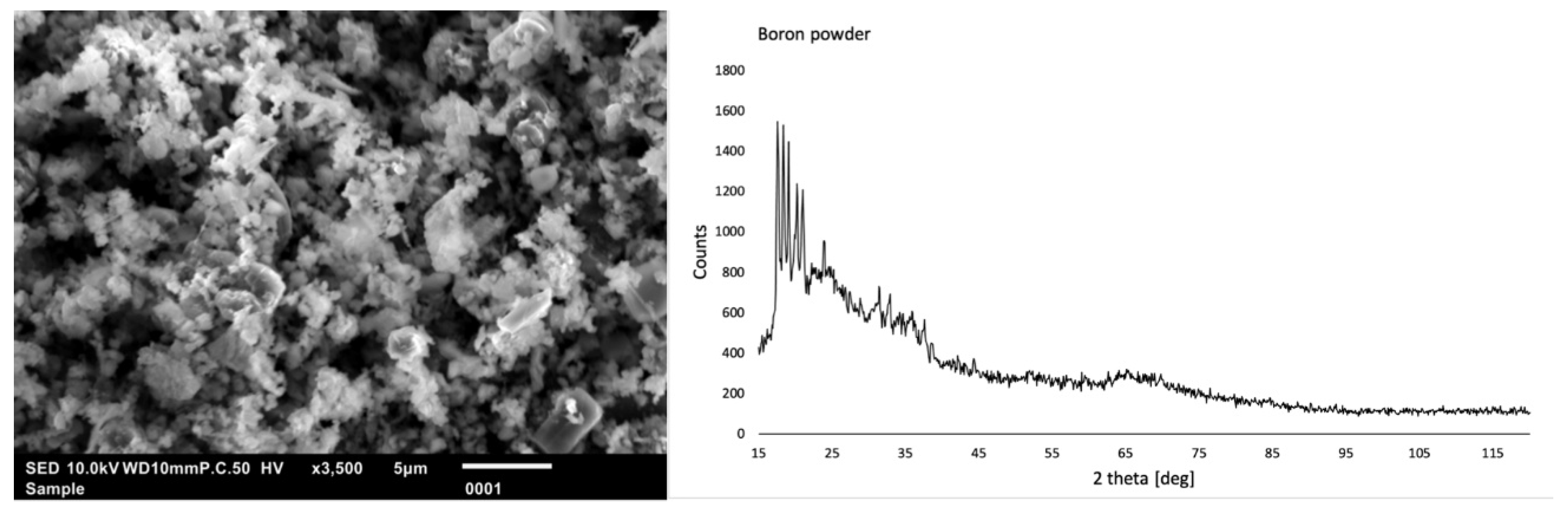

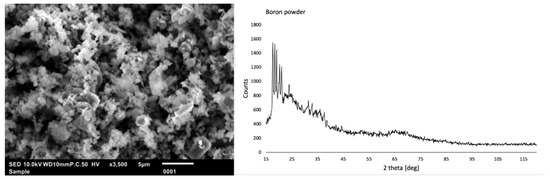

The morphology, the diffraction spectrum, and the chemical composition analysis of the boron powder used are shown in Figure 3 and Table 1.

Figure 3.

SEM image and diffraction pattern of used boron powder.

Table 1.

EDS analysis of the chemical composition of boron powder.

The boron powder exhibits particles of various shapes and sizes within 1 µm along with an amorphous structure. It also tends to form agglomerates in the aqueous solution of the bath, which is an unfavorable phenomenon [20]. The embedding of agglomerates of dispersion phase particles into the coating material may have an adverse effect on the properties of the coatings produced. Research presented in another paper [17] indicated a decrease in the hardness of the composite material when agglomerates of dispersion phase particles were embedded in the matrix material.

3.2. Structure of the Produced Coatings

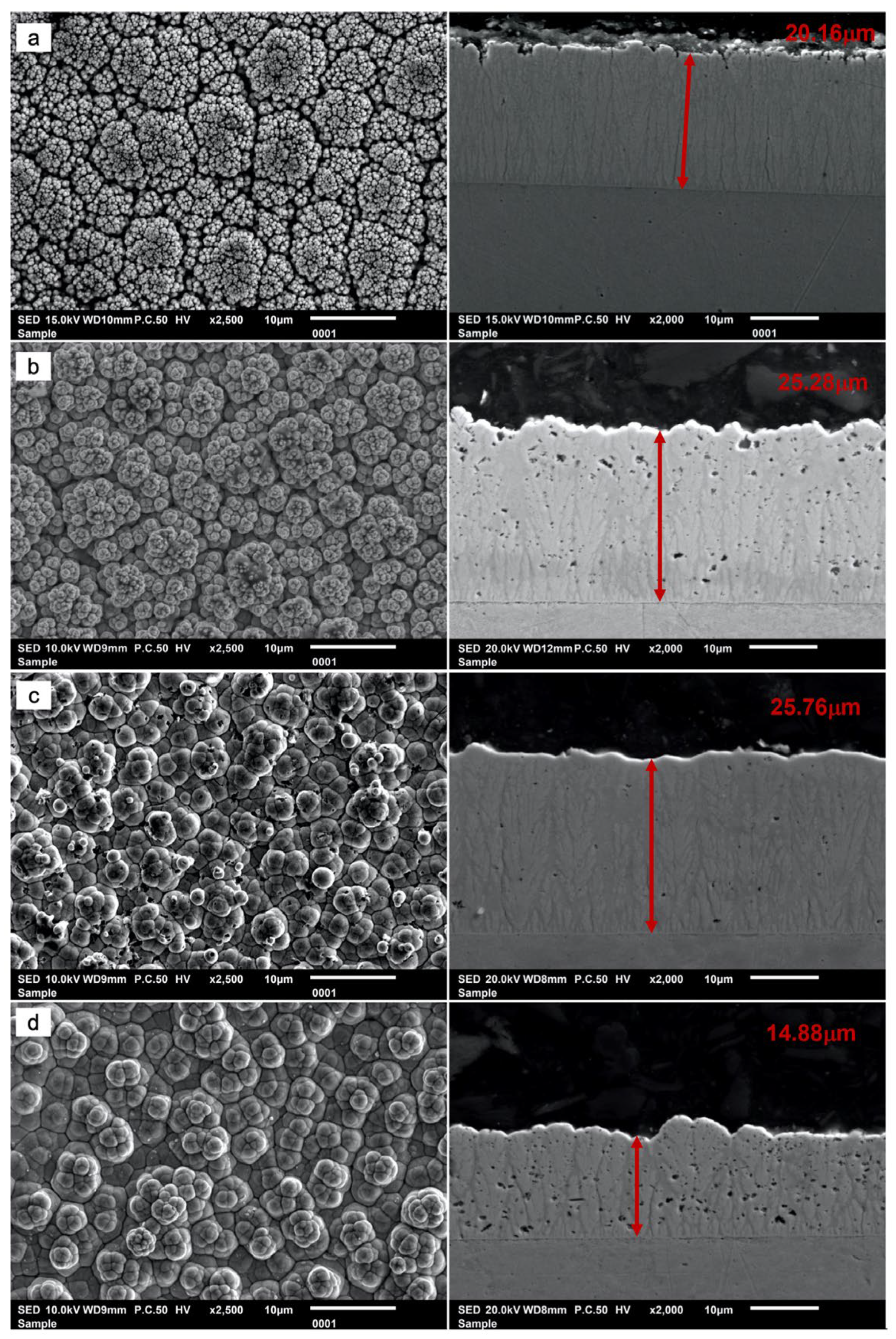

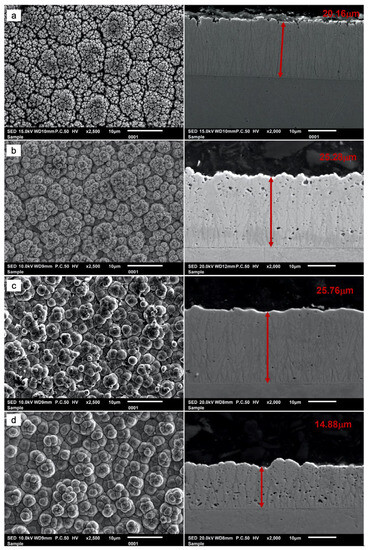

Images of the surface morphology and internal structure of the produced Ni-B and Ni-B/B coatings, observed on cross-sections perpendicular to the surface, are presented in Figure 4.

Figure 4.

Surface morphology and cross-sections of produced coatings: (a) Ni-B; (b) Ni-B/B (0.1); (c) Ni-B/B (0.5); (d) Ni-B/B (1.0).

The produced coatings are characterized by diverse surface morphology. It is affected by the coating deposition from baths with different concentrations of the dispersion phase in the form of boron particles. The surface of the Ni-B coating without embedded boron particles resembles a cauliflower structure (Figure 4a), which is typical of electroless Ni-B coatings [17,26,27]. The formation of the Ni-B layer occurs in the process of chemical reduction of nickel ions in the presence of a reducer. The most commonly used reducing agents in this type of process are sodium borohydride NaBH4 and dimethylamino borate (DMAB). Baths containing DMAB can work at lower temperatures and in a wider pH range, and are less sensitive to changes compared to baths containing sodium borohydride [14]. However, NaBH4, due to its chemical properties, can only be used in alkaline baths, but it provides a higher reducing capacity compared to DMAB. The high efficiency of NaBH4 stems from its ability to provide more electrons. In addition, coatings deposited from baths containing NaBH4 have better properties compared to other reducing agents. These properties include higher hardness and better mechanical properties [7]. The process of chemical deposition of Ni-B coatings is multi-stage and occurs in varying conditions depending on the chosen reducer [26]. The structure of the Ni-B coating is columnar and becomes nodular as the layer develops [7]. The columnar structure of the Ni-B coatings is clearly evident in cross-sections perpendicular to the surface. In the case of alloy coatings, like Ni-B, selecting the deposition process parameters, such as bath volume, surface area of the coated element, bath temperature, mixing speed, and deposition time, is crucial. All these parameters influence the structure of the deposited coating. Another study [13] presents the investigation of supplementing the bath composition during the coating deposition process. This treatment aims to maintain constant concentrations of bath components throughout the process and prevent a decrease in yield. Refilling the bath also helps ensure that the pH remains at the right level. Lowering the pH below 12 leads to the formation of nickel boride (Ni2B), which can cause the self-decomposition of the bath. In this study, the authors selected the process conditions (deposition time, bath volume, sample surface, bath temperature, and mixing speed) to obtain homogeneous coatings with a thickness of approx. 20 µm without the need for bath composition supplementation during the coating production process. The embedded particles of the dispersion phase (B) cause changes in the surface morphology, while the cauliflower-like structures transform into spherical ones. This is due to the embedding of particles and agglomerates of the dispersion phase powder, which, during the process, are gradually encapsulated by the Ni-B matrix. The built-in particles of the dispersion phase in the microscopic images are visible as black dots both on cross-sections and on the surface of the produced composite coatings. Changes in the morphology of Ni-B/B composite coatings are related to the embedding of the boron particles and depend on the amount of dispersion phase particles in the bath [28]. The growth of the coating and the integration of the dispersion phase particles are simultaneous. Integration of the dispersion phase particles within the matrix contributes to the formation of new growth centers [17]. The effect of the concentration of boron particles in the bath on the quantity of built-in boron particles (the dispersion phase) in the fabricated Ni-B/B composite coatings is presented in Table 2.

Table 2.

Boron content in the form of dispersion particles in produced composite coatings.

The deposition of Ni-B/B coatings, together with increasing the concentration of the dispersion phase in the bath, leads to a higher quantity of embedded particles within the deposited coating. The highest content of embedded boron particles, around 4%, was observed in coatings deposited from a bath with a concentration of 1.0 g/dm3. However, these particles predominantly formed agglomerates. The degree of surface development of the Ni-B/B coatings decreased as the concentration of the dispersion phase in the deposition bath increased. This phenomenon can be explained by the change from cauliflower structures (Figure 4a) to spherical structures in the case of composite coatings (Figure 4b–d). A summary of the roughness parameter Ra for both Ni-B and Ni-B/B coatings is provided in Table 3. For composite coatings, the efficiency of the deposition process decreased as the content of boron particles in the bath increased. The embedding of dispersion phase particles led to a reduction in the thickness of the deposited coatings (Figure 4d). Similar findings were also reported by Gültekin et al. [17], who investigated the Ni-B/CeO2 coatings deposited through chemical reduction.

Table 3.

Surface roughness of the tested Ni-B and Ni-B/B coatings.

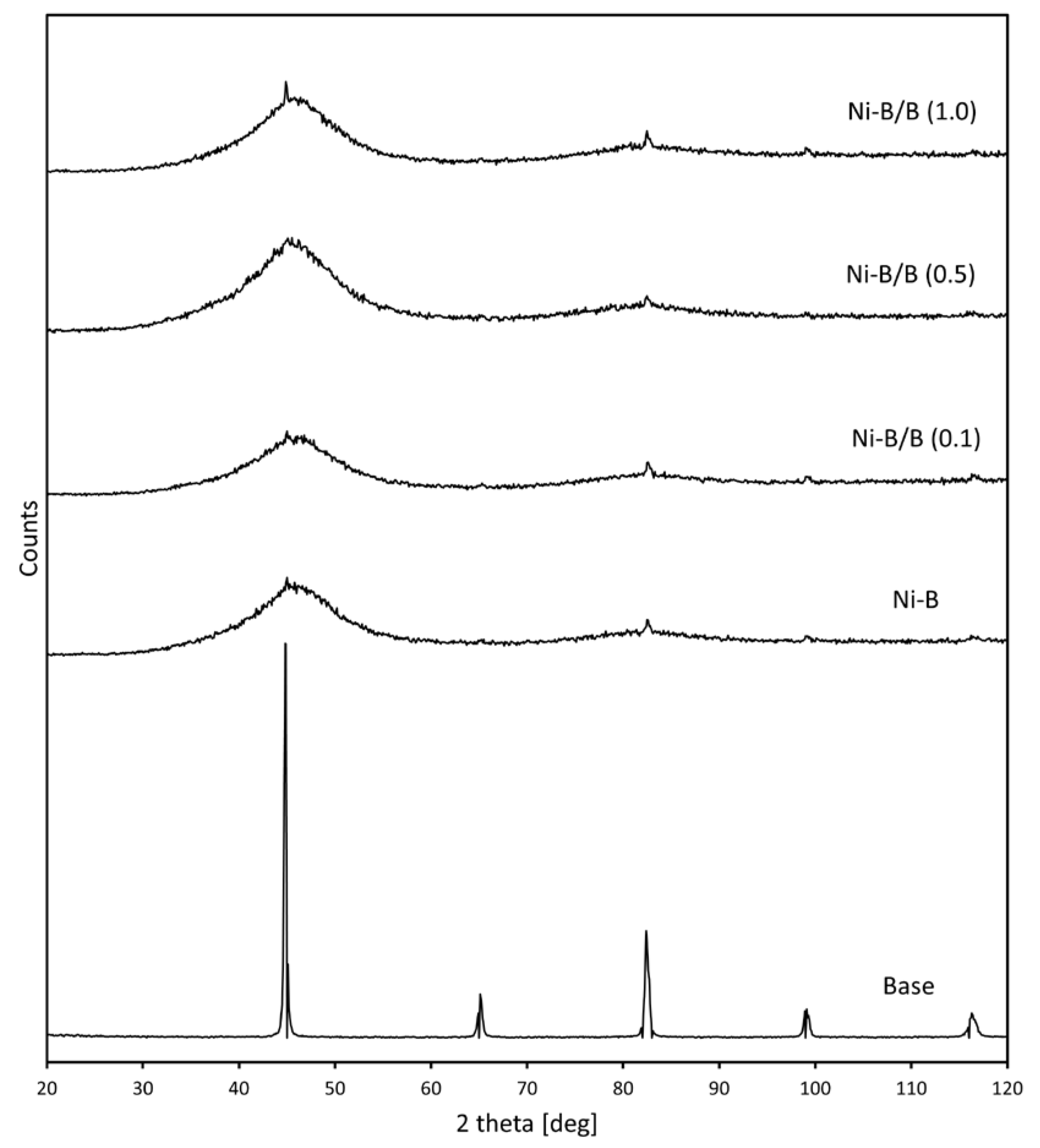

An important parameter in the deposition process of composite coatings is the rate of solution mixing during the coating deposition. Mixing plays a crucial role in dispersing particles of the dispersion phase throughout the bath, facilitating the mixing of other bath components, preventing local overheating and pitting caused by hydrogen release [13]. However, excessively high mixing rates can have negative effects, resulting in a heterogeneous structure of the composite coatings. In the case of hard particles, high mixing rates can lead to erosion of the deposited coating due to abrasion by fast-moving particles of the dispersion phase [13]. The analysis of the chemical composition of the Ni-B alloy coating was performed using the ICP OES method, and the results are presented in Table 4. The results of the XRD analysis of the phase composition of the Ni-B and Ni-B/B coatings are shown in Figure 5.

Table 4.

Chemical composition of Ni-B coating tested by the ICP OES method.

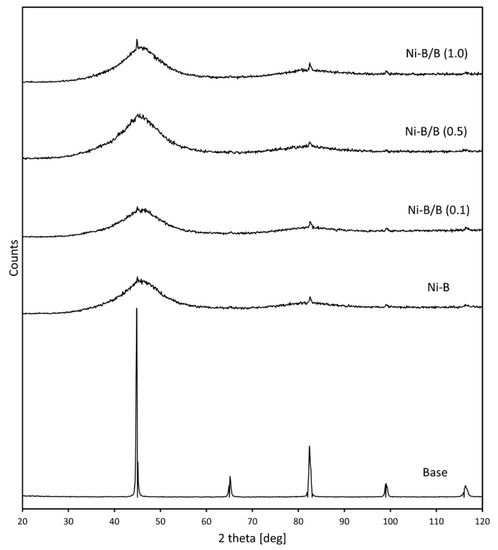

Figure 5.

Diffraction patterns of steel substrate material (base), Ni-B, and Ni-B/B coatings.

The boron content in Ni-B alloy coatings can vary depending on the deposition process parameters, such as bath component concentration, bath temperature, and deposition time. The literature reports indicate that Ni-B coatings with a boron content of up to 5 wt% exhibit a mixed crystalline–amorphous structure. For boron content below 5 wt%, a broad band at 45° 2 theta is observed in the diffraction pattern, indicating the presence of a mixed crystalline–amorphous structure [29]. Coatings with boron content above 5 wt% are typically amorphous [17]. In the studied case, the boron content in the coating exceeds 7% by weight, which indicates the amorphous nature of the coating. Slight crystalline reflections may come from the steel substrate (base). The concentration of the reducing agent in the bath from which the coating is deposited has a significant impact on the content of boron as an alloying component in the Ni-B coating. In another study [30], the influence of NaBH4 concentration on the rate of coating deposition and the structure of the deposited coatings was investigated. Lower concentrations of the reducer (approximately 0.4 g/dm3) resulted in lower boron content in the alloy (around 3%) and the presence of peaks from crystalline nickel in the diffraction pattern. Higher concentrations of the reducing agent in the bath led to a higher boron content in the deposited alloy and an increased share of the amorphous phase. Moreover, the rate of thickness increase was lower for lower borohydride concentrations.

3.3. Mechanical Properties of the Produced Coatings

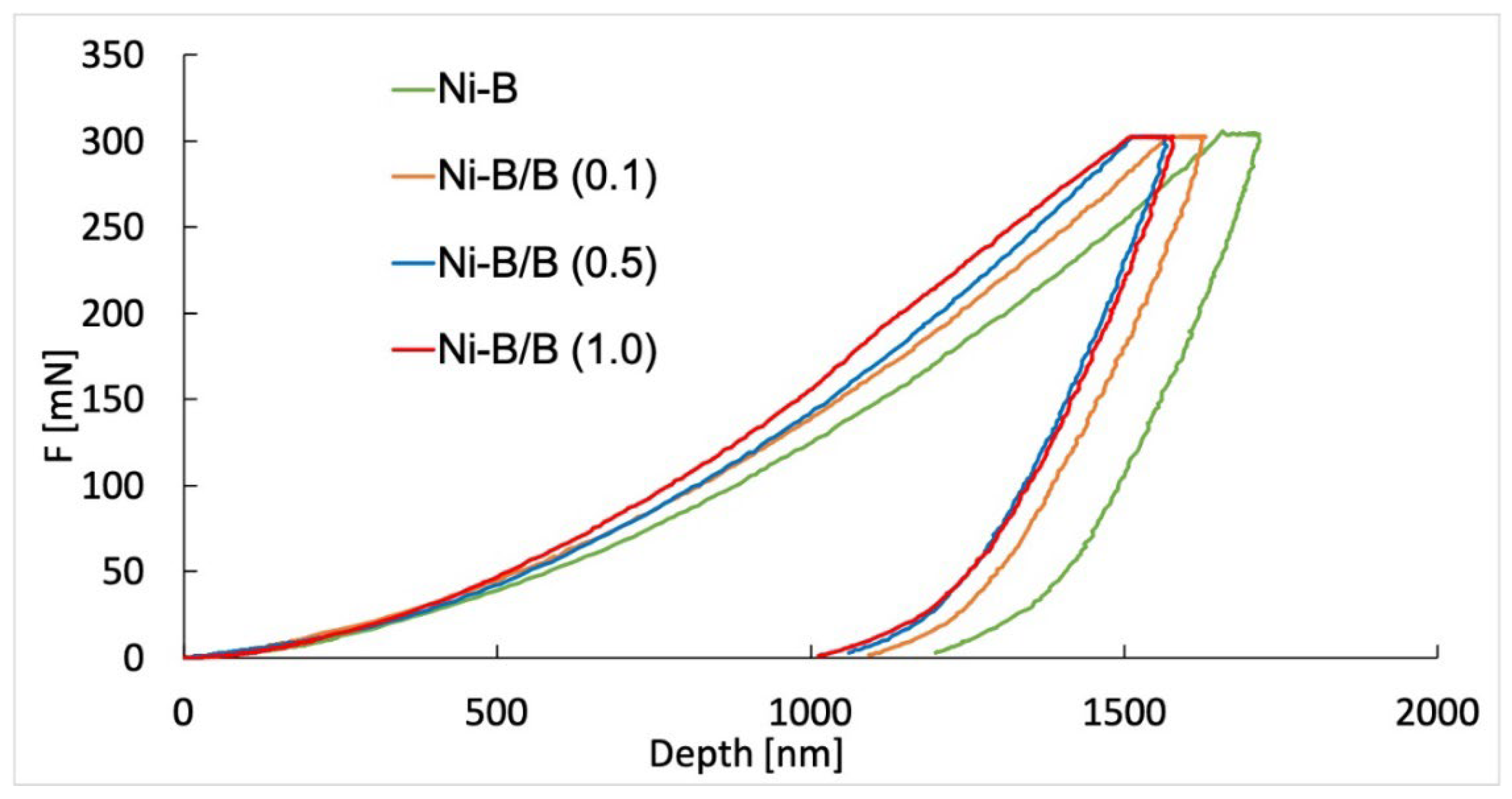

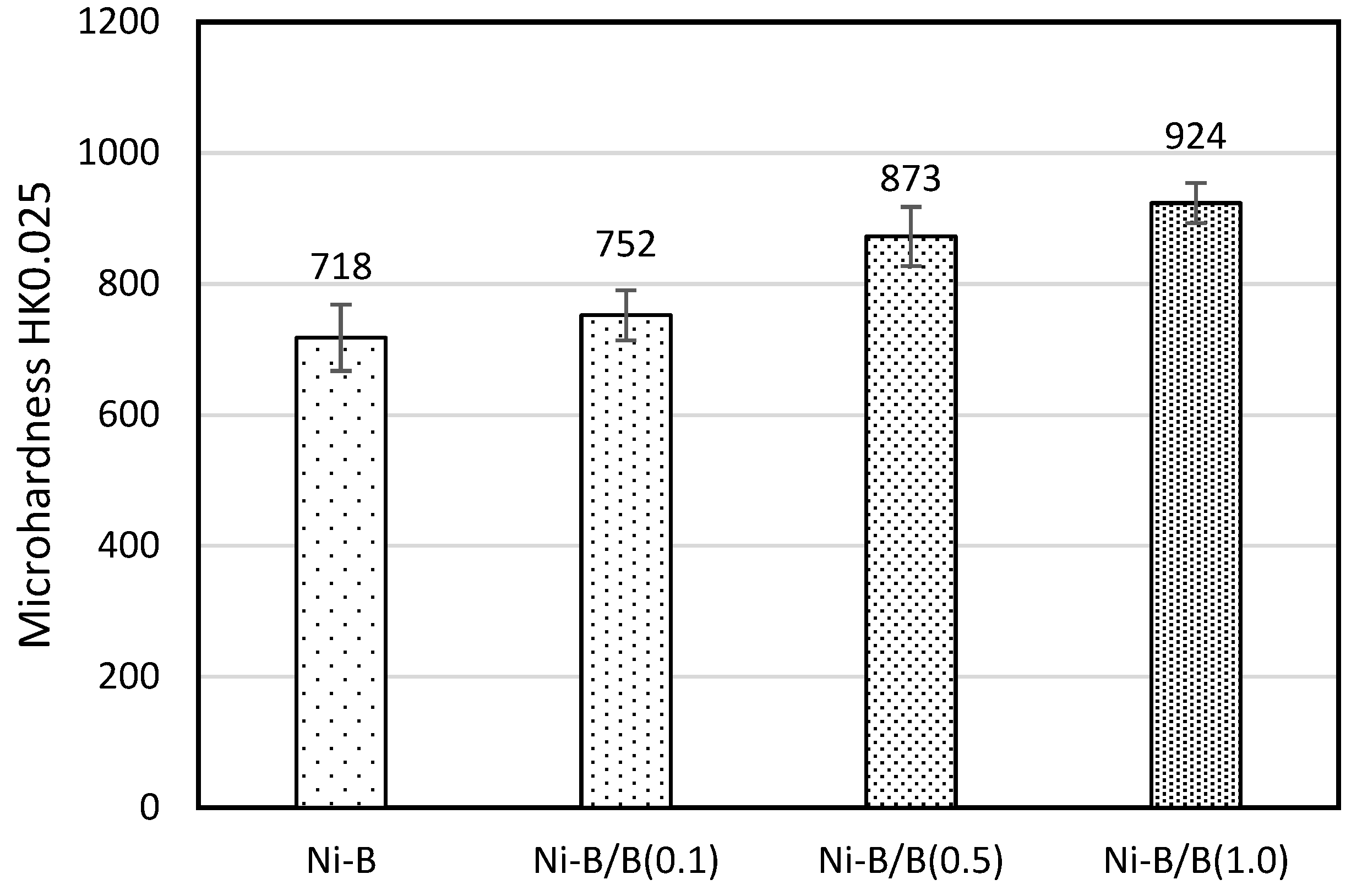

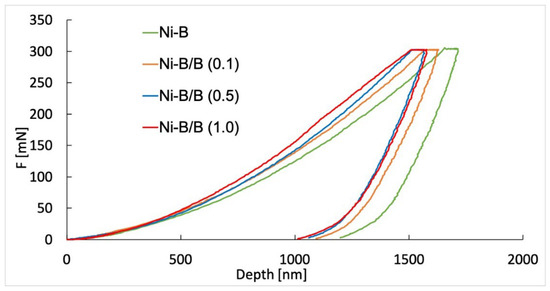

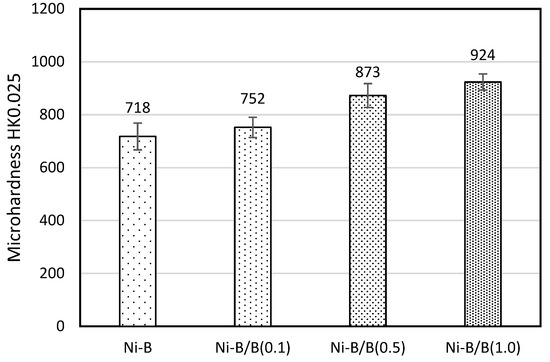

The mechanical properties of the Ni-B and Ni-B/B coatings were evaluated using the DSI method and the Knoop method. The test results are presented in Table 5 and in Figure 6 and Figure 7.

Table 5.

Mechanical properties of Ni-B and Ni-B/B coatings from DSI tests.

Figure 6.

Dependence of load on depth in the process of penetration of the indenter into the material of the tested Ni-B and Ni-B/B coatings.

Figure 7.

Microhardness of Ni-B and Ni-B/B coatings.

The load–unload curves illustrate the resistance of the tested Ni-B and Ni-B/B composite coatings to indentation with progressive loading. The embedding of boron particles into the Ni-B matrix enhances the material’s strength. Coatings deposited from baths with higher concentrations of the dispersion phase show greater resistance to indenter pressure during the test. The least resistant is the Ni-B coating without embedded particles, for which the penetration depth of the indenter is over 1700 nm. As the concentration of boron particles in the bath increases, the depth of the indenter pressing against the coating material decreases. The coatings deposited from baths with a concentration of 0.5 and 1.0 g/dm3 of the dispersion phase show the highest indentation hardness (HIT), Martens hardness (HM), and Young’s modulus (EIT). The analysis of the elastic strain rate in the DSI study of deposited Ni-B and Ni-B/B coatings indicates the dominant role of plastic strain. The Ni-B/B (1.0) coating exhibits the largest portion of elastic deformation (KH), amounting to 36%, while the Ni-B coating without embedded particles exhibits the smallest share of approximately 30%. The embedding of boron particles in the dispersion phase into the Ni-B material causes an increase in the share of elastic deformations. The results of the DSI tests align with the microhardness measurements conducted using the Knoop method (Figure 7), which revealed an increase in hardness with the increasing concentration of the dispersion phase in the bath in which the coatings were deposited. The Ni-B coating without embedded particles exhibits the lowest hardness (approximately 700 HK0.025), whereas the Ni-B/B (1.0) coating demonstrates the highest hardness of about 900 HK0.025. Slight differences in hardness results in DSI and Knoop measurements may be attributed to a non-uniform coating structure and variations in measurement locations. Ni-B alloy coatings are well-known for their high hardness. In this type of materials, the quantity of boron as an alloying component in the Ni-B matrix significantly influences the hardness. As the boron content in the matrix increases, the hardness of the coating material increases [30]. Strengthening of the Ni-B matrix due to the embedding of particles of the dispersion phase may arise from the utilization of particles with high hardness.

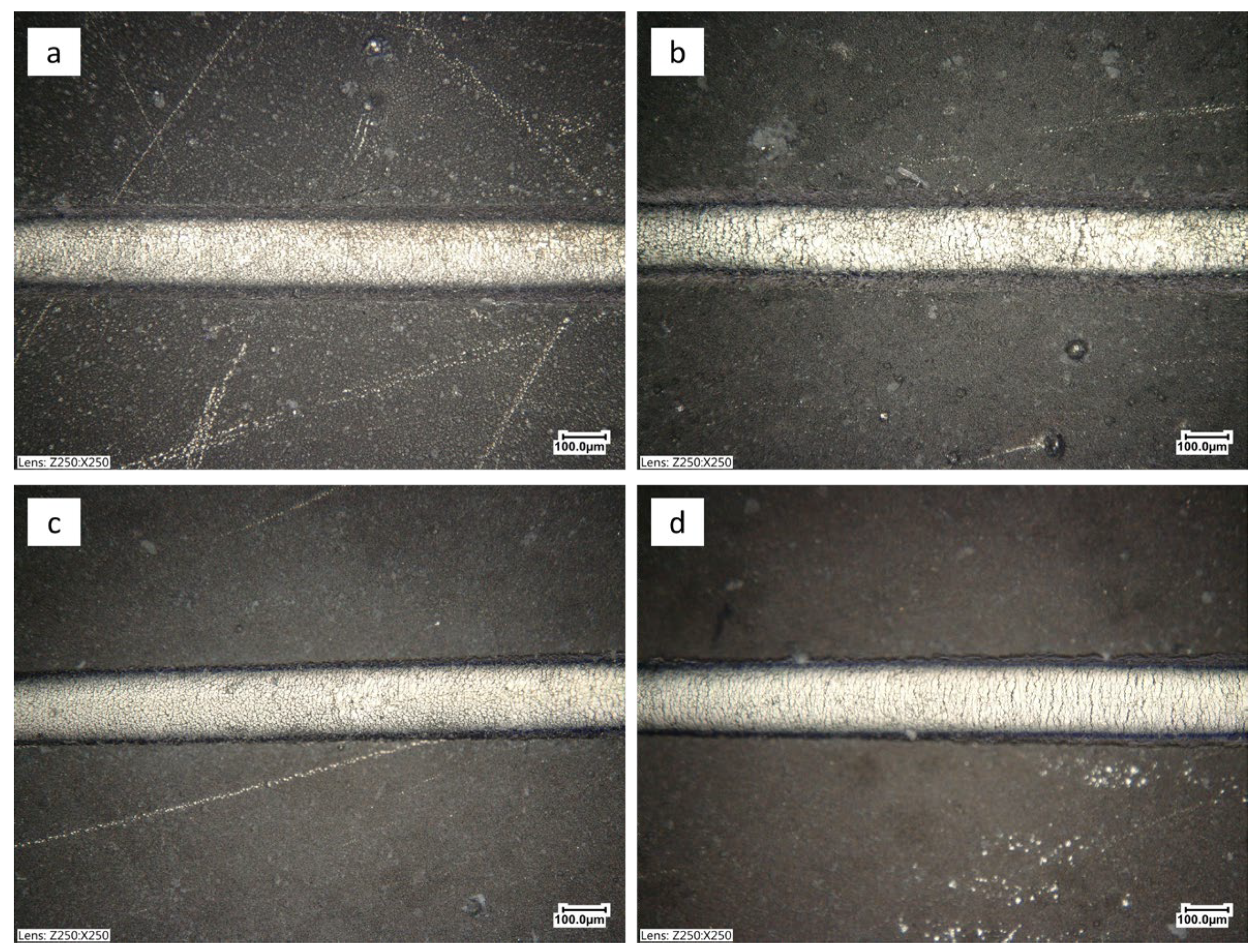

3.4. Tribological Properties of the Produced Coatings

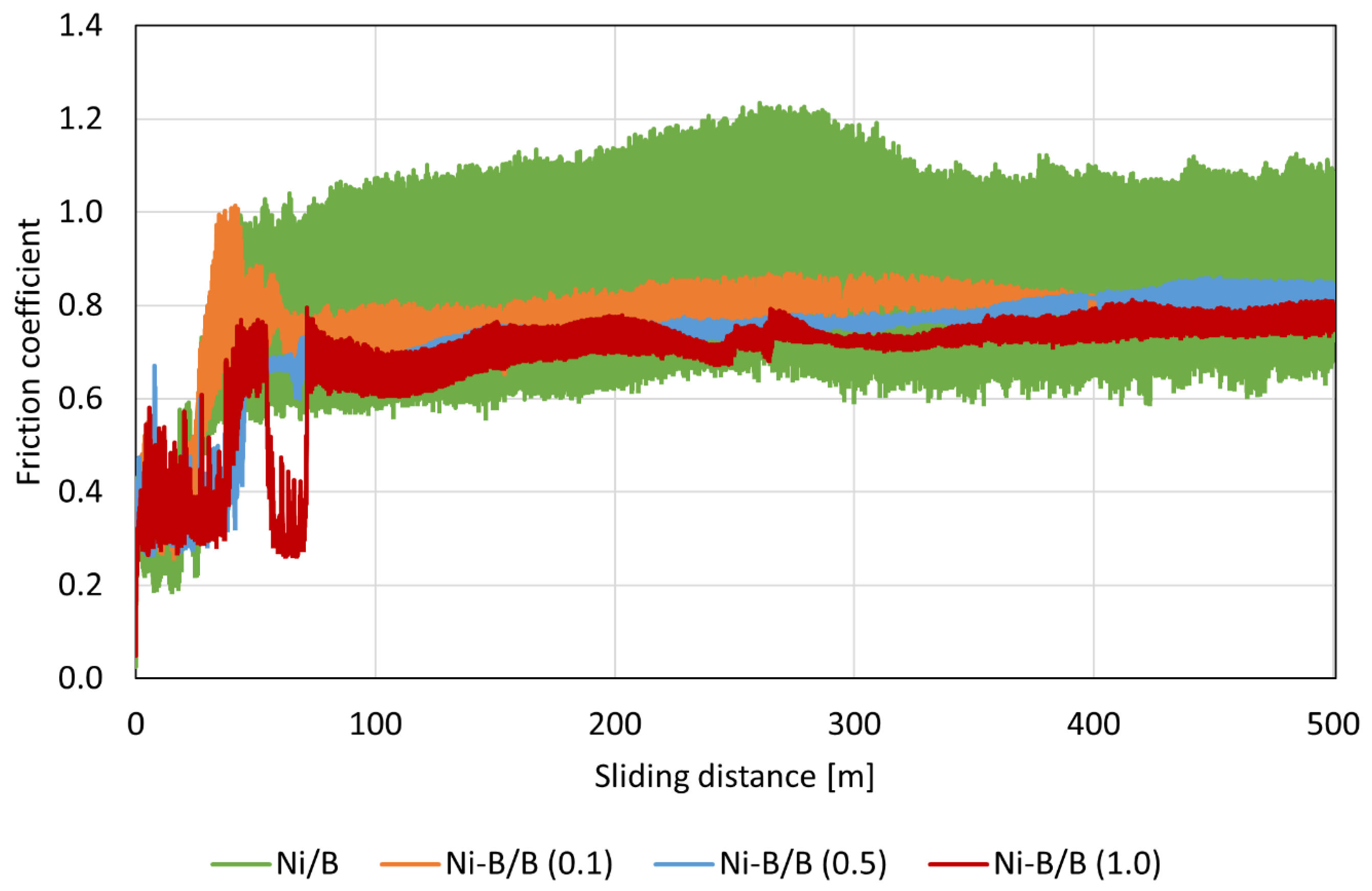

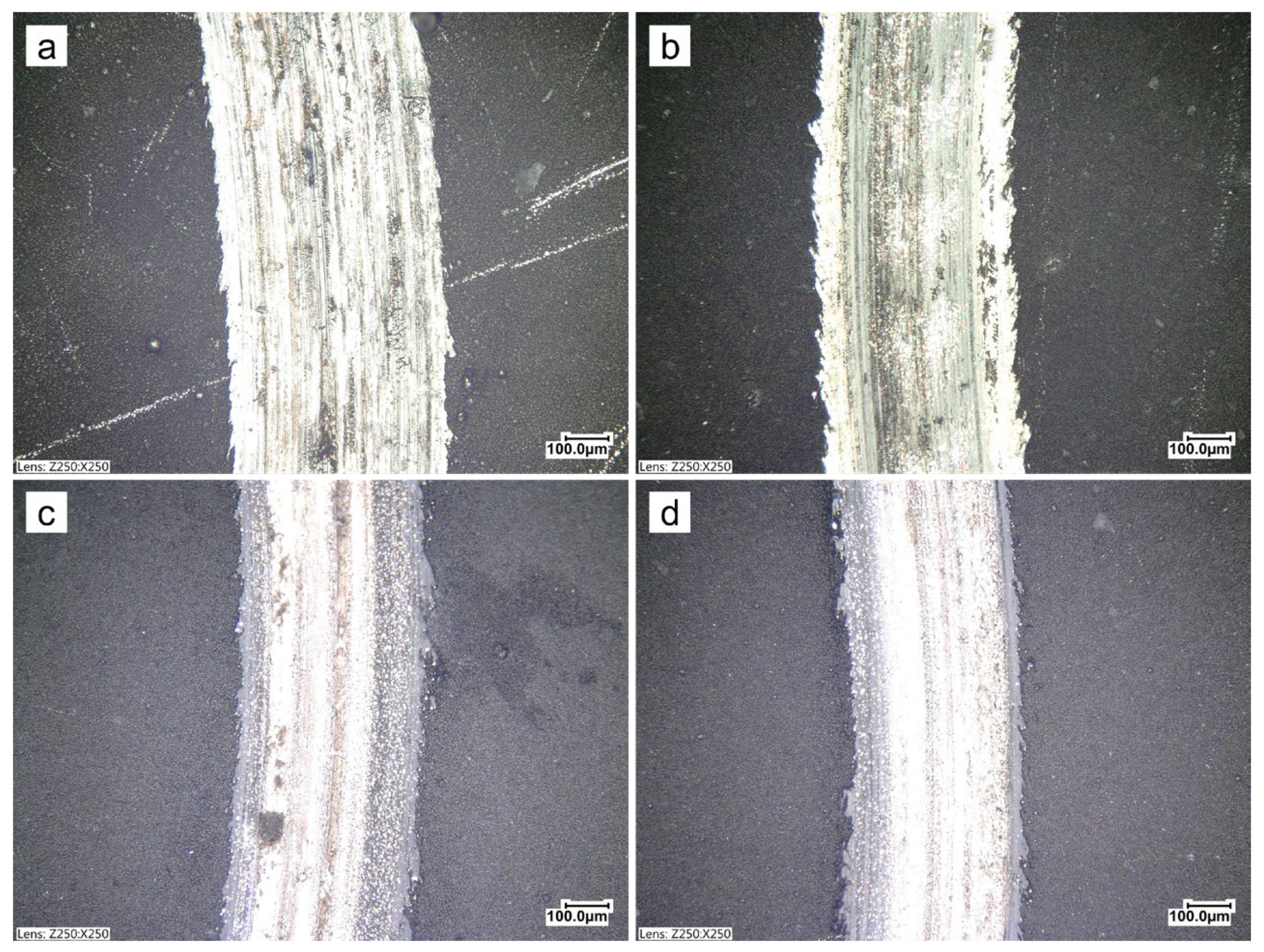

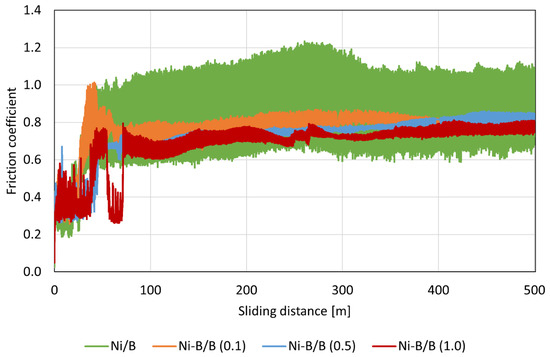

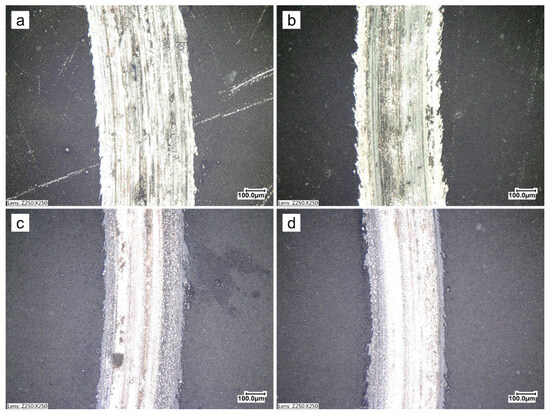

The outcomes of tribological tests conducted using the ball-on-disc method are presented in Table 6, along with the average friction coefficient values, wear track width, and wear track depth. Images displaying the damage after the tribological test are shown in Figure 8.

Table 6.

Friction coefficient of the tested Ni-B and Ni-B/B coatings.

Figure 8.

Friction coefficient as a function of sliding distance for Ni-B and Ni-B/B coatings.

The friction coefficient of the tested Ni-B and Ni-B/B coatings is rather unstable and shows large fluctuations. The Ni/B sample without embedded particles was the least stable in the test data. Scatter in the determination of the friction coefficient for this type of material is also reported in papers [31,32]. The average value of the friction coefficient for the Ni-B coating is relatively high and is 0.8277. The incorporation of boron particles into the Ni-B matrix results in a decrease in the average friction coefficient value. The lowest average coefficient of friction (0.6879) is characteristic for a coating deposited in a bath with a boron concentration of 1.0 g/dm3. With the increase in the concentration of boron particles in the bath in which the coatings were deposited, the coefficient of friction decreases, which is a favorable phenomenon from a technical standpoint. The tribological properties of the tested coatings are influenced by both the hardness of the coating material and the degree of surface development of the deposited composite coatings [33]. In the case of the tested Ni-B and composite Ni-B/B coatings, the predominant damage mechanisms during tribological tests are the following adhesive wear and abrasive wear. The much harder alumina ball wipes a trace in the softer Ni-B coating material, and the friction pair also results in the chipping of coating particles and the dispersion phase (B), which further contributes to the micro-ploughing effect (Figure 9) [34]. Natarajan also reports improved wear resistance in composite materials [35].

Figure 9.

Images of damage after tribology test of Ni-B and Ni-B/B coatings: (a) Ni-B; (b) Ni-B/B (0.1); (c) Ni-B/B (0.5); (d) Ni-B/B (1.0).

3.5. Combination of the Produced Coatings with the Substrate Materials

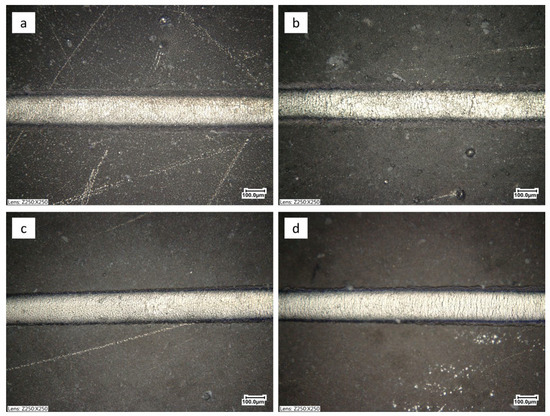

The combination of Ni-B and Ni-B/B composite coatings with a steel substrate was scratch tested. Images of coating damage after the test are shown in Figure 10.

Figure 10.

Images of damage after scratch test of Ni-B and Ni-B/B coatings: (a) Ni-B; (b) Ni-B/B (0.1); (c) Ni-B/B (0.5); (d) Ni-B/B (1.0).

Gradually increasing the load while moving the indenter on the tested material induces initial elastic and subsequent plastic deformations, eventually leading to the destruction of the tested coatings. The harder the material is, the more resistance it exhibits, and its damage can be more severe. The critical load Lc1, which denotes the formation of the first cohesive cracks in the tested material, is a significant parameter. Cohesive cracks occur due to the frictional forces between the moving indenter and the coating, caused by stress accumulation before and after the indenter [36]. In the case of the tested Ni-B and Ni-B/B coatings, slight chippings resulting from the surface morphology were observed. For all the tested composite coatings (Ni-B and Ni-B/B), the first radial cracks (Lc1) were observed within a load range of 15–20 N. As the indenter progresses, the cracks propagate, but the material retains its cohesion. The cracks are formed at the bottom of the scratches and are perpendicular to the direction of the scratches. Both the size and number of radial cracks increase with increasing loading force [37]. There were no specific differences in the scratch test for the tested coatings depending on the concentration of the dispersion phase in the bath. No delamination or destruction of the coatings occurred in the tested materials. Scratch tests of the electroless-deposited Ni-B coatings are discussed in the paper [31], which shows similar trends in coating preservation.

3.6. Corrosion Properties of the Produced Coatings

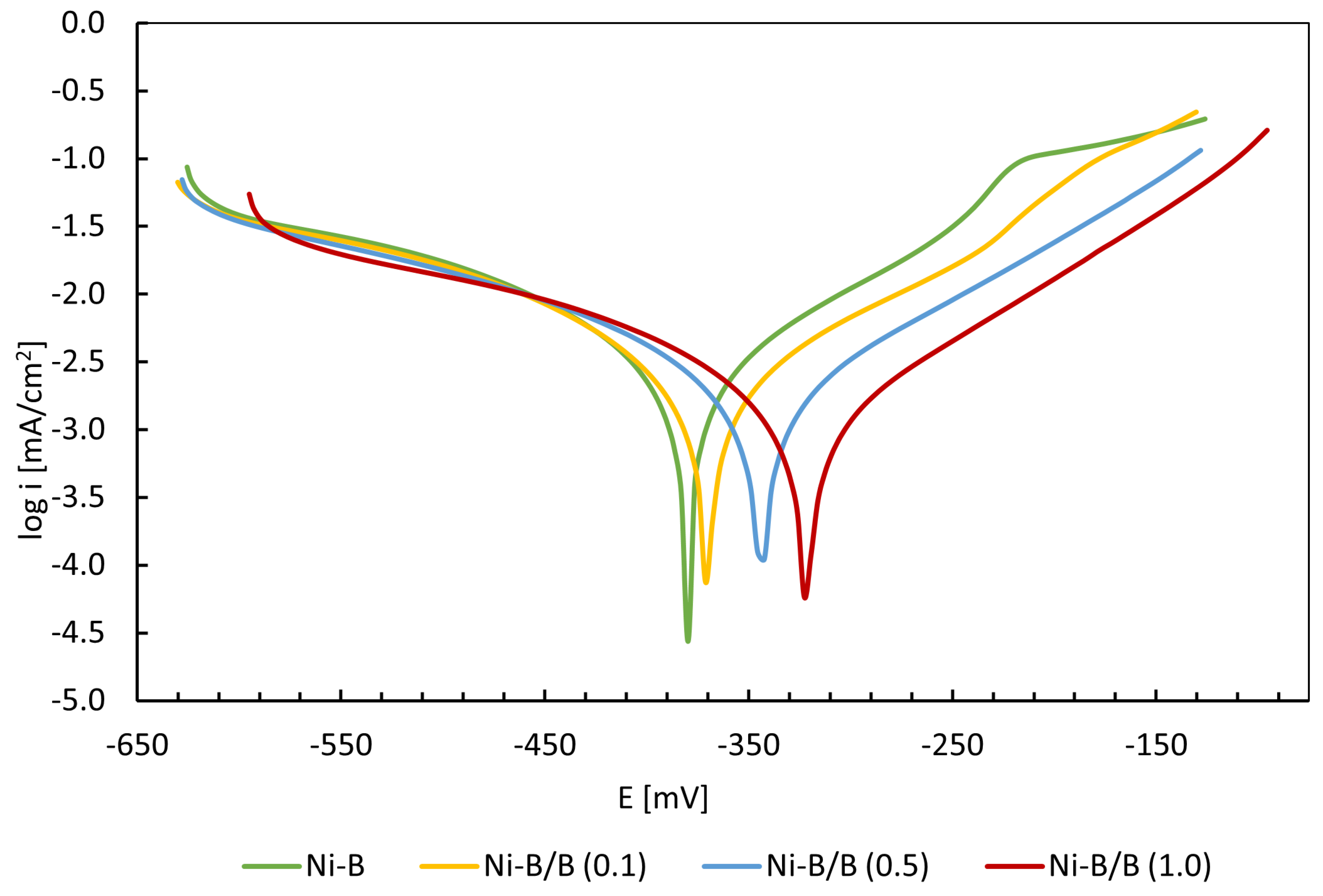

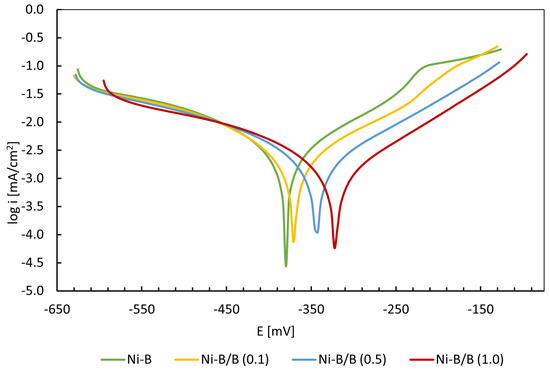

The results of corrosion tests conducted on the studied Ni-B and Ni-B/B coatings are shown in Figure 11 and Table 7.

Figure 11.

Polarization curves recorded for Ni-B and Ni-B/B coatings.

Table 7.

Corrosion parameters of the tested coatings.

The polarization curves recorded for both Ni-B and Ni-B/B composite coatings demonstrate a similar nature of corrosion processes under the tested conditions. In all cases, general corrosion was observed. With the embedding of B particles in the baths with the B content in the range from 0.1 to 1.0 g/dm3, a shift in the corrosion potential towards more positive values was recorded, from −380 mV for the Ni-B coating without embedded particles to −321 mV for the Ni-B/B (1.0). Furthermore, there was a gradual decrease in the corrosion current density, which was 2.2 µA/cm2 for Ni-B and (1.0) 0.85 µA/cm2 for Ni-B/B (1.0). Therefore, it can be concluded that the embedding of boron particles into the Ni-B coating increases the corrosion resistance of the composite coating. For the tested surface, both the anodic and cathodic portions of the polarization curve exhibited the lowest current density values. This phenomenon may be attributed to changes in the coating’s morphology occurring with an increase in the amount of incorporated boron particles.

4. Conclusions

Using chemical reduction on a carbon steel substrate, Ni-B/B composite coatings were successfully produced from baths with varying concentrations of boron particles. The embedding of boron particles into the Ni-B coating significantly influences the structure, morphology, and properties of the produced composite coatings. The Ni-B/B composite coatings exhibit a compact structure and strong adhesion to the steel substrate. Increasing the concentration of the boron dispersion phase in the bath changes the surface morphology from cauliflower-shaped to spherical and reduces the degree of surface roughness of the coatings produced. It also has a positive effect on the tribological, mechanical, and corrosion properties of the produced Ni-B/B composite coatings. The coating deposited from a bath with a dispersion phase particle concentration of 1.0 g/dm3 displayed the most favorable corrosion, mechanical, and tribological properties compared to the Ni-B coating without embedded B particles. The findings are as follows:

- The average coefficient of friction of the Ni/B-B coating (1.0) is 17% lower compared to the Ni-B coating without embedded particles; for all tested coatings the main failure mechanisms are adhesive wear and abrasive wear.

- The hardness of the Ni-B-B (1.0) coating is higher than the hardness of the Ni-B coating without embedded particles: HK0.025 by 28%, HIT by 17%, and HM by 15%.

- The higher corrosion resistance of the Ni-B/B (1.0) coating compared to the Ni-B coating without embedded particles is visible in the lower values of the corrosion potential (−321 mV) and the corrosion current density (0.85 µA/cm2).

Coatings of this type can be applied to metal components to improve their performance properties.

Author Contributions

Conceptualization, G.C. and A.G.-M.; methodology, G.C., M.G. (Marta Gostomska), T.C., K.S., A.D., E.P., E.W. and A.K.; validation, G.C.; investigation, G.C., M.G. (Marta Gostomska), T.C., K.S., A.D., E.P., E.W., M.G. (Michał Głowacki) and A.K.; resources, G.C. and A.G.-M.; data curation, T.C., A.D. and M.G.; writing—original draft preparation, G.C.; writing—review and editing, M.T., M.G., K.S., T.C. and A.D.; visualization, G.C., M.G. (Marta Gostomska), K.S., A.D. and T.C.; supervision, G.C., M.T. and A.G.-M.; project administration, A.G.-M.; funding acquisition, A.G.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was created as part of the project “New electroless Ni-B/B and Ni-B/MoS2 composite coatings with improved mechanical properties” benefits from a EUR 210,000 grant from Norway. The aim of the Small Grant Scheme (SGS) Call is to support applied research projects led by female scientists in technical sciences. The research leading to these results has received funding from the Norway Grants 2014–2021 via the National Centre for Research and Development (Poland). Agreement no. NOR/SGS/GalvaNiB/0168/2020-00.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Solimani, A.; Meiβner, T.M.; Oskay, C.; Galetz, M.C. Electroless Ni–P coatings on low-Cr steels: A cost-efficient solution for solar thermal applications. Sol. Energy Mater. Sol. Cells 2021, 231, 111312. [Google Scholar] [CrossRef]

- Feng, L.; Zhang, Y.-w.; Wen, C.; Li, S.-z.; Li, J.-f.; Cheng, D.; Bai, J.-y.; Cui, Q.-x.; Zhang, L.-g. Effect of initial deposition behavior on properties of electroless Ni−P coating on ZK60 and ME20 magnesium alloys. Trans. Nonferrous Met. Soc. China 2021, 31, 2307–2322. [Google Scholar] [CrossRef]

- Wojewoda-Budka, J.; Wierzbicka-Miernik, A.; Kwiecień, I.; Valenza, F.; Korneva, A.; Janusz-Skuza, M.; Stan-Glowinska, K.; Guspiel, J.; Bugajska, M. Reactivity with tin and corrosion resistance of electroless Ni-P and Ni-P-Re coatings plated on copper. Electrochim. Acta 2022, 406, 139850. [Google Scholar] [CrossRef]

- Chinchu, K.S.; Riyas, A.H.; Ameen Sha, M.; Geethanjali, C.V.; Saji, V.S.; Shibli, S.M.A. ZrO2–CeO2 assimilated electroless Ni–P anti-corrosion coatings. Surf. Interfaces 2020, 21, 100704. [Google Scholar] [CrossRef]

- Wojewoda-Budka, J.; Wierzbicka-Miernik, A.; Szczerba, M.; Kazimierczak, H.; Kwiecień, I.; Morgiel, J.; Stan-Glowinska, K.; Valenza, F. The effect of Re addition on the thermal stability and structure of Ni–P electroless coatings. Mater. Charact. 2021, 171, 110811. [Google Scholar] [CrossRef]

- Rana, A.R.K.; Farhat, Z. Preparation and tribological characterization of graphene incorporated electroless Ni-P composite coatings. Surf. Coat. Technol. 2019, 369, 334–346. [Google Scholar] [CrossRef]

- Barati, Q.; Hadavi, S.M.M. Electroless Ni-B and composite coatings: A critical review on formation mechanism, properties, applications and future trends. Surf. Interfaces 2020, 21, 10070. [Google Scholar] [CrossRef]

- Bülbül, F. Antibacterial activity of electroless Ni–B coating. Mater. Sci. Technol. 2011, 27, 1540–1546. [Google Scholar] [CrossRef]

- Jończyk, S.; Mazurek, A.; Cieślak, G.; Szawłowski, J.; Trzaska, M. Diffusion boronizing of steel by using the Ni-B alloy coating as a source of boron. Przem. Chem. 2019, 98, 604–609. [Google Scholar]

- Trzaska, M.; Cieślak, G.; Mazurek, A. Corrosion properties of Ni-P and Ni-B alloy coatings produced by chemical method. Ochrona Przed Korozją 2015, 11, 426–429. [Google Scholar] [CrossRef]

- Mazurek, A.; Bartoszek, W.; Cieślak, G.; Gajewska-Midziałek, A.; Oleszak, D.; Trzaska, M. Influence of heat treatment on properties of Ni-B/B composite coatings. Arch. Metall. Mater. 2020, 5, 839–844. [Google Scholar]

- Skowron, J.; Konieczka, K. Occupational Exposure to Chromium (VI) Compounds. Med. Pr. 2015, 66, 407–427. [Google Scholar] [CrossRef] [PubMed]

- Georgiza, E.; Gouda, V.; Vassiliou, P. Production and properties of composite electroless Ni-B-SiC coatings. Surf. Coat. Technol. 2017, 325, 46–61. [Google Scholar] [CrossRef]

- Shu, X.; Wang, Y.; Liu, C.; Gao, W. Microstructure and properties of Ni–B–TiO2 nanocomposite coatings fabricated by electroless plating. Mater. Technol. 2015, 30, A41–A45. [Google Scholar] [CrossRef]

- Niksefat, V.; Ghorbani, M. Mechanical and electrochemical properties of ultrasonic-assisted electroless deposition of Ni–B–TiO2 composite coatings. J. Alloys Compd. 2015, 633, 127–136. [Google Scholar] [CrossRef]

- Cieślak, G.; Trzaska, M. Structure and Properties of Ni-B/Graphene Oxide Composite Coatings Produced by Chemical Reduction Method. J. Mater. Eng. Perform. 2020, 29, 1550–1557. [Google Scholar] [CrossRef]

- Gültekin, D.; Duru, E.; Akbulut, H. Improved wear behaviors of lead-free electroless Ni–B and Ni-B/CeO2 composite coatings. Surf. Coat. Technol. 2021, 422, 12752. [Google Scholar] [CrossRef]

- Mazurek, A.; Cieślak, G.; Bartoszek, W.; Trzaska, M. Abrasion resistance of Ni-B/Si3N4 composite layers produced by electroless method. Arch. Mater. Sci. Eng. 2017, 87, 21–26. [Google Scholar] [CrossRef]

- Cieślak, G.; Mazurek, A.; Bartoszek, W.; Trzaska, M. Corrosion properties of Ni-B/Al2O3 composites layers produced by electroless method. Ochrona Przed Korozją 2017, 60, 215–217. [Google Scholar] [CrossRef]

- Gajewska-Midziałek, A. Wpływ struktury nanokrystalicznych elektrochemicznych powłok kompozytowych Ni-B na wybrane właściwości użytkowe. Ph.D. Thesis, Institute of Precision Mechanics, Warsaw, Poland, 2018. [Google Scholar]

- Das, S.K.; Sahoo, P. Electrochemical impedance spectroscopy of Ni-B coatings and optimization by Taguchi method and Grey relational analysis. Port. Electrochim. Acta 2011, 29, 211–231. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indention experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Cieślak, G.; Trzaska, M.; Betiuk, M. Structure and mechanical properties of nanocrystalline Ni/Cu multilayer coatings produced by the electrocrystallization method. Inz. Pow. 2019, 24, 3–10. [Google Scholar] [CrossRef]

- T-11 Elevated Temperature Pin-on-Disk Tribostestr. Available online: https://www.itee.lukasiewicz.gov.pl/images/karty/tribologia/Karta_T-11_ang.pdf (accessed on 2 August 2023).

- T-11 Elevated Temperature Pin-on-Disk Testing Machine for Tribotesting of Lubricants and Engineering Materials. Available online: https://www.tribologia.eu/ptt/inst/rad/T-11_en.pdf (accessed on 2 August 2023).

- Vitry, V.; Hastir, J.; Megret, A.; Yazdani, S.; Yunacti, M.; Bonin, L. Recent advances in electroless nickel-boron coatings. Surf. Coat. Technol. 2022, 429, 12793. [Google Scholar] [CrossRef]

- Algul, H.; Uysal, M.; Alp, A. A comparative study on morphological, mechanical and tribological properties of electroless NiP, NiB and NiBP coatings. Appl. Surf. Sci. Adv. 2021, 4, 100089. [Google Scholar] [CrossRef]

- Ürdem, S.; Duru, E.; Algül, H.; Uysal, M.; Akbulut, H. Evaluation of high temperature tribological behavior of electroless deposited NiB–Al2O3 coating. Wear 2021, 482–483, 20396. [Google Scholar] [CrossRef]

- Nemane, V.; Chatterjee, S. Evaluation of microstructural, mechanical, and tribological characteristics of Ni-B-W-SiC electroless composite coatings involving multi-pass scratch test. Mater. Charact. 2021, 180, 11141. [Google Scholar] [CrossRef]

- Baskaran, I.; Sakthi Kumar, R.; Sankara Narayanan, T.S.N.; Stephen, A. Formation of electroless Ni–B coatings using low temperature bath and evaluation of their characteristic properties. Surf. Coat. Technol. 2006, 200, 6888–6894. [Google Scholar] [CrossRef]

- Vitry, V.; Bonin, L. Increase of boron content in electroless nickel-boron coating by modification of plating conditions. Surf. Coat. Technol. 2017, 311, 164–171. [Google Scholar] [CrossRef]

- Khodaei, M.; Mohammad Gholizadeh, A. SiC nanoparticles incorporation in electroless NiP-Graphene oxide nanocomposite coatings. Ceram. Int. 2021, 47, 25287–25295. [Google Scholar] [CrossRef]

- Dilek, S.; Algul, H.; Akyol, A.; Alp, A.; Akbulut, H.; Uysal, M. Pulse electro co-deposition of submicron-sized TiC reinforced Ni–W coatings: Tribological and corrosion properties. J. Asian Ceram. Soc. 2021, 9, 673–685. [Google Scholar] [CrossRef]

- Eranegh, F.A.; Azadi, M.; Tavakoli, H. Effect of SiO2 Nanoparticles Addition on Tribological and Electrochemical Behaviors of Ni-P-MoS2 Multi-Component Coatings after Heat Treatment. Surf. Eng. Appl. Elect. 2020, 56, 171–183. [Google Scholar] [CrossRef]

- Natarajan, S.; Narayanasamy, R.; Kumaresh Babu, S.P.; Dinesh, G.; Anil Kumar, B.; Sivaprasad, K. Sliding wear behaviour of Al 6063/TiB2 in situ composites at elevated temperatures. Mater. Des. 2009, 30, 2521–2531. [Google Scholar] [CrossRef]

- Chronowska-Przywara, K.; Kot, M. Wpływ parametrów badań na deformacje i pękanie układu powłoka-podłoże w wyniku próby zarysowania. Tribologia 2014, 2, 19–26. [Google Scholar]

- Li, C.; Piao, Y.; Zhang, F.; Zhang, Y.; Hu, Y.; Wang, Y. Understand anisotropy dependence of damage evolution and material removal during nanoscratch of MgF2 single crystals. Int. J. Extrem. Manuf. 2023, 5, 015101. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).